Technical Contents

Engineering Guide: Swimming Pool Matting

Engineering Insight: Material Selection for Swimming Pool Matting

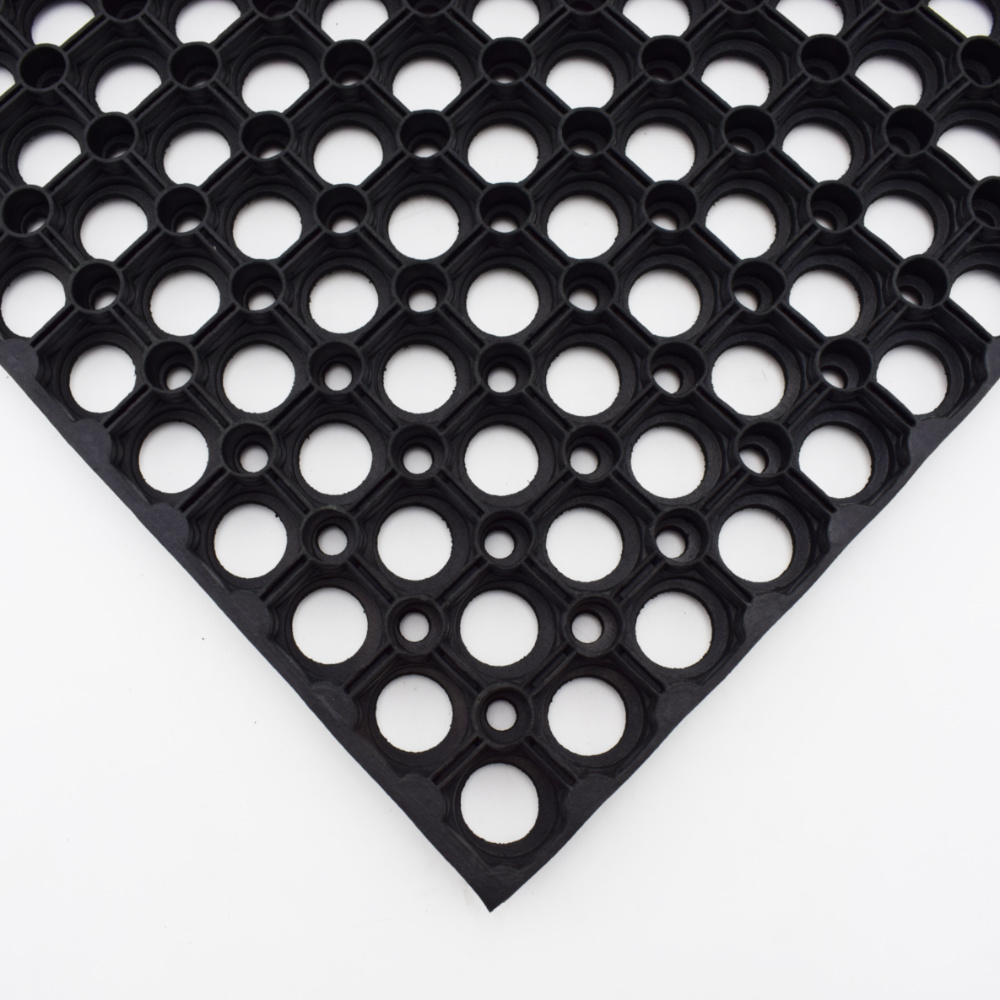

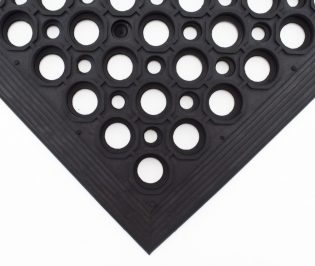

The operational integrity of swimming pool matting hinges on precise material science, not merely dimensional conformity. Off-the-shelf rubber mats frequently fail within 12–18 months due to fundamental incompatibilities with aquatic environments. Chlorine concentrations (typically 1–3 ppm free chlorine) aggressively attack conventional SBR or recycled rubber compounds, causing chain scission, surface chalking, and catastrophic loss of tensile strength. Simultaneously, UV exposure degrades polymer backbones, accelerating embrittlement. Standard mats often lack hydrolytic stability, permitting moisture ingress that swells fillers and disrupts adhesion between rubber phases. The consequence is premature cracking, delamination, and hazardous slip conditions when surface texture erodes.

