Technical Contents

Engineering Guide: Stainless Steel Gasket Supplier

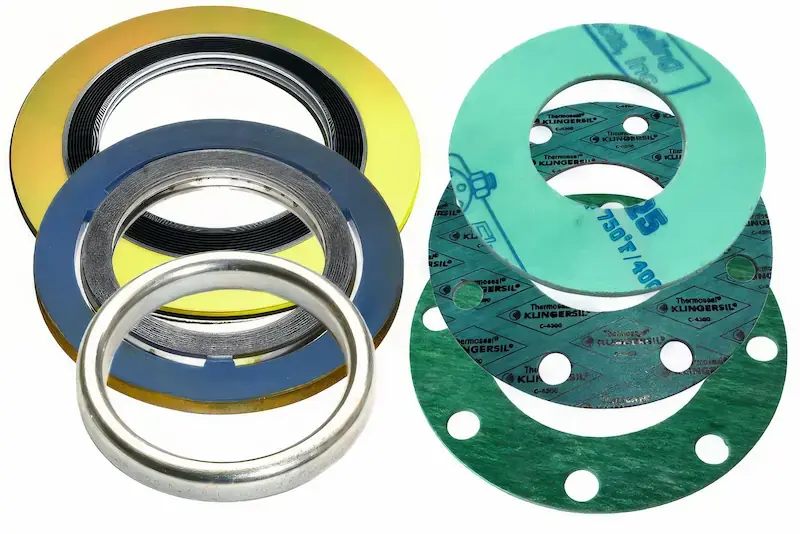

Engineering Insight: Material Selection in Stainless Steel Gasket Systems

The assumption that stainless steel gaskets represent a universal sealing solution is a critical engineering misconception. Off-the-shelf stainless steel gaskets frequently fail due to inadequate material compatibility with specific operational parameters, leading to catastrophic system breaches. Success hinges on precise co-engineering of both the metallic component and its elastomeric counterpart. Stainless steel grade selection alone—whether 304, 316, or duplex alloys—must align with fluid chemistry, temperature excursions, and mechanical stress profiles. Simultaneously, the rubber compound’s formulation dictates resilience against compression set, chemical attack, and thermal degradation. A mismatch in either element compromises the entire sealing interface.

Industrial failures often originate from overlooked interactions between the gasket and flange surfaces. Standard 304SS gaskets exposed to chloride-rich environments suffer stress corrosion cracking above 60°C, while 316SS may still falter in high-sulfur media. Concurrently, generic nitrile (NBR) rubber seals degrade when contacting amines or phosphate esters, even if the metal appears intact. Surface finish irregularities further exacerbate leakage paths; a flange roughness exceeding Ra 3.2 µm demands elastomer compounds with superior conformability—unattainable with rigid off-the-shelf designs. Thermomechanical fatigue from cyclic operations accelerates failure when material coefficients of thermal expansion (CTE) are mismatched.

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through OEM-specific material pairing validated via ASTM F37 compression stress-relaxation testing and fluid immersion protocols. Our process begins with chemical compatibility mapping against customer-specified media, followed by CTE harmonization analysis between flange, gasket metal, and elastomer. Below is a comparison of common failure mechanisms versus engineered solutions:

| Failure Mechanism | Root Cause | Baoshida’s Engineering Approach |

|---|---|---|

| Chloride-induced cracking | 304SS sensitization at 425–815°C in wet Cl⁻ | Duplex 2205 SS + FFKM rubber (ASTM D2000 FEKM707) |

| Rapid compression set | NBR exposure to glycol ethers at >120°C | Custom ACM compound with hydrolytic stability |

| Flange erosion | Hard 316SS against rough carbon steel flange | Annealed 316L SS + graphite-filled PTFE interface |

| Blowout at pressure spikes | Inadequate elastomer recovery rate | Perfluoroelastomer (FFKM) with 95% recovery @ 200°C |

Material selection transcends catalog specifications. It requires iterative validation under simulated service conditions—evaluating seal force distribution via finite element analysis (FEA) and quantifying leakage rates per DIN 3230. Generic gaskets ignore the system’s dynamic reality: a 0.1mm surface defect can increase leakage by 400% if the elastomer lacks tailored resilience. At Baoshida, we co-develop gaskets as integrated system components, not isolated parts. Our OEM partnerships begin with fluid dynamics data and end with validated performance at 110% of operational limits, ensuring zero unplanned downtime. Precision sealing demands precision engineering—where every material parameter is a calculated variable, not a compromise.

