Technical Contents

Engineering Guide: Ss Valve

Engineering Insight: Material Selection Criticality in SS Valve Elastomeric Components

Stainless steel (SS) valve assemblies are engineered for demanding industrial service, yet premature failures persistently trace back to elastomeric components—not the metal body. Off-the-shelf rubber seals, diaphragms, or O-rings often catastrophically degrade under operational stresses, causing leaks, downtime, and safety hazards. This stems from treating elastomers as generic commodities rather than engineered system elements. Generic compounds lack tailored resistance to specific media, temperatures, or dynamic loads inherent to SS valve applications. For instance, a standard EPDM seal may swell irreversibly in hydrocarbon service, while NBR compounds crack under ozone exposure in outdoor installations. Crucially, compression set—the permanent deformation after sustained load—is the silent killer. Off-the-shelf materials frequently exceed 40% compression set at 100°C within 70 hours, losing sealing force. Custom-formulated elastomers address these gaps by optimizing polymer backbone chemistry, filler systems, and cure kinetics for the exact duty cycle. At Suzhou Baoshida, we reverse-engineer failure modes to develop compounds where compression set remains below 20% under identical conditions, ensuring decades of reliable service.

Material selection must align with four non-negotiable parameters: chemical compatibility, thermal stability, mechanical resilience, and regulatory compliance. A valve handling chlorinated solvents at 180°C demands radically different elastomer chemistry than one regulating steam at 120°C. Generic suppliers rarely provide full media resistance data across ASTM D471 or ISO 1817 standards, leading to incompatible material choices. Our OEM engineering process begins with fluid analysis and operational profiling, followed by accelerated aging validation per ISO 2230. This precision prevents common pitfalls like FKM degradation in amine-based fluids or silicone hardening in high-radiation environments.

The table below illustrates performance differentials between standard and engineered compounds in critical SS valve applications:

| Material Type | Temperature Range (°C) | 10% H₂SO₄ Resistance (70h) | 100% Compression Set (70h/100°C) | Typical Off-the-Shelf Failure Mode |

|---|---|---|---|---|

| Standard EPDM | -45 to +150 | Severe Swelling (>30% vol) | 45% | Extrusion in high-pressure steam |

| Standard NBR | -30 to +100 | Moderate Degradation | 52% | Ozone cracking in outdoor service |

| Baoshida Custom FKM | -25 to +230 | Negligible Change (<5%) | 18% | N/A (Validated for sour gas) |

| Baoshida HT Silicone | -60 to +260 | Excellent | 22% | N/A (Pharma-compliant) |

Treating elastomers as interchangeable components ignores their role as the valve’s functional heart. Suzhou Baoshida’s OEM partnership embeds material science into the design phase, converting failure points into reliability assets. We do not sell rubber—we engineer sealing integrity. Contact our formulation lab to prevent your next valve failure at the molecular level.

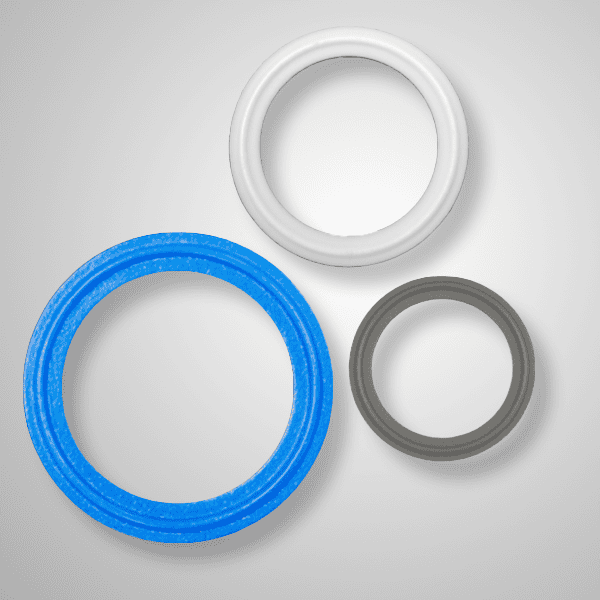

Material Specifications

Material selection is a critical determinant in the performance and longevity of industrial sealing components, particularly in demanding environments where exposure to extreme temperatures, aggressive chemicals, and dynamic mechanical stress is common. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber solutions tailored for high-performance applications, including SS (stainless steel) valves used across oil and gas, chemical processing, pharmaceutical, and automotive industries. Our core elastomer offerings—Viton, Nitrile (NBR), and Silicone—are selected based on their distinct chemical resistance, thermal stability, and mechanical properties to ensure optimal functionality under operational extremes.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oxidation, and a broad spectrum of chemicals, including hydrocarbons, acids, and fuels. With a continuous service temperature range from -20°C to +200°C (short-term up to +250°C), Viton is ideal for sealing applications in aggressive chemical environments where long-term reliability is paramount. Its low gas permeability and excellent aging characteristics further enhance its suitability for critical SS valve systems exposed to harsh process media.

