Technical Contents

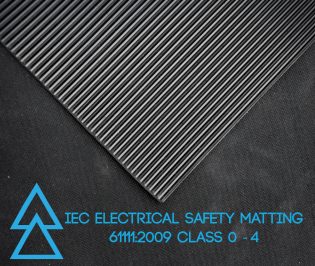

Engineering Guide: Switchboard Matting

Engineering Insight: Material Selection Criticality in Switchboard Matting

Switchboard matting is not merely a passive floor covering; it is an active electrical safety component where material integrity directly dictates personnel protection during fault conditions. Off-the-shelf rubber mats, often sourced for cost minimization, frequently fail under the specific, demanding environment of electrical switchgear rooms, creating unacceptable liability risks. This failure stems from inadequate material science applied to the unique stressors present: sustained high-voltage exposure, potential chemical splashes (oils, cleaning agents), thermal cycling, physical abrasion, and prolonged UV exposure in some facilities. Generic compounds lack the tailored polymer architecture and additive packages necessary to maintain dielectric strength and physical resilience over time.

The core issue lies in the compromise inherent in mass-market solutions. Standard PVC or recycled rubber mats may initially meet basic dielectric requirements per ASTM D178 but degrade rapidly. PVC formulations suffer plasticizer migration when exposed to heat or solvents, becoming brittle and losing flexibility, leading to cracking that compromises insulation. Polyurethane variants often exhibit poor hydrolytic stability, deteriorating in humid environments common near cooling systems. Recycled content introduces uncontrolled variables – inconsistent filler levels, degraded polymer chains, and unknown contaminant profiles – which unpredictably reduce dielectric strength and accelerate surface tracking under electrical stress. Crucially, these materials lack the engineered resistance to partial discharges, allowing localized breakdown paths to form invisible to the naked eye, culminating in catastrophic failure during an arc flash event.

Material selection must prioritize long-term performance stability, not just initial certification. Engineered ethylene propylene diene monomer (EPDM) compounds, such as those developed by Suzhou Baoshida for critical OEM applications, address these failure modes through precise formulation. High-purity, saturated backbone polymers provide inherent ozone and weathering resistance. Customized antioxidant and antiozonant packages prevent oxidative chain scission. Reinforcing fillers like highly dispersed silica enhance tear strength without sacrificing dielectric properties. Critical is the incorporation of specialized voltage stabilizers that suppress electron avalanches, maintaining dielectric integrity even after years of service. This scientific approach ensures the mat remains a reliable barrier, not a latent hazard.

The performance gap between generic and engineered solutions is quantifiable, as demonstrated below:

| Property | Off-the-Shelf Mat (Typical) | Engineered EPDM Mat (Baoshida Spec) | Test Standard |

|---|---|---|---|

| Dielectric Strength | 20-25 kV (initial) | 35-40 kV (initial & aged) | ASTM D149 |

| Oil Resistance (IRM 903) | Swell > 50% | Swell < 15% | ASTM D471 |

| Accelerated Aging (70°C) | Hardness Δ > +15 pts | Hardness Δ < +5 pts | ASTM D573 |

| Volume Resistivity | >1×10^11 Ω·cm (new) | >1×10^13 Ω·cm (new & aged) | ASTM D257 |

Relying on non-specialized matting represents a false economy. The marginal upfront cost saving is eclipsed by the potential for catastrophic equipment damage, severe injury, regulatory penalties, and reputational harm following a preventable electrical incident. True safety demands matting engineered from the molecular level for the specific electrical and environmental stresses encountered. Suzhou Baoshida partners with OEMs to develop and validate switchboard matting solutions where material science is the foundation of operational safety, ensuring compliance and protection endure throughout the product lifecycle. Specify performance, not just price.

Material Specifications

Switchboard matting is a critical safety component in electrical environments, providing insulation and protection against electrical hazards. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions engineered to meet the rigorous demands of electrical switchboard applications. Our formulations are optimized for dielectric strength, mechanical resilience, and environmental stability. The selection of raw material plays a pivotal role in determining the operational efficacy of switchboard matting. We offer switchboard mats manufactured from three advanced elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct performance characteristics tailored to specific industrial conditions.

Viton-based switchboard matting delivers exceptional resistance to high temperatures, ozone, and a broad range of chemicals, including fuels, oils, and acids. This material maintains dielectric integrity even under extreme thermal stress, with continuous service temperatures up to 250°C. Its low gas permeability and outstanding aging resistance make it ideal for use in demanding environments such as power generation facilities, petrochemical plants, and high-voltage substations. However, due to its higher raw material cost, Viton is typically specified where long-term durability under harsh conditions justifies the investment.

