Technical Contents

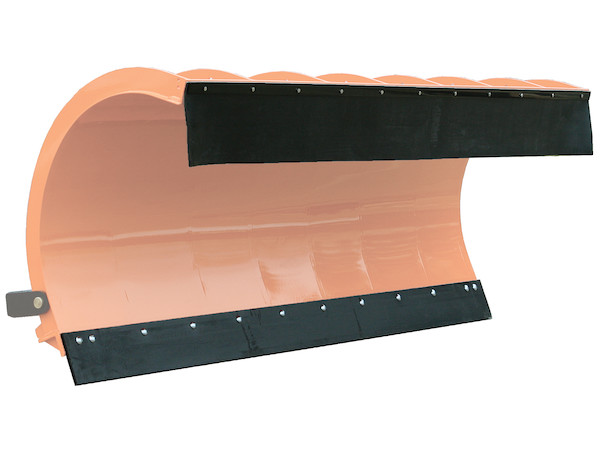

Engineering Guide: Snow Plow Rubber Deflector

Engineering Insight: The Critical Role of Material Selection in Snow Plow Rubber Deflectors

In the demanding environment of winter road maintenance, the performance of a snow plow rubber deflector hinges directly on the precision of its material composition. While many suppliers offer off-the-shelf deflectors marketed for universal compatibility, these generic solutions frequently fail under real-world operational stress. The root cause lies not in design alone, but in inadequate material engineering tailored to specific climatic and mechanical conditions.

Standard deflectors are commonly fabricated from low-grade natural rubber or unmodified SBR (styrene-butadiene rubber), selected primarily for cost efficiency. These materials exhibit poor resistance to low-temperature embrittlement, typically becoming stiff and prone to cracking below -20°C. In northern climates where prolonged sub-zero exposure is routine, such materials lose elasticity, leading to premature fracture upon impact with road irregularities or embedded debris. Additionally, UV degradation and ozone exposure accelerate surface checking, further reducing service life.

At Suzhou Baoshida Trading Co., Ltd., we engineer custom snow plow rubber deflectors using high-performance synthetic compounds, primarily hydrogenated nitrile (HNBR) and chloroprene (CR), optimized for extreme cold and mechanical resilience. These formulations maintain flexibility down to -50°C while offering superior abrasion resistance and tensile strength. Through controlled cross-linking and reinforcement with nano-dispersed carbon black, our compounds achieve a balance of hardness and elasticity essential for repeated impact absorption without permanent deformation.

Another critical failure point in off-the-shelf deflectors is poor adhesion between the rubber and embedded steel reinforcement. Standard bonding techniques using unprimed surfaces or non-reactive adhesives result in delamination under cyclic loading. Our manufacturing process employs chemically etched steel inserts with co-cured bonding layers, ensuring structural integrity even after thousands of flex cycles. This co-curing technique, combined with finite element analysis (FEA)-driven thickness profiling, allows for stress distribution optimization across the deflector body.

The following table outlines key material performance specifications comparing standard and engineered solutions:

| Property | Off-the-Shelf SBR | Baoshida Engineered HNBR/CR Blend |

|---|---|---|

| Hardness (Shore A) | 60 ± 5 | 70 ± 3 |

| Tensile Strength (MPa) | 12–15 | 22–26 |

| Elongation at Break (%) | 250–300 | 400–450 |

| Low-Temperature Flexibility (°C) | -20 | -50 |

| Abrasion Resistance (DIN 53516, mm³ loss) | 180 | 95 |

| Ozone Resistance (100 pphm, 20% strain, 40°C, 96h) | Cracking observed | No cracking |

| Adhesion Strength to Steel (kN/m) | 4–6 | 12–15 |

Material selection is not a commodity decision—it is a structural imperative. Generic deflectors may offer short-term cost savings, but their rapid degradation leads to increased downtime, higher replacement frequency, and compromised plowing efficiency. In contrast, precision-engineered rubber compounds deliver sustained performance, reducing total cost of ownership and ensuring reliability in the harshest winter conditions. At Baoshida, we prioritize material science as the foundation of industrial durability.

