Technical Contents

Engineering Guide: Sturdy Hose Reel

Engineering Insight: Material Selection as the Foundation of Hose Reel Durability

Industrial hose reels face relentless operational demands: cyclic mechanical stress, exposure to aggressive fluids, extreme temperatures, and constant environmental assault. Off-the-shelf solutions frequently succumb prematurely because their material selection prioritizes initial cost reduction over long-term engineering integrity. Standard PVC or generic rubber compounds lack the tailored molecular architecture required to withstand the synergistic degradation mechanisms inherent in demanding applications. Failure is not a matter of if, but when, manifesting as catastrophic cracking, permanent deformation, chemical swelling, or loss of critical sealing force. This necessitates unplanned downtime, replacement costs far exceeding the initial reel price, and potential safety hazards from fluid leaks or component ejection. The core deficiency lies in the absence of purpose-built polymer chemistry addressing the specific operational profile.

Suzhou Baoshida Trading Co., Ltd. engineers hose reels using advanced synthetic rubber formulations, primarily NBR (Nitrile Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer) blends, meticulously optimized for industrial resilience. Unlike generic materials, our compounds undergo rigorous compounding to enhance critical properties. High acrylonitrile content in NBR provides exceptional resistance to petroleum-based hydraulic fluids, greases, and solvents, preventing the swelling and softening that rapidly degrades PVC. EPDM offers superior ozone and UV resistance, crucial for outdoor reels, alongside outstanding thermal stability across a wide range (-50°C to +150°C). Reinforcing fillers and specialized curatives significantly improve tensile strength, tear resistance, and compression set performance, ensuring the reel maintains dimensional stability and sealing integrity under constant pressure and repeated flexing. Crucially, our formulations target low compression set, meaning the material reliably recovers its shape after deformation, preventing permanent seal failure – a common flaw in inferior elastomers.

The performance gap between engineered compounds and standard materials is quantifiable. Consider the critical properties under typical industrial stress:

| Material Property | Standard PVC Reel | Baoshida NBR/EPDM Blend | Performance Impact |

|---|---|---|---|

| Shore A Hardness (Post-Age) | 70 → 95 | 75 → 82 | Resists hardening/brittleness in UV/heat |

| Tensile Strength (MPa) | 12 | 28 | Withstands higher mechanical loads |

| Elongation at Break (%) | 250 | 450 | Greater flexibility without fracture |

| Compression Set (B, 70°C) | 45% | 18% | Maintains seal integrity long-term |

| Fluid Resistance (Hydraulic Oil) | Severe Swelling | Minimal Change | Prevents seal failure & dimensional loss |

This data underscores why off-the-shelf reels falter. Generic materials experience rapid property deterioration under operational stress, leading to predictable failures. Baoshida’s approach integrates deep polymer science with application-specific engineering. We formulate compounds not merely to meet baseline specs, but to exceed the dynamic demands of real-world industrial environments, ensuring operational continuity and maximizing the total cost of ownership. Material selection is the non-negotiable cornerstone of true hose reel durability; it defines the operational lifespan and reliability ceiling. Precision-engineered elastomers are not an optional upgrade – they are the fundamental requirement for reels that perform consistently under pressure.

Material Specifications

Material selection is a critical determinant in the engineering of high-performance hose reels designed for industrial applications. At Suzhou Baoshida Trading Co., Ltd., our expertise in industrial rubber solutions ensures that each hose reel is constructed with materials that meet stringent operational demands. The three primary elastomers employed in our sturdy hose reel systems are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers a distinct balance of chemical resistance, temperature tolerance, mechanical strength, and longevity, tailored to specific service environments.

Viton, a fluorocarbon-based rubber, is renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service temperature range extending up to 200°C and short-term exposure capability beyond 250°C, Viton is ideal for applications in petrochemical, aerospace, and high-temperature industrial processing environments. Its low gas permeability and outstanding aging characteristics further enhance reliability in critical sealing and fluid transfer systems. However, due to its higher formulation cost, Viton is typically reserved for applications where performance under extreme conditions is non-negotiable.

Nitrile rubber, or Buna-N, remains one of the most widely used elastomers in industrial hose applications due to its excellent resistance to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. It offers good abrasion resistance and mechanical durability, making it well-suited for general-purpose and heavy-duty pneumatic or hydraulic systems. Nitrile performs reliably within a temperature range of -30°C to 100°C, with some formulations extending to 125°C for limited durations. While it exhibits poor resistance to ozone and UV exposure, proper housing integration in hose reel assemblies mitigates these limitations effectively.

