Technical Contents

Engineering Guide: Stick On Rubber Bumpers

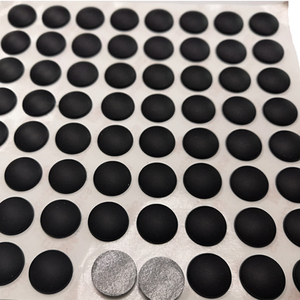

Engineering Insight: The Critical Role of Material Selection in Stick-On Rubber Bumpers

In industrial and commercial applications, stick-on rubber bumpers are more than simple protective pads—they serve as critical interface components that absorb impact, reduce noise, and prevent wear between mating surfaces. Despite their apparent simplicity, the performance and longevity of these components are profoundly influenced by material selection. Off-the-shelf rubber bumpers frequently fail because they are formulated for generalized use cases, lacking the tailored properties required for specific environmental, mechanical, and chemical conditions.

A primary reason for premature failure lies in the mismatch between the elastomer compound and the operational environment. For example, standard rubber bumpers made from unvulcanized or low-grade natural rubber may degrade rapidly when exposed to UV radiation, ozone, or temperature extremes. Similarly, applications involving frequent impact or sustained compression demand materials with high resilience and compression set resistance—properties not uniformly present across generic formulations.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered elastomer solutions based on application-specific parameters. Our approach begins with a thorough analysis of service conditions, including temperature range, exposure to oils or solvents, dynamic loading, and surface adhesion requirements. This enables precise selection from a range of high-performance materials such as EPDM, silicone, nitrile (NBR), and thermoplastic elastomers (TPE), each offering distinct advantages.

EPDM rubber, for instance, excels in outdoor environments due to its exceptional resistance to weathering and UV degradation. Silicone provides stable performance across extreme temperatures (-60°C to +200°C) and is ideal for medical or high-purity applications. Nitrile rubber offers superior resistance to oils and fuels, making it suitable for automotive and machinery applications. TPEs combine the elasticity of rubber with the processability of thermoplastics, allowing for precise molding and strong adhesive bonding.

Adhesion performance is another critical factor often overlooked in standard products. The backing adhesive must be compatible not only with the rubber compound but also with the substrate material—whether metal, plastic, or painted surface. Poor adhesive selection leads to delamination under thermal cycling or mechanical stress. We utilize pressure-sensitive acrylic or rubber-based adhesives with primers when necessary, ensuring long-term bond integrity.

The table below summarizes key material properties and their recommended applications:

| Material | Temperature Range (°C) | Key Properties | Typical Applications |

|---|---|---|---|

| EPDM | -50 to +130 | Excellent weather, ozone, and UV resistance | Outdoor enclosures, construction, HVAC |

| Silicone | -60 to +200 | High thermal stability, low compression set | Medical devices, food processing, electronics |

| Nitrile (NBR) | -40 to +100 | Oil, fuel, and solvent resistance | Automotive, machinery, hydraulic systems |

| TPE | -50 to +120 | Good elasticity, strong adhesive bonding | Consumer electronics, appliances, office equipment |

Generic stick-on bumpers often compromise on material quality and adhesive technology, leading to reduced service life and increased maintenance costs. In contrast, engineered rubber solutions from Suzhou Baoshida ensure reliability, durability, and optimal performance under real-world conditions. Material selection is not a detail—it is the foundation of effective rubber component design.

Material Specifications

Material Specifications for Industrial Stick-On Rubber Bumpers

Selecting the appropriate elastomer for stick-on rubber bumpers is critical for performance in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science to ensure optimal vibration damping, impact absorption, sealing integrity, and longevity. Our core formulations—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each address distinct operational challenges. Temperature extremes, chemical exposure, mechanical stress, and adhesion requirements dictate material selection. Incorrect specification risks premature failure, contamination, or safety hazards. Below we detail key properties and applications for each compound, validated per ASTM D2000 and ISO 37 standards.

Viton (FKM) excels in high-temperature and aggressive chemical environments. Its fluorocarbon structure provides exceptional resistance to oils, fuels, acids, and ozone up to 250°C continuous service. This makes it indispensable for aerospace, semiconductor manufacturing, and chemical processing equipment where NBR or silicone would degrade. Hardness ranges from 60 to 90 Shore A, with tensile strength exceeding 15 MPa. However, Viton’s higher cost necessitates justified application scenarios.

Nitrile (NBR) remains the industry standard for oil and fuel resistance in cost-sensitive applications. Operating effectively between -40°C and 125°C, it offers robust performance in automotive under-hood components, hydraulic systems, and machinery exposed to petroleum derivatives. With hardness typically 50–80 Shore A and superior abrasion resistance, NBR balances durability and economy. Limitations include poor ozone resistance and stiffening below -30°C, requiring careful environmental assessment.

