Technical Contents

Engineering Guide: Step Guards Stairs

Engineering Insight: The Critical Role of Material Selection in Step Guards for Stairs

In industrial and commercial environments, step guards for stairs are not merely aesthetic or regulatory compliance items—they are engineered safety components subjected to continuous mechanical stress, environmental exposure, and dynamic load cycles. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is the cornerstone of long-term performance and safety assurance in rubber step guard systems. Off-the-shelf solutions often fail prematurely due to a fundamental oversight: the assumption that all rubber compounds behave similarly under real-world conditions.

Standard rubber extrusions, typically made from generic EPDM or SBR compounds, are frequently marketed as universal solutions. However, they lack the tailored formulation necessary to endure specific site conditions such as oil exposure, UV degradation, temperature extremes, or high foot traffic abrasion. For instance, a stairway in a food processing facility may require resistance to sanitizing chemicals and frequent washdowns, while an outdoor industrial staircase may face thermal cycling and prolonged UV exposure. Generic materials degrade rapidly in such environments, leading to cracking, delamination, and loss of traction—compromising safety and increasing lifecycle costs.

The failure of off-the-shelf step guards is not always immediate. Often, the degradation is progressive, beginning with micro-cracking at stress points or loss of surface texture due to abrasive wear. Over time, this diminishes slip resistance, a critical safety parameter. In high-traffic zones, even a 20% reduction in tread depth can significantly increase slip risk, particularly in wet or oily conditions. Moreover, poor adhesion between the rubber profile and mounting substrate—often due to incompatible bonding agents or inadequate surface preparation—leads to edge lifting and eventual detachment.

At Baoshida, our engineered rubber solutions are formulated using application-specific compounds. We utilize high-abrasion-resistant NBR for oil-prone environments, UV-stabilized EPDM for outdoor installations, and halogen-free flame-retardant compounds for transit and public infrastructure. Each formulation is validated through accelerated aging tests, Shore A hardness profiling, and slip resistance measurement under both dry and wet conditions.

The following table outlines key performance specifications of our industrial-grade step guard compounds compared to standard off-the-shelf alternatives:

| Property | Baoshida Engineered NBR | Standard SBR (Off-the-Shelf) | Test Method |

|---|---|---|---|

| Shore A Hardness | 65 ± 5 | 55 ± 5 | ASTM D2240 |

| Tensile Strength | ≥18 MPa | ≥10 MPa | ASTM D412 |

| Abrasion Loss (Taber, 1000 cycles) | ≤80 mg | ≤150 mg | ASTM D1044 |

| Oil Resistance (IRM 903, 70°C, 70h) | Volume Swell ≤20% | Volume Swell ≤45% | ASTM D471 |

| UV Resistance (1000h QUV) | No cracking, ΔE <3 | Cracking observed, ΔE >6 | ASTM G154 |

| Slip Resistance (R10 min) | Yes | Marginal (R9) | DIN 51130 |

Material selection is not a cost-saving exercise—it is a risk management decision. By choosing purpose-built rubber compounds, facility managers and OEMs ensure compliance, reduce maintenance frequency, and most importantly, protect personnel. At Suzhou Baoshida, we engineer for performance, not just price.

Material Specifications

Material Specifications for Industrial Step Guard Stair Applications

Material selection for step guard stairs directly impacts operational safety, longevity, and compliance in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we engineer rubber compounds to withstand mechanical stress, chemical exposure, and thermal fluctuations inherent in facility access points. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent our core formulations for these critical safety components, each optimized for specific environmental challenges. Selection requires rigorous evaluation of temperature profiles, fluid resistance, and mechanical durability to prevent premature failure.

Viton fluorocarbon rubber delivers exceptional performance in extreme chemical and thermal conditions. Its molecular structure provides superior resistance to oils, acids, jet fuels, and chlorinated solvents, making it ideal for aerospace, petrochemical, and heavy machinery applications. Viton step guards maintain integrity from -20°C to 250°C continuous service, with short-term peaks up to 300°C. The compound exhibits low gas permeability and outstanding ozone resistance but carries a higher material cost. Empirical validation confirms Viton’s suitability where exposure to aggressive media negates alternatives.

Nitrile butadiene rubber remains the industry standard for cost-effective oil and fuel resistance. Optimized NBR formulations balance acrylonitrile content to target specific swell resistance; higher ACN grades (45-50%) withstand hydraulic fluids and aliphatic hydrocarbons while retaining flexibility down to -30°C. NBR step guards excel in automotive assembly lines, hydraulic equipment platforms, and marine environments but exhibit vulnerability to ozone, weathering, and polar solvents like ketones. Abrasion resistance is superior to silicone, critical for high-traffic stair treads subject to repeated foot impact.

