Technical Contents

Engineering Guide: Slip Strips For Stairs

Engineering Insight: Material Selection in Slip Strips for Stairs

In industrial and commercial environments, slip strips for stairs are not merely safety accessories—they are engineered components designed to withstand dynamic mechanical stresses, environmental exposure, and continuous foot traffic. The performance and longevity of these strips are directly tied to material selection, a factor often overlooked when opting for off-the-shelf solutions. Standardized products, while cost-attractive, frequently fail due to their generic composition, which lacks the tailored resilience required for specific operational conditions.

At Suzhou Baoshida Trading Co., Ltd., we emphasize that rubber-based slip strips must be formulated with precision, considering hardness, abrasion resistance, temperature stability, and adhesion properties. Off-the-shelf variants typically employ low-grade recycled rubber or unmodified thermoplastics, which exhibit rapid wear under heavy use. These materials often degrade when exposed to UV radiation, moisture, or industrial chemicals, leading to delamination, cracking, or loss of traction—compromising safety and increasing lifecycle costs.

A critical failure point in generic slip strips is inadequate bonding performance. Many pre-fabricated options use weak adhesive backings or non-reactive bonding agents that cannot sustain long-term attachment on concrete, metal, or composite substrates. In contrast, engineered rubber compounds with chloroprene or neoprene bases offer superior adhesion when paired with solvent-based or epoxy primers, ensuring structural integrity even in high-moisture environments such as stairwells in food processing plants or outdoor infrastructure.

Another underappreciated factor is dynamic coefficient of friction (COF). Standard strips may meet minimum static COF requirements but fail under wet or oily conditions where dynamic traction is essential. High-performance formulations incorporate aluminum oxide or silicon carbide aggregates embedded into nitrile or EPDM matrices, maintaining consistent slip resistance across variable service conditions.

To illustrate the performance gap, consider the following comparative specifications:

| Property | Off-the-Shelf PVC Strip | Engineered Rubber Strip (Baoshida) |

|---|---|---|

| Base Material | Recycled PVC | Chloroprene / Nitrile Blend |

| Shore A Hardness | 70 ± 5 | 65 ± 3 |

| Abrasion Resistance (DIN) | 180 mm³ loss | 95 mm³ loss |

| Operating Temperature Range | -10°C to 60°C | -40°C to 120°C |

| Adhesion Strength (peel) | 0.6 kN/m | 1.8 kN/m |

| Dynamic COF (wet) | 0.35 | 0.72 |

| UV Resistance | Poor | Excellent |

The data underscores why standardized solutions fall short in demanding applications. At Baoshida, our slip strips are formulated using industrial-grade elastomers and reinforced with anti-slip mineral fillers, ensuring compliance with ISO 22196 for microbial resistance and DIN 51130 for slip testing. Custom curing profiles and substrate-specific priming protocols further enhance field performance.

Material selection is not a cost center—it is a risk mitigation strategy. By investing in purpose-engineered rubber slip strips, facility managers reduce maintenance frequency, enhance occupant safety, and achieve long-term cost efficiency. Off-the-shelf alternatives may appear economical initially, but their premature failure results in higher total cost of ownership and increased liability exposure.

Material Specifications

Material Specifications for Industrial Stair Slip Strips

Selection of the optimal elastomeric compound for stair slip strips is a critical engineering decision directly impacting safety performance, service life, and total cost of ownership in demanding industrial environments. Suzhou Baoshida Trading Co., Ltd. prioritizes material science rigor to ensure our slip strip solutions meet exacting OEM and end-user requirements. The three primary high-performance rubber materials employed are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct chemical, thermal, and mechanical property profiles essential for specific application challenges. Understanding these specifications is paramount for specifying the correct product.

Viton fluoroelastomers represent the pinnacle of chemical and thermal resistance within our portfolio. Their saturated polymer backbone provides exceptional stability against aggressive hydrocarbons, acids, bases, and ozone, maintaining integrity where other rubbers degrade rapidly. Viton slip strips reliably operate continuously at temperatures up to 200°C (392°F), with short-term excursions possible to 250°C (482°F). This makes them indispensable for stair applications in chemical processing plants, semiconductor fabrication cleanrooms, and high-temperature manufacturing zones where exposure to solvents, fuels, or extreme heat is routine. However, Viton commands a premium cost and exhibits lower flexibility at ambient temperatures compared to NBR or Silicone, requiring careful design consideration for tread pattern geometry to ensure optimal slip resistance underfoot.

