Technical Contents

Engineering Guide: Sponge Mattress

Engineering Insight: Material Selection Criticality in Sponge Mattress Manufacturing

Material selection represents the foundational engineering decision in sponge mattress production, directly dictating product longevity, performance consistency, and end-user satisfaction. Generic, off-the-shelf rubber sponge formulations frequently fail in demanding commercial or high-cycle applications due to inherent compromises in polymer chemistry and cellular structure design. These compromises prioritize initial cost reduction over sustained mechanical integrity under load, leading to premature failure modes such as irreversible compression set, loss of resiliency, and accelerated degradation. Understanding the specific stressors—continuous compressive load, thermal cycling, and exposure to environmental factors like ozone—is paramount. Standard commodity sponges often utilize basic SBR (Styrene-Butadiene Rubber) or low-grade EPDM (Ethylene Propylene Diene Monomer) with minimal stabilization packages. These materials lack the tailored crosslink density and polymer backbone stability required to resist permanent deformation over time. The consequence is a mattress core that rapidly loses its supportive structure, resulting in uncomfortable “bottoming out” and necessitating early replacement, significantly increasing the total cost of ownership for the end user.

The core failure mechanism in substandard materials is inadequate resistance to compression set. Under sustained load, the polymer network undergoes irreversible viscous flow rather than elastic recovery. Commodity sponges frequently exhibit compression set values exceeding 30% after 22 hours at 70°C (ASTM D395 Method B), indicating severe permanent deformation. Furthermore, insufficient antioxidant and antiozonant packages lead to oxidative chain scission and surface cracking when exposed to ambient conditions, particularly in regions with high UV exposure or pollution. Hydrolytic degradation can also plague formulations using moisture-sensitive additives or fillers, causing internal structural breakdown. These failures are not merely cosmetic; they represent fundamental material science shortcomings where the formulation does not align with the dynamic mechanical demands of the application. Suzhou Baoshida Trading Co., Ltd. addresses this through engineered closed-cell EPDM and specialized polymer blends. Our formulations incorporate high-purity monomers, precision-controlled crosslinking systems, and synergistic stabilizer packages designed specifically for long-term compressive resilience and environmental resistance. This targeted approach ensures the cellular structure maintains integrity, providing consistent support and extending service life significantly beyond generic alternatives.

The performance differential between engineered and off-the-shelf sponge materials is quantifiable through critical physical property testing. Key parameters must be rigorously evaluated under simulated service conditions:

| Critical Parameter | Off-the-Shelf Sponge (Typical) | Baoshida Engineered Sponge | Test Standard |

|---|---|---|---|

| Compression Set (50% Strain, 22h @70°C) | 35% – 50% | ≤ 15% | ASTM D395 Method B |

| Tensile Strength Retention (After 72h @100°C Air Oven Aging) | 40% – 60% | ≥ 85% | ISO 188 |

| Closed Cell Content (%) | 60% – 75% | ≥ 92% | ASTM D2856 |

Selecting a material based solely on initial density or cost per cubic meter ignores the complex interplay of polymer physics governing long-term behavior. Suzhou Baoshida Trading Co., Ltd. collaborates with OEM partners to define precise material specifications aligned with the mattress’s intended load profile, environmental exposure, and lifecycle requirements. This engineering-first approach mitigates field failure risks, protects brand reputation, and delivers superior value through demonstrably extended product lifespan and performance consistency. The true cost of a sponge mattress is realized not at purchase, but through its operational endurance.

Material Specifications

Sponge rubber mattresses used in industrial applications require precise material selection to ensure performance under demanding conditions. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance elastomeric solutions tailored for sealing, cushioning, and vibration damping in sectors such as automotive, aerospace, oil & gas, and industrial equipment. The core materials utilized in our sponge rubber mattress production include Viton, Nitrile (NBR), and Silicone, each offering distinct advantages depending on environmental exposure, temperature range, and chemical resistance requirements.