Silicone rubber provides unmatched thermal stability across extreme ranges, functioning reliably from -60°C to 230°C. Its inert composition meets stringent food and pharmaceutical hygiene standards (FDA 21 CFR 177.2600), while excellent electrical insulation properties benefit utility access stairs. Silicone step guards resist UV degradation and maintain flexibility in cryogenic settings but demonstrate lower tensile strength and abrasion resistance versus NBR or Viton. This necessitates design adjustments like thicker profiles or fabric reinforcement for high-wear zones.

The following comparative analysis details critical performance parameters for informed material selection. All data reflects standard cured compounds per ASTM D2000 classification M2BA 710 A14 B14 EF11 EF21 EF31.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -40 to 125 | -60 to 230 |

| Tensile Strength (MPa) | 10-15 | 15-25 | 5-10 |

| Abrasion Resistance | Moderate | Excellent | Fair |

| Oil/Fuel Resistance | Exceptional | Excellent | Poor |

| Ozone/Weather Resistance | Exceptional | Poor | Excellent |

| Compression Set (%) | 10-20 (200°C/70h) | 20-35 (100°C/70h) | 15-25 (200°C/70h) |

| Typical Hardness (ShA) | 60-80 | 50-90 | 30-80 |

Material choice must align with empirical site conditions. Viton is non-negotiable for refinery catwalks exposed to aromatic solvents, while NBR offers optimal lifecycle economics for warehouse loading docks. Silicone becomes imperative in freezer facilities or cleanrooms. Suzhou Baoshida provides OEM-specific compound tuning—including hardness adjustments, conductive fillers, or flame-retardant additives—to meet exact operational requirements. All formulations undergo ISO 9001-certified validation for slip resistance (ASTM F2913) and durability prior to deployment. Consult our engineering team for application-specific testing protocols.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Step Guard Stairs

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our value proposition in the industrial rubber solutions sector. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the design, material development, and manufacturing processes for step guard stairs. This integrated technical structure enables us to deliver highly customized, performance-optimized products tailored to the rigorous demands of industrial environments.

Our mould engineers bring over 15 years of collective experience in precision tooling design, utilizing advanced CAD/CAM software and CNC machining to develop robust, high-tolerance moulds. Each step guard stair mould is engineered for dimensional accuracy, structural integrity, and long-term durability under repetitive mechanical stress. Finite element analysis (FEA) is routinely applied during the design phase to simulate load distribution, deformation resistance, and fatigue life, ensuring optimal performance in real-world applications.

Complementing our tooling expertise, our two rubber formula engineers specialize in polymer chemistry and compound formulation. They develop proprietary rubber blends that meet exacting requirements for abrasion resistance, slip resistance, temperature stability, and mechanical strength. By controlling the formulation process in-house, we eliminate dependency on third-party compounds and ensure batch-to-batch consistency. Our formulations are optimized for both performance and processability, enabling efficient vulcanization and seamless integration with metal substrates in bonded step guard designs.

We offer comprehensive OEM services, supporting clients from concept to mass production. Our engineers work directly with OEM partners to interpret technical drawings, validate material specifications, and conduct prototyping with rapid turnaround. This collaborative approach allows for early-stage validation of form, fit, and function, reducing time-to-market and minimizing costly design iterations. All development data—including mould designs, compound recipes, and test reports—are maintained under strict confidentiality protocols.

The following table outlines key technical specifications achievable through our engineering platform for industrial step guard stairs:

| Parameter | Specification |

|---|---|

| Material Types | NR, SBR, NBR, EPDM, CR, and custom blends |

| Hardness Range (Shore A) | 50–85 ±5 |

| Operating Temperature Range | -40°C to +120°C (dependent on compound) |

| Tensile Strength | ≥12 MPa (ASTM D412) |

| Elongation at Break | ≥250% (ASTM D412) |

| Abrasion Resistance (DIN 53516) | ≤120 mm³ volume loss |

| Slip Resistance (DIN 51130) | R11–R13 classification |

| Adhesion Strength (Rubber-to-Metal) | ≥8 kN/m (peel test, ISO 813) |

| Mould Tolerance | ±0.2 mm (critical dimensions) |

Our engineering team adheres to ISO 9001 quality management standards and supports full traceability across all development and production stages. By combining advanced material science with precision engineering, Suzhou Baoshida delivers step guard stair solutions that meet the highest benchmarks in safety, durability, and industrial performance.

Customization Process

Customization Process for Industrial Step Guard Stairs

At Suzhou Baoshida Trading Co., Ltd., precision-engineered rubber step guards are critical for workplace safety in high-traffic industrial environments. Our OEM customization process ensures each component meets exact mechanical, chemical, and ergonomic demands. This structured workflow eliminates guesswork and accelerates time-to-market while guaranteeing compliance with ISO 14122-3 safety standards for permanent access equipment.

