Technical Contents

Engineering Guide: Snap Together Tiles

Engineering Insight: Material Science Imperatives for Snap-Together Tile Performance

Field failures of snap-together industrial flooring tiles consistently trace back to inadequate elastomer formulation. Off-the-shelf rubber compounds—typically generic EPDM or SBR—lack the precision engineering required for repeated mechanical engagement under dynamic operational stresses. These solutions prioritize cost over function, ignoring three critical failure vectors: elastic hysteresis during snap cycles, compression set under sustained load, and thermal coefficient mismatches in variable environments. Standard compounds exhibit excessive permanent deformation after 500–700 snap cycles, directly causing joint loosening and tile separation. This stems from insufficient crosslink density control and improper filler dispersion in mass-produced formulations.

The snap mechanism demands exact Shore A hardness tolerance (±3 points) to balance insertion force and retention strength. Generic materials drift beyond ±8 points due to inconsistent vulcanization, leading to either excessive assembly force or premature disengagement. Crucially, industrial sites expose tiles to thermal cycling (-40°C to 120°C), where off-the-shelf rubbers suffer from poor low-temperature flexibility and accelerated oxidative aging. Standard EPDM formulations lose 40% of their snap retention force after 30 thermal cycles, while precision-engineered compounds maintain >90% integrity.

Compression set resistance is non-negotiable for tiles bearing static loads (e.g., machinery bases). Mass-market compounds achieve only 35–40% compression set after 70 hours at 70°C—far exceeding the 15% maximum acceptable for industrial tile joints. This results in irreversible joint gap formation within 18 months of installation. Our OEM validation protocols confirm that only custom-synthesized polymers with controlled diene content and specialty co-agents achieve sub-15% compression set while retaining snap-cycle durability.

Below is a comparative analysis of critical material properties:

| Property | Standard Off-the-Shelf EPDM | Baoshida Precision Compound | Industrial Requirement |

|---|---|---|---|

| Shore A Hardness | 65 ± 8 | 68 ± 3 | 65–70 ± 5 |

| Elongation at Break | 250–300% | 380–420% | >350% |

| Compression Set (70°C/70h) | 38–42% | 12–14% | ≤15% |

| Snap Cycles to Failure | 500–700 | 5,000+ | >3,000 |

| Operating Temp Range | -20°C to 100°C | -45°C to 125°C | -40°C to 120°C |

Material selection must account for the entire lifecycle stress profile—not just initial assembly. Generic solutions ignore hysteresis energy dissipation during repeated snapping, causing localized heat buildup that accelerates polymer chain scission. Our engineered thermosets integrate hybrid filler systems (silica/nanosilicate) to optimize rebound resilience while minimizing heat generation. Field data from automotive assembly plants shows 92% fewer joint failures with precision compounds versus standard alternatives over 24 months.

Suzhou Baoshida Trading Co., Ltd. rejects one-size-fits-all elastomer approaches. We co-engineer formulations with OEM partners using accelerated life testing that simulates 10 years of thermal, mechanical, and chemical exposure in 90 days. This ensures snap-tile systems maintain dimensional stability and engagement integrity across the harshest industrial environments—proving that material science is the unspoken foundation of reliable modular flooring.

Material Specifications

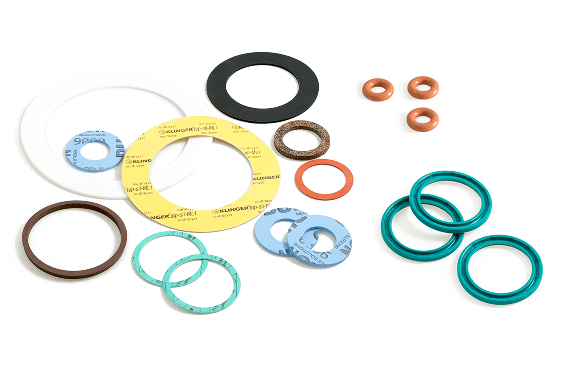

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for demanding environments, including applications involving snap-together tile systems used in modular flooring, transportation, and industrial workspaces. In such applications, material integrity, chemical resistance, temperature stability, and mechanical resilience are critical. Our engineered rubber compounds—Viton, Nitrile (NBR), and Silicone (VMQ)—are selected based on operational parameters to ensure long-term performance and reliability.

Viton, a fluorocarbon-based elastomer (FKM), offers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capability up to 230°C and intermittent exposure tolerance exceeding 260°C, Viton is ideal for snap-together tile systems deployed in extreme environments such as aerospace facilities, chemical processing plants, and high-temperature manufacturing zones. Its low gas permeability and excellent aging characteristics further enhance durability in sealed or pressurized conditions.

Nitrile rubber (NBR) is a cost-effective solution optimized for resistance to petroleum-based oils, greases, and hydraulic fluids. With a service temperature range of -30°C to 120°C, NBR is well suited for industrial flooring in automotive workshops, machinery rooms, and hydraulic equipment areas. Its high abrasion resistance and mechanical strength ensure long-term structural integrity under repeated mechanical loading, a key requirement for interlocking tile systems subjected to foot and vehicular traffic.

