Technical Contents

Engineering Guide: Snowman Doormat

Engineering Insight: The Critical Role of Material Selection in Snowman Doormat Performance

In industrial and commercial environments, the performance of a snowman doormat extends far beyond basic functionality. It serves as the first line of defense against moisture, debris, and contaminants tracked indoors during winter conditions. Despite their apparent simplicity, many off-the-shelf doormats fail prematurely due to inadequate material engineering. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration—it is the foundation of durability, safety, and long-term cost efficiency.

Standard consumer-grade doormats are typically constructed from recycled rubber compounds or low-density thermoplastics. These materials exhibit poor resistance to temperature cycling, UV degradation, and mechanical abrasion. When exposed to repeated foot traffic, snow-melt chemicals, and freeze-thaw cycles, such mats crack, delaminate, or lose structural integrity within weeks. Moreover, inferior rubber formulations often lack the necessary Shore A hardness to maintain tread definition, resulting in reduced scraping efficiency and increased slip risk.

In contrast, engineered industrial rubber solutions utilize high-density, vulcanized EPDM (ethylene propylene diene monomer) or SBR (styrene-butadiene rubber) compounds. These materials are specifically formulated to withstand extreme environmental stressors while maintaining elasticity and tensile strength. Vulcanization enhances cross-linking within the polymer matrix, significantly improving resistance to ozone, oxidation, and hydrolytic degradation—common failure points in seasonal doormats.

A critical factor in performance is the balance between hardness and flexibility. A mat that is too rigid becomes brittle in cold climates; one that is too soft deforms under load and fails to scrape effectively. Through precise compounding and curing processes, we achieve an optimal Shore A hardness range of 65–75, ensuring consistent performance from -30°C to +80°C. Additionally, advanced surface texturing techniques maximize snow and slush retention while minimizing wear on footwear.

Another often-overlooked aspect is chemical resistance. De-icing agents such as calcium chloride and magnesium chloride are highly corrosive and can degrade standard rubber matrices. Our formulations incorporate protective additives that resist chemical attack, preserving the mat’s integrity over extended exposure.

The following table outlines the comparative material specifications between standard off-the-shelf mats and our engineered industrial solution:

| Property | Off-the-Shelf Mat (Typical) | Baoshida Engineered Rubber Mat |

|---|---|---|

| Base Material | Recycled SBR or TPR | Virgin EPDM/SBR Blend |

| Shore A Hardness | 50–60 | 65–75 |

| Tensile Strength | 5–7 MPa | 12–15 MPa |

| Elongation at Break | 200–300% | 400–500% |

| Operating Temperature Range | -10°C to +60°C | -30°C to +80°C |

| Abrasion Resistance (DIN) | 180 mm³ loss | <90 mm³ loss |

| Chemical Resistance | Poor (swells with deicers) | Excellent (resists CaCl₂, MgCl₂) |

Material selection directly determines lifecycle cost, safety compliance, and user satisfaction. By leveraging industrial-grade rubber compounds and precision manufacturing, Suzhou Baoshida ensures that our snowman doormats perform reliably under real-world conditions—where standard alternatives fall short.

Material Specifications

Material Specifications for Industrial Snowman Doormat Production

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions optimized for demanding outdoor applications. Our snowman doormats require materials balancing weather resistance, structural integrity, and cost efficiency. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) each offer distinct performance profiles critical for longevity in variable climates. Selection depends on operational environment, chemical exposure, and lifecycle cost analysis.

Viton excels in extreme chemical and thermal resistance, maintaining stability from -20°C to 230°C. Its fluorocarbon structure resists ozone, UV degradation, and automotive fluids, making it suitable for garage or industrial entryways exposed to oils and solvents. However, its high raw material cost and complex processing limit economic viability for standard residential applications. Viton’s tensile strength (15-20 MPa) and compression set (15-25% at 200°C) ensure dimensional stability but require specialized molding equipment.

Nitrile rubber is the optimal balance for mainstream snowman doormats. With a functional range of -30°C to 100°C, it provides exceptional abrasion resistance and moderate oil/fuel tolerance (critical for snow-melt slush containing road salts or antifreeze). Its tensile strength (10-18 MPa) and hardness (50-90 Shore A) allow deep embossing of intricate snowman designs without tearing. NBR’s compression set (20-35% at 100°C) ensures consistent sealing against drafts, while cost efficiency supports high-volume OEM production.