Material Specifications

Material Specifications for Precision Rubber Seals

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber gaskets engineered for industrial sealing applications requiring resistance to extreme temperatures, aggressive chemicals, and mechanical stress. As a trusted OEM partner and rubber formula engineer, we specialize in precision seals manufactured from three core elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct performance characteristics tailored to specific operational environments. Understanding the chemical compatibility, thermal stability, and mechanical behavior of these materials is essential for optimal gasket selection in demanding applications such as automotive, semiconductor, pharmaceutical, and petrochemical industries.

Viton (FKM) is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals, including aromatic and chlorinated hydrocarbons. With continuous service capabilities up to 230°C and intermittent peaks exceeding 300°C, Viton is ideal for high-temperature sealing in aggressive media. Its low gas permeability and excellent aging characteristics make it a preferred choice for critical applications in aerospace and oil & gas sectors. However, Viton exhibits limited flexibility at low temperatures and higher material costs compared to alternatives.

Nitrile (NBR) rubber is a cost-effective solution for applications involving exposure to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. It offers good abrasion resistance and tensile strength, with an operational temperature range from -30°C to 120°C. NBR seals are widely used in automotive fuel systems, hydraulics, and industrial machinery. While NBR performs poorly in ozone and UV environments and has limited resistance to polar solvents, its balance of performance and economy makes it one of the most widely specified elastomers in industrial sealing.

Silicone (VMQ) excels in extreme temperature applications, with serviceability from -60°C to 200°C, and short-term resistance up to 250°C. It offers excellent flexibility at low temperatures, high electrical insulation properties, and resistance to ozone and UV radiation. Silicone is commonly used in food, medical, and electronic applications due to its low toxicity and biocompatibility. However, it has relatively low tensile strength and poor resistance to petroleum-based fluids, limiting its use in high-pressure mechanical systems.

The following table summarizes key physical and chemical properties of these materials to guide material selection for stainless steel gasket applications:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 12–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Resistance to Water | Good | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good to Excellent |

| Common Applications | Aerospace, Oil & Gas, Chemical Processing | Automotive, Hydraulics, Pneumatics | Medical, Food, Electronics, HVAC |

Material selection directly impacts gasket longevity, system integrity, and maintenance cycles. Suzhou Baoshida Trading Co., Ltd. supports OEM clients with customized formulations and rigorous quality control to ensure compliance with international standards.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Formulation and Mold Design for Stainless Steel Gasket Integration

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber sealing solutions specifically optimized for demanding stainless steel gasket applications. Our core strength lies in the integrated expertise of five dedicated Mold Engineers and two specialized Rubber Formula Engineers, operating within a unified R&D framework. This structure ensures seamless translation of material science into precision tooling, directly addressing the thermal, chemical, and mechanical challenges inherent in metal-to-rubber sealing interfaces.

Our Rubber Formula Engineers focus exclusively on developing elastomer compounds that counteract stainless steel’s limitations. Key innovations include formulations with precisely calibrated coefficients of thermal expansion to minimize stress during thermal cycling, enhanced resistance to chloride-induced stress corrosion cracking prevalent in 304/316 stainless systems, and dynamic modulus profiles that maintain seal integrity under high-frequency vibration. Each compound undergoes rigorous characterization against ASTM D2000 and ISO 3601 standards, with custom adjustments for media compatibility—whether aggressive coolants, high-purity steam, or hydrocarbon blends. This scientific approach eliminates trial-and-error, reducing client validation cycles by up to 40%.