Nitrile rubber (NBR) remains the dominant material for general industrial slip strips due to its outstanding balance of properties and cost-effectiveness. Its high acrylonitrile content delivers excellent resistance to oils, greases, and aliphatic hydrocarbons, crucial for factory floors, automotive facilities, and workshops. NBR provides superior abrasion resistance and mechanical strength, ensuring long-term durability under heavy foot traffic and wheeled equipment. Operational temperature range is typically -30°C to +100°C (-22°F to +212°F), suitable for most indoor and sheltered outdoor environments. While NBR offers good compression set resistance, prolonged exposure to strong oxidizing agents, ozone, or significant UV radiation can accelerate aging, necessitating formulation adjustments or protective topcoats for extended outdoor use.

Silicone rubber (VMQ) excels in extreme temperature applications and environments demanding high purity. Its inert nature provides an operational range from -60°C to +230°C (-76°F to +446°F), unmatched by other common elastomers. Silicone slip strips are non-toxic, FDA-compliant, and exhibit exceptional resistance to weathering, ozone, and UV radiation, making them ideal for exterior staircases, food and beverage processing plants, pharmaceutical facilities, and cleanrooms. They maintain flexibility across this vast temperature spectrum. However, standard silicone formulations possess lower tensile strength and abrasion resistance compared to NBR, potentially limiting lifespan in high-wear industrial traffic areas unless reinforced compounds are utilized. Cost is also higher than NBR.

The following table summarizes critical comparative specifications for informed material selection:

| Material | Temperature Range (Continuous) | Key Strengths | Primary Limitations | Best Application Environments |

|---|---|---|---|---|

| Viton (FKM) | -20°C to +200°C (-4°F to +392°F) | Exceptional chemical resistance (acids, fuels, solvents), High thermal stability, Outstanding ozone resistance | High cost, Lower flexibility at low temps, Poor resistance to ketones/esters | Chemical plants, Semiconductor fabs, High-heat processing areas |

| Nitrile (NBR) | -30°C to +100°C (-22°F to +212°F) | Excellent oil/fuel resistance, Superior abrasion resistance, Good mechanical strength, Cost-effective | Moderate heat resistance, Poor ozone/UV resistance without protection | General manufacturing, Automotive plants, Warehouses, Oil/gas facilities |

| Silicone (VMQ) | -60°C to +230°C (-76°F to +446°F) | Extreme temperature range, Excellent weather/ozone/UV resistance, High purity (FDA compliant), Good flexibility retention | Lower abrasion resistance (standard grades), Higher cost than NBR, Poor tear strength | Food/pharma processing, Exterior staircases, Cleanrooms, Cryogenic environments |

Material selection must be validated against the specific tribological demands, environmental exposures, and regulatory requirements of the installation site to ensure optimal slip resistance and longevity. Suzhou Baoshida Trading Co., Ltd. provides comprehensive technical support for OEM integration and material qualification.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber engineering, delivering precision-engineered slip strips for stairs tailored to demanding architectural and safety standards. Our Engineering Capability division is anchored by a dedicated team of five certified mould engineers and two advanced rubber formulation specialists, ensuring end-to-end control from concept to production.

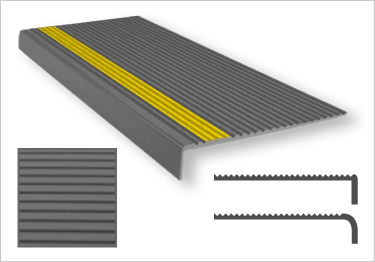

Our mould engineers utilize state-of-the-art CAD/CAM software and CNC prototyping systems to design high-tolerance steel and aluminum tooling optimized for long production cycles and consistent part geometry. Each mould is subjected to rigorous thermal and stress simulations to ensure dimensional stability under repeated vulcanization cycles. This precision guarantees that every slip strip maintains exact profile consistency, critical for both aesthetic integration and functional reliability in stair applications.

