Technical Contents

Engineering Guide: Sunjoe 3000Xt O-Rings

Engineering Insight: Material Selection for sunjoe 3000xt O-Rings

The performance and longevity of O-rings in high-pressure mechanical systems such as the sunjoe 3000xt pressure washer hinge critically on precise material selection. While off-the-shelf elastomeric seals may appear functionally equivalent, they frequently fail under real-world operating conditions due to inadequate resistance to environmental stressors, dynamic loads, and chemical exposure. This mismatch arises from a fundamental misunderstanding: not all rubber compounds behave identically under identical conditions. The sunjoe 3000xt operates in environments characterized by thermal cycling, exposure to detergents and solvents, and sustained mechanical compression, demanding a tailored elastomer formulation rather than generic solutions.

Standard NBR (nitrile butadiene rubber) O-rings, commonly used in general sealing applications, often degrade prematurely in the sunjoe 3000xt due to limited resistance to oxidizing agents and elevated temperatures. These compounds exhibit acceptable tensile strength and compression set resistance at room temperature but undergo accelerated chain scission when exposed to hot water and alkaline cleaning solutions. As a result, seal integrity diminishes, leading to leaks, pressure loss, and potential equipment downtime. Additionally, low-grade NBR formulations may contain inconsistent filler dispersion or insufficient crosslink density, further compromising performance.

In contrast, high-performance hydrogenated nitrile (HNBR) or fluorocarbon (FKM) elastomers offer superior stability under the operational profile of the sunjoe 3000xt. HNBR provides enhanced thermal resistance (up to 150°C), improved tensile properties, and greater resistance to ozone and UV degradation—key factors in outdoor equipment applications. FKM compounds, while more expensive, deliver exceptional chemical inertness, making them ideal for systems exposed to aggressive surfactants or chlorinated water sources. The crosslinking architecture in these advanced elastomers also contributes to lower compression set, ensuring long-term sealing force retention.