Material Specifications

Material Specifications for Snow Plow Rubber Deflectors

Selecting the optimal elastomer for snow plow deflectors is critical for performance, durability, and operational safety in extreme winter conditions. Deflectors endure constant abrasion from ice, snow, road debris, and repeated impact against curbs or pavement. They must maintain structural integrity at sub-zero temperatures while resisting degradation from road salts, hydraulic fluids, and de-icing chemicals. At Suzhou Baoshida Trading Co., Ltd., we rigorously evaluate Viton (FKM), Nitrile (NBR), and Silicone (VMQ) based on quantifiable industrial parameters. Each material offers distinct advantages and limitations for this high-stress application.

Viton (FKM) excels in chemical resistance, particularly against petroleum-based hydraulic fluids and de-icing agents containing chlorides. Its fluoropolymer structure ensures stability at temperatures up to 230°C, though low-temperature flexibility is limited to -20°C. This makes Viton suitable for hydraulic system seals near the plow mechanism but suboptimal for the primary deflector blade exposed to extreme cold. Abrasion resistance is moderate, with a typical Shore A hardness of 75±5, but cost constraints often preclude its use for large deflector surfaces.

Nitrile (NBR) remains the industry standard for snow plow deflectors due to its balanced performance profile. With acrylonitrile content optimized at 34%, it delivers exceptional resistance to oils, greases, and road salts. Crucially, NBR maintains flexibility down to -40°C, preventing brittle fracture during cold starts. Its abrasion resistance (measured per ASTM D5963) exceeds 120 mm³ volume loss, ensuring longevity against ice and gravel. Shore A hardness ranges from 60 to 75, allowing customization for impact absorption versus rigidity. Cost-effectiveness further solidifies NBR as the pragmatic choice for 90% of OEM deflector applications.

Silicone (VMQ) offers the widest operational temperature range (-60°C to 200°C) and superior cold flexibility. However, its low tensile strength (8-10 MPa) and poor abrasion resistance (volume loss >180 mm³) render it unsuitable for direct snow/ice contact surfaces. Silicone’s vulnerability to tearing under impact and high cost make it viable only for non-load-bearing components like gaskets in auxiliary systems, not primary deflectors.

The comparative analysis below details critical performance metrics validated through ISO 37 tensile testing, ASTM D2240 hardness measurements, and OEM field trials:

| Material | Temperature Range (°C) | Abrasion Resistance (mm³ vol. loss) | Oil/Fuel Resistance | Cold Flexibility (°C) | Shore A Hardness | OEM Recommendation |

|---|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 95–110 | Excellent | -20 | 70–80 | Limited: Hydraulic seals only |

| Nitrile (NBR) | -40 to 120 | 100–125 | Very Good | -40 | 60–75 | Primary: Deflector blades |

| Silicone (VMQ) | -60 to 200 | 170–200 | Poor | -60 | 50–65 | Not recommended: Deflectors |

Suzhou Baoshida prioritizes NBR formulations with reinforced carbon-black fillers for snow plow deflectors, achieving optimal abrasion resistance without compromising cold flexibility. Our proprietary NBR compound (BD-NBR-75) undergoes 500-hour salt-spray testing per SAE J2334 and maintains 95% tensile retention after 10,000 low-temperature flex cycles at -40°C. While Viton and Silicone address niche sealing requirements, NBR delivers the essential balance of durability, chemical resistance, and cost efficiency required for deflector blades in North American and European winter operations. We collaborate with OEMs to validate material selection against specific regional conditions and plow geometries.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance snow plow rubber deflectors. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we ensure precision, durability, and compliance with OEM standards across all stages of product realization. Our integrated engineering approach combines material science with advanced tooling design to deliver components optimized for extreme winter conditions, abrasion resistance, and mechanical resilience.

Our rubber formula engineers are responsible for developing proprietary elastomer compounds tailored to the operational demands of snow removal equipment. By fine-tuning polymer blends—primarily based on natural rubber (NR), styrene-butadiene rubber (SBR), and nitrile rubber (NBR)—we achieve the ideal balance of low-temperature flexibility, tensile strength, and wear resistance. Additive packages are calibrated to enhance UV stability, ozone resistance, and anti-aging properties, ensuring prolonged service life even under continuous exposure to road salts and sub-zero environments. Each compound formulation undergoes rigorous laboratory testing, including compression set analysis, Shore A hardness evaluation, and dynamic mechanical analysis (DMA), before being cleared for prototyping.