Nitrile rubber (NBR) is a cost-effective solution offering superior resistance to oils, fuels, and aliphatic hydrocarbons. It performs reliably within a temperature range of -30°C to +100°C, with some formulations extending to +120°C for limited durations. NBR is widely used in hydraulic and pneumatic valve systems due to its excellent abrasion resistance and compressive strength. While it lacks the chemical inertness of Viton, NBR remains a preferred choice for applications involving petroleum-based fluids and moderate thermal exposure.

Silicone rubber (VMQ) provides outstanding thermal stability across a wide range, typically from -60°C to +200°C, with excellent performance in both extreme cold and heat. It exhibits good resistance to ozone and UV radiation, making it suitable for outdoor and high-temperature environments. However, its mechanical strength and resistance to oils and solvents are limited compared to Viton and NBR. Silicone is often selected for food-grade, medical, or electrical insulation applications where purity and thermal resilience are essential.

The following table summarizes key physical and chemical properties of these materials to facilitate informed selection for SS valve sealing applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 (+250 short-term) | -30 to +100 (+120 short-term) | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Acids/Bases | Very Good | Fair | Good |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Gas Permeability | Low | Moderate | High |

| Typical Applications | Chemical valves, aerospace, fuel systems | Hydraulic systems, automotive, industrial machinery | Medical devices, food processing, electrical insulation |

Each elastomer presents a unique balance of performance attributes, and selection must align with the specific operational demands of the valve system. Suzhou Baoshida Trading Co., Ltd. provides comprehensive technical support to ensure optimal material pairing for enhanced durability, safety, and efficiency in industrial sealing solutions.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Integration for SS Valve Systems

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions for stainless steel (SS) valve applications through a synergistic fusion of material science and precision manufacturing. Our dedicated team of five Mold Engineers and two Rubber Formula Engineers operates as a unified technical unit, ensuring every component meets stringent industrial performance criteria. This integrated approach eliminates siloed development, enabling seamless translation of client specifications into validated production-ready parts. We specialize in optimizing rubber-to-metal bonding, compression set resistance, and dynamic sealing performance under extreme thermal and chemical exposure—critical factors for SS valve reliability in oil and gas, chemical processing, and water treatment systems.

Material science forms the cornerstone of our SS valve component development. Our Formula Engineers leverage advanced polymer chemistry to tailor compound formulations for specific media compatibility, including aggressive acids, hydrocarbons, and high-purity fluids. Each rubber grade undergoes rigorous accelerated aging, fluid immersion, and dynamic fatigue testing per ASTM D2000 and ISO 3601 standards. Concurrently, Mold Engineers employ 3D flow simulation and thermal analysis to eliminate knit lines, sink marks, and flash in complex geometries—ensuring dimensional stability within ±0.05mm tolerances. This dual-expertise model guarantees that material properties and mold design co-evolve, preventing field failures caused by interface incompatibility.

Our OEM capabilities extend beyond standard manufacturing to full technical partnership. Clients provide functional requirements or failure mode data; we respond with engineered solutions including custom durometer profiles, low-extraction-force sealing lips, and anti-extrusion designs for high-pressure differentials. The process incorporates iterative prototyping with real-time pressure decay validation and finite element analysis (FEA) for stress distribution mapping. All compounds are traceable to ISO 9001-certified batch records, with full documentation of raw material sourcing, cure kinetics, and post-vulcanization stability metrics.

Critical performance parameters for our SS valve sealing solutions are summarized below:

| Parameter | Standard Range | Customizable Range | Test Standard |

|---|---|---|---|

| Temperature Resistance | -40°C to +150°C (EPDM) | -60°C to +230°C (FKM) | ASTM D573 |

| Pressure Rating | Up to 40 bar (static) | Up to 100 bar (dynamic) | ISO 5208 |

| Media Compatibility | Water, oils, mild acids | Strong acids, amines, steam | ASTM D471 |

| Compression Set | ≤20% (70 hrs, 100°C) | ≤10% (custom compounds) | ASTM D395 |

| Dimensional Tolerance | ±0.10 mm (standard) | ±0.05 mm (precision) | ISO 3302 |

This technical infrastructure enables rapid adaptation to emergent industry challenges, such as hydrogen service compatibility or ultra-high-purity semiconductor fluid handling. By embedding material science expertise directly into the OEM workflow, Suzhou Baoshida ensures SS valve systems achieve extended service life with zero leakage incidents under operational extremes. Clients gain not just a supplier, but a certified engineering extension of their R&D team—delivering validated solutions from concept to serial production.

Customization Process

Drawing Analysis: The Foundation of Precision Customization

At Suzhou Baoshida Trading Co., Ltd., the customization journey for SS valves in industrial rubber applications begins with rigorous drawing analysis. This initial phase ensures that every dimensional specification, tolerance requirement, and functional interface is fully understood. Our engineering team evaluates client-provided technical drawings—compliant with ISO or ASME standards—for critical features such as flange alignment, sealing surface geometry, and flow path integrity. We assess material clearance zones, compression set requirements, and dynamic stress points to predict performance under operational conditions. Any ambiguities or potential design conflicts are flagged early, and our OEM managers initiate technical dialogue to resolve them before progression. This stage is critical to avoid downstream manufacturing deviations and ensure seamless integration of the rubber component within the stainless steel valve assembly.

