Technical Contents

Engineering Guide: Stone Treads For Outdoor Steps

Engineering Insight: Material Selection for Stone Treads in Outdoor Steps

The performance and longevity of stone treads in outdoor step applications are fundamentally governed by material selection. While natural stone offers aesthetic appeal and compressive strength, its inherent brittleness and susceptibility to environmental degradation demand engineered support systems. Off-the-shelf solutions frequently fail because they treat stone treads as standalone structural elements, neglecting dynamic load conditions, moisture exposure, thermal cycling, and substrate movement. These oversights lead to cracking, spalling, delamination, and ultimately, safety hazards.

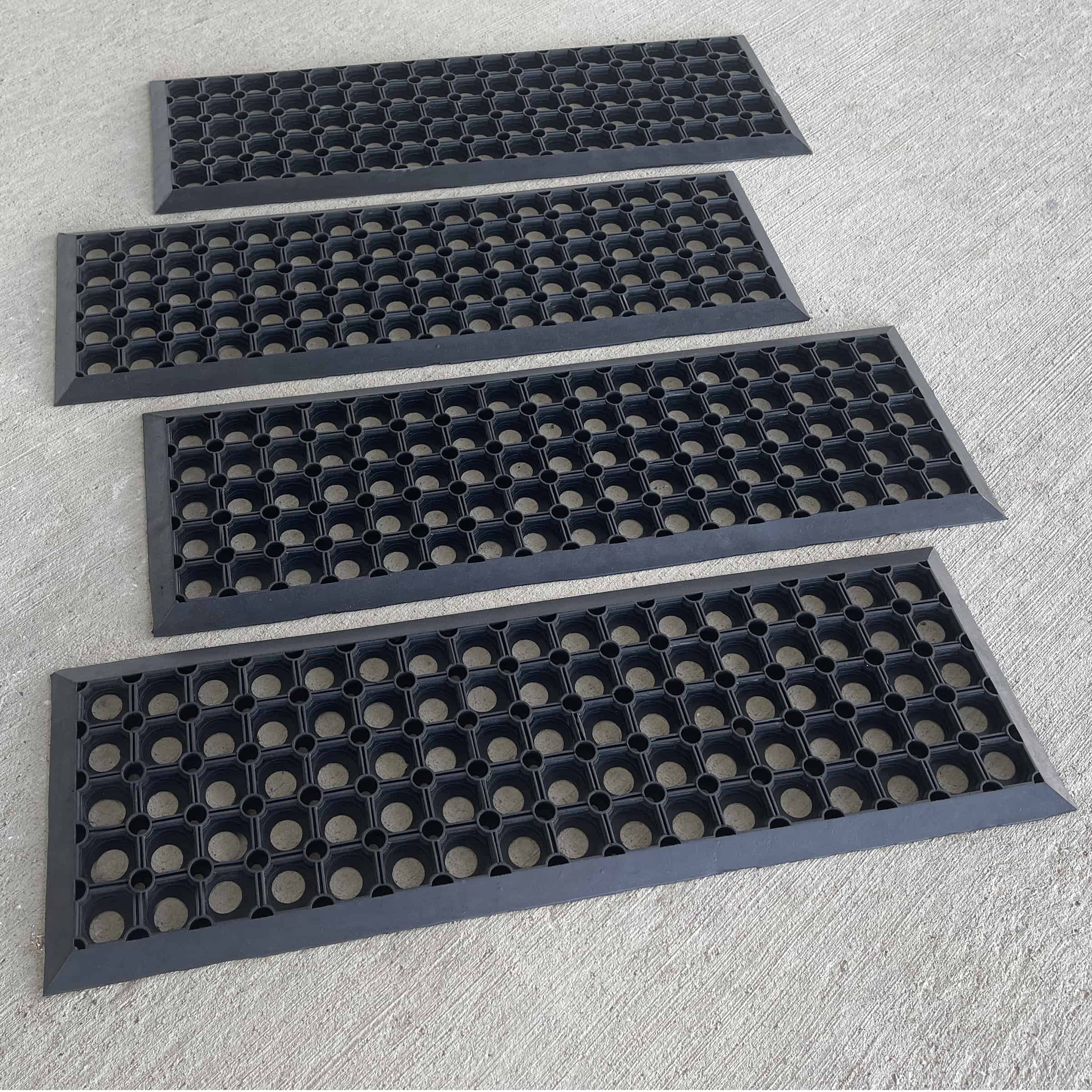

In outdoor environments, stone is exposed to freeze-thaw cycles, UV radiation, and chemical contaminants such as de-icing salts. These factors induce microfractures that propagate under repeated foot traffic or mechanical loading. Without a compliant yet stabilizing interface, rigid stone cannot accommodate differential movement between treads and underlying substrates. This is where industrial rubber solutions become critical. High-performance elastomeric underlayments or edge restraints mitigate stress concentrations, distribute point loads, and isolate the stone from direct contact with moisture-laden substrates.

