Technical Contents

Engineering Guide: Stair Gripper Strips

Engineering Insight: The Critical Role of Material Selection in Stair Gripper Strips

In industrial and commercial environments, stair gripper strips are not merely safety accessories—they are engineered components designed to withstand repetitive mechanical stress, environmental exposure, and continuous foot traffic. The performance and longevity of these strips are fundamentally determined by material selection, a factor frequently overlooked when off-the-shelf solutions are adopted without technical scrutiny. At Suzhou Baoshida Trading Co., Ltd., we emphasize that generic rubber profiles fail in demanding applications due to inadequate formulation and structural integrity.

Standard stair gripper strips often utilize low-grade recycled rubber or soft thermoplastic elastomers (TPE) optimized for cost, not performance. These materials exhibit rapid wear under abrasion, lose elasticity in temperature extremes, and degrade when exposed to UV radiation or industrial chemicals. In high-traffic facilities such as factories, transit hubs, and multi-story warehouses, such premature failure leads to increased maintenance costs, safety hazards, and non-compliance with occupational safety standards.

In contrast, engineered rubber compounds—such as nitrile butadiene rubber (NBR), ethylene propylene diene monomer (EPDM), or high-abrasion resistant natural rubber blends—deliver superior performance. These materials offer enhanced tensile strength, consistent coefficient of friction, and resistance to oil, ozone, and thermal cycling. For instance, EPDM-based gripper strips maintain functionality from -40°C to +130°C, making them ideal for outdoor or unheated environments. NBR variants excel in oil-prone areas such as mechanical rooms or automotive service floors.

Another critical factor is durometer hardness. A Shore A hardness between 65 and 75 ensures optimal balance: soft enough to provide tactile grip and noise damping, yet hard enough to resist indentation and deformation under load. Off-the-shelf strips often fall below this range, leading to permanent compression set and loss of profile definition within months of installation.

Adhesion performance is equally dependent on material chemistry. The bonding layer between the rubber strip and aluminum or stainless-steel carrier must resist delamination under shear stress. Engineered solutions employ primers and vulcanization techniques that create covalent bonds between the rubber and metal substrate—something commodity products rarely achieve.

Below is a comparative specification table highlighting key performance metrics between standard and engineered stair gripper strips.

| Property | Standard Off-the-Shelf Strip | Engineered Rubber Strip (Baoshida) |

|---|---|---|

| Base Material | Recycled Rubber / TPE | EPDM or NBR Compound |

| Shore A Hardness | 50–60 | 65–75 |

| Abrasion Resistance (DIN 53516) | 180 mm³ loss | ≤90 mm³ loss |

| Temperature Range | -10°C to +70°C | -40°C to +130°C |

| Oil Resistance | Poor | Excellent (NBR) / Good (EPDM) |

| UV/Ozone Resistance | Low | High (EPDM) |

| Bond Strength to Metal | ≤0.8 kN/m | ≥1.8 kN/m |

| Expected Service Life | 12–18 months | 5+ years |

Material selection is not a compromise between cost and quality—it is a determinant of system reliability. At Suzhou Baoshida, we design stair gripper strips as engineered safety components, not disposable accessories. By integrating industrial-grade rubber formulations with precision manufacturing, we deliver solutions that perform consistently in the world’s most demanding environments.

Material Specifications

Material Specifications for Stair Gripper Strips: Performance-Driven Selection Criteria

Selecting the optimal elastomer for stair gripper strips is critical for ensuring long-term safety, durability, and compliance in high-traffic industrial and commercial environments. At Suzhou Baoshida Trading Co., Ltd., our formulations undergo rigorous OEM validation testing to meet ASTM D2000 and ISO 37 standards. Material choice directly impacts traction retention, environmental resistance, and lifecycle cost. Below, we detail the three primary compounds used in our stair safety solutions: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material addresses distinct operational challenges, from chemical exposure to extreme temperatures.