Complementing our tooling expertise, our two in-house rubber formula engineers specialize in developing custom elastomer compounds tailored to specific environmental and mechanical requirements. Utilizing advanced rheometry, tensile testing, and accelerated aging protocols, we formulate rubber blends that deliver optimal Shore A hardness, wear resistance, and anti-slip performance under wet or oily conditions. Our formulations are engineered to meet international safety standards, including DIN 51130 for slip resistance and ISO 48-4 for physical durability.

We offer full OEM manufacturing services, enabling clients to co-develop proprietary slip strip designs with complete intellectual property protection. Our vertical integration allows seamless transition from prototype to mass production, with cycle times reduced by up to 30% compared to industry benchmarks. Clients benefit from DFM (Design for Manufacturability) analysis at the concept stage, minimizing rework and accelerating time-to-market.

Our production facility supports multiple rubber processing methods, including compression moulding, transfer moulding, and continuous extrusion with in-line curing, allowing flexibility in profile complexity and volume scalability. All compounds are free from harmful phthalates and comply with REACH and RoHS regulations.

The following table outlines the key technical specifications achievable for custom slip strips:

| Property | Standard Range | Test Method |

|---|---|---|

| Shore A Hardness | 50–80 ±5 | ISO 48-4 |

| Tensile Strength | 8–15 MPa | ISO 37 |

| Elongation at Break | 250–450% | ISO 37 |

| Abrasion Loss (DIN) | ≤120 mm³ | DIN 53516 |

| Slip Resistance (R Value) | R9–R13 | DIN 51130 |

| Operating Temperature | -30°C to +80°C | ISO 188 |

| Fire Rating (UL94) | HB to V-0 | UL 94 |

All products undergo 100% visual inspection and batch sampling for physical property validation. Suzhou Baoshida Trading Co., Ltd. remains committed to engineering excellence, offering unmatched technical depth in rubber formulation and mould design for industrial safety applications.

Customization Process

Customization Process for Industrial Stair Slip Strips

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for stair slip strips integrates material science with precision manufacturing to deliver solutions meeting exact safety and durability requirements. This four-phase workflow ensures technical alignment with client specifications while adhering to global safety standards such as ASTM F1637 and ISO 13036-1.

Drawing Analysis

Initial engagement begins with rigorous technical drawing validation. Our engineering team scrutinizes CAD files for critical parameters including tread depth, edge geometry, and substrate adhesion zones. We cross-reference dimensional tolerances against ISO 2768-mK standards and identify potential stress points where rubber-metal bonding may require reinforcement. This phase includes collaborative review with the client to resolve ambiguities in load distribution or environmental exposure conditions, preventing downstream rework. Only after mutual sign-off on finalized schematics do we proceed to material formulation.

Formulation Development

Leveraging our in-house polymer laboratory, we engineer custom rubber compounds tailored to the slip strip’s operational demands. Key variables include Shore A hardness for optimal grip without excessive wear, tear resistance for high-traffic zones, and thermal stability for outdoor installations. Formulations may incorporate silica-reinforced SBR for cold-climate resilience or EPDM for UV/ozone resistance. Each compound undergoes accelerated aging tests per ASTM D573 and abrasion validation via DIN 53516 protocols. Material certifications, including RoHS and REACH compliance documentation, are generated prior to prototyping.

Prototyping and Validation

Functional prototypes are produced using client-approved tooling under controlled vulcanization conditions. We conduct three-tiered testing:

1. Laboratory analysis of coefficient of friction (ASTM E303) on wet/dry surfaces

2. Real-world installation trials simulating 10,000+ foot cycles

3. Adhesion strength verification per ASTM D429 Method B

Clients receive detailed performance reports with quantifiable metrics. Iterations address any deviations in slip resistance or dimensional stability, typically requiring 1–2 revision cycles before final approval.

Mass Production Execution

Upon prototype sign-off, production transitions to our ISO 9001-certified facility with seamless scalability. Automated mixing systems ensure batch consistency, while inline spectrometers monitor cure state in real time. Every 500 units undergo抽样 inspection for critical attributes. Final packaging includes serialized traceability tags linking to material batch records and test certificates. This phase maintains ≤0.5% defect rates through statistical process control, with standard lead times of 15–25 days for 10,000+ unit orders.