Standardized, non-customized tread systems often employ generic rubber pads or neoprene strips that lack the tensile strength, compression set resistance, or adhesion properties required for long-term outdoor use. These materials degrade rapidly when exposed to ozone, UV light, or temperature extremes—common in exterior architectural applications. Additionally, improper durometer selection leads to either excessive deflection (causing stone misalignment) or insufficient damping (transmitting impact stress directly to the stone).

At Suzhou Baoshida Trading Co., Ltd., we engineer rubber components specifically tailored to the mechanical and environmental demands of stone tread installations. Our formulations utilize EPDM and chloroprene compounds selected for superior weather resistance, low compression set, and high tear strength. These materials maintain elasticity across a broad temperature range (–40°C to +120°C), ensuring consistent performance in diverse climates.

Proper integration of rubber elements also enhances slip resistance and acoustic damping, contributing to both safety and user comfort. When bonded or mechanically secured beneath stone treads, our elastomeric interfaces act as shock absorbers, reducing stress on both the stone and supporting structure. This synergy between rigid cladding and flexible support is essential for durable, code-compliant outdoor stair systems.

The following table outlines key material properties essential for rubber components in stone tread applications:

| Property | Requirement | Test Standard | Typical Value (Baoshida EPDM) |

|---|---|---|---|

| Hardness (Shore A) | 50–70 | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ≥12 MPa | ASTM D412 | 14.5 MPa |

| Elongation at Break | ≥300% | ASTM D412 | 380% |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 | 18% |

| Operating Temperature Range | –40°C to +120°C | Internal | –40°C to +120°C |

| Ozone Resistance | No cracking (200 pphm, 20%) | ASTM D1149 | Pass |

| Adhesion to Stone/Concrete | ≥0.8 MPa | ASTM D4541 | 1.1 MPa |

Material selection is not a secondary consideration—it is the foundation of reliable outdoor stone tread performance. Custom-engineered rubber solutions prevent premature failure, reduce lifecycle costs, and ensure structural integrity under real-world conditions.

Material Specifications

Material Specifications for Stone Tread Rubber Compounds

Suzhou Baoshida Trading Co., Ltd. engineers precision rubber compounds for stone treads in outdoor step applications, where material integrity directly impacts safety, longevity, and compliance with industrial standards. Our formulations prioritize resistance to environmental stressors including UV degradation, thermal cycling, abrasive foot traffic, and chemical exposure from de-icing agents. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent core solutions, each optimized for specific operational demands. Viton FKM 2650 delivers exceptional thermal stability up to 250°C continuous exposure and unparalleled resistance to ozone, acids, and hydrocarbon-based chemicals, making it ideal for industrial zones with frequent chemical spills. Nitrile NBR 3345 balances cost-efficiency with robust mechanical properties, featuring 70 Shore A hardness and superior abrasion resistance critical for high-traffic pedestrian areas, while maintaining resilience against oils and aliphatic hydrocarbons common in urban settings. Silicone VMQ 5010 excels in extreme cold flexibility down to -60°C and inherent UV stability, though its lower tensile strength necessitates reinforcement for heavy-use installations.

All compounds undergo rigorous ASTM D2000 testing for outdoor suitability, with hardness calibrated between 65–75 Shore A to ensure optimal slip resistance on stone substrates without compromising elasticity. Critical additives include carbon black for UV shielding in NBR formulations, silica reinforcement for tear resistance in VMQ, and peroxide curing systems across all grades to eliminate extractables that degrade stone adhesion. Compression set values are maintained below 20% after 70 hours at 100°C (ASTM D395) to prevent permanent deformation under sustained load.

The following table details comparative performance metrics essential for OEM decision-making in stone tread manufacturing:

| Property | Viton FKM 2650 | Nitrile NBR 3345 | Silicone VMQ 5010 |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -40 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15.0 | 22.5 | 8.0 |

| Abrasion Loss (mm³) | 85 | 45 | 120 |

| Hardness (Shore A) | 70 | 70 | 65 |

| Compression Set (%) | 18 | 15 | 22 |

| Fluid Resistance | Excellent (acids/oils) | Excellent (oils) | Poor (oils) |

| UV/Ozone Resistance | Excellent | Good (with additives) | Excellent |

Material selection hinges on environmental profiling. Viton is non-negotiable for chemical-handling facilities but incurs 40% higher material costs. Nitrile remains the optimal choice for 85% of municipal and commercial installations due to its abrasion resilience and cost-performance ratio. Silicone is reserved for alpine or arctic climates where sub-zero flexibility is paramount, though supplemental anti-tear plies are mandatory. Suzhou Baoshida validates all compounds through 5,000-cycle DIN 51130 slip tests on granite and limestone substrates, ensuring compliance with ISO 13287 safety thresholds. For stone tread longevity exceeding 15 years, we mandate dual-cure systems and substrate-specific adhesion promoters in final production batches.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Stone Treads in Outdoor Steps