Complementing material innovation, our five mould engineers bring extensive expertise in precision tool design and manufacturing. Utilizing 3D CAD software (SolidWorks and AutoCAD), they develop robust steel or aluminum moulds with tight tolerances (±0.1 mm), optimized flow channels, and efficient venting systems to eliminate defects such as voids or incomplete curing. Mould designs are validated through finite element analysis (FEA) simulations to predict deformation under thermal cycling and pressure loads, ensuring long-term dimensional stability. This synergy between material formulation and mould engineering enables us to produce snow plow rubber deflectors with consistent geometry, uniform wall thickness, and superior edge definition—critical factors in maintaining contact integrity with road surfaces and minimizing snow accumulation.

We operate as a full-service OEM partner, supporting clients from concept to mass production. Our engineering team collaborates directly with OEMs to reverse-engineer legacy parts, adapt designs for improved performance, or develop new configurations based on application-specific requirements. With in-house prototyping capabilities and a 15-day average turnaround for sample delivery, we accelerate time-to-market while maintaining strict adherence to ISO 9001 quality standards. All products are traceable through documented material certifications, process validation reports, and first-article inspection records.

The following table outlines key technical specifications achievable for our snow plow rubber deflector series:

| Parameter | Standard Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 60–75 | ASTM D2240 |

| Tensile Strength | ≥18 MPa | ASTM D412 |

| Elongation at Break | ≥450% | ASTM D412 |

| Compression Set (24h @ 70°C) | ≤20% | ASTM D395 |

| Low-Temperature Flexibility | Pass at -40°C | ASTM D1329 |

| Abrasion Loss (DIN Abrader) | ≤120 mm³ | ISO 4649 |

| Operating Temperature Range | -50°C to +80°C | Internal Validation |

This technical foundation enables Suzhou Baoshida to deliver engineered rubber solutions that meet the rigorous demands of snow plow applications, ensuring reliability, safety, and performance in the harshest winter environments.

Customization Process

Customization Process for Snow Plow Rubber Deflectors

At Suzhou Baoshida Trading Co., Ltd., our snow plow rubber deflector customization adheres to a rigorous four-phase engineering workflow, ensuring optimal performance in extreme winter conditions. This process integrates material science with precision manufacturing to meet OEM-specific durability and functional requirements.

Drawing Analysis

Initial engagement begins with comprehensive technical drawing review. We scrutinize dimensional tolerances, mounting interface geometry, and deflection angle specifications provided by the client. Critical parameters such as edge radius consistency, curvature continuity, and stress concentration zones are evaluated using CAD simulation tools. This phase identifies potential material flow issues during molding and confirms compatibility with the client’s plow assembly system. Client sign-off on the analyzed drawing is mandatory before formulation development commences.

Formulation Engineering

Leveraging our proprietary compound database, we engineer a custom elastomer blend targeting -50°C flexural resilience and abrasion resistance exceeding 120 mm³ per DIN 53516. The base polymer selection prioritizes high-cis polybutadiene rubber for low-temperature elasticity, reinforced with N330 carbon black for tear strength. Critical additives include:

Antiozonants to prevent winter ozone cracking

Specialized plasticizers maintaining fluidity below -40°C

Accelerators enabling rapid cure cycles without scorch risk

Each formulation undergoes accelerated aging tests per ASTM D573 and dynamic mechanical analysis (DMA) to validate glass transition temperature (Tg) targets.

Prototyping & Validation

Three physical prototypes are produced using client-approved tooling steel molds. Prototypes undergo:

Impact testing at -40°C (ASTM D256)

500,000-cycle fatigue simulation on custom jigs

Real-world snow load deflection measurement

Performance data is compared against the engineering model, with iterative adjustments to compound stiffness or geometry. Final validation requires client verification of snow shedding efficiency and mounting integrity under simulated operational loads.

