Technical Contents

Engineering Guide: T Shape Weather Strip

Engineering Insight: Material Selection Criticality in T-Shape Weather Strip Performance

The functional integrity of a T-shape weather strip hinges fundamentally on precise material science, not merely geometric conformity. Off-the-shelf solutions frequently fail in demanding industrial and automotive applications due to generic material formulations incapable of addressing specific environmental and mechanical stressors. Standard compounds often prioritize initial cost reduction over long-term performance, leading to premature degradation that compromises sealing efficacy, energy efficiency, and product lifespan. Understanding the nuanced interplay between polymer chemistry, application parameters, and failure mechanisms is paramount for reliable sealing.

Common failure modes of non-engineered T-strips stem directly from inadequate material selection. Exposure to extreme temperature fluctuations induces thermal degradation; low-cost EPDM may harden significantly below -40°C, losing resilience, while inferior silicone can soften excessively above 200°C, causing permanent compression set. Simultaneously, prolonged UV and ozone exposure rapidly cracks unsaturated polymers lacking robust stabilizer packages. Chemical resistance is equally critical; exposure to automotive fluids, industrial solvents, or even aggressive cleaning agents can cause swelling, extraction of plasticizers, or surface crazing in incompatible materials. Crucially, the dynamic compression set resistance – the strip’s ability to recover shape after sustained deflection – is often insufficient in generic compounds, leading to permanent gaps and air/water infiltration within months of service. These failures manifest as increased energy consumption, moisture ingress, noise penetration, and ultimately, costly warranty claims and reputational damage for the OEM.

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through proprietary rubber compounding tailored to the exact operational profile. We reject one-size-fits-all approaches. Our engineering process begins with a detailed analysis of the end-use environment: temperature extremes, fluid exposure, compression load, cycle frequency, and regulatory requirements. This data drives the selection of base polymer (EPDM, Silicone, ACM, TPE), precise filler systems, advanced stabilizer packages, and optimized cure chemistry. For instance, aerospace applications demand silicone formulations exceeding 250°C stability with ultra-low compression set, while heavy-duty truck door seals require EPDM with exceptional ozone resistance and fuel tolerance. This targeted formulation ensures the T-strip maintains its critical sealing force, dimensional stability, and flexibility throughout its intended service life, directly translating to reduced lifecycle costs and enhanced product reliability for our OEM partners.

The table below illustrates key material property differentials critical for T-shape weather strip selection, highlighting why generic solutions fall short:

| Property | Standard Off-the-Shelf EPDM | Baoshida Engineered EPDM | Baoshida High-Performance Silicone |

|---|---|---|---|

| Hardness Range (Shore A) | 60 ± 5 | 55-75 (Customizable) | 45-80 (Customizable) |

| Temp. Range (°C) | -40 to +120 | -55 to +150 | -60 to +260 |

| Compression Set (70°C, 22h) | >35% | <25% | <15% |

| Ozone Resistance (100pphm, 40°C) | Poor (Cracking <48h) | Excellent (No Cracking >500h) | Excellent (No Cracking >500h) |

| Fuel Resistance (B) | Moderate Swelling | Low Swelling | Excellent |

Partnering with Suzhou Baoshida ensures your T-shape weather strip is not merely a component, but a precisely engineered system solution. Our material science expertise eliminates the guesswork and risk inherent in off-the-shelf alternatives, delivering sealing performance that meets the uncompromising demands of modern industrial and automotive manufacturing.

Material Specifications

Material selection for t shape weather strips is a critical determinant of performance, longevity, and compatibility in industrial sealing applications. At Suzhou Baoshida Trading Co., Ltd., we engineer t shape weather strips to meet the rigorous demands of dynamic sealing environments, including exposure to extreme temperatures, chemical agents, and mechanical stress. Our primary elastomer offerings—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each present distinct advantages based on application-specific requirements. Understanding the intrinsic properties of each material enables optimal selection for sealing integrity and service life.

Viton, a fluorocarbon-based rubber, delivers superior resistance to high temperatures, oils, fuels, and a broad spectrum of aggressive chemicals. With a continuous service temperature range of -20°C to 250°C (short-term up to 300°C), Viton is ideal for aerospace, automotive engine compartments, and chemical processing equipment where thermal stability and chemical inertness are paramount. Its low gas permeability and excellent aging characteristics further enhance reliability in critical sealing interfaces. However, Viton exhibits lower flexibility at sub-zero temperatures and higher material cost compared to alternatives, making it best suited for high-performance environments.

Nitrile rubber, or Buna-N, remains one of the most widely used elastomers in industrial sealing due to its excellent resistance to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. It operates effectively within a temperature range of -30°C to 120°C, offering good abrasion resistance and mechanical strength. Nitrile-based t shape weather strips are frequently specified in automotive, hydraulics, and general industrial machinery where cost-efficiency and oil resistance are primary concerns. While Nitrile performs poorly in ozone and UV exposure environments without compounding enhancements, its versatility and economical profile make it a preferred choice for many standard sealing applications.