Key Performance Specifications

| Property | Test Standard | Typical Range | Client Customization Range |

|————————-|——————-|———————|—————————-|

| Shore A Hardness | ASTM D2240 | 65–75 | 50–85 |

| Abrasion Loss (mm³) | DIN 53516 | ≤120 | ≤80 (premium grade) |

| Operating Temperature | ISO 188 | -40°C to +100°C | -55°C to +130°C |

| Static CoF (wet) | ASTM E303 | ≥0.6 | ≥0.8 (high-safety zones) |

| Tensile Strength (MPa) | ASTM D412 | 18–22 | 15–25 |

This structured approach guarantees stair slip strips that exceed safety mandates while optimizing lifecycle cost. Suzhou Baoshida’s OEM framework transforms client specifications into certified, field-proven products through uncompromising material science and process control.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Slip Strips for Stairs

When it comes to industrial safety and long-term durability in high-traffic environments, selecting the right slip-resistant stair tread solutions is critical. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions that meet rigorous performance standards across construction, transportation, and public infrastructure sectors. Our slip strips for stairs are designed to deliver maximum traction, weather resistance, and structural integrity under demanding conditions. As your trusted OEM partner in industrial rubber components, we ensure every product is precision-manufactured to meet exact technical and regulatory requirements.

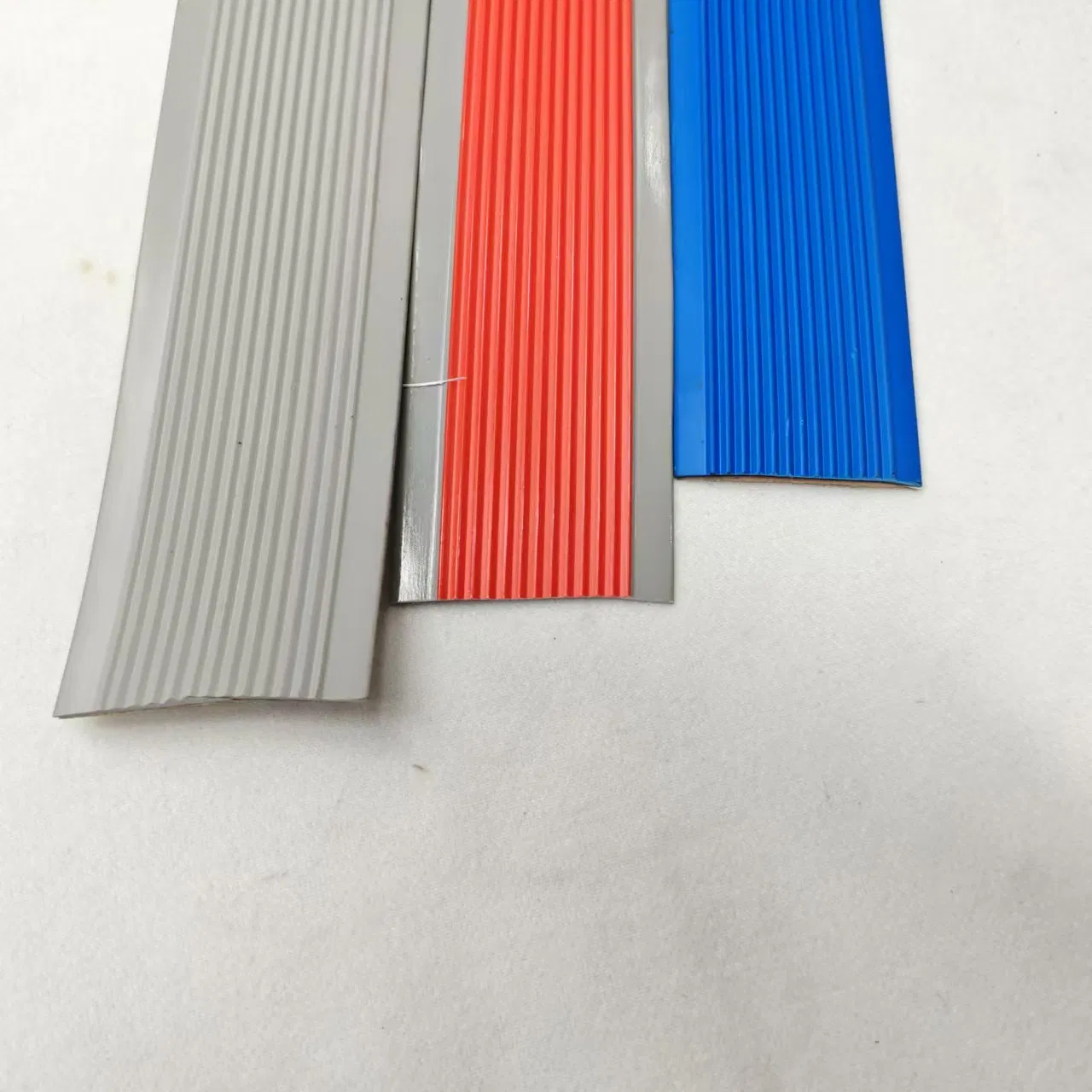

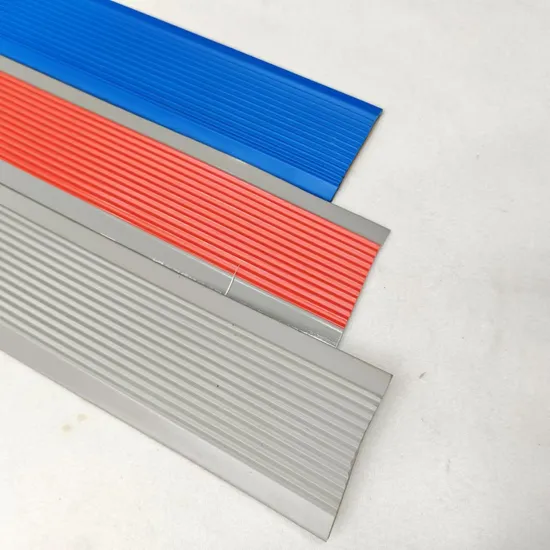

Our slip strips are formulated using high-grade EPDM, Nitrile, or SBR rubber compounds, depending on application needs such as oil resistance, UV stability, or low-temperature flexibility. Each strip is embedded with aluminum oxide or ceramic granules to enhance surface friction, significantly reducing slip-and-fall risks on both indoor and outdoor staircases. We offer custom profiles, lengths, and adhesive backing options to integrate seamlessly with metal, concrete, or wooden substrates. Whether you require recessed inserts, surface-mounted strips, or anti-slip nosings for commercial buildings, our engineering team works closely with clients to develop tailored solutions that comply with ISO, ASTM, and EN safety standards.