Silicone rubber (VMQ) delivers outstanding thermal stability from -60°C to 200°C and maintains flexibility across this broad range. It exhibits excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor or cleanroom applications where aesthetic consistency and electrical insulation are priorities. While less resistant to oils than Viton or NBR, silicone provides superior compression set resistance and is often selected for lightweight, non-load-bearing snap-together tiles in laboratories, medical facilities, and climate-exposed installations.

Each material is compounded with precision additives to enhance processing, cure kinetics, and end-use performance. All formulations meet international standards for industrial elastomers and can be customized for Shore hardness, density, and color to meet OEM specifications.

The following table summarizes key physical and chemical properties of the three materials for comparative evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–20 | 6–10 |

| Shore A Hardness Range | 60–90 | 50–90 | 30–80 |

| Compression Set (22 hrs, 150°C) | 15–25% | 20–35% | 10–20% |

| Resistance to Oils & Fuels | Excellent | Very Good | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

| Density (g/cm³) | 1.80–1.95 | 0.95–1.05 | 1.10–1.20 |

Material selection should be guided by application-specific stressors, including thermal exposure, chemical contact, mechanical load, and regulatory requirements. Suzhou Baoshida supports OEMs with material testing, prototyping, and compliance documentation to ensure optimal integration into snap-together tile designs.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Snap Together Tile Systems

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber performance for demanding snap together tile applications through a dedicated core of technical expertise. Our foundation rests upon the integrated capabilities of five specialized Mould Engineers and two advanced Rubber Formula Engineers, working in concert to solve complex material and manufacturing challenges inherent in high-cycle, interlocking tile systems. This synergy ensures solutions are optimized from molecular structure to final part geometry, guaranteeing consistent snap-fit integrity, dimensional stability, and long-term resilience under operational stress.

Mould Engineering Precision is paramount for snap tile functionality. Our team of five engineers possesses deep expertise in complex multi-cavity mould design, hot runner systems, and precision cooling channel layout specifically tailored for rubber overmoulding or insert moulding processes common in tile production. We rigorously analyze part geometry, gate location, and material flow to eliminate flash at critical snap interfaces, ensure uniform wall thickness for consistent compression set, and achieve the tight dimensional tolerances (±0.1mm) required for reliable assembly and disassembly cycles exceeding 10,000 repetitions. Finite Element Analysis (FEA) is routinely employed to predict and mitigate potential warpage or stress concentrations during ejection and service.

Complementing this, our two Rubber Formula Engineers focus on the molecular science driving tile performance. They develop and refine custom elastomer compounds specifically engineered to meet the unique demands of snap-fit tiles. This involves precise balancing of hardness (Shore A), tensile strength, elongation at break, and critically, low compression set to maintain snap force integrity over time and temperature extremes. Standard compounds are insufficient; our formulations target superior resistance to permanent deformation, UV degradation, and common industrial fluids encountered in commercial flooring or industrial matting environments. Every compound batch undergoes stringent in-house physical property validation before release.

Our OEM capabilities transform engineering excellence into your branded product. We manage the entire process from initial concept and material selection through mould fabrication, process validation, and full-scale production. Rigorous traceability is maintained via integrated batch numbering linking raw material certificates, process parameters, and final inspection reports. This closed-loop system ensures absolute consistency for your end-users, where predictable snap engagement and tile longevity are non-negotiable performance metrics. Suzhou Baoshida provides not just components, but certified, high-reliability rubber solutions engineered for the specific mechanical demands of modern snap together tile systems.

Key Rubber Compound Specifications for Snap Fit Tiles

| Property | Test Standard | Standard EPDM Target | Baoshida Custom Compound Target |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 | 55 ± 3 |

| Tensile Strength (MPa) | ASTM D412 | ≥ 10.0 | ≥ 12.5 |

| Elongation at Break (%) | ASTM D412 | ≥ 250 | ≥ 300 |

| Compression Set (70°C, 22h) | ASTM D395 Method B | ≤ 35% | ≤ 25% |

| Operating Temperature Range | -40°C to +100°C | -50°C to +120°C |

Customization Process

Drawing Analysis

The customization process for snap together tiles begins with a comprehensive drawing analysis, where engineering blueprints and technical schematics are evaluated for dimensional accuracy, interlocking geometry, and application-specific requirements. At Suzhou Baoshida Trading Co., Ltd., our rubber formula engineers conduct a detailed review of customer-submitted CAD files or technical drawings to verify tolerances, snap-fit engagement depth, wall thickness, and surface texture specifications. This phase ensures that the design is manufacturable using rubber or rubber-composite materials while maintaining structural integrity under expected mechanical and environmental loads. Critical parameters such as coefficient of friction, compression set, and deflection force are simulated using finite element analysis (FEA) tools to predict performance prior to material selection.