Suzhou Baoshida addresses these failures through engineered EPDM formulations. Our proprietary compounds integrate high-purity monomers with tailored saturation levels (≥70% ethylene) to resist chlorine oxidation. Critical additives include hindered amine light stabilizers (HALS) for UV resilience and nano-silica reinforcement for tear resistance without compromising flexibility. Shore A hardness is precisely calibrated to 65±3°—sufficient to maintain structural integrity under foot traffic while allowing drainage channel retention. Crucially, surface texture is molded via CNC-carved tooling to achieve consistent 2.5–3.0 mm pyramid profiles, ensuring dynamic coefficient of friction (DCOF) remains >0.60 even when wet per ASTM F2948.

Material performance disparities are quantifiable. The table below compares industry-standard mats against Baoshida’s engineered solution under accelerated aging:

| Property | Standard SBR Mat | Baoshida EPDM Mat | Test Standard |

|---|---|---|---|

| Tensile Strength (Aged) | 4.2 MPa | 12.8 MPa | ASTM D412 |

| Elongation at Break (Aged) | 180% | 420% | ASTM D412 |

| Chlorine Resistance (1000ppm) | Severe cracking | No degradation | ISO 188 (70°C/72h) |

| UV Resistance (500h QUV) | ΔE=12.3 | ΔE=2.1 | ASTM G154 |

| Wet DCOF | 0.35 | 0.68 | ASTM F2948 |

Generic mats prioritize cost over chemistry, utilizing high-filler loads (>40 phr) that compromise elasticity. Under thermal cycling (common in outdoor pools), these compounds develop microfissures, allowing chlorine penetration to the mat core. Our OEM process begins with client-specific water chemistry analysis—bromine, saltwater, or ozonated systems demand distinct antioxidant packages. Tooling precision ensures uniform thickness tolerance (±0.3 mm), eliminating pooling zones where organic growth accelerates.

For facility managers, the cost of premature replacement extends beyond material expenditure. Failed matting increases slip-and-fall liability and necessitates pool closures for remediation. Baoshida’s engineering-led approach delivers 8–10 year service life by treating material selection as a systems problem, not a commodity purchase. Partner with us to convert matting from a maintenance liability into a safety asset.

Material Specifications

Swimming pool matting requires resilient, chemically stable materials capable of withstanding prolonged exposure to chlorinated water, UV radiation, temperature fluctuations, and constant foot traffic. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered for durability and safety in demanding environments. Our technical-grade swimming pool matting systems utilize high-performance elastomers, including Viton, Nitrile (NBR), and Silicone, each selected based on specific operational requirements. These materials offer distinct advantages in terms of chemical resistance, mechanical strength, and thermal stability, making them suitable for commercial, municipal, and high-traffic aquatic facilities.

Viton, a fluoropolymer rubber, exhibits exceptional resistance to oxidation, ozone, and aggressive chemicals, including chlorine and bromine-based sanitizers commonly used in pool maintenance. Its thermal stability ranges from -20°C to 200°C, allowing for reliable performance in both heated indoor pools and outdoor installations under direct sunlight. While Viton is typically more expensive than other elastomers, its longevity in harsh chemical environments justifies its use in premium-grade applications where long-term integrity is critical.

Nitrile rubber, also known as Buna-N or NBR, provides excellent resistance to oils, greases, and aliphatic hydrocarbons, but more importantly, it demonstrates strong performance in aqueous chlorine environments. With a service temperature range of -30°C to 100°C, NBR is well-suited for standard poolside conditions. It offers high abrasion resistance and mechanical strength, making it ideal for high-traffic deck areas. Nitrile-based matting delivers a cost-effective balance between performance and durability, particularly in commercial pool decks and public aquatic centers.

Silicone rubber is distinguished by its outstanding thermal stability, operating effectively from -60°C to 200°C, and superior resistance to UV degradation. While it has moderate resistance to chlorinated water, its performance can be enhanced through specialized compounding. Silicone is non-toxic, inherently flame-retardant, and offers excellent flexibility over a wide temperature range. It is particularly favored in sensitive environments such as therapeutic pools, spas, and facilities requiring high hygiene standards.

The selection of the appropriate elastomer depends on the specific environmental and operational demands of the installation. Below is a comparative summary of key material properties relevant to swimming pool matting applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 100 | -60 to 200 |

| Chlorine Resistance | Excellent | Good | Moderate to Good |

| UV Resistance | Excellent | Fair | Excellent |

| Abrasion Resistance | Good | Excellent | Moderate |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Service Life (years) | 10–15 | 5–8 | 8–12 |

Each material is compounded with reinforcing fillers, stabilizers, and anti-slip additives to meet industrial safety and performance standards. At Suzhou Baoshida Trading Co., Ltd., we provide customized formulations to match client specifications, ensuring optimal performance, safety, and lifecycle cost efficiency in aquatic environments.

