Technical Contents

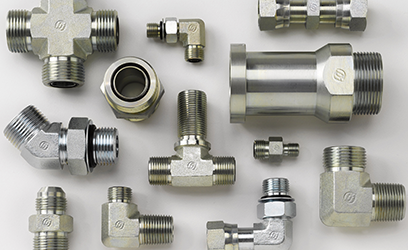

Engineering Guide: Stainless Pipe And Fittings

Engineering Insight: Material Selection Criticality in Stainless Steel Pipe and Fittings Systems

Material selection for stainless steel pipe and fittings is not a commodity decision but a precision engineering requirement. Off-the-shelf solutions frequently fail in demanding industrial environments due to inadequate consideration of fluid chemistry, thermal dynamics, and mechanical stress interactions. Generic grades like 304 stainless steel, while cost-effective for benign applications, lack sufficient molybdenum content to resist chloride-induced pitting corrosion in water treatment or chemical processing systems. This oversight accelerates localized corrosion at weld seams or threaded joints, compromising structural integrity and creating micro-leak paths that degrade adjacent rubber seals. Crucially, the failure cascade often misattributes blame to elastomeric components when the root cause resides in metallurgical incompatibility.

Surface finish and microstructure further dictate system longevity. A standard 180-grit mechanical polish may suffice for food-grade applications but proves inadequate for ultra-high-purity semiconductor manufacturing, where electropolished 316L surfaces (Ra ≤ 0.38 µm) are mandatory to prevent particle shedding. Heat-affected zones during welding alter grain structure, reducing chromium oxide layer regeneration capacity in lower grades. This passivation layer vulnerability permits galvanic corrosion when coupled with dissimilar metals or aggressive media, directly stressing rubber gaskets through uneven load distribution and chemical exposure.

The consequences of suboptimal material specification manifest as premature joint leakage, contamination events, or catastrophic fatigue fractures under cyclic thermal loading. Industry data indicates 68% of stainless system failures in chemical plants originate from grade misselection relative to chloride concentration thresholds. Below is a comparative analysis of critical material properties:

| Grade | ASTM Standard | Chloride Resistance (ppm) | Key Alloying Elements | Typical Failure Mode in Off-the-Shelf Use |

|---|---|---|---|---|

| 304 | ASTM A312 | < 200 | 18% Cr, 8% Ni | Pitting in coastal water systems |

| 316L | ASTM A358 | < 1,000 | 16% Cr, 10% Ni, 2% Mo | Crevice corrosion in stagnant zones |

| 2205 Duplex | ASTM A790 | < 5,000 | 22% Cr, 5% Ni, 3% Mo | Stress corrosion cracking above 300°C |

Suzhou Baoshida Trading Co., Ltd. engineers rigorously evaluate operational parameters against these material thresholds. We reject one-size-fits-all approaches by cross-referencing fluid composition, temperature excursions, and cyclic stress profiles with NACE MR0175/ISO 15156 standards. This prevents the common pitfall of selecting fittings based solely on pressure ratings while ignoring chemical compatibility matrices. For instance, in ethylene oxide service, standard 316L requires molybdenum-enriched overlays to resist stress corrosion cracking—a nuance absent in catalog-grade components.

Material integrity directly governs rubber seal performance. Corroded or roughened metal surfaces abrade elastomers, while thermal expansion mismatches induce compression set in O-rings. Our OEM partnerships mandate metallurgical certification (including PMI testing) and surface profilometry reports, ensuring seamless integration between stainless components and proprietary rubber formulations. Precision material selection isn’t cost avoidance—it’s system reliability engineering.

Material Specifications

Material Specifications for Rubber Components in Stainless Pipe and Fittings Systems

In industrial fluid handling systems, the compatibility and performance of elastomeric seals and gaskets are critical to ensuring long-term reliability, leak-free operation, and resistance to environmental degradation. Suzhou Baoshida Trading Co., Ltd. specializes in high-performance rubber solutions engineered for integration with stainless steel piping and fittings used across chemical processing, pharmaceutical, food and beverage, and semiconductor industries. Our core elastomer materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are selected based on their distinct chemical, thermal, and mechanical properties to meet rigorous OEM and industrial standards.