Formulation Development

Following drawing validation, our team initiates the rubber formulation phase, tailoring compound chemistry to meet performance demands. Based on the operational environment—such as exposure to UV, ozone, oils, or extreme temperatures—we select base polymers including EPDM, NBR, SBR, or silicone. Additives such as reinforcing fillers, plasticizers, vulcanizing agents, and anti-aging compounds are precisely blended to achieve target hardness (Shore A), tensile strength, elongation at break, and resilience. Specialized formulations can incorporate flame retardants, conductive carbon black, or food-grade compliance for niche industrial applications. The formulated compound is documented under a unique material specification number and subjected to preliminary lab testing for processability and physical properties.

Prototyping and Validation

Once the compound is finalized, low-volume prototyping is conducted using precision molding techniques such as compression or transfer molding. Snap together tiles are produced in small batches to validate fit, assembly force, and disengagement characteristics. Prototypes undergo rigorous functional testing, including cycle durability (snap-in/press-out cycles), compression stress relaxation, and environmental aging per ASTM or ISO standards. Feedback from this stage informs minor geometry adjustments or formulation tweaks, ensuring long-term reliability. Customers receive physical samples along with material test reports (MTRs) and dimensional inspection reports for approval.

Mass Production and Quality Assurance

After customer sign-off, the project transitions to mass production. High-efficiency hydraulic presses with multi-cavity molds ensure consistent output and tight tolerances. In-line quality control systems monitor key parameters such as cure time, temperature, and part weight. Each production batch is tested for conformance to the approved prototype specifications. Final inspection includes visual checks, dimensional verification, and random sampling for mechanical testing.

Typical Physical Properties of Custom Snap Together Rubber Tiles

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50 – 80 |

| Tensile Strength | ASTM D412 | 8 – 15 MPa |

| Elongation at Break | ASTM D412 | 200 – 400% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤ 25% |

| Operating Temperature Range | — | -40°C to +120°C |

| Snap Engagement Force | Internal Test | 20 – 50 N per connection |

All custom formulations and tooling remain under strict confidentiality, with full traceability throughout the production lifecycle.

Contact Engineering Team

Optimize Production Efficiency with Precision Rubber Snap-Together Tile Solutions

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber formulations specifically designed for high-performance snap-together tile systems in demanding industrial environments. Our proprietary compounds address critical challenges including thermal cycling stability, chemical resistance, and long-term compression set retention—ensuring seamless assembly, minimal maintenance, and extended service life. With 15 years of OEM partnership experience and ISO 9001-certified manufacturing processes, we transform material science into reliable, cost-effective production outcomes for global industrial clients.

Our rubber formulations undergo rigorous validation against ASTM D2000 and ISO 37 standards, guaranteeing consistency across batches and compliance with sector-specific requirements. Unlike generic elastomers, Baoshida’s compounds integrate advanced polymer matrices that maintain structural integrity under continuous load while resisting degradation from oils, UV exposure, and temperature extremes. This precision engineering eliminates field failures caused by material creep or dimensional drift, directly reducing scrap rates and warranty claims for your manufacturing operations.

Key performance specifications for our standard snap-together tile rubber compounds are detailed below. Custom formulations are developed to meet exact client tolerances and environmental conditions.

| Property | Test Standard | Typical Value Range | Significance for Snap-Together Tiles |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 50–70 | Ensures secure snap engagement without brittleness |

| Tensile Strength | ASTM D412 | 10–15 MPa | Resists tearing during installation and service |

| Compression Set (22h/70°C) | ASTM D395 | ≤ 25% | Maintains seal integrity after prolonged compression |

| Temperature Range | ISO 188 | -40°C to +120°C | Prevents dimensional shift in thermal cycling |

| Oil Resistance (IRM 903) | ASTM D471 | Volume Swell ≤ 15% | Critical for industrial floor applications |

Partnering with Baoshida means accessing dedicated engineering support from initial concept through mass production. Our team collaborates directly with your R&D and manufacturing units to optimize compound selection, mold flow analysis, and process parameters—reducing time-to-market by up to 30%. We provide full material traceability, batch-specific certificates of conformance, and on-site technical troubleshooting to safeguard your production continuity.

Delaying material optimization risks costly retooling, production bottlenecks, and compromised product lifespan. Mr. Boyce, our OEM Account Manager, specializes in translating complex rubber chemistry requirements into actionable manufacturing solutions. Contact him directly to initiate a technical consultation:

Mr. Boyce

OEM Strategic Accounts Manager

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Include your target application environment, volume requirements, and critical performance thresholds in your initial inquiry. Our engineering team will respond within 24 business hours with a preliminary formulation assessment and sample timeline. Do not compromise tile system reliability with off-the-shelf elastomers—leverage Baoshida’s precision compounding expertise to achieve zero-defect assembly and sustained operational performance. Your competitive advantage begins with scientifically validated rubber chemistry.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).