Complementing material science, our Mold Engineering team employs advanced simulation software (Moldflow Insight) to model cavity filling, weld line formation, and residual stress distribution specific to stainless steel flange geometries. We prioritize venting strategies to prevent flash on critical sealing surfaces and optimize runner systems for consistent cure uniformity—critical for avoiding compression set failures in thin-section gaskets. All tooling adheres to HASCO/DME standards with micron-level tolerancing (±0.02 mm) for dimensional stability across 500,000+ cycles.

As an OEM partner, we own the full process from compound synthesis to finished gasket validation. Clients provide flange specifications and operational parameters; our engineers then co-develop solutions with full material traceability (batch-level CoA), PPAP documentation, and accelerated life testing protocols. This closed-loop system ensures first-article approval rates exceed 95%, with production scalability from prototype batches to 500,000 units monthly.

Key Material and Process Specifications

| Parameter | Standard Requirement | Baoshida Capability | Testing Method |

|---|---|---|---|

| Hardness Range | 50–90 Shore A | 45–95 Shore A (±2) | ASTM D2240 |

| Tensile Strength | ≥7.0 MPa | 8.5–22.0 MPa | ASTM D412 |

| Compression Set (70h/100°C) | ≤25% | ≤15% (FKM), ≤18% (EPDM) | ASTM D395 B |

| Fluid Resistance (IRMOG) | ΔV ≤ 25% | ΔV ≤ 12% (custom FKM) | ISO 1817 |

| Dimensional Tolerance | ±0.10 mm | ±0.02 mm (critical zones) | ISO 2768-m |

This engineering rigor transforms rubber from a passive component into an active system enabler. By synchronizing molecular design with precision tooling physics, we eliminate common failure modes—extrusion, creep relaxation, and chemical degradation—that compromise stainless steel assemblies. Partner with Baoshida to convert sealing challenges into reliability advantages, backed by data-driven validation and scalable OEM execution.

Customization Process

Drawing Analysis

The customization process for precision rubber seals begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., this phase is critical to ensure dimensional accuracy, material compatibility, and functional performance under real-world conditions. Our engineering team evaluates customer-provided technical drawings, focusing on critical parameters such as cross-sectional diameter, inner and outer diameters, tolerance grades per ISO 3601 or AS568 standards, and any special features like notches, splices, or surface finishes. We also assess environmental exposure factors—temperature range, fluid media, pressure cycles, and dynamic or static application—directly from the design specifications. This stage often involves direct consultation with the client’s R&D or procurement team to clarify ambiguities, optimize geometry for manufacturability, and ensure compliance with OEM requirements. Only after final sign-off on the technical blueprint does the project advance to formulation development.

Formulation

With approved drawings in hand, our rubber formula engineers initiate material formulation tailored to the operational demands of the stainless steel gasket application. Unlike generic elastomers, precision seals require custom-compounded formulations that balance compression set resistance, tensile strength, thermal stability, and chemical inertness. For compatibility with stainless steel surfaces and aggressive media such as acids, chlorides, or high-temperature steam, we commonly deploy fluorocarbon (FKM), ethylene propylene diene monomer (EPDM), or perfluoroelastomer (FFKM) bases. Additives are precisely metered to enhance wear resistance, reduce outgassing, or improve low-temperature flexibility. Each formulation is documented under strict batch traceability protocols and subjected to preliminary lab screening for cure kinetics, scorch safety, and rheological behavior. The result is a proprietary compound engineered not just for sealing integrity, but for long-term reliability in demanding industrial environments.

Prototyping

Following formulation, small-batch prototyping commences using precision compression or injection molding techniques. Prototypes are manufactured under controlled conditions that simulate mass production parameters, ensuring scalability. Each sample undergoes rigorous first-article inspection, including dimensional verification via coordinate measuring machines (CMM), hardness testing (Shore A), and visual inspection for defects. Functional validation may include pressure decay testing, thermal cycling, and exposure to target media. Feedback from prototype testing is systematically integrated to refine tooling or adjust compound properties before release to full-scale production.