Silicone offers unmatched low-temperature flexibility down to -60°C and UV stability, ideal for Arctic or high-altitude installations. Its biocompatibility and non-toxicity align with eco-certification standards, though tear strength (4-8 MPa) is lower than NBR. Silicone’s compression set (10-20% at 200°C) prevents permanent deformation under heavy foot traffic. Premium pricing applies, but its 20-year+ outdoor lifespan justifies investment for municipal or luxury residential projects.

Comparative Material Properties for Snowman Doormats

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15-20 | 10-18 | 4-8 |

| Compression Set (%)* | 15-25 (200°C) | 20-35 (100°C) | 10-20 (200°C) |

| Hardness (Shore A) | 60-90 | 50-90 | 30-80 |

| Oil Resistance | Excellent | Good | Poor |

| UV/Ozone Resistance | Excellent | Moderate | Excellent |

| Typical Cost Factor | 3.5x | 1.0x (Baseline) | 2.8x |

*Tested per ASTM D395 Method B at specified temperature for 70 hours.

Suzhou Baoshida prioritizes application-specific formulation. For 95% of snowman doormat projects, custom NBR compounds with 35% acrylonitrile content deliver optimal ROI—resisting -25°C freeze cycles while embedding non-slip granules at 150°C molding temperatures. Viton is reserved for chemical-handling facilities; Silicone for extreme cold zones. All materials undergo ISO 188 accelerated aging tests to validate 5-year outdoor durability. Our OEM team tailors durometer (65±5 Shore A standard) and pigment stability to client specifications, ensuring brand consistency across 50,000+ unit production runs. Contact our engineering department for climate-specific compound validation data.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber manufacturing excellence. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific solutions tailored to the rigorous demands of global OEMs. Our expertise spans the complete product development lifecycle—from concept and material formulation to precision mould design and high-volume production—ensuring optimal performance, durability, and cost efficiency.

Our mould engineering team leverages advanced CAD/CAM software and finite element analysis (FEA) to design high-tolerance, long-life rubber compression and injection moulds. Each design undergoes rigorous simulation for flow dynamics, curing uniformity, and thermal stability, minimizing defects and maximizing production efficiency. With in-house CNC machining and EDM capabilities, we maintain tight dimensional control, achieving tolerances down to ±0.05 mm. This precision is critical for complex geometries such as the interlocking features and textured surfaces required in high-performance snowman doormats, where both aesthetic detail and functional resilience are paramount.

Complementing our mould expertise is our advanced rubber formulation capability. Our two in-house formula engineers specialize in developing custom elastomer compounds tailored to environmental and mechanical requirements. Utilizing a systematic approach based on ASTM and ISO standards, we engineer compounds that balance hardness, compression set, abrasion resistance, and low-temperature flexibility. For snowman doormats, this means formulating EPDM or SBR-based compounds that resist UV degradation, remain flexible in sub-zero temperatures, and provide superior traction and dirt-scraping performance under repeated use.

We support full OEM integration with confidential material development, design-for-manufacturability (DFM) reviews, and rapid prototyping. Our engineering team collaborates directly with clients to translate functional requirements into optimized rubber products, ensuring seamless scale-up from prototype to mass production. All formulations and mould designs are documented and controlled under a strict quality management system compliant with ISO 9001 standards.

The following table summarizes key engineering specifications and capabilities relevant to our snowman doormat production:

| Parameter | Specification |

|---|---|

| Mould Tolerance | ±0.05 mm |

| Material Types | EPDM, SBR, NR, CR (custom compounds available) |

| Hardness Range (Shore A) | 40–80 |

| Operating Temperature Range | -40°C to +120°C |

| Compression Set (ASTM D395) | ≤20% after 70 hrs at 70°C |

| Tensile Strength | ≥8 MPa (customizable) |

| Mould Development Lead Time | 15–25 days (depending on complexity) |

| Sample Production | 3–7 days after mould approval |

| OEM Design Support | Full DFM, material certification, IP protection |

Through the integration of advanced material science and precision engineering, Suzhou Baoshida delivers technically superior rubber products that meet the exacting standards of industrial and consumer applications alike. Our engineering team is committed to innovation, reliability, and long-term partnership with OEM clients worldwide.

Customization Process

Customization Process for Industrial Rubber Doormats

At Suzhou Baoshida Trading Co., Ltd., our snowman doormat customization leverages precision engineering to transform client specifications into durable, high-performance products. The process begins with Drawing Analysis, where our technical team rigorously evaluates CAD files or sketches provided by the client. We verify dimensional tolerances, structural integrity, and underfoot texture depth to ensure optimal debris-trapping capability. Critical parameters such as edge definition for snow shedding, mat thickness (typically 8–12 mm), and logo embossing depth are cross-referenced against material behavior models. This phase identifies potential molding challenges early, preventing costly revisions during tooling.