Silicone rubber provides superior flexibility and thermal stability across extreme low- and high-temperature extremes, operating effectively from -60°C to 200°C. It is highly resistant to ozone, UV radiation, and weathering, making it suitable for outdoor or sterilizable applications. Although silicone demonstrates lower tensile strength and abrasion resistance compared to Viton or Nitrile, its biocompatibility and low toxicity make it a preferred choice in food processing, pharmaceutical, and medical-grade fluid handling systems.

The following table summarizes key performance characteristics of these materials to assist in informed selection for hose reel applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250°C short-term) | -30 to 100 (up to 125°C intermittent) | -60 to 200 |

| Fluid Resistance | Excellent (oils, fuels, acids, aromatics) | Excellent (petroleum oils, hydraulic fluids) | Fair (poor with oils, fuels) |

| Chemical Resistance | Outstanding | Moderate | Good (ozone, oxygen) |

| Abrasion Resistance | Good | Excellent | Fair |

| UV/Ozone Resistance | Excellent | Poor | Excellent |

| Tensile Strength | High | High | Moderate |

| Typical Applications | Petrochemical, aerospace, high-temp seals | Industrial hydraulics, pneumatic systems | Food, medical, outdoor use |

Selecting the appropriate elastomer ensures optimal service life, safety, and operational efficiency in hose reel deployment. Suzhou Baoshida Trading Co., Ltd. provides customized material integration based on client-specific environmental and mechanical requirements.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Industrial Hose Reels

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated engineering team of seven specialists—five Mould Engineers and two Rubber Formula Engineers—to deliver unmatched technical rigor in industrial hose reel manufacturing. Our integrated approach ensures every component, from structural housings to critical sealing elements, meets exacting performance demands under extreme operational conditions. This synergy between material science and precision tooling enables us to solve complex challenges in pressure resilience, chemical resistance, and mechanical fatigue, directly translating client specifications into field-proven products.

Material science forms the cornerstone of our engineering excellence. Our Rubber Formula Engineers optimize proprietary elastomer compounds using advanced NBR (Nitrile Butadiene Rubber) and HNBR (Hydrogenated Nitrile) blends, tailored for hydraulic, pneumatic, and chemical transfer applications. Through iterative lab testing and finite element analysis (FEA), we fine-tune polymer cross-linking density, filler dispersion, and additive packages to achieve optimal Shore A hardness, compression set resistance, and thermal stability. This precision eliminates common failure modes like extrusion, swelling, or ozone cracking in demanding environments, ensuring consistent hose reel functionality across 10,000+ operational cycles.

Our OEM capabilities extend beyond standard manufacturing to full co-engineering partnerships. Clients collaborate directly with our technical team during the design phase to validate material selections, optimize part geometry for injection molding efficiency, and conduct accelerated life testing against application-specific stressors. We support rapid prototyping via 3D-printed tooling inserts and in-house compound mixing, reducing time-to-market by 30% while adhering to ISO 9001 and ASTM D2000 standards. All production leverages automated molding cells with real-time cavity pressure monitoring, guaranteeing dimensional repeatability within ±0.05mm tolerances.

Critical material specifications for our standard industrial hose reel compounds are validated per international test protocols:

| Property | Value | Test Standard |

|---|---|---|

| Shore A Hardness | 70 ± 5 | ASTM D2240 |

| Tensile Strength | ≥15 MPa | ASTM D412 |

| Elongation at Break | ≥400% | ASTM D412 |

| Compression Set (70h/100°C) | ≤25% | ASTM D395 |

| Temperature Range | -40°C to +120°C | ISO 188 |

| Pressure Rating | 25 bar (static) | ISO 1402 |

| Fluid Resistance (ISO 1817) | Excellent (Hydraulic Oils) | ISO 1817 |

This technical foundation empowers clients to specify hose reels with confidence in longevity and safety. By embedding material intelligence into every design iteration and maintaining strict process control from compound formulation to final assembly, Suzhou Baoshida delivers engineered rubber solutions that minimize downtime and extend service life in heavy-duty industrial settings. Our engineering team stands ready to develop custom formulations and tooling strategies that align precisely with your operational requirements and quality benchmarks.