Silicone (VMQ) delivers unmatched flexibility across extreme temperatures (-60°C to 230°C) and excellent electrical insulation. Its inert composition suits food processing, medical devices, and electronics where purity and thermal stability are paramount. Silicone maintains elasticity in cryogenic conditions and resists UV degradation but exhibits lower tensile strength (5–8 MPa) and poor resistance to concentrated acids or solvents compared to Viton.

Adhesion integrity for stick-on bumpers depends on substrate preparation per ISO 8501-1 and precise adhesive selection. All materials require clean, dry surfaces; silicone often needs primers for optimal bond strength. Peel resistance must exceed 4.5 N/cm (ASTM D3330) to prevent dislodgement under vibration.

Material Comparison for Stick-On Rubber Bumpers

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -40 to +125 | -60 to +230 |

| Key Chemical Resistance | Fuels, acids, ozone | Petroleum oils, water | Water, steam, mild chemicals |

| Typical Hardness (Shore A) | 60–90 | 50–80 | 30–80 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Adhesion Method | Solvent-based acrylic | Solvent-based acrylic | Silane-modified acrylic |

| Primary Applications | Chemical valves, jet engines | Automotive grommets, seals | Medical enclosures, food handling |

Material choice must align with fluid compatibility, thermal cycling, and mechanical loads. Consult our engineering team for chemical compatibility testing per ASTM D471 to prevent field failures. Suzhou Baoshida ensures rigorous QC through compression set analysis (ASTM D395) and accelerated aging protocols, guaranteeing bumper reliability in your operational ecosystem.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, enabling us to deliver high-performance stick-on rubber bumpers tailored to exacting OEM requirements. Our technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, working in tandem to ensure precision, durability, and consistency across all production batches. This integrated approach allows us to control every phase of development—from material formulation and mould design to prototyping and mass production.

Our formula engineers possess in-depth knowledge of elastomer chemistry and polymer compounding, enabling the development of custom rubber compounds optimized for specific performance criteria such as compression set resistance, abrasion resistance, temperature stability, and adhesion strength. Whether the application demands EPDM for UV resistance, NBR for oil resistance, or silicone for extreme temperature performance, our team formulates materials that meet functional and environmental demands. These proprietary formulations are rigorously tested in-house using standardized ASTM and ISO methodologies to ensure repeatability and long-term reliability.

Complementing our material expertise, our five mould engineers bring extensive experience in precision tooling for rubber injection and compression moulding. They utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to design and validate moulds before fabrication. Finite element analysis (FEA) is employed to simulate flow dynamics and cure behavior, minimizing defects and optimizing cycle times. All moulds are manufactured using high-grade tool steel and subjected to strict quality checks to ensure dimensional accuracy and extended service life.

We specialize in OEM manufacturing, providing end-to-end support from concept to delivery. Our clients benefit from rapid prototyping, design for manufacturability (DFM) reviews, and full documentation packages including material certifications, process validation reports, and first article inspections. With a focus on scalability, we support low-volume pilot runs as well as high-volume production, maintaining consistent quality through statistical process control (SPC) and automated inspection systems.

Our commitment to engineering excellence ensures that every stick-on rubber bumper we produce delivers precise fit, reliable adhesion, and long-term performance in demanding industrial environments.

Typical Physical and Performance Specifications of Custom Stick-On Rubber Bumpers

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40–80 |

| Tensile Strength | ASTM D412 | 6–15 MPa |

| Elongation at Break | ASTM D412 | 200–400% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +120°C (varies by compound) |

| Adhesion Strength (to steel) | ASTM D903 | ≥8 N/cm |

| Specific Gravity | ASTM D297 | 1.10–1.30 |

Customization Process

Customization Process for Industrial Stick-On Rubber Bumpers

Precision customization for stick-on rubber bumpers begins with rigorous Drawing Analysis. Our engineering team conducts a comprehensive review of client-provided CAD files or technical sketches, focusing on critical dimensions, geometric tolerances per ISO 2768-mK, and substrate interface requirements. We verify adhesive zone specifications, including surface area, contour compatibility, and environmental exposure factors such as UV, oil, or ozone resistance. Any dimensional conflicts or material limitations are flagged immediately, with collaborative feedback provided within 72 hours to ensure manufacturability aligns with functional intent. This phase prevents downstream errors, reducing time-to-market by up to 30%.