Formulation follows, where our rubber compound engineers design a bespoke EPDM or SBR blend tailored to the application’s environmental demands. For snow-prone regions, we prioritize compounds with exceptional low-temperature flexibility (down to -40°C), UV resistance to prevent snowman graphic fading, and high carbon black content for abrasion resistance against salt and grit. Hardness is calibrated between 55–70 Shore A to balance comfort and structural stability, while density is optimized to 1.15–1.25 g/cm³ for weight efficiency without sacrificing durability. Anti-slip properties are enhanced through controlled silica filler ratios, ensuring coefficient of friction exceeds 0.6 on wet surfaces.

Prototyping validates both design and formulation. Using CNC-machined aluminum molds, we produce 3–5 functional samples within 10–14 days. Each prototype undergoes accelerated testing: 50,000-cycle abrasion trials, freeze-thaw cycling (-30°C to 40°C), and colorfastness assessments under 500-hour xenon arc exposure. Client feedback on texture, graphic clarity, and flexibility informs final adjustments. Only after sign-off do we proceed to mass production.

Mass Production employs automated vulcanization presses with ±0.5°C temperature control and real-time pressure monitoring. Every mat is inspected via laser scanners for dimensional accuracy (±0.3 mm tolerance) and surface defects. Batch consistency is maintained through ASTM D2240 hardness checks and weight variance limits of ≤2%. We implement statistical process control (SPC) charts for critical-to-quality attributes, ensuring 99.8% defect-free output. Production scalability ranges from 500 to 50,000 units monthly, with logistics support for global OEM shipments.

Key performance specifications for customized snowman doormats are summarized below:

| Parameter | Standard Specification | Customizable Range | Test Method |

|---|---|---|---|

| Material | EPDM | EPDM, SBR, TPE | ISO 1629 |

| Hardness (Shore A) | 60 ± 5 | 55–70 | ASTM D2240 |

| Thickness | 10 mm ± 0.5 | 8–15 mm | ISO 23529 |

| Density | 1.20 g/cm³ ± 0.03 | 1.15–1.30 g/cm³ | ASTM D297 |

| Low-Temp Flexibility | Pass at -40°C | Down to -50°C | ISO 188 |

This structured approach guarantees that every snowman doormat meets stringent industrial durability standards while fulfilling aesthetic and functional client requirements. Suzhou Baoshida’s integration of material science and precision manufacturing ensures consistent performance in demanding commercial environments.

Contact Engineering Team

For industrial manufacturers and supply chain partners seeking precision-engineered rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of innovation and reliability in the rubber product sector. Specializing in high-performance rubber formulations and custom manufacturing, we serve global clients across diverse industries, including automotive, construction, consumer goods, and industrial equipment. Our expertise extends to the development of specialized rubber-based products such as the snowman doormat—a durable, weather-resistant, and functionally designed entry mat engineered for both residential and commercial applications. Built from advanced synthetic rubber compounds, the snowman doormat exemplifies our commitment to material integrity, dimensional accuracy, and long-term performance under demanding environmental conditions.