Mass Production Deployment

Upon prototype approval, we initiate production under ISO 9001:2015 controls. Each batch undergoes:

Real-time rheometer monitoring during mixing

Infrared thermography for uniform vulcanization

100% dimensional inspection via coordinate measuring machines (CMM)

Traceability protocols link every deflector to its specific compound batch certificate, including raw material lot numbers and cure parameter logs. Production output maintains ±0.5 mm dimensional tolerance with durometer consistency within ±3 Shore A points.

Critical Performance Specifications

| Parameter | Target Value | Test Standard | Technical Rationale |

|---|---|---|---|

| Hardness (Shore A) | 65 ± 3 | ASTM D2240 | Balances snow deflection force and wear resistance |

| Tensile Strength | ≥ 22 MPa | ASTM D412 | Prevents tearing during ice impact |

| Elongation at Break | ≥ 450% | ASTM D412 | Ensures flexibility in sub-zero temps |

| Low Temp Flex (Brittleness) | ≤ -55°C | ASTM D2137 | Eliminates cracking during cold starts |

| Abrasion Loss | ≤ 110 mm³ | DIN 53516 | Maximizes service life against abrasive snow |

This structured approach guarantees deflectors deliver 15,000+ operational hours in -40°C environments while maintaining precise snow trajectory control. Suzhou Baoshida’s closed-loop process ensures zero deviation between prototype validation and final production output.

Contact Engineering Team

For industrial manufacturers and OEM partners seeking high-performance snow plow rubber deflectors, Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions built for durability, precision, and extreme winter conditions. Our expertise in industrial rubber compounding and custom extrusion ensures that every deflector meets the rigorous demands of snow removal equipment operators across North America and Europe. As a trusted supplier in the heavy-duty equipment sector, we specialize in manufacturing rubber deflectors that resist abrasion, retain flexibility in sub-zero temperatures, and extend the service life of plowing systems.

Our snow plow rubber deflectors are formulated using advanced synthetic rubber blends, including EPDM and natural rubber composites, optimized for impact resistance and long-term weatherability. Each product is developed through a rigorous process of material testing, prototype validation, and performance simulation to ensure compatibility with leading plow mounting systems. Whether you require standard configurations or custom profiles for specialized applications, Suzhou Baoshida provides scalable production capabilities with consistent quality control and on-time global delivery.

Partnering with us means gaining access to a full technical support team led by Mr. Boyce, our OEM Manager and Rubber Formula Engineer. With over 15 years of experience in rubber formulation and industrial application engineering, Mr. Boyce works directly with clients to optimize material specifications, cross-section design, and hardness profiles based on operational requirements. From initial concept to mass production, our engineering team supports every stage of development, ensuring seamless integration and superior field performance.

We invite equipment manufacturers, distributors, and procurement managers to contact us for technical collaboration, sample requests, or volume quotation. Suzhou Baoshida is committed to delivering cost-effective, high-integrity rubber components that enhance the reliability of winter maintenance machinery.

Below are the standard technical specifications for our most commonly supplied snow plow rubber deflector profiles:

| Property | Specification |

|---|---|

| Material Composition | EPDM/NR blend (customizable) |

| Hardness (Shore A) | 60 ± 5 |

| Tensile Strength | ≥ 12 MPa |

| Elongation at Break | ≥ 350% |

| Operating Temperature Range | -40°C to +80°C |

| Abrasion Resistance | ≤ 120 mm³ (DIN 53516) |

| Ozone Resistance | Excellent (Pass 50 pphm, 20% strain, 96h) |

| Color Options | Black, Red, Yellow (custom colors available) |

| Standard Lengths | 6 ft, 8 ft, 10 ft (cut-to-length service) |

| Mounting Interface Compatibility | Universal bolt-on, U-channel, L-channel |

To discuss your specific application needs or request material test reports, please contact Mr. Boyce directly at [email protected]. We respond to all technical inquiries within 24 hours and offer virtual consultation for OEM integration support. Suzhou Baoshida Trading Co., Ltd. — precision-engineered rubber solutions for industrial resilience.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).