To ensure consistent quality, all slip strips undergo stringent testing for abrasion resistance, adhesion strength, and slip coefficient (COF) under wet and dry conditions. Our manufacturing facility in Suzhou is equipped with advanced vulcanization presses, CNC cutting systems, and quality control labs to maintain tight tolerances and repeatability across large production runs. As an ISO 9001-certified supplier, Suzhou Baoshida is committed to on-time delivery, material traceability, and full documentation support for audits and compliance reporting.

Below are key technical specifications for our standard slip strip offerings:

| Property | EPDM Base | Nitrile Base | SBR Base |

|---|---|---|---|

| Hardness (Shore A) | 60 ± 5 | 65 ± 5 | 70 ± 5 |

| Tensile Strength (MPa) | ≥12 | ≥14 | ≥10 |

| Elongation at Break (%) | ≥250 | ≥200 | ≥220 |

| Operating Temperature Range | -40°C to +120°C | -30°C to +100°C | -20°C to +90°C |

| Slip Resistance (COF, wet) | ≥0.65 | ≥0.60 | ≥0.62 |

| Abrasion Loss (mm³) | ≤120 | ≤100 | ≤130 |

| Adhesive Type | Pressure-sensitive acrylic or heat-activated |

For project-specific requirements, including flame-retardant grades, conductive variants, or custom colors, we provide full technical consultation and sample prototyping. Our global logistics network ensures reliable delivery to North America, Europe, Southeast Asia, and the Middle East.

To discuss your application and receive a detailed quotation, contact Mr. Boyce, OEM Sales Manager, directly at [email protected]. Include your technical specifications, volume requirements, and target delivery timeline for a rapid response. Partner with Suzhou Baoshida Trading Co., Ltd. and leverage our expertise in industrial rubber engineering to enhance safety, compliance, and product longevity in your stair safety systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).