Material Formulation follows, leveraging Suzhou Baoshida’s proprietary compound database and OEM-specific performance criteria. Our rubber chemists select base polymers—typically EPDM, silicone, or nitrile rubber—based on required hardness, temperature range, and chemical resistance. Key parameters like Shore A hardness, tensile strength, and elongation at break are optimized through controlled crosslink density adjustments. Additives for UV stabilizers, plasticizers, or adhesion promoters are precisely dosed to meet operational demands. Below summarizes standard formulation capabilities:

| Property | Range/Value | Test Standard |

|---|---|---|

| Hardness (Shore A) | 30–90 | ASTM D2240 |

| Temperature Resistance | -50°C to +150°C (EPDM) | ISO 188 |

| Tensile Strength | 5–15 MPa | ASTM D412 |

| Elongation at Break | 150–600% | ASTM D412 |

| Adhesion Strength | ≥1.0 kN/m (peel, steel) | ASTM D3330 |

| Compression Set (22h) | ≤25% (70°C) | ASTM D395 |

Prototyping utilizes rapid tooling from validated designs, producing 10–50 units for client validation. Samples undergo accelerated aging, adhesion testing on specified substrates (e.g., painted metal, ABS plastic), and dynamic load simulations. We measure performance against client KPIs, including vibration damping efficiency and shear/peel strength retention after thermal cycling. Iterative refinements occur within 5–7 days per feedback loop, ensuring final geometry and material behavior match real-world application stresses.

Transition to Mass Production employs automated injection molding with in-line SPC monitoring. Each batch undergoes 100% visual inspection for surface defects and dimensional verification via CMM. Adhesive coating thickness is controlled to ±0.05mm tolerance, with peel strength tested per ASTM D3330 on every production lot. Full traceability—from raw material lot numbers to operator IDs—is maintained via our ERP system, enabling rapid root-cause analysis if deviations occur. Production scalability supports volumes from 10,000 to 2 million units monthly, with consistent adherence to ISO 9001 quality protocols and client-specific PPAP documentation. This end-to-end control guarantees bumpers deliver reliable impact absorption and substrate integrity throughout their service life.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Stick-On Rubber Bumpers

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to meet the rigorous demands of modern manufacturing, automotive, electronics, and consumer goods industries. Our stick-on rubber bumpers are engineered for durability, vibration dampening, surface protection, and noise reduction across a wide range of applications. Whether you’re securing components in electronic enclosures, protecting furniture edges, or isolating sensitive equipment from impact, our rubber bumpers offer precise adhesion, consistent performance, and long-term reliability.

We understand that every industrial application presents unique challenges—load requirements, environmental exposure, surface compatibility, and dimensional tolerances all play critical roles in material selection. That’s why our team, led by Mr. Boyce, provides personalized technical consultation to ensure you receive the optimal rubber bumper solution. From material formulation to adhesive backing selection, we support your engineering and procurement teams with data-driven recommendations and rapid prototyping capabilities.

Our manufacturing process integrates advanced compounding technologies with strict quality control protocols, ensuring each batch meets international standards for consistency and performance. We offer customization in hardness, size, color, durometer, and adhesive type—including acrylic, rubber-based, and silicone adhesives for low-energy surfaces. With in-house tooling and molding facilities, we deliver fast turnaround times without compromising precision.

For OEMs and contract manufacturers, partnering with Suzhou Baoshida means access to scalable production, reliable supply chain management, and full documentation including material certifications, RoHS compliance, and batch traceability. Our rubber bumpers are widely used in control panels, medical devices, industrial machinery, and home appliances, where silent operation and surface integrity are paramount.

Below are typical technical specifications for our standard stick-on rubber bumpers. Custom configurations are available upon request.

| Property | Specification |

|---|---|

| Material | Nitrile (NBR), Silicone, EPDM, or Neoprene |

| Hardness (Shore A) | 40° to 80° (customizable) |

| Temperature Range | -30°C to +120°C (varies by compound) |

| Adhesive Type | Pressure-sensitive acrylic or rubber-based |

| Bond Strength | ≥1.5 kN/m on clean metal surface |

| Color Options | Black, gray, transparent, white, or custom |

| Density | 1.15–1.35 g/cm³ |

| Compression Set (70°C, 22h) | ≤25% |

| Certifications | RoHS, REACH compliant |

To discuss your specific application requirements or request samples, contact Mr. Boyce directly at [email protected]. We respond to all technical inquiries within 24 business hours and provide detailed support including CAD drawings, material test reports, and application notes. Let Suzhou Baoshida be your trusted partner in engineered rubber solutions—where precision meets performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).