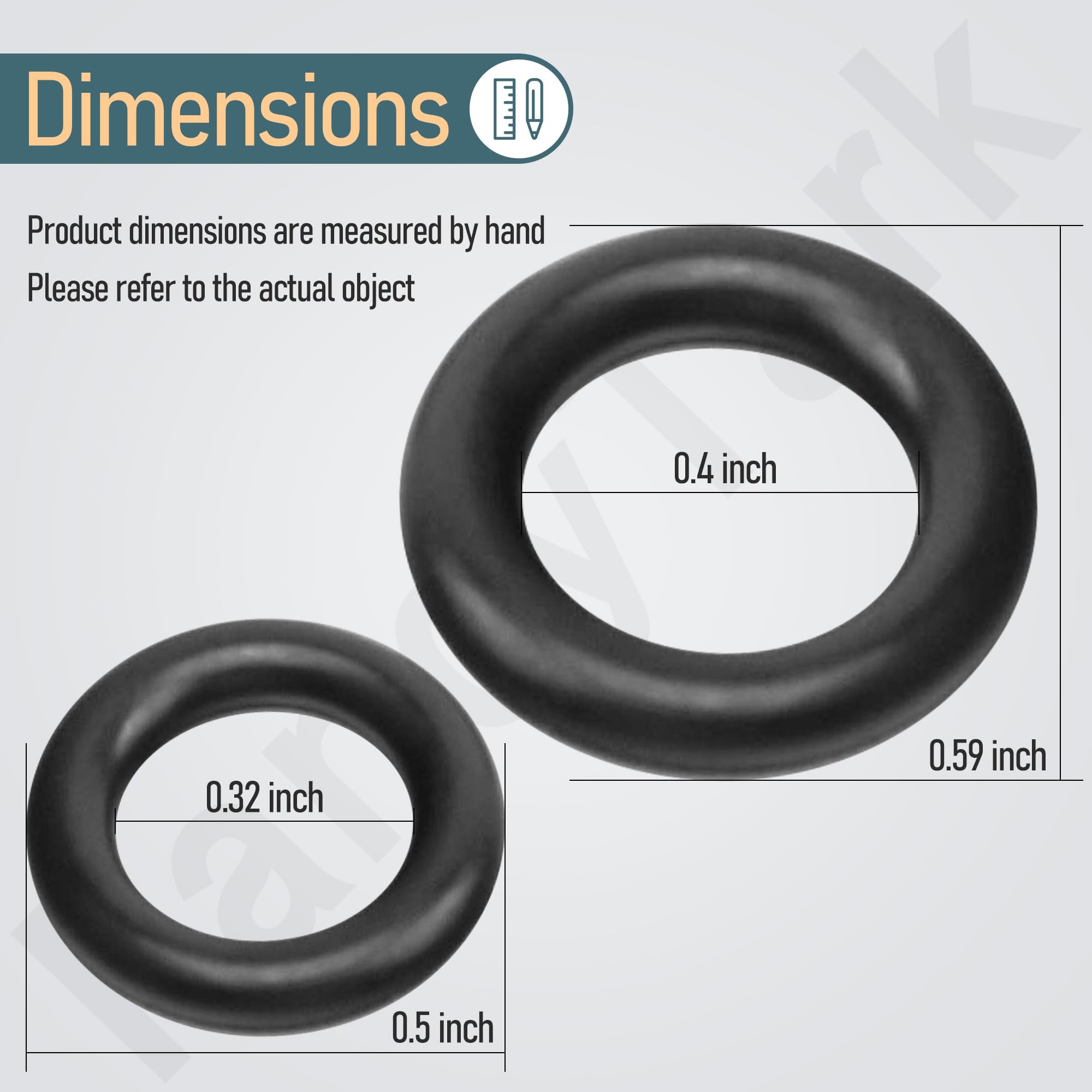

Another critical factor is the precision of durometer and dimensional tolerances. Off-the-shelf O-rings are often produced to commercial-grade tolerances (±0.010″), which can result in inconsistent gland fill and extrusion under pressure. In high-cycle applications like the sunjoe 3000xt, even minor deviations lead to premature wear. Suzhou Baoshida Trading Co., Ltd. employs ISO 3601-1 tolerances (±0.004″) and controls durometer within ±3 Shore A units, ensuring repeatable performance across batches.

The following table outlines key material properties relevant to sunjoe 3000xt O-ring performance:

| Property | Standard NBR | HNBR | FKM |

|---|---|---|---|

| Temperature Range (°C) | -30 to +100 | -40 to +150 | -20 to +200 |

| Tensile Strength (MPa) | 15–20 | 25–30 | 12–18 |

| Compression Set (22 hrs, 100°C) | 25–35% | 15–20% | 10–15% |

| Resistance to Alkaline Cleaners | Moderate | High | Excellent |

| Cost Level | Low | Medium | High |

Material selection is not a cost-driven compromise but an engineering decision directly tied to system reliability. At Suzhou Baoshida, we prioritize application-specific elastomer design, ensuring that every O-ring meets the dynamic and chemical demands of the sunjoe 3000xt—far beyond the capability of generic alternatives.

Material Specifications

Material Specifications for sunjoe 3000xt O-Rings

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber sealing solutions meeting stringent OEM requirements for the sunjoe 3000xt platform. Material selection directly impacts sealing integrity, service life, and operational safety under dynamic pressure and environmental stress. Our formulations adhere to ASTM D2000 and ISO 3601 standards, ensuring dimensional stability and chemical resistance. Three primary elastomers are validated for this application: Viton® (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers distinct performance characteristics tailored to specific fluid exposure, temperature extremes, and mechanical demands.

Viton® fluorocarbon rubber is specified for sunjoe 3000xt systems exposed to aggressive chemicals, high-temperature fuels, or synthetic lubricants. With continuous service capability from -20°C to +230°C and intermittent resistance up to 300°C, FKM maintains resilience in aerospace hydraulic fluids, biodiesel, and ozone-rich environments. Its low gas permeability and exceptional resistance to swelling in aromatic hydrocarbons make it ideal for critical fuel delivery subsystems. However, Viton® exhibits higher compression set above 200°C and increased cost versus hydrocarbon rubbers.

Nitrile butadiene rubber (NBR) remains the optimal balance of performance and economy for standard hydraulic and pneumatic circuits. Operating effectively between -40°C and +120°C (extended to +150°C for peroxide-cured grades), NBR delivers superior resistance to petroleum-based oils, water-glycol fluids, and aliphatic hydrocarbons. Its high tensile strength and abrasion resistance ensure durability in high-cycle applications. Limitations include poor performance in phosphate ester brake fluids, ketones, and ozone exposure above 70 ppm.

Silicone rubber (VMQ) is deployed where extreme low-temperature flexibility or high-purity requirements dominate. Functioning from -60°C to +200°C, VMQ resists degradation in steam, food-grade lubricants, and medical-grade fluids. Its inert composition meets USP Class VI and FDA 21 CFR 177.2600 standards for sanitary applications. Silicone’s primary constraints are lower tensile strength, susceptibility to撕裂 in high-pressure dynamic seals, and swelling in non-polar solvents like toluene.