Viton sponge rubber is a fluorocarbon-based material renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It maintains structural integrity in continuous service temperatures up to 200°C and short-term exposure up to 250°C. This makes Viton ideal for high-performance sealing applications in engine compartments, chemical processing units, and aerospace systems where reliability under extreme conditions is non-negotiable. Its sponge variant provides compressibility and resilience while retaining the inherent chemical inertness of solid Viton.

Nitrile sponge rubber, derived from acrylonitrile butadiene copolymer, is widely used for its excellent resistance to petroleum-based oils, greases, and hydraulic fluids. It performs reliably in temperature ranges from -30°C to 100°C, with certain formulations extending to 120°C. Nitrile sponge offers good mechanical strength and abrasion resistance, making it a cost-effective solution for industrial gaskets, sealing strips, and vibration isolation pads in machinery and automotive under-hood applications. Its closed-cell structure provides low water absorption and consistent compression set performance.

Silicone sponge rubber stands out for its outstanding thermal stability across a wide range, typically from -60°C to 200°C, and excellent resistance to UV, ozone, and weathering. While it exhibits lower mechanical strength compared to Viton or Nitrile, its inertness and biocompatibility make it suitable for food-grade, medical, and outdoor applications. Silicone sponge is frequently used in architectural sealing, electronic enclosures, and HVAC systems where long-term durability under thermal cycling is critical. Its open or closed-cell variants allow customization for specific compression and recovery needs.

The selection of the appropriate sponge rubber material depends on balancing operational environment, regulatory compliance, and performance longevity. Below is a comparative overview of key technical specifications for Viton, Nitrile, and Silicone sponge rubbers used in industrial mattress and sealing applications.

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 short-term) | -30 to 100 (up to 120 intermittent) | -60 to 200 |

| Hardness Range (Shore A) | 40–90 | 30–80 | 30–80 |

| Tensile Strength (MPa) | 8–12 | 6–10 | 5–9 |

| Elongation at Break (%) | 200–300 | 200–400 | 200–600 |

| Compression Set (22 hrs, 150°C) | Excellent | Good | Very Good |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Water Absorption | Low | Low to Moderate | Low |

Each material offers a unique performance profile, and Suzhou Baoshida Trading Co., Ltd. provides customized formulation and manufacturing support to match client-specific engineering requirements.

Manufacturing Capabilities

Engineering Excellence in Sponge Mattress Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered sponge mattress solutions through deep-rooted industrial rubber expertise. Our core strength lies in an integrated engineering team dedicated to material science and production optimization. This team comprises five specialized Mould Engineers and two dedicated Rubber Formula Engineers, working in concert to solve complex manufacturing challenges inherent in high-performance sponge mattress production. This structure ensures every component, from the cellular structure of the foam to the intricate geometry of the final product, is rigorously defined and controlled.

Our Rubber Formula Engineers possess advanced mastery in polymer chemistry and compounding. They meticulously develop and refine proprietary rubber and polyurethane formulations specifically tailored for mattress applications. This involves precise balancing of critical parameters: achieving the target density for optimal support, ensuring consistent cell structure for breathability and resilience, and incorporating additives for essential properties like flame retardancy, ozone resistance, and long-term compression set stability. Every formula undergoes stringent laboratory testing and real-world validation to guarantee performance meets exacting OEM specifications under diverse environmental conditions. Material consistency batch-to-batch is non-negotiable.

The five Mould Engineers translate these advanced formulations into flawless physical products. They leverage sophisticated CAD/CAM systems and deep understanding of rubber flow dynamics, curing kinetics, and demolding mechanics. This expertise is critical for designing and maintaining complex molds that produce intricate mattress profiles, consistent thickness, and precise edge definition – factors directly impacting comfort, durability, and assembly efficiency for our clients. They proactively address challenges like sink marks, voids, or surface imperfections through iterative mold design refinement and precise process parameter control during vulcanization or foaming.

