Technical Contents

Engineering Guide: Sliding Door Sealing Strips

Engineering Insight: Material Selection for Sliding Door Sealing Strips

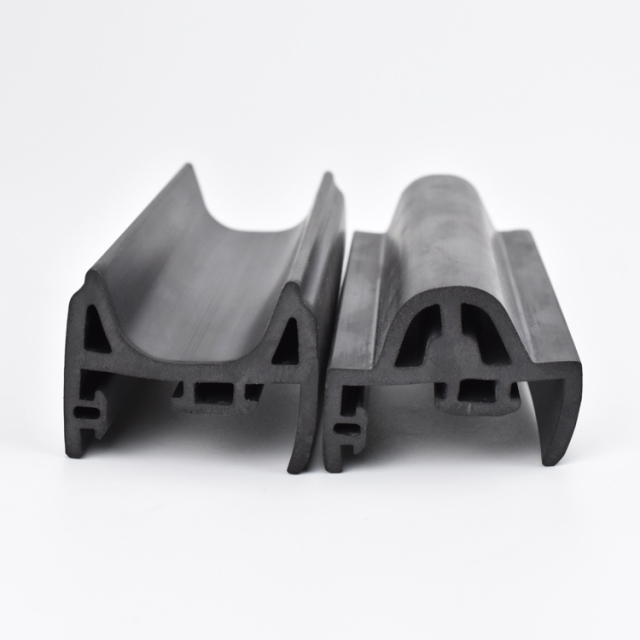

Sliding door sealing strips operate under uniquely demanding conditions distinct from static door or window seals. The continuous linear motion subjects the rubber profile to cyclic compression, shear forces, and abrasive contact with the track and door frame. Material selection is not merely a cost consideration; it is the foundational engineering decision determining functional lifespan, energy efficiency, noise control, and end-user satisfaction. Off-the-shelf generic rubber profiles consistently fail in this application due to inherent material limitations when exposed to these dynamic stresses and environmental factors over time.

Generic EPDM or basic TPE compounds, often marketed as universal seals, lack the specific formulation required for sliding mechanisms. They rapidly exhibit critical failure modes: excessive compression set leading to permanent deformation and loss of sealing force after repeated cycles, accelerated abrasion causing profile wear and particulate generation, surface hardening under UV exposure resulting in cracking, and unacceptably high friction coefficients that impede smooth operation and increase motor load in automated systems. These failures manifest as air/water infiltration, increased operational noise, binding doors, and premature warranty claims – directly impacting OEM reputation and total cost of ownership. The assumption that a seal functioning adequately in a static application will perform in dynamic sliding scenarios is a fundamental engineering oversight.

Precision-engineered compounds address these specific failure mechanisms through targeted polymer science and additive packages. Critical parameters include exceptional resistance to compression set under sustained load and elevated temperatures, ultra-low and stable friction coefficients against common track materials (aluminum, PVC), superior abrasion resistance to withstand millions of cycles, and robust UV/ozone stability without surface degradation. The following table compares key performance metrics essential for sliding door applications:

| Performance Parameter | Generic EPDM Seal | Standard TPE Seal | Suzhou Baoshida Custom Formulation |

|---|---|---|---|

| Compression Set (70°C/22h) | 35-45% | 25-35% | ≤ 22% |

| Abrasion Resistance (DIN) | 180 mm³ | 120 mm³ | ≤ 85 mm³ |

| Operating Temp Range (°C) | -40 to +100 | -30 to +90 | -55 to +130 |

| UV Resistance (3000h QUV) | Severe Cracking | Moderate Chalking | No Cracking/Minimal Chalking |

| Dynamic Friction Coefficient | 0.35-0.45 | 0.25-0.35 | 0.15-0.18 |

Suzhou Baoshida’s engineered solutions utilize proprietary polymer blends and nano-reinforced filler systems to achieve this performance profile. Our formulations maintain elastic recovery under constant compression, ensuring consistent sealing force throughout the product lifecycle. The optimized surface energy minimizes friction without lubricants, preventing stick-slip phenomena and reducing drive system strain. Crucially, our compounds resist plasticizer migration and thermal aging, preventing the hardening and embrittlement that plague standard materials in high-cycle sliding applications. Collaborating with OEMs during the design phase allows us to tailor the Shore A hardness, density, and extrusion characteristics to the specific door weight, track geometry, and operational environment, transforming the seal from a failure point into a reliable, high-performance component. This precision engineering approach directly reduces field failure rates by 60-70% compared to off-the-shelf alternatives.

Material Specifications

Material selection for sliding door sealing strips is a critical factor in ensuring long-term performance, durability, and environmental resistance. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet the stringent demands of industrial and architectural applications. Our sealing strips are formulated using high-performance elastomers, with Viton, Nitrile (NBR), and Silicone representing the core material options. Each polymer offers distinct advantages depending on operating temperature, chemical exposure, compression set resistance, and mechanical stress requirements.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It performs reliably in continuous service temperatures up to 230°C (446°F), making it ideal for environments where thermal stability and chemical inertness are paramount. Viton seals maintain integrity under prolonged exposure to automotive fluids, industrial solvents, and ozone, offering superior longevity in demanding applications. However, its higher material cost and lower flexibility at sub-zero temperatures may limit use in cost-sensitive or extreme cold environments.