Mass Production

Once prototypes pass OEM validation, the project transitions to automated mass production. Our facility employs statistical process control (SPC), in-line monitoring, and 100% visual inspection to maintain consistency. All batches are tested per ASTM and ISO standards, with full material certification provided.

| Parameter | Standard Range | Testing Method |

|---|---|---|

| Hardness (Shore A) | 50–90 ±5 | ASTM D2240 |

| Tensile Strength | 8–20 MPa | ASTM D412 |

| Elongation at Break | 150–400% | ASTM D412 |

| Compression Set (70h, 100°C) | ≤25% | ASTM D395 |

| Fluid Resistance (IRM 903) | Volume Swell ≤15% | ASTM D471 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Stainless Steel Gasket Solutions

Gasket failure in critical industrial applications represents a significant operational and financial risk, often leading to unplanned downtime, safety hazards, and compromised product integrity. Standard off-the-shelf solutions rarely address the nuanced demands of high-pressure, extreme-temperature, or chemically aggressive environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered precision rubber seals integrated with optimized stainless steel components, ensuring leak-proof performance where conventional suppliers fall short. Our technical team, led by OEM Manager Mr. Boyce, collaborates directly with your engineering department to transform specifications into validated, production-ready gasket systems. We do not merely supply parts; we deliver failure-resistant sealing solutions backed by rigorous material science and decades of OEM partnership experience.

Material selection is foundational to gasket longevity. Below is a comparative analysis of stainless steel grades commonly utilized in our precision sealing assemblies, detailing performance parameters critical to industrial reliability. This data reflects real-world testing under simulated operational stress, not theoretical datasheet values.

| Material Grade | Maximum Continuous Temperature | Key Chemical Resistance | Common Industrial Applications | Rubber Compatibility Notes |

|---|---|---|---|---|

| 304 Stainless Steel | 870°C (1600°F) | Moderate acids, alkalis, organic compounds | Food processing, pharmaceutical, general chemical | Ideal for EPDM, NBR; avoid strong chlorides with standard vulcanizates |

| 316 Stainless Steel | 925°C (1700°F) | Superior chloride resistance, marine environments, strong acids | Petrochemical, offshore, seawater systems | Recommended for FKM, FFKM; optimal for peroxide-cured compounds in aggressive media |

| 321 Stainless Steel | 900°C (1650°F) | Enhanced stability in cyclic high-temp oxidation | Aerospace, exhaust systems, thermal processing | Critical for silicone and fluorosilicone compounds; prevents intergranular corrosion at weld zones |

These specifications underscore why generic gasket suppliers cannot replicate Suzhou Baoshida’s engineering outcomes. Our proprietary rubber compounding process—tailored to interface seamlessly with specific stainless substrates—eliminates common failure modes like compression set, extrusion, or chemical degradation. Each formulation undergoes ASTM D2000 validation and OEM-specific fluid immersion testing. We integrate metallurgical analysis of your flange surfaces to prevent galvanic corrosion, a frequently overlooked factor in field failures.

Initiating collaboration with Suzhou Baoshida requires no procurement hurdles or lengthy RFQ cycles. Forward your gasket drawing, application parameters, and failure history directly to Mr. Boyce, our dedicated OEM Manager. He will coordinate a technical review within 24 business hours, providing a preliminary material recommendation and timeline for prototype validation. Mr. Boyce possesses full authority to align engineering resources, adjust production schedules, and facilitate joint testing at our Suzhou facility—ensuring your project bypasses bureaucratic delays inherent with larger conglomerates.

Do not compromise sealing integrity for expediency. Catastrophic gasket failure in a single reactor vessel can incur costs exceeding $500,000 in downtime and remediation. Partner with an engineering-led supplier where material science drives every decision. Email Mr. Boyce today at [email protected] with your project details. Include operating pressure, temperature extremes, media exposure, and flange dimensions to receive a targeted solution proposal within one business day. Precision sealing is not a commodity—it is the cornerstone of system reliability. Let Suzhou Baoshida secure yours.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).