Nitrile rubber is widely used for switchboard matting due to its excellent balance of electrical insulation properties, mechanical strength, and oil resistance. It performs reliably in environments with exposure to hydraulic fluids, greases, and non-polar solvents. With a service temperature range of -30°C to +100°C, NBR-based mats are well-suited for general industrial electrical rooms and manufacturing facilities. The material also exhibits good abrasion resistance, contributing to extended service life under foot traffic and frequent handling.

Silicone rubber is selected when extreme temperature flexibility and high dielectric strength are paramount. Capable of operating from -60°C to +200°C, silicone maintains elasticity and insulation performance across wide thermal cycles. It also demonstrates superior resistance to UV radiation and weathering, making it suitable for both indoor and outdoor switchboard installations. While less resistant to oils and solvents than Nitrile or Viton, silicone excels in clean environments where thermal stability and consistent electrical performance are critical.

The following table summarizes key material specifications for Viton, Nitrile, and Silicone switchboard matting:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Dielectric Strength (kV/mm) | 20 | 18 | 22 |

| Temperature Range (°C) | -20 to +250 | -30 to +100 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–15 | 6–9 |

| Elongation at Break (%) | 200–300 | 250–350 | 300–600 |

| Hardness (Shore A) | 70–80 | 60–75 | 50–70 |

| Oil Resistance | Excellent | Excellent | Poor |

| Ozone & UV Resistance | Excellent | Good | Excellent |

| Flame Resistance | Very Good | Good | Good |

Each material is precision-compounded and tested to ensure compliance with international safety standards, including IEC 61111 and ASTM D178. Our technical team supports OEM integration with custom thickness, color coding, surface texture, and dimensional tolerances to meet client-specific requirements.