Our OEM capabilities are built upon this engineering foundation, offering true partnership beyond simple contract manufacturing. We engage clients early in the development cycle, providing comprehensive technical consultation on material selection, design for manufacturability, and cost-optimization strategies without compromising performance. Suzhou Baoshida manages the entire process from concept validation through full-scale production, ensuring strict adherence to client IP protocols and quality standards. Our facility operates under rigorous ISO-compliant quality management systems, with in-house testing labs verifying every critical property before shipment.

The following table outlines key engineered specifications achievable through our integrated approach:

| Specification Parameter | Typical Range | Test Standard | Significance for Sponge Mattress |

|---|---|---|---|

| Density | 25 – 80 kg/m³ | ASTM D3574 | Determines support level, durability, and material cost |

| Compression Force Deflection (CFD) | 50 – 300 N | ASTM D3574 | Measures firmness and load-bearing capacity |

| Compression Set (50%, 22h) | ≤ 10% | ASTM D3574 | Critical indicator of long-term resilience and recovery |

| Tensile Strength | ≥ 100 kPa | ASTM D3574 | Reflects material integrity and resistance to tearing |

| Elongation at Break | ≥ 100% | ASTM D3574 | Indicates flexibility and resistance to permanent deformation |

| Air Flow | 1.0 – 5.0 L/s | ASTM D3574 | Governs breathability and thermal regulation |

This engineering-led methodology guarantees that Suzhou Baoshida’s sponge mattress components consistently exceed industry benchmarks for performance, reliability, and manufacturability, providing OEM partners with a decisive competitive advantage in demanding markets.

Customization Process

Drawing Analysis

The foundation of any successful sponge rubber mattress manufacturing project begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we initiate the customization process by evaluating technical drawings provided by the client. These drawings must include dimensional specifications, tolerance ranges, intended application environment, and critical performance zones such as load-bearing areas or compression zones. Our engineering team conducts a detailed review to assess manufacturability, material feasibility, and compliance with OEM standards. This phase also involves cross-referencing the design with existing mold libraries to determine whether tooling modification or full custom mold fabrication is required. Precision in this stage ensures alignment between design intent and production capability, minimizing downstream adjustments.