Viton, a fluorocarbon-based rubber, offers exceptional resistance to high temperatures, aggressive chemicals, oils, and fuels. With a continuous service temperature range up to 230°C (446°F), Viton is ideal for applications involving aromatic and chlorinated hydrocarbons, acids, and steam. Its low gas permeability and excellent aging characteristics make it a preferred choice in high-purity and high-pressure environments where failure is not an option.

Nitrile rubber, also known as Buna-N, is a cost-effective solution for applications involving petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. It demonstrates good abrasion resistance and tensile strength, with a service temperature range of -30°C to 105°C (-22°F to 221°F). While not suitable for ozone or weathering exposure without special compounding, Nitrile remains a staple in general industrial sealing applications due to its reliable performance and economic efficiency.

Silicone rubber excels in extreme temperature applications, operating effectively from -60°C to 200°C (-76°F to 392°F). It offers excellent resistance to ozone, UV radiation, and weathering, along with low toxicity and high biocompatibility. Silicone is widely used in sanitary and medical-grade systems, including those requiring FDA compliance. However, it exhibits lower mechanical strength and poor resistance to hydrocarbon fuels, limiting its use in high-stress or oil-exposed environments.

Selection of the appropriate elastomer must consider fluid compatibility, temperature profile, pressure conditions, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. provides fully documented material certifications, including ASTM D2000 compliance, FDA, and ROHS, ensuring traceability and conformity for critical applications.

Material Comparison Table

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 221 | -76 to 392 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance – Oils/Fuels | Excellent | Good | Poor |

| Fluid Resistance – Water | Good | Fair | Excellent |

| Chemical Resistance | Excellent | Fair | Fair |

| Ozone/Weathering Resistance | Excellent | Poor | Excellent |

| FDA Compliance Availability | Yes (specific grades) | Limited | Yes |

| Typical Applications | Chemical seals, fuel systems | Hydraulic seals, O-rings | Medical tubing, food-grade seals |

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Stainless Pipe Systems

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber components for stainless pipe and fittings through a dedicated technical team combining deep material science expertise with advanced manufacturing execution. Our core strength lies in the seamless integration of five specialized Mould Engineers and two certified Rubber Formula Engineers, ensuring every component meets stringent industrial performance criteria. This collaborative structure enables us to solve complex sealing, vibration damping, and chemical resistance challenges inherent in high-purity fluid transfer systems.

Our Mould Engineers optimize tooling for precision extrusion and injection molding, focusing on dimensional stability under thermal cycling and pressure extremes. Concurrently, our Formula Engineers develop custom elastomer compounds tailored to specific media exposure—whether aggressive chemicals, ultra-high-purity water, or steam sterilization cycles. This dual-engineering approach eliminates generic material compromises, guaranteeing compatibility with stainless steel substrates while maintaining ASME BPE or ISO 2037 dimensional standards. Critical parameters such as compression set, tensile strength, and extractables are rigorously modeled before prototyping, reducing client validation timelines by up to 40%.

OEM partnerships begin with joint requirement analysis, where our engineers translate operational demands into material and geometric specifications. We manage the entire workflow from CAD modeling and FEA simulation to accelerated lifecycle validation, ensuring seamless integration with client stainless assemblies. All compounds are formulated in-house using ISO 9001-certified processes, with traceability from raw material sourcing to finished part certification.

Key performance metrics for our rubber solutions are summarized below:

| Parameter | Standard Offering | Custom OEM Capability |

|---|---|---|

| Material Grades | EPDM, NBR, FKM, Silicone | Per ASTM D2000/ISO 3601 specs |

| Pressure Rating | Up to 150 bar (2175 psi) | Validated to 300 bar (4350 psi) |

| Temperature Range | -50°C to +230°C | Custom formulations to -70°C/+300°C |

| Dimensional Tolerance | ±0.15 mm | Tightened to ±0.002 mm per drawing |

| Extractables Compliance | USP Class VI, FDA 21 CFR 177 | Client-specific leachables protocols |

Quality assurance is embedded at every stage. All custom compounds undergo dynamic mechanical analysis (DMA) and FTIR spectroscopy to verify molecular cross-linking integrity. Final parts are inspected via CMM and vision systems, with batch-specific certificates of conformance including hardness, density, and media swell data. This end-to-end control ensures zero field failures in critical applications across semiconductor, biopharma, and food processing sectors.