Manufacturing Capabilities

Engineering Capability: Precision-Engineered Solutions for Swimming Pool Matting

Suzhou Baoshida Trading Co., Ltd. delivers advanced industrial rubber solutions through integrated material science and precision tooling expertise. Our dedicated engineering division comprises five specialized mold engineers and two certified rubber formula engineers, collectively enabling end-to-end development of high-performance swimming pool matting systems. This structure ensures rigorous control over material composition, structural integrity, and manufacturing scalability for demanding aquatic environments.

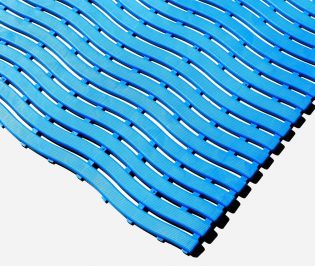

Our formula engineering team focuses on optimizing elastomer compounds for critical pool-specific challenges. We develop proprietary EPDM and SBR blends engineered for exceptional resistance to chlorine, bromine, UV degradation, and hydrolytic aging. Each formulation undergoes accelerated weathering tests per ASTM G154 and ISO 4892-3, targeting 15+ years of service life under continuous chemical exposure. Key innovations include micro-textured surfaces for slip resistance (achieving DIN 51130 R11 ratings) and closed-cell structures that prevent water absorption while maintaining flexibility at low temperatures. Material hardness is precisely calibrated between 55–75 Shore A to balance user comfort with structural stability under foot traffic.

Complementing material science, our mold engineering division executes precision tooling for complex mat geometries. We utilize SolidWorks and Moldflow simulation to optimize drainage channel profiles, edge sealing, and interlocking mechanisms—critical for rapid water evacuation and installation efficiency. All molds undergo finite element analysis (FEA) to eliminate weld lines and ensure uniform compression during vulcanization. This capability supports rapid prototyping (within 15 business days) and seamless transition to high-volume production, with tolerances maintained at ±0.3 mm across 2m x 1m mat sections.

As an OEM partner, Suzhou Baoshida provides full technical collaboration from concept to certification. We integrate client specifications into material selection, tooling design, and process validation under ISO 9001 protocols. Our engineers conduct joint failure mode analysis to preempt installation or performance issues, while maintaining strict confidentiality for proprietary designs. Volume production leverages automated compression molding lines with real-time cure monitoring, ensuring batch consistency for orders exceeding 50,000 m² annually.

Critical Performance Specifications for Swimming Pool Matting

| Property | Test Standard | Typical Value | Significance |

|---|---|---|---|

| Durometer (Shore A) | ASTM D2240 | 65 ± 5 | Balance of comfort and load-bearing |

| Tensile Strength | ASTM D412 | ≥12 MPa | Resistance to tearing during use |

| Elongation at Break | ASTM D412 | ≥350% | Flexibility for uneven surfaces |

| Chlorine Resistance | ISO 188 (70°C) | <15% property loss | Long-term chemical stability |

| Slip Resistance (Wet) | DIN 51130 | R11 | Safety compliance for pool decks |

| Compression Set (22h) | ASTM D395 | ≤20% | Recovery after sustained load |

| UV Resistance (1000h) | ISO 4892-2 | ΔE < 3.0 | Color/fade stability in sunlight |

This engineering synergy—material innovation paired with precision tooling—ensures our pool matting exceeds global safety and durability benchmarks while offering OEM clients scalable, certified manufacturing solutions. Suzhou Baoshida maintains full traceability from raw material batches to finished goods, guaranteeing performance consistency across all production tiers.

Customization Process

Customization Process for Swimming Pool Matting: From Design to Delivery

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the rigorous demands of commercial and public aquatic environments. The customization process for swimming pool matting follows a structured, science-driven sequence: Drawing Analysis, Formulation, Prototyping, and Mass Production. This ensures dimensional accuracy, material performance, and compliance with international safety and durability standards.

The process begins with Drawing Analysis, where engineering teams evaluate client-submitted technical drawings or CAD models. Critical parameters such as surface texture, thickness, drainage channel geometry, and interlocking mechanisms are assessed. Tolerances are verified to ensure compatibility with installation substrates and expected foot traffic loads. Our engineers also conduct finite element analysis (FEA) simulations to predict deformation under wet, high-slip conditions, optimizing structural integrity prior to material selection.

Following design validation, the Formulation stage determines the optimal rubber compound. For swimming pool matting, resistance to chlorine, UV degradation, and microbial growth is essential. We utilize EPDM (Ethylene Propylene Diene Monomer) as the base polymer due to its superior weathering resistance and color stability. The compound is enhanced with anti-slip fillers, such as silica or aluminum trihydrate, and includes UV stabilizers and mold inhibitors. Shore A hardness is typically maintained between 65–75 to balance comfort and resilience. Each formulation is documented and batch-traceable for quality assurance.