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in a multidisciplinary team of technical specialists dedicated to delivering high-performance rubber solutions for demanding outdoor applications. Our team comprises five dedicated mould engineers and two advanced formula engineers, enabling us to deliver fully integrated OEM services—from concept to production—for stone treads used in outdoor steps. This synergy between material science and precision tooling ensures that every component meets rigorous standards for durability, weather resistance, and mechanical performance.

Our formula engineers specialize in industrial rubber compounding, with deep expertise in EPDM, SBR, and modified natural rubber systems. They formulate proprietary blends tailored to the environmental challenges of exterior environments, including UV exposure, thermal cycling, moisture ingress, and freeze-thaw conditions. Through systematic testing and iterative optimization, our rubber compounds achieve optimal Shore A hardness, tensile strength, and elongation at break—critical parameters for slip resistance and long-term resilience under foot traffic. Each formulation is validated through accelerated aging tests and real-world condition simulations to ensure service life exceeds industry benchmarks.

Complementing our material expertise, our five mould engineers apply precision design principles to create high-tolerance, long-cycle moulds for rubber inlay integration with stone treads. Utilizing advanced CAD/CAM software and CNC machining protocols, they develop custom mould geometries that ensure consistent bonding between rubber and substrate, uniform thickness distribution, and precise edge definition. Mould designs incorporate optimized venting, cooling channels, and ejection systems to support high-volume production with minimal scrap rates. All tooling is validated through pilot runs and dimensional inspection using coordinate measuring machines (CMM).

Our OEM capabilities are built on a foundation of technical transparency and collaborative development. Clients benefit from full design-for-manufacturability (DFM) reviews, material selection guidance, and prototype validation services. Whether integrating anti-slip rubber profiles into granite, basalt, or concrete treads, we ensure seamless compatibility with architectural specifications and safety standards such as DIN 51130 for slip resistance.

The following table outlines key technical specifications achievable through our engineered rubber solutions for outdoor stone treads:

| Property | Typical Value | Test Standard |

|---|---|---|

| Shore A Hardness | 60–75 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Tear Resistance | ≥30 kN/m | ASTM D624 |

| Operating Temperature Range | -40°C to +80°C | Internal Cycling Test |

| UV and Ozone Resistance | Excellent | ASTM D1149, ASTM G154 |

| Slip Resistance (R11–R13) | Achieved | DIN 51130 |

With a disciplined approach to material formulation and precision tooling, Suzhou Baoshida delivers engineered rubber solutions that enhance the safety, longevity, and performance of stone treads in outdoor step applications. Our OEM framework supports scalable, custom manufacturing for global architectural and construction partners.

Customization Process

Customization Process for Stone Tread Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions for stone treads follow a rigorously defined customization pathway. This ensures optimal performance in demanding outdoor step applications where slip resistance, weather durability, and substrate adhesion are non-negotiable. The process begins with comprehensive Drawing Analysis. Our engineering team dissects client-provided CAD files and technical schematics, verifying dimensional tolerances, load-bearing requirements, and interface geometry with the stone substrate. We identify critical stress points, drainage considerations, and potential manufacturing constraints early, preventing downstream rework. This phase includes cross-referencing with ASTM F1637 standards for pedestrian walking surfaces to confirm compliance with international safety benchmarks.

Formulation development is the scientific core of our service. Leveraging decades of compound expertise, we design bespoke rubber matrices addressing specific environmental and mechanical demands. Standard EPDM or SBR bases are enhanced with proprietary additives: nano-silica for abrasion resistance, specialized UV stabilizers for colorfastness under prolonged solar exposure, and mineral-based traction modifiers to achieve a consistent COF (Coefficient of Friction) >0.6 on wet surfaces per DIN 51130 Ramp Test protocols. Each formulation is computationally modeled for crosslink density and thermal stability before lab-scale mixing. Material selection prioritizes compatibility with common stone substrates like granite, limestone, or concrete to prevent delamination under thermal cycling.