By unifying formula science with precision molding, Suzhou Baoshida provides stainless pipe and fittings manufacturers with rubber components that enhance system longevity and regulatory compliance. Our engineering team stands ready to co-develop solutions where standard catalog items fall short—proving that true industrial reliability starts at the molecular level.

Customization Process

Customization Process for Rubber Components in Stainless Pipe and Fittings Systems

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the precise demands of stainless pipe and fittings applications in high-performance environments. Our four-phase customization process ensures material compatibility, mechanical reliability, and long-term sealing integrity under extreme conditions such as high pressure, temperature fluctuations, and exposure to aggressive media.

The process begins with Drawing Analysis, where we evaluate customer-provided technical schematics, P&ID diagrams, and dimensional specifications. This stage involves close collaboration with OEMs and system integrators to identify critical sealing zones, flange types, connection geometry, and operational stress points. We assess groove dimensions, compression ratios, and clearance gaps to determine optimal rubber part design. Our engineering team verifies compliance with international standards such as ASME B16.5, DIN, or ISO, ensuring dimensional accuracy for seamless integration into stainless steel piping systems.

Following design validation, we proceed to Formulation Development. Based on the operating environment—such as exposure to steam, acids, oils, or high-purity fluids—we select the appropriate elastomer compound. Our in-house compounding capabilities allow us to tailor formulations using EPDM, FKM (Viton®), NBR, silicone, or FFKM, depending on thermal stability, chemical resistance, and regulatory requirements (e.g., FDA, USP Class VI). Each formulation is optimized for hardness (typically 60–90 Shore A), tensile strength, compression set, and low outgassing properties. We conduct accelerated aging tests and chemical immersion analysis to verify performance under real-world conditions.

The third phase, Prototyping, enables physical validation of the design and material selection. Using precision molding techniques—compression, transfer, or injection—we produce small-batch samples for customer testing. These prototypes undergo dimensional inspection via CMM (Coordinate Measuring Machine) and are subjected to functional trials including pressure cycling, thermal shock, and leak testing. Feedback from these trials informs final adjustments to the mold geometry or compound formulation, ensuring optimal fit and performance.

Upon approval, we transition to Mass Production, leveraging automated molding lines and statistical process control (SPC) to maintain consistency across large volumes. Each batch is traceable, with full material certificates (MTRs) and quality documentation provided. Our production capacity supports both just-in-time delivery and bulk inventory programs for global OEMs.

The table below outlines typical performance specifications for commonly used elastomers in stainless pipe and fittings applications.

| Material | Temperature Range (°C) | Hardness (Shore A) | Key Resistance Properties | Common Applications |

|---|---|---|---|---|

| EPDM | -50 to +150 | 70–80 | Steam, water, alkalis | Sanitary processing, HVAC |

| FKM (Viton®) | -20 to +200 | 75–90 | Oils, acids, hydrocarbons | Petrochemical, semiconductor |

| NBR | -30 to +100 | 60–75 | Fuels, hydraulic fluids | Industrial hydraulics |

| Silicone | -60 to +180 | 40–80 | High/low temp, ozone | Food & beverage, medical |

Through this structured approach, Suzhou Baoshida delivers customized rubber components that enhance the reliability and efficiency of stainless pipe and fittings systems across demanding industrial sectors.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Stainless Pipe and Fitting Solutions