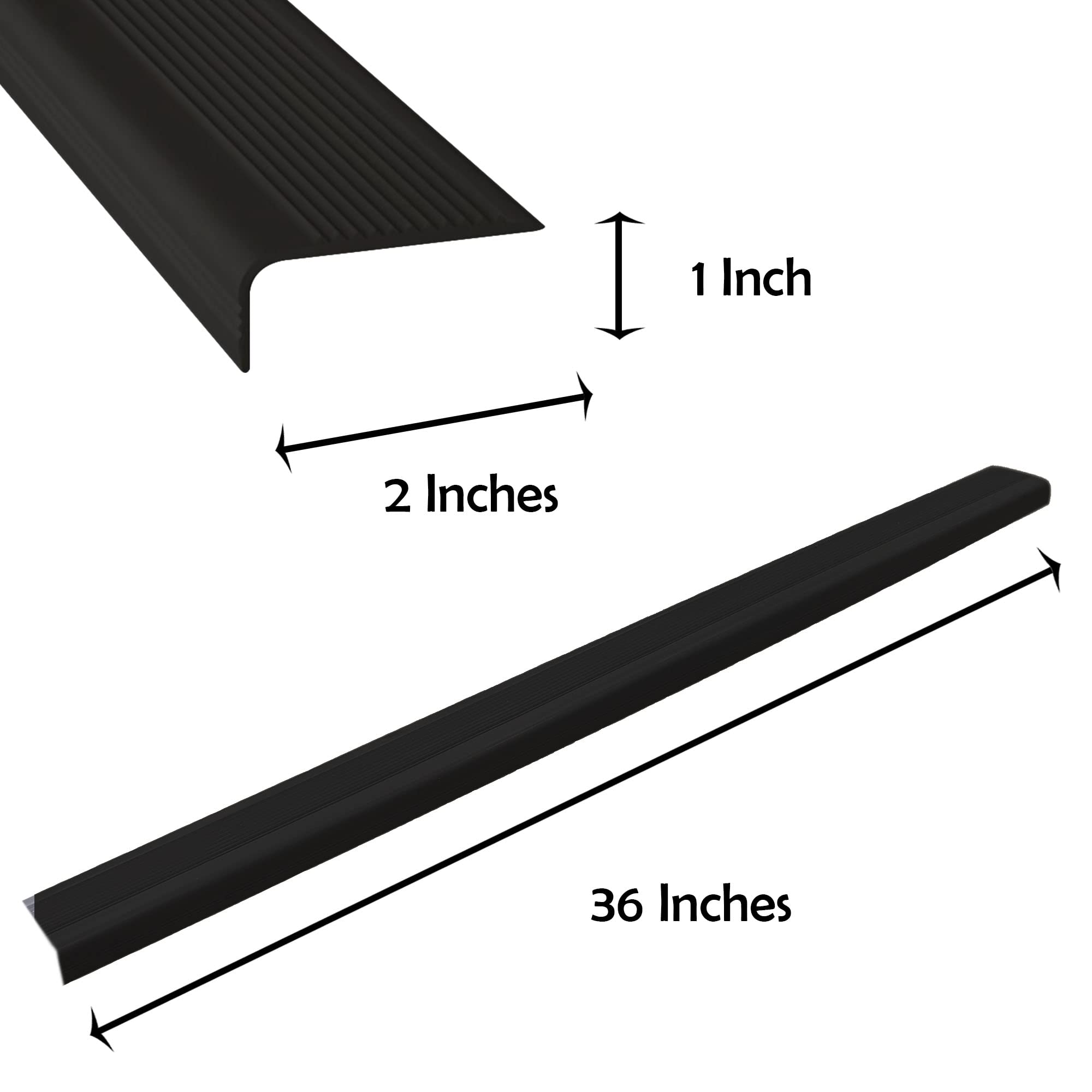

The process begins with rigorous Drawing Analysis. Our engineering team dissects CAD files provided by the client, focusing on dimensional tolerances, load-bearing requirements, and integration points with existing stair structures. We validate critical parameters such as tread depth, riser height, and anti-slip pattern geometry against ASTM F1637 guidelines. This phase identifies potential manufacturing constraints early, such as undercuts or thin sections that could compromise vulcanization integrity. Material thickness is cross-referenced with expected footfall impact energy to prevent premature fatigue.

Subsequently, Formulation Design leverages our proprietary polymer science database. Based on the operational environment—whether chemical exposure in food processing plants or extreme UV conditions on offshore platforms—we select base elastomers like EPDM for ozone resistance or nitrile rubber for oil immersion. Hardness (Shore A 50–70) is calibrated to balance slip resistance and user comfort, while reinforcing fillers like silica or carbon black optimize abrasion resistance. Accelerator systems are fine-tuned to achieve target crosslink density, ensuring the compound withstands repeated compression without permanent deformation. All formulations adhere to REACH and RoHS compliance frameworks.