Customization Process

Drawing Analysis

The customization process for a sturdy hose reel begins with a comprehensive drawing analysis, where engineering schematics and technical blueprints provided by the client are rigorously evaluated. At Suzhou Baoshida Trading Co., Ltd., our technical team conducts dimensional verification, material compatibility checks, and stress-point assessment to ensure the design aligns with industrial performance standards. This phase includes evaluating bending radii, coupling interfaces, wall thickness distribution, and expected operational pressures. We also assess environmental exposure factors such as UV resistance, temperature range, and chemical contact to preempt degradation risks. Any discrepancies or optimization opportunities are communicated through formal engineering feedback, ensuring alignment before advancing to material development.

Formulation

Once the design is validated, our Rubber Formula Engineers initiate the compound formulation stage. This is a precision-driven process where elastomer selection—such as NBR, EPDM, or silicone—is determined based on the operational requirements identified during drawing analysis. Additives including reinforcing fillers, antioxidants, plasticizers, and vulcanizing agents are calibrated to achieve target properties: tensile strength, elongation at break, compression set, and abrasion resistance. Each formulation is documented under controlled batch records and subjected to preliminary lab testing for rheological behavior and cure kinetics. For applications demanding extreme durability—such as in mining, construction, or hydraulic systems—custom blends are engineered to exceed OEM specifications. The formulated rubber compound is then cleared for prototyping under controlled environmental simulation conditions.

Prototyping

Prototyping serves as the physical validation of both design integrity and material performance. Using precision molding techniques—compression, transfer, or injection—initial hose reel samples are produced in a controlled pilot run. These prototypes undergo a battery of performance tests, including pressure cycling, torsion fatigue, ozone exposure, and leak integrity checks. Dimensional accuracy is verified using coordinate measuring machines (CMM), ensuring compliance with the original technical drawings. Clients are provided with test reports, material certificates, and physical samples for field evaluation. Feedback from this stage is incorporated into final adjustments, ensuring the product meets or exceeds functional expectations prior to scale-up.

Mass Production

Following prototype approval, the project transitions into mass production. Our manufacturing facilities operate under ISO 9001-certified quality management systems, ensuring consistency across batches. Automated mixing lines, CNC-controlled molding presses, and inline inspection systems guarantee repeatability and reduce process variability. Every hose reel is subjected to 100% visual inspection and抽 spot performance testing. Final packaging is customized per client logistics requirements, with traceability maintained via batch coding and digital records.

Typical Physical Properties of Custom Rubber Hose Reels

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–85 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +120°C |

| Fluid Resistance (oil, water) | ASTM D471 | Excellent |

This end-to-end customization framework ensures that each sturdy hose reel delivers optimal performance in demanding industrial environments.

Contact Engineering Team

Contact Suzhou Baoshida for Engineered Hose Reel Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing excellence. As your dedicated Rubber Formula Engineer and OEM Manager, we engineer hose reels not merely as components but as critical system elements designed for longevity under extreme operational stress. Our formulations leverage proprietary blends of EPDM, NBR, and HNBR elastomers, rigorously tested to exceed ISO 15540 and SAE J30 specifications. This ensures consistent performance across temperature ranges from -40°C to +150°C, with resistance to hydraulic fluids, ozone degradation, and abrasion-induced failure. We prioritize material integrity at the molecular level, optimizing cross-link density and filler dispersion to achieve tensile strengths exceeding 25 MPa while maintaining flexibility. This scientific approach directly translates to hose reels that minimize downtime, reduce total cost of ownership, and comply with stringent global safety standards.

The following table details core technical specifications for our standard industrial hose reel series, reflecting our commitment to precision engineering and repeatability:

| Parameter | Specification | Test Standard |

|---|---|---|

| Maximum Working Pressure | 300 bar (4350 psi) | ISO 1436 |

| Burst Pressure | ≥ 900 bar (13,050 psi) | ISO 1402 |

| Hose Material | Custom EPDM/NBR Composite | ASTM D2000 |

| Reel Core Material | Anodized Aluminum 6061-T6 | ASTM B221 |

| Temperature Range | -40°C to +150°C | ISO 188 |

| Leakage Rate | < 0.02 ml/min at 300 bar | ISO 15540 Class A |

| Cycle Life | > 50,000 cycles (full extension/retraction) | Internal Protocol |

Our engineering process integrates finite element analysis (FEA) for stress distribution modeling and accelerated life testing under simulated field conditions. Every reel undergoes 100% validation for rotational torque consistency, hose kink resistance, and seal integrity before shipment. As an OEM partner, we offer full customization of polymer compounds, reel geometry, and mounting configurations to align with your specific fluid handling requirements and integration constraints. Our Suzhou-based facility maintains ISO 9001:2015 certification with real-time SPC monitoring across all production lines, ensuring batch-to-batch uniformity critical for high-volume industrial applications.