Viton (FKM) excels in applications demanding exceptional resistance to oils, fuels, and aggressive chemicals. With a continuous service temperature range of -20°C to +230°C, it maintains structural integrity in aerospace hangars, petrochemical facilities, and semiconductor manufacturing floors where hydraulic fluid or solvent exposure is routine. Its high fluorine content prevents swelling and degradation, though its hardness range (70–90 Shore A) requires precise molding to ensure optimal tread conformity. Viton’s premium cost is justified only where NBR or Silicone would fail catastrophically; it is unsuitable for general-purpose stair use due to limited flexibility at ambient temperatures.

Nitrile (NBR) remains the industry standard for 80% of stair gripper strip installations, balancing cost efficiency with robust performance. Formulated to 60–80 Shore A hardness, it provides superior abrasion resistance and grip on wet or oily surfaces, critical for factory walkways, marine decks, and food processing plants. Our Baoshida NBR compound withstands temperatures from -30°C to +120°C and resists animal/vegetable oils, hydraulic fluids, and mild acids. Accelerated aging tests confirm >15,000 cycles of flex fatigue resistance per ISO 132, ensuring decades of service without cracking. However, prolonged UV exposure necessitates carbon-black stabilization, and ozone resistance remains inferior to EPDM alternatives.

Silicone (VMQ) is indispensable for extreme-temperature environments, operating reliably from -60°C to +200°C. Its low compression set (≤20% per ASTM D395) guarantees consistent grip force retention in cryogenic labs, bakery ovens, and outdoor staircases in Arctic climates. With hardness options from 40–70 Shore A, it offers unmatched flexibility for curved or irregular treads. Silicone’s inherent hydrophobicity prevents moisture absorption, but its lower tensile strength (8–10 MPa) requires reinforced backing in high-shear applications. Notably, standard VMQ lacks oil resistance; Baoshida’s proprietary fluorosilicone variants address this for limited chemical exposure.

Material selection must align with site-specific stressors. The following comparative analysis distills key technical parameters for informed OEM decision-making:

| Material | Hardness Range (Shore A) | Temperature Range (°C) | Key Properties | Primary Applications |

|---|---|---|---|---|

| Viton (FKM) | 70–90 | -20 to +230 | Exceptional chemical/fuel resistance; low gas permeability; high cost | Petrochemical plants; aircraft maintenance; semiconductor cleanrooms |

| Nitrile (NBR) | 60–80 | -30 to +120 | Superior abrasion/oil resistance; cost-effective; moderate UV stability | Industrial factories; marine platforms; food processing facilities |

| Silicone (VMQ) | 40–70 | -60 to +200 | Extreme temp stability; flexibility; hydrophobic; poor oil resistance | Cold storage; bakeries; outdoor staircases in severe climates |

OEM partners must validate material choice against ISO 14122-3 stair safety directives and site-specific hazard assessments. Baoshida’s engineering team provides free compound customization—including durometer adjustments, conductive fillers for ESD control, or antimicrobial additives—to ensure compliance with global safety standards. Never compromise on material integrity; substandard elastomers risk delamination, reduced coefficient of friction, and regulatory non-conformance. Partner with us to specify the precise formulation matching your operational reality.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering engineered performance to global manufacturers of stair gripper strips. Our engineering capability is anchored in a dedicated team of five specialized mould engineers and two advanced rubber formulation scientists, enabling us to provide fully integrated OEM services from concept to mass production. This technical synergy allows us to meet the rigorous demands of durability, dimensional accuracy, and material performance required in high-traffic stair safety systems.

Our mould engineering team brings extensive experience in precision tooling design for complex extrusion and compression moulding processes. Each engineer applies finite element analysis (FEA) and 3D simulation tools to optimize flow dynamics, minimize material waste, and ensure consistent part geometry across production batches. This attention to detail is critical in stair gripper strip manufacturing, where edge definition, surface texture, and fitment accuracy directly impact installation reliability and slip resistance. We design and validate moulds for both standard and custom profiles, supporting rapid prototyping and scalable tooling deployment.