Formulation Development

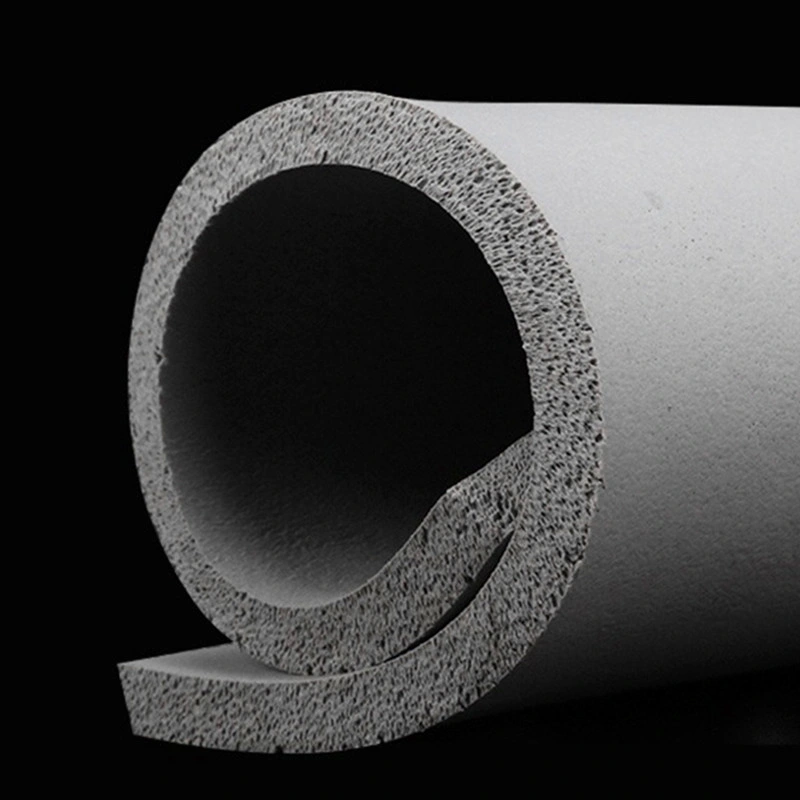

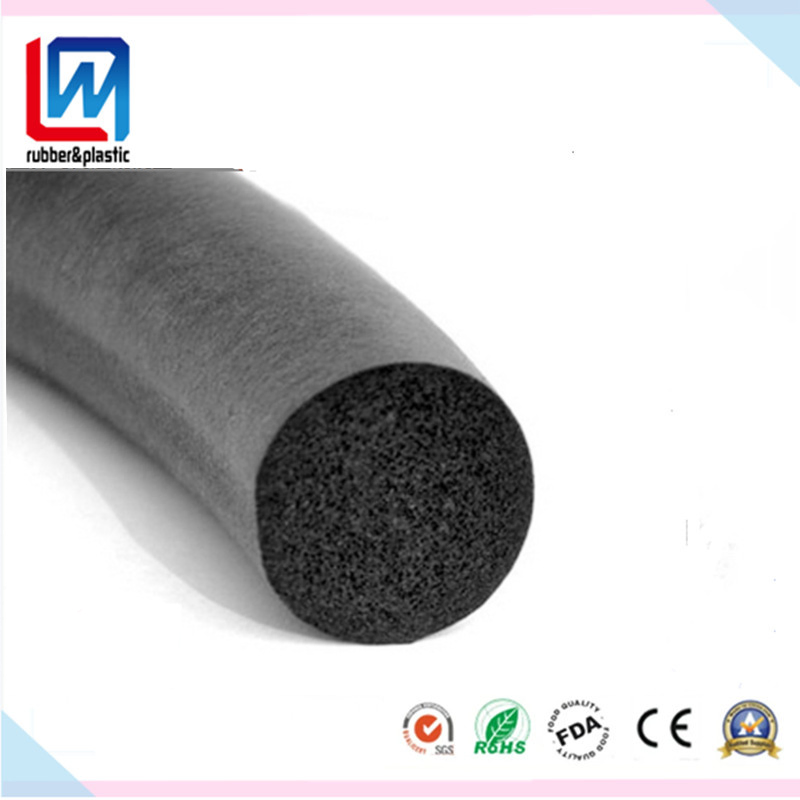

Following drawing validation, our rubber formula engineers develop a tailored compound formulation to meet the functional demands of the sponge mattress. The formulation process integrates key performance indicators such as compression deflection, resilience, thermal stability, and aging resistance. We utilize closed-cell or open-cell nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), or blends, depending on oil resistance, weatherability, and softness requirements. Additives including blowing agents, cross-linking accelerators, and flame retardants are precisely metered to achieve the target density and cell structure. Each formulation is documented under controlled batch records to ensure repeatability and traceability. Clients receive a material data sheet (MDS) outlining physical and chemical properties prior to prototyping.

Prototyping and Validation

Once the formulation is finalized, we proceed to prototype production using precision compression or continuous vulcanization (CV) molding. Prototypes are subjected to rigorous in-house testing, including compression set (ASTM D395), tensile strength (ASTM D412), and hardness (Shore 00 scale). Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity to the original drawing. We provide clients with physical samples and test reports for functional evaluation. Feedback from this stage informs any necessary refinement in formulation or tooling geometry, ensuring optimal performance prior to scale-up.

Mass Production Execution

Upon prototype approval, the project transitions to mass production. Our facility operates under ISO 9001-certified processes, with real-time monitoring of temperature, pressure, and cure time to maintain batch consistency. Sponge rubber mattresses are produced in continuous strips or discrete slabs, followed by automated cutting and finishing. Final quality control includes 100% visual inspection and statistical sampling for mechanical testing. Logistics coordination ensures timely delivery to OEM assembly lines or distribution hubs.