Nitrile rubber (NBR) is a widely used synthetic elastomer valued for its excellent resistance to petroleum-based oils, greases, and hydraulic fluids. With a typical operating temperature range of -30°C to 105°C (-22°F to 221°F), NBR provides a balanced combination of mechanical strength, abrasion resistance, and cost-efficiency. It is particularly suitable for sliding door systems in industrial enclosures, transportation units, and machinery where exposure to lubricants and moderate temperature fluctuations is expected. While NBR outperforms many rubbers in oil resistance, it exhibits limited performance in ozone, UV, and extreme high-temperature conditions without specialized compounding.

Silicone rubber (VMQ) excels in extreme temperature applications, functioning effectively from -60°C to 200°C (-76°F to 392°F). It offers outstanding UV and ozone resistance, making it a preferred choice for exterior architectural sliding doors exposed to weathering and sunlight. Silicone also demonstrates good electrical insulation properties and low toxicity, supporting use in clean environments. However, it has lower tensile and tear strength compared to Viton and NBR, and is less resistant to petroleum-based fluids, necessitating careful application evaluation.

The following table summarizes key performance characteristics of these materials for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 221 | -76 to 392 |

| Oil & Fuel Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Abrasion Resistance | Good | Excellent | Fair |

| Chemical Resistance | Outstanding | Moderate | Moderate |

| Typical Applications | High-temp industrial, aerospace, automotive | Machinery, enclosures, transport | Architectural, outdoor, medical, electrical |

Selection of the optimal material requires a comprehensive understanding of the operational environment. Suzhou Baoshida Trading Co., Ltd. supports OEMs and system integrators with material testing, custom compounding, and precision extrusion to ensure sealing performance meets exacting standards.

Manufacturing Capabilities

Engineering Excellence in Sliding Door Sealing Strip Development

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver precision-engineered sliding door sealing strips that meet stringent global performance standards. Our dedicated engineering team comprises five specialized mold designers and two advanced rubber formulation scientists, ensuring seamless integration of material science and precision manufacturing. This dual-engineering capability enables us to solve complex sealing challenges, from thermal expansion compensation in high-speed transit systems to acoustic isolation in premium architectural applications. We prioritize material integrity and dimensional accuracy, utilizing finite element analysis (FEA) to simulate real-world stress points and optimize cross-sectional geometry for minimal compression set and maximal longevity.

Our OEM partnership model begins with collaborative design validation, where our engineers translate client specifications into actionable technical blueprints. We maintain full control over the development lifecycle, from compound formulation to mold validation and final product testing. This vertical integration eliminates third-party dependencies, ensuring intellectual property security and accelerated time-to-market. Clients benefit from reduced non-recurring engineering (NRE) costs through our proprietary mold database, which houses over 1,200 validated sliding door profile designs adaptable to new requirements. Rigorous in-house testing protocols—including ASTM D2000 compression set analysis, ISO 1817 fluid resistance checks, and DIN 7863 weathering cycles—guarantee compliance with automotive, construction, and industrial OEM standards.

Material innovation defines our competitive edge. Our formula engineers develop custom EPDM, TPE, and silicone compounds tailored to operational demands, such as low-temperature flexibility for arctic climates or UV-stable formulations for coastal installations. Below is a representative comparison of standard versus custom-engineered properties for sliding door seals:

| Property | Standard EPDM | Custom Formulation | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 70 ± 5 | 55–85 (client-specified) | ASTM D2240 |

| Temperature Range (°C) | -40 to +120 | -55 to +150 | ISO 188 |

| Compression Set (%) | ≤ 25 | ≤ 15 | ASTM D395 |

| Tensile Strength (MPa) | ≥ 8.0 | ≥ 12.0 | ISO 37 |

| Density (g/cm³) | 1.15 ± 0.05 | 1.05–1.30 (optimized) | ISO 2781 |

This technical rigor extends to our OEM execution. We deploy real-time process monitoring during extrusion and vulcanization, with SPC data tracking critical dimensions to ±0.1 mm tolerances. Clients receive comprehensive documentation packages, including PPAP Level 3 submissions, material traceability records, and 3D mold flow analysis reports. Our engineers conduct joint failure mode analysis (FMEA) sessions to preempt field issues, ensuring zero defect delivery for high-volume production runs. By embedding our formula and mold engineering teams within the client’s development workflow, we transform sealing strip specifications into mission-critical components that enhance end-product performance and user experience. Suzhou Baoshida operates as an extension of your engineering department, committed to precision outcomes through scientific methodology and industrial-scale execution.

Customization Process

Customization Process for Sliding Door Sealing Strips

At Suzhou Baoshida Trading Co., Ltd., our engineering-led approach ensures that every sliding door sealing strip is tailored to meet exact functional and environmental demands. Our four-phase customization process—Drawing Analysis, Formulation, Prototyping, and Mass Production—combines material science precision with industrial scalability to deliver high-performance rubber seals for global OEMs.