Complementing our mould expertise, our two in-house rubber formula engineers specialize in elastomer chemistry tailored to industrial applications. They develop proprietary rubber compounds that balance abrasion resistance, tensile strength, compression set, and coefficient of friction—key performance indicators for stair safety components. Using advanced testing protocols, including Shore A hardness profiling, DIN abrasion testing, and thermal aging analysis, our formulations are engineered to withstand prolonged mechanical stress, UV exposure, and fluctuating environmental conditions. We work with a range of base polymers, including EPDM, SBR, and NBR, customizing filler systems, vulcanization agents, and anti-aging additives to meet specific OEM requirements.

Our OEM capabilities are built on a foundation of co-engineering collaboration. We partner directly with manufacturers to refine product specifications, conduct material validation, and ensure compliance with international safety standards such as ISO 4586 and EN 13329. Our end-to-end service includes design for manufacturability (DFM) reviews, prototyping, tooling production, and batch validation under ISO 9001-certified processes.

The following table outlines key technical specifications achievable through our engineering platform:

| Parameter | Capability | Test Standard |

|---|---|---|

| Hardness Range | 50–85 Shore A | ASTM D2240 |

| Tensile Strength | Up to 18 MPa | ASTM D412 |

| Elongation at Break | Up to 450% | ASTM D412 |

| Abrasion Loss | ≤120 mm³ | DIN 53516 |

| Operating Temperature | -40°C to +100°C | ISO 188 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395B |

By integrating advanced rubber formulation with precision mould engineering, Suzhou Baoshida delivers technically superior stair gripper strip solutions that enhance product longevity and safety performance. Our OEM partnerships are driven by engineering rigor, material science expertise, and a commitment to industrial excellence.

Customization Process

Customization Process for Industrial Stair Gripper Strips

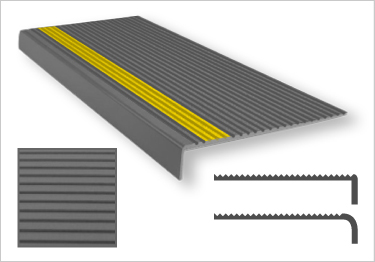

At Suzhou Baoshida Trading Co., Ltd., our stair gripper strip customization follows a rigorously defined engineering workflow to ensure dimensional accuracy, material resilience, and compliance with industrial safety standards. This process begins with comprehensive drawing analysis, where our technical team deconstructs client-provided CAD files or sketches to verify critical parameters including tread depth, land width, anti-slip pattern geometry, and substrate adhesion zones. We cross-reference these against ISO 14122-3 structural safety requirements and conduct finite element analysis (FEA) to simulate load distribution under dynamic pedestrian traffic. Any deviations from manufacturable tolerances (±0.2 mm for extrusion profiles) are flagged for collaborative redesign prior to material selection.

Material formulation is subsequently engineered to match the operational environment. For high-traffic commercial staircases, we prioritize EPDM/NR blends with Shore A 65–75 hardness, incorporating silica reinforcement for abrasion resistance and carbon black for UV stability. Marine or chemical-exposed applications trigger FKM-based compounds with fluorine content >66% to withstand hydrocarbon exposure. Each formulation undergoes accelerated aging tests per ASTM D573 and ozone resistance validation at 50 ppm per ISO 1431-1. Critical performance metrics are validated through our internal material database, ensuring optimal balance between coefficient of friction (0.6–0.8 wet/dry) and flex fatigue endurance.

Prototyping employs precision aluminum molds with controlled thermal gradients to eliminate knit lines in complex geometries. Three physical samples undergo iterative testing:

ISO 48-4 hardness verification

ISO 4649 abrasion index measurement

ISO 6603-2 impact resistance at -20°C

Client feedback on grip texture, color consistency (tolerance ΔE <1.5), and adhesion strength dictates final adjustments before tooling sign-off.