Silicone rubber provides exceptional thermal stability across a wide range, from -60°C to 200°C, with formulations capable of enduring brief exposures beyond 250°C. It exhibits excellent resistance to UV radiation, ozone, and weathering, making it highly suitable for outdoor and architectural applications. Silicone is also biocompatible and often used in food-grade or medical environments. However, it has relatively low tensile strength and poor resistance to petroleum oils and solvents. Its high gas permeability may limit use in vacuum or fuel-handling systems. Despite these limitations, silicone excels in low-temperature flexibility and long-term environmental durability.

The following table summarizes key physical and chemical properties of these materials for comparative analysis:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Chemical Resistance | Outstanding | Moderate | Poor to Fair |

Selection of the appropriate elastomer for t shape weather strips must balance operational conditions, media exposure, mechanical loading, and lifecycle cost. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and testing support to ensure material alignment with OEM and industrial specifications.

Manufacturing Capabilities

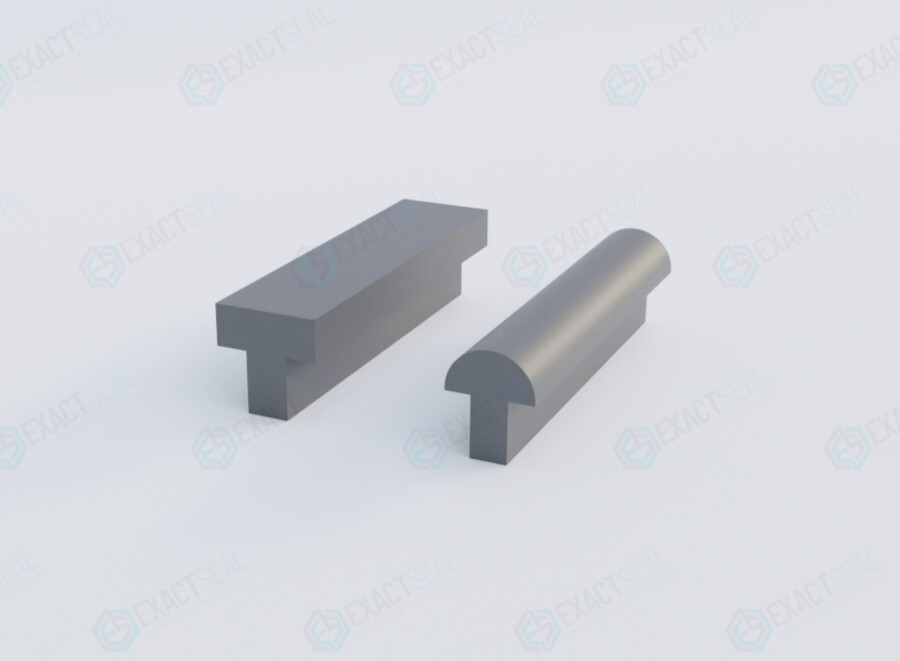

Engineering Capability: Precision-Driven T-Shape Weather Strip Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the bedrock of reliable T-shape weather strip manufacturing for demanding industrial and automotive applications. We integrate deep material science expertise with advanced mould design to deliver solutions meeting exacting dimensional, performance, and durability specifications. Our dedicated team comprises five specialized Mould Engineers and two certified Rubber Formula Engineers, operating within a tightly controlled industrial framework to ensure consistent product integrity from concept to mass production.

Our Mould Engineering team possesses extensive proficiency in designing and refining complex rubber extrusion and splicing tooling. They utilize advanced CAD/CAM systems to model intricate T-profile geometries, optimizing flow dynamics, minimizing weld line visibility at splice points, and ensuring precise dimensional stability across varying durometers and compound types. This expertise is critical for achieving the consistent cross-section tolerances required in dynamic sealing applications, where even micron-level deviations impact performance. Concurrently, our Formula Engineering team focuses on the molecular architecture of the rubber compound. They develop and validate proprietary EPDM, silicone, and thermoplastic elastomer (TPE) formulations tailored to specific environmental challenges. This includes rigorous optimization of compression set resistance, low-temperature flexibility down to -50°C, ozone/weathering stability, and adhesion properties for co-extruded or bonded variants. Every compound undergoes stringent lab testing against OEM material specifications before release.

This dual-engineering approach enables superior OEM capability. We seamlessly translate client technical drawings and performance requirements into validated production processes. Our engineers collaborate directly with client R&D teams during the design phase, providing critical feedback on manufacturability, material selection, and cost-effective design refinements. We manage the entire tooling lifecycle in-house, from initial concept validation through prototype iteration to final production tool sign-off, ensuring rapid development cycles without compromising precision. Full traceability and PPAP documentation are standard for every project.