Prototyping validates theoretical performance through empirical testing. We produce 3–5 sample units using client-specified tooling, subjecting them to accelerated wear cycles, slip resistance trials on wet/oily surfaces (per ASTM D2047), and thermal aging at 70°C for 72 hours. Compression set is measured at 25% deflection to confirm resilience retention. Clients receive detailed test reports alongside physical samples for on-site validation. Critical performance metrics are summarized below.

| Test Parameter | Standard | Acceptance Criteria | Measurement Method |

|---|---|---|---|

| Slip Resistance (Dry) | ASTM D2047 | ≥ 0.5 SCOF | James Machine |

| Compression Set | ISO 815-1 | ≤ 20% after 22h/70°C | Specified Deflection |

| Abrasion Loss | ISO 4649 | ≤ 120 mm³ | Akron Abrader |

| Tensile Strength | ISO 37 | ≥ 15 MPa | Type 2 Dumbbell Specimen |

Upon client approval, Mass Production commences under stringent IATF 16949 protocols. Each batch undergoes real-time rheometer monitoring during vulcanization to maintain cure consistency. Dimensional checks via CMM (Coordinate Measuring Machine) verify tolerances within ±0.3 mm, while every 10th unit undergoes destructive testing for material property verification. Traceability is maintained through serialized lot coding, enabling full lifecycle accountability from raw material sourcing to end-user installation. This end-to-end control ensures step guards deliver predictable lifecycle performance exceeding 10 years in harsh industrial settings.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber components, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of engineered rubber solutions. Specializing in custom-molded rubber products for demanding environments, we deliver precision, durability, and consistency across a broad spectrum of industrial applications. One of our key product lines—step guards for stairs—exemplifies our commitment to safety, wear resistance, and long-term performance in high-traffic and heavy-load environments.

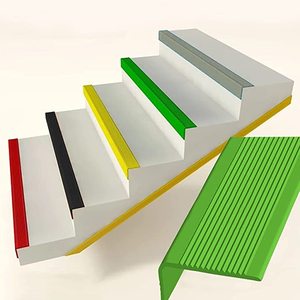

Our step guards for stairs are engineered using advanced rubber compounding techniques, tailored to meet the mechanical and environmental challenges of industrial facilities, commercial buildings, transportation hubs, and marine applications. These components are designed to absorb impact, reduce noise, prevent slip hazards, and extend the service life of stair structures under continuous use. Whether deployed in factory walkways, offshore platforms, or public infrastructure, our step guards provide reliable protection and operational safety.

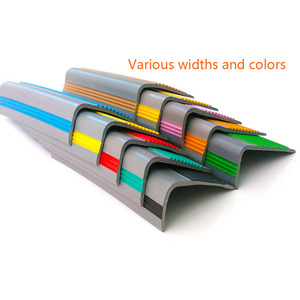

Each step guard is manufactured under strict quality control protocols, ensuring dimensional accuracy, adhesion strength, and resistance to abrasion, oil, ozone, and temperature extremes. Our in-house R&D team works closely with clients to customize formulations based on application-specific requirements, including Shore hardness, color, density, and flame retardancy. This collaborative approach enables seamless integration into existing systems while optimizing performance and lifecycle cost.

To support global clients, Suzhou Baoshida maintains a scalable production infrastructure with ISO-certified processes, rapid prototyping capabilities, and efficient logistics networks. We serve OEMs, construction firms, and industrial equipment manufacturers with consistent delivery and technical documentation, including material test reports, CAD drawings, and compliance certifications.

For technical inquiries, product customization, or sample requests, we invite you to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 15 years of experience in polymer science and industrial component design, Mr. Boyce leads the technical interface between client needs and product realization. He is available to discuss material selection, performance expectations, and integration strategies for your specific application.

Below are the standard technical specifications for our most commonly supplied rubber step guards:

| Property | Value | Test Method |

|---|---|---|

| Material | SBR/NR/EPDM (customizable) | ASTM D412 |

| Hardness (Shore A) | 50–75 ±5 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Abrasion Resistance | ≤120 mm³ loss | DIN 53516 |

| Operating Temperature | -30°C to +80°C | — |

| Flame Resistance | Optional (UL94 HB/V0) | UL 94 |

| Color | Black, gray, yellow (custom) | — |

Partnering with Suzhou Baoshida means gaining access to not just a supplier, but a technical collaborator focused on solving real-world engineering challenges. We ensure every component meets or exceeds industrial standards while aligning with your production timelines and performance goals.

Contact Mr. Boyce directly at [email protected] to initiate a technical discussion, request material samples, or receive a project quotation. Let us help you enhance safety, durability, and efficiency through precision rubber engineering.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).