The following comparative analysis details critical material parameters for sunjoe 3000xt O-ring qualification

| Material | Temperature Range (°C) | Key Fluid Resistances | Key Limitations | Typical sunjoe 3000xt Applications |

|---|---|---|---|---|

| Viton® (FKM) | -20 to +230 (300 intermittent) | Fuels, synthetic oils, acids, ozone | High cost, poor ketone resistance, stiffens below -20°C | Fuel injectors, turbocharger seals, chemical processing |

| Nitrile (NBR) | -40 to +120 (+150 peroxide) | Mineral oils, water, aliphatic hydrocarbons | Swells in esters, poor ozone resistance >70ppm | Hydraulic cylinders, pneumatic actuators, gearboxes |

| Silicone (VMQ) | -60 to +200 | Steam, water, food oils, oxidizing chemicals | Low tear strength, swells in hydrocarbons, high gas permeability | Coolant systems, medical fluid paths, low-pressure vacuum |

Material validation requires empirical testing under actual sunjoe 3000xt operating conditions. Suzhou Baoshida Trading Co., Ltd. conducts accelerated aging per ASTM D573, compression set analysis per ASTM D395, and fluid immersion testing to ISO 1817. Final selection must account for fluid composition, pressure cycles, and surface finish of mating hardware. Consult our engineering team for application-specific formulation adjustments to meet your operational envelope.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Seal Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in the precision rubber seals industry. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific o-rings tailored to meet the exacting demands of industrial clients. Our expertise spans material science, elastomer compounding, and precision tooling design—ensuring every sunjoe 3000xt o-ring we produce meets the highest standards of performance, durability, and dimensional accuracy.

Our two in-house rubber formula engineers possess deep knowledge in polymer chemistry and elastomer behavior under dynamic conditions. They are responsible for developing custom rubber compounds optimized for specific environmental challenges such as temperature extremes, chemical exposure, and mechanical stress. By formulating proprietary blends using NBR, EPDM, FKM, and other high-performance elastomers, we ensure that each o-ring maintains seal integrity in demanding operational environments. These formulations are rigorously tested for compression set, tensile strength, elongation, and fluid resistance to guarantee long-term reliability.

Complementing our formulation expertise, our team of five precision mould engineers specializes in the design and refinement of o-ring tooling. Utilizing advanced CAD/CAM systems and CNC machining, they develop high-tolerance moulds that ensure consistent geometry, minimal flash, and precise cross-sectional control. Every mould undergoes strict validation through first-article inspection and process capability (Cp/Cpk) analysis to ensure repeatability in high-volume production. This integration of material science and precision tooling enables us to produce sunjoe 3000xt o-rings that exceed OEM specifications and perform reliably across diverse applications.

As an OEM manufacturing partner, Suzhou Baoshida offers full-service development support—from initial concept and material selection to prototyping, validation, and mass production. Our engineering team collaborates directly with client technical departments to reverse-engineer legacy components, improve existing designs, or develop new sealing solutions optimized for cost, performance, and manufacturability. With in-house tooling, formulation, and testing capabilities, we reduce lead times and maintain full control over quality and intellectual property.

The following table outlines the key technical specifications achievable for sunjoe 3000xt o-rings under our engineering and manufacturing protocols:

| Parameter | Specification Range |

|---|---|

| Material Types | NBR, EPDM, FKM, Silicone, CR, ACM |

| Hardness (Shore A) | 50–90 ±5 |

| Inner Diameter Tolerance | ±0.05 mm (per ISO 3601) |

| Cross Section Tolerance | ±0.03 mm (per ISO 3601) |

| Operating Temperature | -40°C to +230°C (depending on material) |

| Compression Set (70 hrs) | ≤20% (at 100°C) |

| Tensile Strength | ≥8 MPa (ASTM D412) |

| Elongation at Break | ≥200% (ASTM D412) |

| Fluid Resistance | Custom formulated for oils, fuels, water, acids |

Our engineering-driven approach ensures that every sunjoe 3000xt o-ring we manufacture is not only dimensionally precise but also chemically and mechanically optimized for its intended application. This technical depth, combined with our OEM agility, positions Suzhou Baoshida as a trusted partner in high-integrity sealing solutions.

Customization Process

Customization Process for Sunjoe 3000XT O-Rings

At Suzhou Baoshida Trading Co., Ltd., our customization process for Sunjoe 3000XT O-rings begins with rigorous drawing analysis to ensure dimensional and functional compliance. We meticulously review client-provided technical schematics, focusing on critical parameters including inner diameter (ID), cross-section (CS), tolerance classes per ISO 3601, and surface finish requirements. Our engineering team conducts tolerance stack analysis to preempt assembly interferences, particularly addressing the Sunjoe 3000XT’s high-pressure hydraulic system demands where groove geometry directly impacts seal longevity. Any ambiguities in material callouts or environmental specifications trigger immediate client consultation to eliminate interpretation risks before progression.