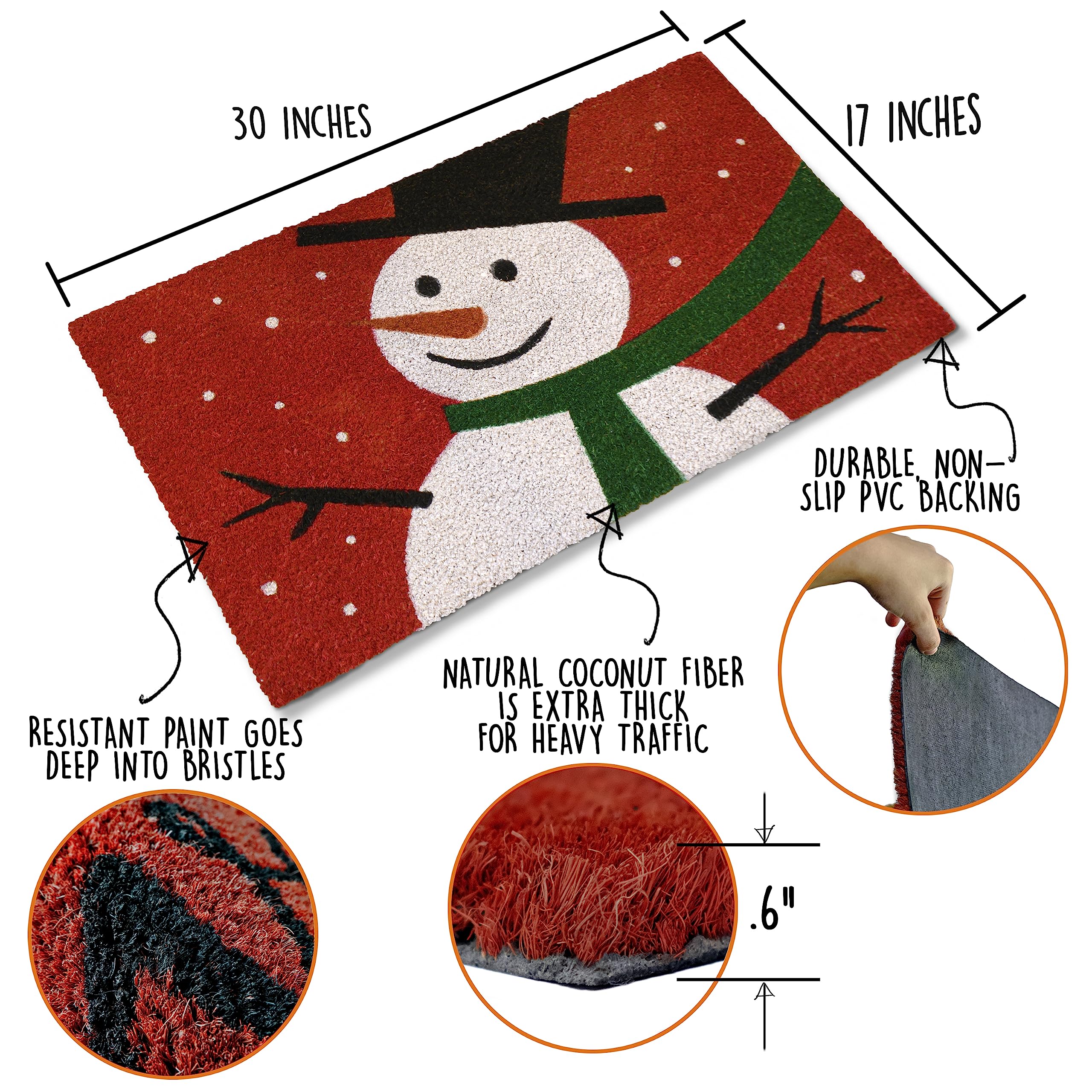

Our manufacturing process integrates rigorous quality control protocols, from raw material selection to final product inspection. Each doormat is produced using vulcanized rubber technology, ensuring superior tensile strength, abrasion resistance, and dimensional stability. The textured surface is specifically molded to maximize dirt and moisture retention, while the non-slip backing provides secure placement on a variety of flooring types. These attributes make the snowman doormat not only an effective functional product but also a symbol of our engineering precision and attention to detail.

We invite OEMs, distributors, and procurement managers to engage directly with our technical team to discuss customization options, volume production capabilities, and compliance with international standards such as REACH, RoHS, and ASTM D2000. Whether you require color matching, logo embossing, specific durometer ratings, or packaging configurations, Suzhou Baoshida delivers scalable solutions tailored to your market requirements.

For immediate technical consultation or quotation requests, please contact Mr. Boyce, our dedicated OEM and Engineering Manager, who oversees client collaboration and product development initiatives. With over 15 years of experience in industrial rubber applications, Mr. Boyce ensures seamless communication between design, production, and delivery phases, guaranteeing that every project meets exacting specifications and timelines.

Below are the technical specifications of our standard snowman doormat, illustrating the engineered performance characteristics that define our product quality.

| Property | Specification |

|---|---|

| Material Composition | Styrene-Butadiene Rubber (SBR) + Carbon Black Reinforcement |

| Hardness (Shore A) | 65 ± 5 |

| Tensile Strength | ≥ 12 MPa |

| Elongation at Break | ≥ 250% |

| Compression Set (22 hrs at 70°C) | ≤ 20% |

| Operating Temperature Range | -30°C to +80°C |

| Dimensions (Standard) | 450 mm × 750 mm × 12 mm |

| Surface Profile | Deep-tread snowman relief pattern |

| Backing Type | Anti-slip flat compound with floor-grip texture |

| Color Options | Black, Dark Grey, Custom (Pantone Matching Available) |

| Certifications | REACH, RoHS, ASTM D2000 compliant |

To initiate a technical discussion, request samples, or submit a formal inquiry, contact Mr. Boyce at [email protected]. We respond to all inquiries within 12 business hours and support client engagement in English, Mandarin, and German. Partner with Suzhou Baoshida Trading Co., Ltd. for rubber solutions engineered to perform.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).