Typical Physical Properties of Custom Sponge Rubber Mattress Compounds

| Property | Test Method | Typical Value Range |

|---|---|---|

| Density | ASTM D3574 | 0.15–0.35 g/cm³ |

| Hardness (Shore 00) | ASTM D2240 | 20–60 |

| Tensile Strength | ASTM D412 | 0.8–2.5 MPa |

| Elongation at Break | ASTM D412 | 150–300% |

| Compression Deflection (25%) | ASTM D3574 | 0.8–2.0 kPa |

| Compression Set (50%, 22h, 70°C) | ASTM D395 | ≤35% |

| Cell Structure | Visual/Microscopy | Closed-cell (>90%) |

Contact Engineering Team

Technical Partnership for Industrial Sponge Mattress Manufacturing

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber formulation and OEM manufacturing, specializing in high-performance elastomeric solutions for demanding applications such as commercial-grade sponge mattresses. Our engineering team possesses deep expertise in polymer science, vulcanization chemistry, and material processing, enabling us to deliver consistent, specification-driven rubber compounds that meet the rigorous durability, comfort, and safety standards required by global mattress producers. We understand that the core performance of a sponge mattress—its resilience, support longevity, thermal stability, and resistance to permanent deformation—is fundamentally determined by the precision of the rubber formulation and manufacturing process. Generic solutions often fail under sustained industrial use; our value lies in engineered material integrity.

Our proprietary rubber compounds are developed through rigorous laboratory testing and scaled via controlled production environments. We optimize critical parameters including density distribution, closed-cell structure integrity, compression set resistance, and rebound resilience to ensure mattresses maintain structural performance over thousands of compression cycles. This scientific approach minimizes material waste during fabrication and guarantees end-product consistency batch after batch. The table below illustrates key performance differentiators between standard commercial compounds and our premium engineered solutions for sponge mattress cores.

| Property | Standard Commercial Compound | Suzhou Baoshida Premium Compound |

|---|---|---|

| Density (kg/m³) | 45-55 | 50-60 (±2% tolerance) |

| Hardness (Shore A) | 25-35 | 30-40 (±3 points) |

| Compression Set (22h, 70°C) | ≤ 25% | ≤ 12% |

| Tensile Strength (MPa) | ≥ 0.8 | ≥ 1.5 |

| Tear Strength (kN/m) | ≥ 2.5 | ≥ 4.0 |

| Rebound Resilience (%) | 40-50 | 55-65 |

Material customization is not an afterthought but our core methodology. Whether your application requires enhanced flame retardancy meeting US CA 117 or EU EN 597 standards, improved thermal conductivity for climate-responsive comfort, or specific odor-neutralization properties for sensitive consumer markets, our R&D facility develops formulations tailored to your exact performance matrix and regulatory landscape. We collaborate closely with OEM partners from initial concept through DFM optimization, tooling validation, and full-scale production, ensuring seamless integration into your manufacturing workflow. Our ISO 9001-certified processes guarantee traceability from raw material sourcing to finished compound delivery, mitigating supply chain risk.

Initiate a technical consultation to transform your sponge mattress performance specifications into realized product excellence. Contact Mr. Boyce, our dedicated OEM Manager for Industrial Rubber Solutions, to discuss material formulation data sheets, request prototype samples, or schedule a factory audit. Mr. Boyce possesses direct oversight of our compounding engineers and production teams, enabling rapid technical dialogue and solution iteration. Provide your specific density targets, lifecycle requirements, and regulatory constraints for a customized compound proposal within 24 business hours. Elevate your mattress core performance with scientifically validated rubber engineering—reach out today to establish a precision manufacturing partnership.

Email Mr. Boyce directly at [email protected] for immediate technical engagement. Include your company name, target application volume, and key performance indicators to expedite the qualification process. Suzhou Baoshida commits to responsive, data-driven collaboration for industrial manufacturers demanding uncompromised material science.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).