For technical collaboration on hose reel integration, material specification validation, or bespoke OEM development, direct engagement with our engineering leadership is essential. Mr. Boyce, our dedicated Technical Account Manager, possesses 12 years of expertise in industrial rubber compounding and fluid system design. He will provide immediate access to material datasheets, FEA reports, and prototyping timelines tailored to your operational parameters. Contact Mr. Boyce directly at [email protected] to initiate a technical consultation. Include your application’s pressure profile, fluid media composition, and environmental exposure conditions to receive a comprehensive engineering proposal within 48 hours. Suzhou Baoshida delivers not just components, but scientifically validated solutions engineered for operational resilience. Initiate your project with precision-focused partnership today.

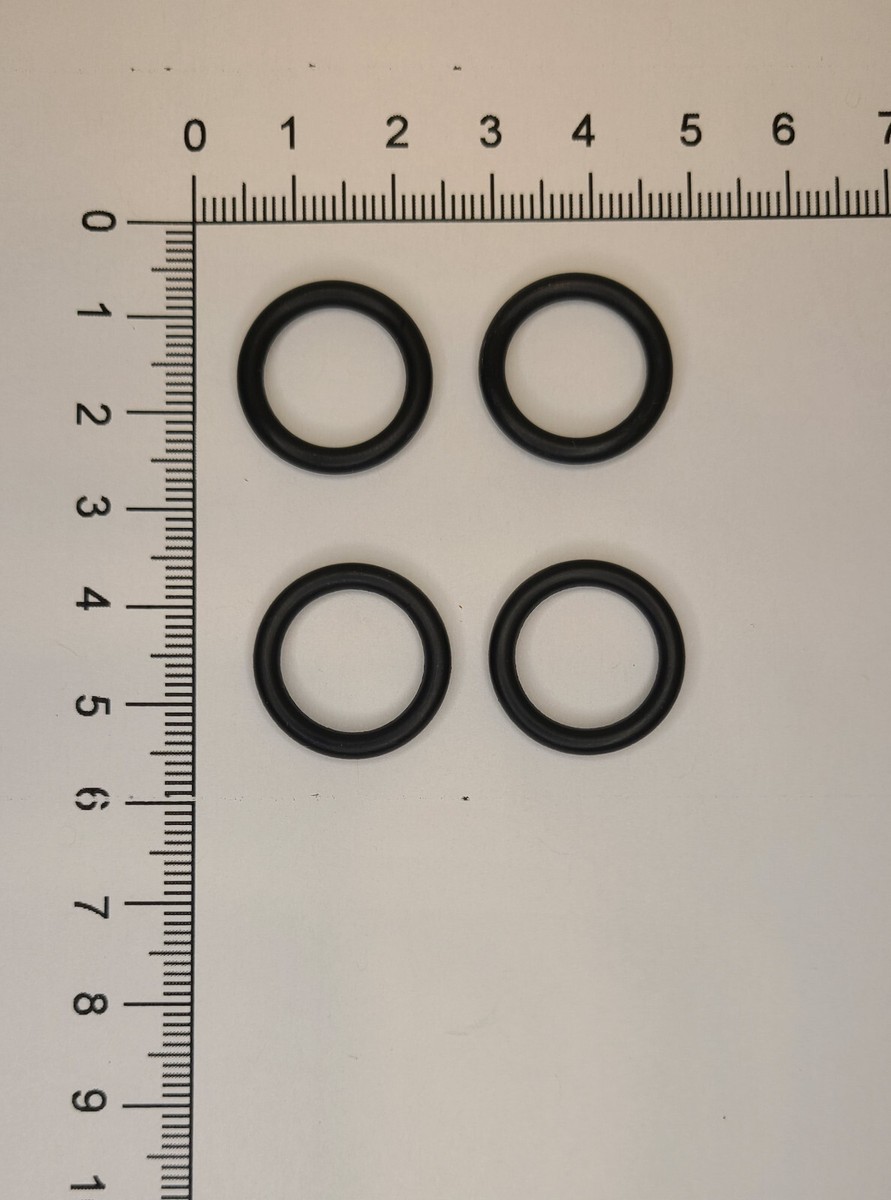

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).