Rubber Formulation: Engineering Material to Match Application Demands

Following validated drawing analysis, our rubber formula engineers develop a tailored elastomer compound. The selection of base polymer—be it EPDM, NBR, FKM, or silicone—is dictated by the valve’s operational environment, including temperature range, chemical exposure, and pressure cycling. For SS valves handling aggressive media such as acids, chlorinated solvents, or high-purity water, fluorocarbon (FKM) or perfluoroelastomer (FFKM) compounds are often specified for their superior chemical resistance. Fillers, vulcanizing agents, and stabilizers are precisely dosed to achieve target hardness (Shore A), tensile strength, and compression set performance. All formulations are documented under strict batch traceability protocols and tested against ASTM D2000 standards to ensure repeatability and compliance with industrial certifications.

Prototyping: Validating Design and Material Synergy

Once the compound is finalized, low-volume prototyping is conducted using precision molding techniques—compression, transfer, or injection—depending on part complexity. Prototypes are subjected to dimensional inspection via coordinate measuring machines (CMM) and functional testing, including leak rate evaluation under simulated service pressure. Feedback from this phase informs final adjustments to mold design or cure parameters. Client validation is encouraged at this stage to confirm fit, form, and function within their SS valve systems.

Mass Production: Scalable Quality with Industrial Rigor

Upon prototype approval, we transition to mass production under ISO 9001-certified processes. Automated mixing, mold monitoring systems, and 100% visual inspection ensure consistency. Each batch undergoes periodic physical testing to maintain compliance.

| Property | Test Standard | Typical Value (FKM Example) |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 75 ±5 |

| Tensile Strength | ASTM D412 | ≥15 MPa |

| Elongation at Break | ASTM D412 | ≥180% |

| Compression Set (70h, 150°C) | ASTM D395 | ≤25% |

| Fluid Resistance (IRM 903, 70°C) | ASTM D471 | Volume swell ≤15% |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Solutions in SS Valve Manufacturing

Achieving optimal sealing performance in stainless steel (SS) valves demands elastomeric compounds engineered for extreme pressure differentials, chemical exposure, and thermal cycling. Generic rubber formulations risk premature extrusion, compression set, or fluid incompatibility—directly impacting valve service life and system integrity. At Suzhou Baoshida Trading Co., Ltd., our rubber formula engineering team specializes in custom SS valve sealing solutions validated through ISO 9001:2015-certified compounding processes. We address critical failure points like stem leakage in high-purity fluid handling or diaphragm fatigue in aggressive chemical transfer systems through molecular-level polymer modification. Our proprietary peroxide-cured FKM and hydrogenated nitrile (HNBR) compounds deliver consistent performance under 10,000+ PSI hydrostatic pressure testing while resisting degradation from hydraulic fluids, acids, and superheated steam.

Material selection directly dictates valve reliability in critical applications. Below are representative specifications for our industry-proven SS valve sealing compounds, all manufactured in Suzhou with traceable lot control and ASTM D2000-22 compliance:

| Compound Designation | Base Polymer | Hardness (Shore A) | Temp Range (°C) | Fluid Resistance (ASTM D471) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| SB-SSV-70HNBR | HNBR | 70 ± 2 | -40 to +150 | Excellent (Hydraulic Oils) | ≥ 22.0 |

| SB-FFKM-85 | FFKM | 85 ± 2 | -20 to +327 | Exceptional (Concentrated Acids) | ≥ 15.0 |

| SB-NBR-60 | NBR | 60 ± 2 | -30 to +120 | Good (Aliphatic Hydrocarbons) | ≥ 18.0 |

These formulations undergo rigorous validation per API 641 fugitive emissions standards and NORSOK M-710 sour gas testing. Our OEM partnership model integrates early-stage material consultation—providing finite element analysis (FEA) support for seal geometry optimization and accelerated life cycle testing against your specific media and pressure profiles. This eliminates costly field failures during valve qualification.

For SS valve manufacturers seeking to exceed OEM durability specifications, direct collaboration with our technical team is essential. Mr. Boyce, our dedicated OEM Manager, possesses 14 years of experience resolving complex sealing challenges in oil & gas, semiconductor, and pharmaceutical valve systems. He will coordinate a technical deep dive into your application parameters, including media composition, dynamic stroke rates, and regulatory requirements (e.g., FDA 21 CFR 177.2600, EC 1935/2004). This ensures your rubber components meet both functional demands and global compliance frameworks without over-engineering costs.

Initiate your valve reliability upgrade by contacting Mr. Boyce directly at [email protected]. Include your valve model number, operating conditions, and current failure mode analysis for a targeted technical assessment within 24 business hours. Suzhou Baoshida commits to providing material data sheets, sample kits for prototyping validation, and co-branded technical documentation to accelerate your time-to-market. Do not compromise sealing integrity with off-the-shelf elastomers—engineer failure out of your SS valve design with precision rubber science from Suzhou.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).