The next phase is Prototyping, where small-scale production runs generate sample mats using calibrated hydraulic presses and precision molds. Prototypes undergo a battery of tests, including slip resistance (ASTM F2913), tensile strength (ISO 37), and accelerated aging (ISO 188). Samples are also evaluated for colorfastness after 500 hours of QUV exposure. Client feedback is incorporated at this stage, allowing for geometry or compound adjustments before tooling finalization.

Upon approval, the project transitions to Mass Production. Mats are manufactured in our ISO-certified facility using automated curing lines, ensuring uniform cross-linking and dimensional consistency. Each batch undergoes inline quality checks, including thickness profiling and visual defect scanning. Finished products are packaged in moisture-resistant wrapping and shipped with material test reports (MTRs) and compliance documentation.

Our end-to-end customization guarantees that every swimming pool matting solution meets the functional, aesthetic, and safety requirements of modern aquatic facilities.

Typical Technical Specifications for Custom EPDM Swimming Pool Matting

| Property | Test Standard | Typical Value |

|---|---|---|

| Material | — | EPDM + Anti-slip Fillers |

| Shore A Hardness | ISO 48-4 | 65–75 |

| Tensile Strength | ISO 37 | ≥10 MPa |

| Elongation at Break | ISO 37 | ≥250% |

| Slip Resistance (Wet) | ASTM F2913 | DCOF ≥0.42 |

| UV Resistance | ISO 188 (150h) | No cracking, <15% ΔE color |

| Chlorine Resistance | Custom Immersion | No degradation after 1000h |

| Thickness Tolerance | ISO 3302 | ±0.5 mm |

Contact Engineering Team

Technical Partnership for Industrial-Grade Swimming Pool Matting Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber solutions for demanding aquatic environments. Our swimming pool matting systems are not generic floor coverings but precision-formulated industrial products designed to withstand continuous exposure to chlorinated water, UV radiation, thermal cycling, and heavy foot traffic. With over 15 years of OEM collaboration in the rubber compounding sector, we deliver matting that meets stringent ISO 22301 and ASTM F1936 safety standards while optimizing lifecycle cost for commercial pool operators, resort developers, and municipal infrastructure projects.

The core advantage of Baoshida matting lies in our proprietary EPDM-based compound architecture. Unlike commodity PVC alternatives prone to plasticizer migration and surface degradation, our formulations integrate nano-silica reinforcement and advanced antioxidant packages to ensure dimensional stability and slip resistance (R10/R11 classification) across 10,000+ hours of accelerated weathering tests. This scientific approach eliminates premature cracking, fading, or loss of traction—critical failure points in high-moisture settings where safety and liability are paramount.

Key performance specifications for our standard commercial pool matting grade are summarized below. All parameters are validated through third-party laboratory testing per ISO 37, ISO 48, and ISO 188 protocols.

| Specification Parameter | Test Standard | Performance Value | Industrial Significance |

|---|---|---|---|

| Hardness (Shore A) | ISO 48 | 65 ± 5 | Optimal balance: comfort vs. structural integrity |

| Thickness Tolerance | ASTM D375 | ±0.3 mm | Uniform drainage & installation precision |

| Tensile Strength | ISO 37 | ≥12.5 MPa | Resists tearing under dynamic loads |

| Elongation at Break | ISO 37 | ≥350% | Accommodates thermal expansion without buckling |

| Accelerated Weathering | ISO 4892-2 | >3000 hours | No measurable UV degradation at 60°C |

| Slip Resistance (Wet) | DIN 51130 | R11 | Exceeds commercial safety thresholds |

Beyond standardized products, we specialize in bespoke formulation adjustments for unique project demands. Whether requiring enhanced chemical resistance for therapeutic mineral pools, custom color integration for brand alignment, or modified durometer profiles for therapeutic hydrotherapy zones, our R&D team collaborates directly with your engineering staff. Our OEM partnership model includes full material traceability, batch-specific QC documentation, and on-site technical support during installation—ensuring seamless integration into your manufacturing or construction workflow.

For immediate technical consultation or project-specific quotation, contact Mr. Boyce, our dedicated OEM Account Manager. Specify your application environment, volume requirements, and performance priorities to receive a data-driven proposal within 48 business hours. All inquiries undergo direct engineering review—no generic sales scripts. Provide reference code POOL-MAT-2024 to expedite technical validation.

Reach Mr. Boyce via email at [email protected] with subject line: OEM Inquiry – Swimming Pool Matting Specification Review. Include critical parameters such as installation climate zone, expected foot traffic density (persons/hour), and substrate type for targeted solution mapping. As your industrial rubber partner, Suzhou Baoshida commits to delivering matting that performs as engineered—not merely as specified. Initiate your technical dialogue today to eliminate compromise in aquatic safety and longevity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).