The process begins with Drawing Analysis, where our rubber formula engineers conduct a comprehensive review of customer-provided technical drawings and performance requirements. We assess cross-sectional geometry, dimensional tolerances, installation forces, and interface surfaces. Special attention is given to compression set resistance, UV and ozone exposure, temperature range, and dynamic friction characteristics. This phase ensures design feasibility and identifies potential stress points or sealing inefficiencies before material selection.

Next, the Formulation stage leverages our in-house polymer laboratory to develop a custom rubber compound. Based on the operational environment, we select base elastomers such as EPDM for outdoor weather resistance, silicone for extreme temperature stability, or TPE for recyclability and soft-touch sealing. Additives including reinforcing fillers, antioxidants, plasticizers, and processing aids are precisely balanced to achieve target hardness (Shore A), tensile strength, elongation at break, and low-temperature flexibility. Each formulation is documented and archived for batch traceability.

Once the compound is finalized, we proceed to Prototyping. Using precision extrusion and vulcanization techniques, we produce sample sealing strips in controlled batches. These prototypes undergo rigorous in-house testing, including compression deflection analysis, aging tests (per ASTM D573 and ISO 188), and adhesion evaluation for co-extruded variants. Dimensional conformity is verified using digital calipers and optical measurement systems. We provide customers with test reports and physical samples for fit, form, and function validation.

Upon approval, the project transitions to Mass Production. Our automated extrusion lines, equipped with laser-based diameter control and inline curing, ensure consistent quality at scale. All production runs follow ISO 9001-certified workflows with 100% visual inspection and statistical process control (SPC). We support just-in-time delivery models and offer packaging customized to assembly line requirements.

The table below outlines typical performance specifications achievable through our customization process:

| Property | Test Standard | Typical Value Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–80 |

| Tensile Strength | ASTM D412 | 8–15 MPa |

| Elongation at Break | ASTM D412 | 250–450% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Temperature Range | — | -40°C to +120°C (EPDM) |

| UV and Ozone Resistance | ASTM D1149 | Excellent (Grade 2 or better) |

| Friction Coefficient | ISO 8295 | 0.3–0.6 (adjustable) |

Every sliding door sealing strip we manufacture reflects our commitment to material integrity, dimensional accuracy, and long-term sealing performance.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Sliding Door Sealing Solutions

Achieving optimal performance in sliding door systems demands sealing strips engineered beyond generic specifications. Standard off-the-shelf profiles often fail under real-world stressors like thermal cycling, UV degradation, and sustained compression loads, leading to premature failure, energy leakage, and compromised user experience. At Suzhou Baoshida Trading Co., Ltd., we address these challenges through material science rigor and OEM-centric collaboration. Our rubber formula engineering team specializes in developing bespoke EPDM and TPE compounds tailored to your exact operational parameters—whether for residential, commercial, or industrial applications. We prioritize critical performance metrics such as compression set resistance, low-temperature flexibility, and extrusion tolerance consistency, ensuring your seals maintain integrity across 100,000+ duty cycles. Partnering with us translates laboratory precision into field reliability, directly impacting your product’s longevity and end-user satisfaction.

The table below outlines core performance specifications achievable through our engineered solutions, validated per ASTM D2000 and ISO 3384 standards. These benchmarks reflect our baseline capabilities; all formulations undergo iterative refinement to align with your unique environmental and mechanical requirements.

| Performance Parameter | Baoshida Precision Seal Standard | Test Method |

|---|---|---|

| Hardness (Shore A) | 55 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 10.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 300 | ASTM D412 |

| Compression Set (22h, 70°C) | ≤ 25% | ASTM D395 |

| Temperature Range (°C) | -50 to +135 | ISO 188 |

| Extrusion Tolerance (mm) | ± 0.15 | ISO 3302 |

Our value extends beyond material formulation. As your OEM technical partner, we integrate early in your design phase to optimize profile geometry, tooling strategy, and production scalability. We conduct finite element analysis (FEA) to simulate seal behavior under dynamic loads, preventing costly redesigns post-tooling. Our Suzhou-based manufacturing facility maintains ISO 9001-certified processes with real-time rheometry monitoring, guaranteeing batch-to-batch consistency critical for automated assembly lines. This end-to-end control—from raw material sourcing to final inspection—eliminates supply chain variables that compromise seal performance in mass production.

Initiate a technical dialogue to transform your sliding door sealing challenges into engineered advantages. Contact Mr. Boyce, our dedicated OEM Technical Manager, for a confidential consultation. He will coordinate our engineering team to review your application specifics, provide material compatibility analysis, and deliver a validated prototype within 15 business days. Specify your performance thresholds, environmental conditions, and volume requirements to receive a data-driven proposal.

Reach Mr. Boyce directly at [email protected]. Include your project timeline and technical dossier for expedited evaluation. For urgent inquiries, reference code SDS-2024 in your subject line to prioritize engineering resource allocation. Suzhou Baoshida commits to resolving your sealing complexities with scientific precision—ensuring every extrusion meets the uncompromising standards your brand demands. Partner with us to elevate sliding door system performance through material innovation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).