Material formulation follows, leveraging our 15+ years of OEM compound development expertise. For the Sunjoe 3000XT application—which operates under aggressive conditions including 3000 PSI pressure, ozone exposure, and temperatures from -30°C to +120°C—we prioritize NBR (Nitrile) or FKM (Fluoroelastomer) bases. NBR formulations optimize cost-effectiveness for petroleum-based fluid resistance, while FKM variants deliver superior thermal stability for extreme environments. Each compound is engineered with precision accelerator systems to achieve target hardness (Shore A), tensile strength, and compression set values. Below are typical material specifications validated for Sunjoe 3000XT compatibility:

| Property | NBR Standard | FKM Premium | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 70 ±5 | 75 ±5 | ASTM D2240 |

| Tensile Strength (MPa) | ≥15 | ≥12 | ASTM D412 |

| Elongation at Break (%) | ≥250 | ≥180 | ASTM D412 |

| Compression Set (%) | ≤25 | ≤15 | ASTM D395 |

| Temp Range (°C) | -30 to +100 | -20 to +200 | ISO 1817 |

Prototyping utilizes CNC-machined molds from client-approved 3D models, producing 10–15 sample O-rings per batch. These undergo accelerated life testing in our lab, simulating 500+ pressure cycles at 120% of operational load while monitoring extrusion gaps and leakage rates. Dimensional validation via optical comparators ensures CS uniformity within ±0.05mm tolerance. Client sign-off on prototype performance data is mandatory before tooling release.

Mass production commences only after final approval, executed under ISO 9001-certified workflows. We deploy automated injection molding with real-time cavity pressure monitoring to maintain consistency across batches exceeding 50,000 units. Every lot undergoes 100% visual inspection for surface defects and statistical sampling for critical dimensions. Traceability is enforced via laser-etched batch codes linked to raw material certificates and cure curve logs. Suzhou Baoshida guarantees on-time delivery through dedicated production cells, with rigorous final audit reports provided for seamless OEM integration into Sunjoe 3000XT assembly lines. This end-to-end precision ensures zero field failures in demanding industrial applications.

Contact Engineering Team

For precision rubber sealing solutions tailored to industrial applications such as the Sunjoe 3000XT O-rings, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered elastomer technology. As a specialized manufacturer and exporter in the field of precision rubber seals, we combine advanced material science with rigorous quality control to deliver components that meet exact OEM specifications. Our expertise extends to custom formulation development, dimensional accuracy assurance, and long-term performance validation under dynamic operating conditions.

The Sunjoe 3000XT O-rings require consistent sealing integrity under variable pressure and temperature conditions. At Suzhou Baoshida, we manufacture replacement and upgrade O-rings using high-purity Nitrile Butadiene Rubber (NBR) and Fluorocarbon (FKM/Viton®) compounds, selected for their resistance to oil, fuel, ozone, and thermal degradation. Each seal is produced under ISO 9001-certified processes, ensuring batch-to-batch consistency and compliance with international standards. Our in-house testing laboratory conducts compression set analysis, tensile strength evaluation, and volume swell testing to validate performance against real-world service environments.

We understand that reliability in power equipment directly correlates with seal performance. That is why our engineering team works closely with OEMs and maintenance suppliers to reverse-engineer, test, and optimize sealing solutions that exceed original equipment lifespans. Whether you are sourcing for inventory replacement, bulk equipment servicing, or custom formulation upgrades, Suzhou Baoshida provides technical data sheets, material certifications, and sample kits upon request.

To ensure seamless integration and supply chain continuity, we offer rapid prototyping, tolerance verification via coordinate measuring machines (CMM), and packaging options suitable for industrial distribution channels. Our global logistics network supports just-in-time delivery to North America, Europe, and Asia-Pacific markets, backed by documented traceability and customs compliance.

For immediate technical consultation or quotation on Sunjoe 3000XT O-rings, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Direct inquiries to [email protected]. Mr. Boyce specializes in industrial seal applications and leads our technical response team for custom specifications, material selection, and volume production scheduling. We respond to all qualified requests within 4 business hours and provide sample turnaround in 7–10 days, depending on material complexity.

Below are the standard specifications for our engineered O-rings compatible with the Sunjoe 3000XT system:

| Parameter | Specification |

|---|---|

| Material | NBR (70 Shore A) or FKM (75 Shore A) |

| Inner Diameter | 18.5 ± 0.15 mm |

| Cross Section | 2.65 ± 0.10 mm |

| Hardness (Shore A) | 65–75 (ASTM D2240) |

| Temperature Range | -30°C to +120°C (NBR), -20°C to +200°C (FKM) |

| Color | Black (standard), custom upon request |

| Standards Compliance | ASTM D2000, ISO 3601, ISO 9001:2015 |

| Packaging | 100 pcs/bag, anti-static, moisture-resistant |

Partner with Suzhou Baoshida for technically validated, industrially proven sealing solutions. Contact Mr. Boyce today at [email protected] to discuss your Sunjoe 3000XT O-ring requirements.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).