Mass production leverages our ISO 9001-certified extrusion lines with real-time rheometer monitoring. Each batch undergoes 100% dimensional scanning via CMM and batch-release testing per the specifications below:

| Property | Test Standard | Requirement | Measurement Method |

|---|---|---|---|

| Hardness (Shore A) | ISO 48-4 | 70 ± 5 | Durometer at 23°C |

| Abrasion Resistance | ISO 4649 | ≤ 120 mm³ loss | Akron Abrader, 1.0 kPa load |

| Tensile Strength | ISO 37 | ≥ 15 MPa | Type 2 dumbbell, 500 mm/min |

| Elongation at Break | ISO 37 | ≥ 350% | Type 2 dumbbell, 500 mm/min |

| Coefficient of Friction | ASTM D2047 | ≥ 0.6 (wet ceramic) | James Machine, 50 lbf load |

Final shipment includes material traceability logs, cure curve validation, and third-party test certificates. This closed-loop process guarantees stair gripper strips that meet OEM durability expectations while minimizing field failure risks in high-traffic infrastructure.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Stair Gripper Strip Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber components designed for durability, safety, and performance in demanding industrial and commercial environments. As a trusted OEM manufacturer and supplier of stair gripper strips, we deliver customized solutions that meet exact client specifications, from material formulation to dimensional tolerances and surface texture. Our expertise in rubber compounding ensures that every stair safety profile we produce offers superior traction, abrasion resistance, and long-term adhesion under heavy foot traffic and variable environmental conditions.

Stair gripper strips are critical safety components in public infrastructure, transportation systems, industrial facilities, and commercial buildings. Whether installed on metal, concrete, or wooden stair treads, our rubber profiles are formulated to prevent slip hazards, reduce wear on step edges, and enhance user confidence in high-traffic areas. We work with EPDM, SBR, NBR, and CR (neoprene) compounds, selecting the optimal material based on UV resistance, oil resistance, low-temperature flexibility, and flame retardancy requirements.

Our production process integrates precision extrusion, continuous vulcanization, and strict quality control to ensure consistency across large-volume orders. We support both standard and custom cross-sectional profiles, with options for pre-drilled holes, adhesive backing, or mechanical fastening systems. All products are manufactured in compliance with international safety standards, including ISO 9001-certified processes, and can be tested for slip resistance (e.g., DIN 51130, BS 7976).

To ensure seamless integration into your assembly or installation workflow, we offer technical collaboration from design phase to final validation. Our engineering team provides material data sheets, 3D drawings, and sample kits upon request, enabling fast prototyping and qualification.

For OEM partners, construction material distributors, or safety equipment integrators seeking a reliable source for high-performance stair gripper strips, Suzhou Baoshida offers competitive pricing, scalable production capacity, and on-time global logistics support. We serve clients across Europe, North America, Southeast Asia, and the Middle East, maintaining inventory hubs to ensure short lead times and supply chain resilience.

Technical Specifications Overview

| Property | Value/Range | Test Standard |

|---|---|---|

| Hardness (Shore A) | 50–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥8 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Abrasion Loss (Taber, 1000 cycles) | ≤120 mg | ASTM D1044 |

| Operating Temperature Range | -40°C to +100°C | — |

| Slip Resistance (R9–R13) | Available | DIN 51130 |

| Adhesion Strength (to substrate) | ≥0.8 MPa | Internal Method |

| Flame Resistance | Optional (UL94 HB/V-0) | UL94, BS476 |

Partner with Suzhou Baoshida to develop stair safety solutions that meet your exact performance, regulatory, and volume needs. Contact Mr. Boyce directly at [email protected] to discuss your project requirements, request technical documentation, or receive a tailored quotation. We respond to all inquiries within 12 hours and support communication in English, Mandarin, and German. Let us be your precision rubber solutions provider for stair gripper strip manufacturing.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).