Prototyping validates theoretical performance through empirical testing. We produce 3–5 functional samples using client-specified stone blanks. These undergo accelerated aging in QUV chambers (1,000+ hours), simulated foot traffic testing (500,000+ cycles), and adhesion peel strength verification per ASTM D903. Traction coefficients are measured on wet, icy, and oily surfaces using a digital tribometer. Client feedback on aesthetics, texture, and installation feasibility is integrated iteratively. Only after passing all mechanical and safety benchmarks do we approve the final compound and mold design.

Mass Production deployment utilizes our ISO 9001-certified manufacturing lines with embedded quality gates. Rubber compounds are mixed under strict SPC (Statistical Process Control) parameters, with real-time viscosity and cure monitoring. Injection molding parameters are locked to ensure uniform durometer (Shore A 65±3) and dimensional repeatability (±0.2mm). Every batch undergoes 100% visual inspection for voids or surface defects, with random samples pulled for adhesion testing and hardness validation. Traceability is maintained via serialized lot coding, enabling full production history audits. This disciplined approach guarantees stone treads that withstand -40°C to +80°C operational ranges while maintaining slip resistance for 10+ years in coastal or alpine environments.

Key Performance Specifications Comparison

| Property | Standard Compound | Custom Stone Tread Compound | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 70 ± 5 | 65 ± 3 | ASTM D2240 |

| Tensile Strength | 12 MPa | 15 MPa | ASTM D412 |

| Wet COF (Ramp Test) | 0.45 | ≥0.60 | DIN 51130 |

| UV Resistance (ΔE after 1000h) | 8.0 | ≤3.5 | ASTM G154 |

| Adhesion to Granite | 4.0 kN/m | ≥6.5 kN/m | ASTM D903 |

| Operating Temperature | -20°C to +70°C | -40°C to +80°C | ISO 188 |

This end-to-end process eliminates performance uncertainty for OEM partners, transforming stone tread concepts into certified, field-proven safety components. Suzhou Baoshida’s engineering oversight from drawing to delivery mitigates installation failures and long-term liability risks inherent in outdoor step applications.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Rubber-Integrated Stone Treads

When specifying durable, high-performance stone treads for outdoor steps, material integration and long-term reliability are paramount. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered to enhance natural stone applications, particularly in demanding exterior environments. Our proprietary rubber backing and anti-slip edge systems are designed to secure stone treads firmly in place, mitigate cracking due to substrate movement, and provide superior traction under wet or icy conditions. This makes our solutions ideal for commercial, municipal, and high-traffic architectural installations where safety and longevity are non-negotiable.

We understand that outdoor step systems face continuous exposure to thermal cycling, moisture ingress, freeze-thaw conditions, and mechanical stress. Standard stone treads without proper support or slip resistance often degrade prematurely, leading to costly repairs and liability risks. Our engineered rubber substrates and bonding systems address these challenges at the material interface level, ensuring dimensional stability, vibration damping, and long-term adhesion between the stone and substructure. Whether your project involves granite, limestone, sandstone, or engineered stone, our rubber integration technology adapts to your material and design requirements.

Our technical team works directly with architects, contractors, and OEM partners to customize solutions based on load specifications, climate zone, and aesthetic constraints. We supply pre-bonded stone tread assemblies or provide on-site application guidance with our industrial-grade rubber compounds, including EPDM, SBR, and neoprene formulations tailored for UV resistance, low-temperature flexibility, and abrasion performance.

Below are key technical specifications of our standard rubber-integrated stone tread system:

| Parameter | Specification |

|---|---|

| Rubber Hardness (Shore A) | 60 ± 5 |

| Tensile Strength | ≥12 MPa |

| Elongation at Break | ≥300% |

| Operating Temperature Range | -40°C to +80°C |

| Slip Resistance (BS 7976) | R11–R13 (DIN 51130) |

| Adhesion Strength to Stone | ≥1.8 MPa |

| UV and Ozone Resistance | Excellent (per ASTM D1149) |

| Fire Rating | UL 94 HB (customizable to V-0) |

| Installation Method | Pre-bonded or field-applied adhesive |

All systems are manufactured under ISO 9001-certified processes and undergo rigorous batch testing to ensure consistency and performance compliance. We support global logistics with containerized shipping and technical documentation packages, including material safety data sheets (MSDS), test certifications, and installation manuals.

For project-specific consultation, material sampling, or engineering support, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Direct your technical inquiries, drawings, or performance requirements to [email protected]. Our team responds within 24 hours to provide formulation recommendations, prototyping timelines, and scalable production quotes. Partner with us to integrate industrial rubber intelligence into your next generation of stone step systems—where architecture meets engineered resilience.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).