Manufacturing Capabilities

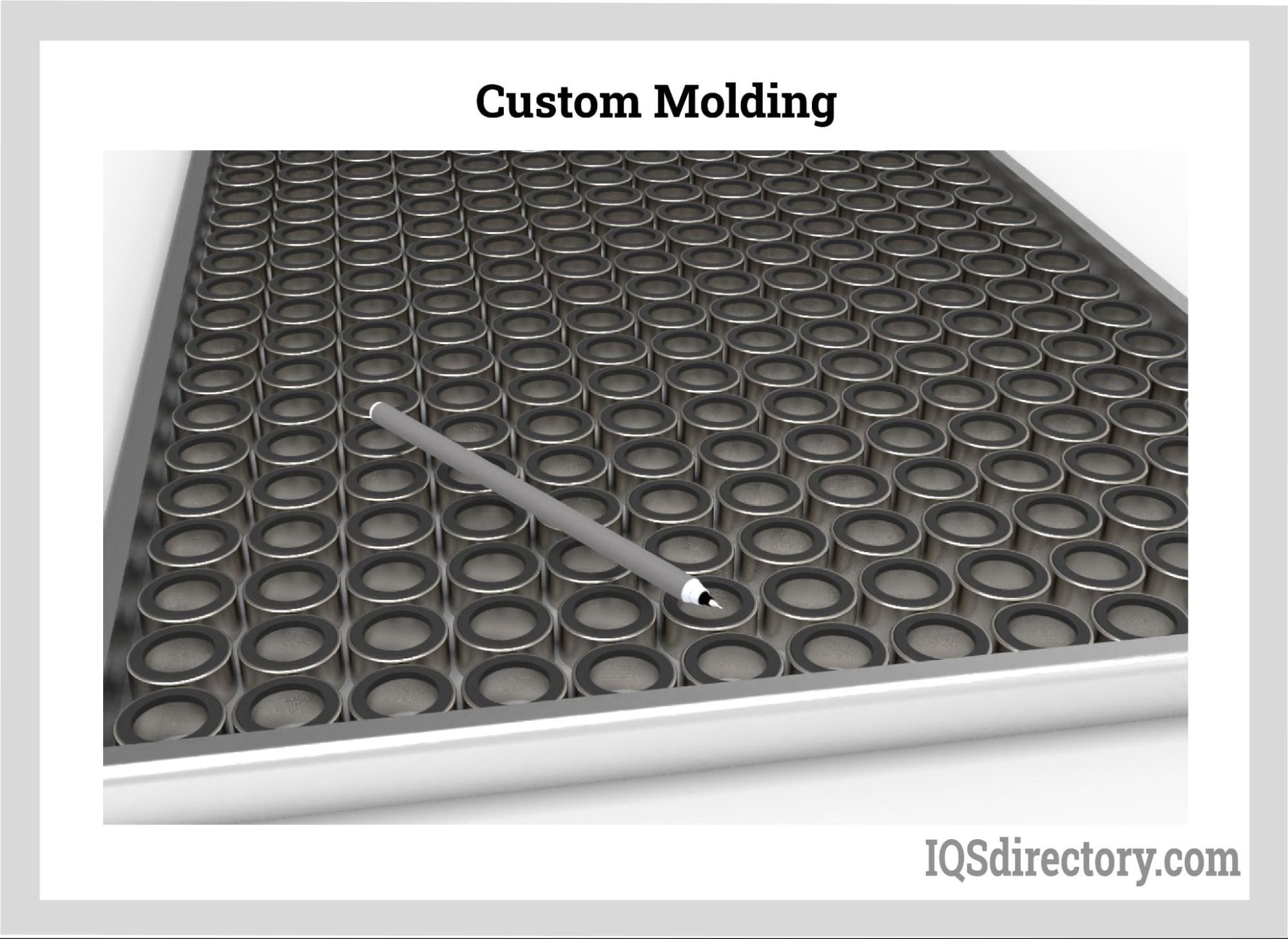

Engineering Capability: Precision Rubber Solutions for Switchboard Matting

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in polymer science and precision manufacturing to deliver switchboard matting solutions meeting the most stringent electrical safety and operational demands. Our core strength resides in the integrated capabilities of our dedicated engineering teams: five specialized Mould Engineers and two advanced Rubber Formula Engineers. This structure ensures seamless translation of complex material requirements into flawlessly executed, high-performance products.

Our Formula Engineering team operates at the molecular level, meticulously designing and optimizing custom rubber compounds specifically for electrical insulation applications. We focus on achieving the critical balance between dielectric strength, arc resistance, flame retardancy (UL 94 V-0 compliance), and long-term physical property retention under thermal and environmental stress. This involves precise control over polymer chain architecture, filler dispersion, crosslink density, and additive synergies. Every formulation undergoes rigorous laboratory validation against ASTM D178, IEC 61111, and client-specific electrical safety standards before progression to production. We do not rely on generic recipes; each compound is engineered for the exact voltage class, environmental exposure, and mechanical duty cycle required by the end application.

Complementing this material science foundation, our Mould Engineering team ensures geometric precision and manufacturing repeatability essential for consistent electrical performance. Utilizing advanced CAD/CAM systems and cavity pressure mapping during development, we design and validate moulds that guarantee uniform wall thickness, critical for dielectric integrity, and exact dimensional tolerances required for secure installation within switchgear enclosures. Our engineers optimize gating, cooling channels, and venting to eliminate flow lines, weld marks, or porosity that could compromise insulation properties. This precision extends to complex features like integrated anti-slip patterns or mounting flanges, manufactured with micron-level accuracy to ensure perfect fit and function every time.

This integrated engineering approach underpins our robust OEM capabilities. We provide true turnkey solutions, managing the entire process from initial concept and material selection through prototyping, validation testing, and high-volume production. Our clients benefit from confidential compound development, rapid iteration based on performance feedback, and strict adherence to proprietary specifications. We implement comprehensive process control protocols, including real-time rheometry monitoring during mixing and automated dimensional inspection post-moulding, ensuring batch-to-batch consistency critical for electrical safety components. Suzhou Baoshida functions as an extension of your engineering department, delivering not just parts, but engineered performance with documented traceability and full IP protection.

The following table summarizes key performance specifications achievable through our engineered approach compared to typical industry baselines:

| Property | Baoshida Engineered Standard | Typical Industry Baseline |

|---|---|---|

| Dielectric Strength (kV/mm) | ≥ 35 | 25 – 30 |

| Volume Resistivity (Ω·cm) | ≥ 1.0 x 10¹² | ≥ 1.0 x 10¹¹ |

| Arc Resistance (ASTM D495) | ≥ 180 seconds | 120 – 150 seconds |

| Flame Rating (UL 94) | V-0 (1.5mm min) | HB or V-1 |

| Hardness Range (Shore A) | 55 – 85 (Precise Control) | 60 – 80 (Wider Tolerance) |

| Dimensional Tolerance | ±0.3 mm | ±0.8 mm |

This commitment to engineered precision, validated performance, and seamless OEM execution ensures Suzhou Baoshida switchboard matting provides the ultimate reliability safeguarding critical electrical infrastructure.

Customization Process

Drawing Analysis

The customization process for switchboard matting begins with a comprehensive drawing analysis, where the client’s technical specifications are meticulously reviewed. At Suzhou Baoshida Trading Co., Ltd., our engineering team evaluates dimensions, load-bearing requirements, surface texture, electrical resistance needs, and environmental exposure conditions. This stage includes assessing installation methods, such as adhesion, mechanical fastening, or free-lay configurations, to ensure compatibility with the end application. Any deviations from standard designs are documented, and feasibility studies are conducted to confirm manufacturability. Precision in this phase ensures that the final product meets both safety standards and performance expectations in high-voltage environments.