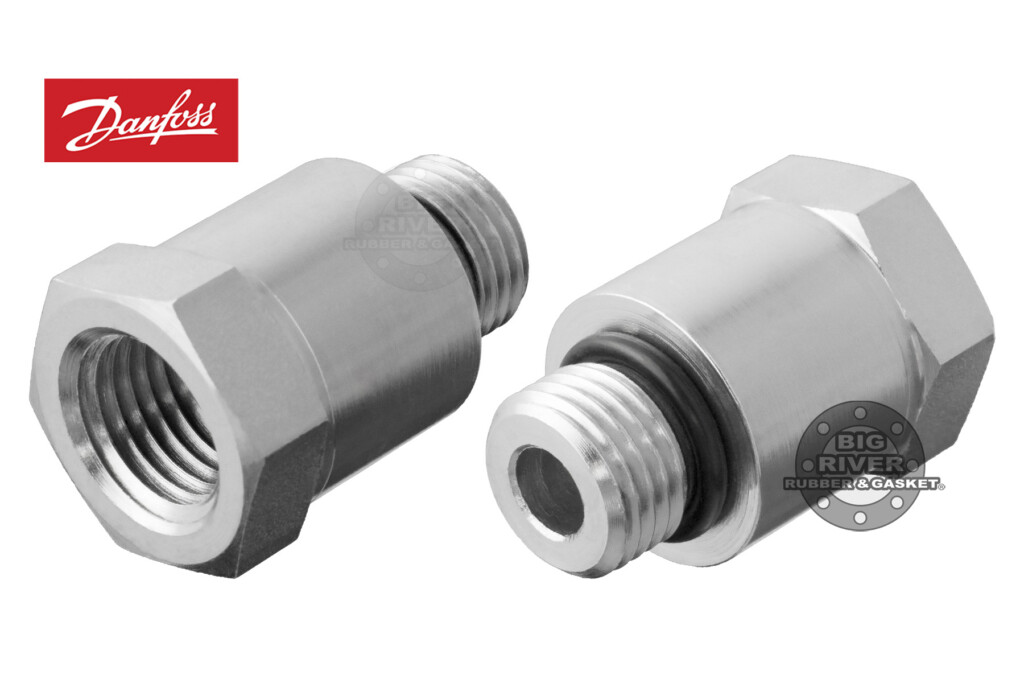

As the Rubber Formula Engineer and OEM Manager at Suzhou Baoshida Trading Co., Ltd., I emphasize that seamless integration between stainless steel components and advanced elastomeric systems defines modern industrial fluid handling. Our technical expertise extends beyond standard supply; we engineer holistic solutions where material compatibility, pressure integrity, and chemical resistance converge. Stainless pipe and fittings must perform flawlessly alongside rubber seals, hoses, and gaskets under extreme operational stress. Generic components risk system failure, whereas our OEM-partnered approach ensures every specification aligns with your application’s thermodynamic and chemical profile. We do not merely distribute—we co-develop.

Our validation protocols exceed ISO 9001 standards, with rigorous testing for cyclic fatigue, permeation resistance, and thermal expansion coefficients. This precision is critical when stainless assemblies interface with rubber elements in oil & gas, semiconductor, or pharmaceutical processing. For instance, improper surface finish on 316L fittings can accelerate elastomer degradation in high-purity bioreactors. We mitigate such risks through data-driven material pairing, leveraging our dual competency in metallurgy and polymer science. The table below summarizes key performance metrics for our certified stainless components, validated for synergy with industrial rubber systems.

| Specification Category | Performance Parameter | Industrial Standard |

|---|---|---|

| Material Grade | ASTM A312 TP316L Seamless | ASTM A269 / ASME BPE |

| Pressure Rating | 3000 PSI @ 100°F (38°C) | ASME B31.3 |

| Temperature Range | -40°C to 260°C | EN 10216-5 |

| Surface Finish | Ra ≤ 0.8 μm (Electropolished) | ASTM A967 |

| Testing Protocol | 100% PMI, Hydrostatic, Dye Penetrant | ASTM F1387 |

These parameters are non-negotiable in critical applications. Our engineering team cross-references stainless specifications with rubber compound data—such as fluorocarbon (FKM) or perfluoroelastomer (FFKM) formulations—to prevent galvanic corrosion, seal extrusion, or permeation leaks. This integrated analysis reduces total cost of ownership by eliminating field failures and unplanned downtime.

Initiate a technical consultation with me to resolve your specific system challenges. Provide your operational parameters—media composition, pressure cycles, temperature excursions—and we will deliver a validated component specification sheet within 48 hours. Our OEM partnerships include tier-1 semiconductor equipment manufacturers and offshore energy providers who demand zero tolerance for interface failures. Do not compromise on component interoperability; generic suppliers lack the polymer-metal interaction expertise required for next-generation systems.

Contact Mr. Boyce directly to advance your project. He possesses full authority to coordinate engineering reviews, prototype validation, and volume production scheduling. Specify your application’s critical control points in your initial communication to expedite our technical assessment. Time-to-resolution begins with precise data exchange.

Mr. Boyce

OEM Technical Liaison

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Include project reference code: SS-FIT-2024-ENG for priority engineering review

Partner with us where material science meets operational reality. Your system’s reliability depends on the weakest interface—we eliminate that variable.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).