Formulation Development

Following drawing validation, our Rubber Formula Engineers develop a tailored compound formulation. The base polymer—typically EPDM, neoprene, or SBR—is selected based on dielectric strength, flame resistance, ozone stability, and temperature tolerance. Additives such as reinforcing fillers, vulcanizing agents, anti-aging compounds, and flame retardants are precisely balanced to achieve optimal mechanical and electrical properties. For switchboard applications, the formulation must comply with IEC 61111 and ASTM D178 standards for insulating rubber mats. Special attention is given to surface resistivity, ensuring values remain within the 1×10¹² Ω range to prevent electrical conduction. All raw materials are sourced from certified suppliers and subjected to incoming quality checks before batching.

Prototyping and Validation

Once the formulation is finalized, a prototype is produced using pilot-scale calendering or molding equipment. The prototype undergoes rigorous laboratory testing, including dielectric withstand voltage tests (up to 30 kV), tensile strength analysis, tear resistance, and slip resistance evaluation (using ASTM F1679). Dimensional accuracy is verified against the original drawing using coordinate measuring methods. Clients are provided with test reports and physical samples for field evaluation. Feedback is incorporated into any necessary design or material adjustments before final approval.

Mass Production and Quality Assurance

After prototype validation, the project transitions to mass production. Our facility utilizes automated batching systems, precision calendering lines, and continuous vulcanization tunnels to ensure consistency across large volumes. Each production batch is monitored for hardness (Shore A), thickness uniformity, and surface integrity. Final products are inspected per AQL Level II standards and packaged to prevent deformation during shipping. Traceability is maintained through batch coding and material certifications.

The table below outlines key technical specifications for standard switchboard matting:

| Property | Test Standard | Typical Value |

|---|---|---|

| Dielectric Strength | IEC 61111 | 30 kV (1 min) |

| Surface Resistance | ASTM D257 | ≥1×10¹² Ω |

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥7 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Flame Resistance | UL 94 | V-0 Rated |

All custom switchboard mats are manufactured under ISO 9001-certified processes, ensuring reliability and compliance in critical electrical environments.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Switchboard Matting Solutions

Electrical safety in industrial environments demands uncompromising material integrity. Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber solutions meeting stringent global electrical safety standards. Our switchboard matting undergoes rigorous vulcanization and quality control protocols to ensure dielectric reliability, dimensional stability, and resistance to environmental degradation. As your dedicated Rubber Formula Engineer and OEM Manager, I oversee the molecular design and production processes that transform raw elastomers into certified safety barriers. Each matting formulation is optimized for specific voltage ranges, mechanical stress conditions, and operational lifespans, eliminating field failures through precision compounding.

Our manufacturing facility adheres to ISO 9001:2015 and IATF 16949 standards, with in-house testing capabilities for dielectric strength, flame resistance, and physical properties. The table below summarizes critical specifications for our standard industrial switchboard matting series:

| Property | Test Standard | Value |

|---|---|---|

| Dielectric Strength | ASTM D178 | ≥ 30 kV (1/8″ thickness) |

| Flame Resistance | UL 94 | V-0 Rating |

| Tensile Strength | ASTM D412 | ≥ 18 MPa |

| Elongation at Break | ASTM D412 | ≥ 300% |

| Volume Resistivity | ASTM D257 | ≥ 1.0 x 10¹² Ω·cm |

| Operating Temperature | IEC 61111 | -40°C to +100°C |

| Surface Resistance | ASTM D257 | ≤ 1.0 x 10⁹ Ω |

These values represent baseline performance; custom formulations for extreme environments (e.g., oil resistance, anti-static additives, or enhanced UV stability) are developed through collaborative engineering with our clients. We provide full technical documentation, including material test reports (MTRs) and compliance certificates for IEC 61111, ASTM F1506, and EN 50110-1. Our OEM partnerships integrate seamless scalability from prototype to high-volume production, with dedicated batch traceability and just-in-time logistics for global supply chains.

Initiate your project with Suzhou Baoshida by contacting Mr. Boyce, our Technical Sales Director. With 15 years of expertise in industrial rubber compounding and electrical safety applications, Mr. Boyce provides direct engineering consultation to align material properties with your operational requirements. He facilitates technical data review, sample validation, and commercial terms negotiation without intermediary delays. For urgent safety compliance needs or custom formulation requests, email [email protected] with project specifications. All inquiries receive a detailed technical response within 24 business hours, including feasibility assessment and timeline projection.

Do not compromise on electrical safety infrastructure. Suzhou Baoshida’s switchboard matting delivers measurable risk reduction through scientifically validated material science. Contact Mr. Boyce to secure certified protection for critical infrastructure—where precision engineering meets operational continuity. Your facility’s safety integrity begins with a single technical consultation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).