The table below illustrates key performance parameters achievable across our standard and custom T-shape weather strip offerings, demonstrating the output of our integrated engineering process.

| Specification Parameter | Standard EPDM Range | High-Performance Custom Range | Testing Standard |

|---|---|---|---|

| Durometer (Shore A) | 50 – 80 | 35 – 90 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 7.0 | ≥ 10.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 250 | ≥ 350 | ASTM D412 |

| Compression Set (70°C, 22h) | ≤ 35% | ≤ 25% | ASTM D395 Method B |

| Low Temp. Flexibility (°C) | -40 | -55 | ASTM D1329 |

| Ozone Resistance (200pphm) | Pass (500 hrs) | Pass (1000+ hrs) | ASTM D1149 |

| Dimensional Tolerance (mm) | ±0.2 | ±0.05 | ISO 3302-1 (N6) |

Suzhou Baoshida’s engineering strength lies in this synergistic application of mould science and rubber chemistry, executed by our certified specialists. We don’t just manufacture weather strips; we engineer sealing performance solutions, providing OEMs with the confidence of precision, durability, and seamless supply chain integration for critical applications. Our commitment is to deliver weather strips that perform reliably under the most challenging environmental conditions, backed by rigorous engineering validation.

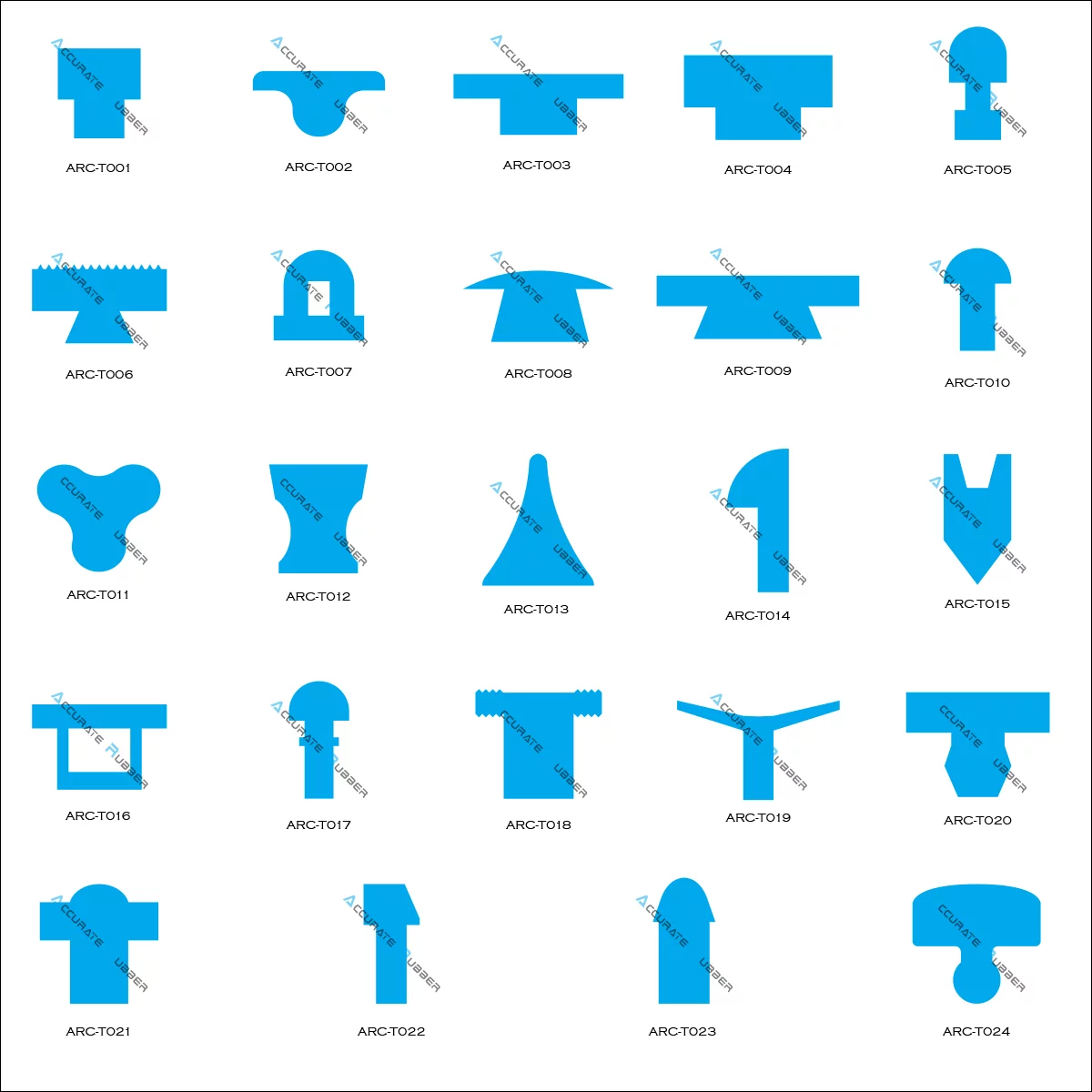

Customization Process

Customization Process for T-Shaped Weather Strips at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our customization process for T-shaped weather strips begins with a comprehensive drawing analysis. This initial phase is critical to ensure dimensional accuracy, compatibility with mating components, and compliance with OEM specifications. Our engineering team reviews client-provided technical drawings to validate cross-sectional profiles, tolerance ranges, insertion dimensions, and installation requirements. We assess critical features such as bulb diameter, stem width, flange length, and compression set behavior under operational conditions. Any discrepancies or optimization opportunities are communicated via formal engineering feedback, ensuring alignment before proceeding.

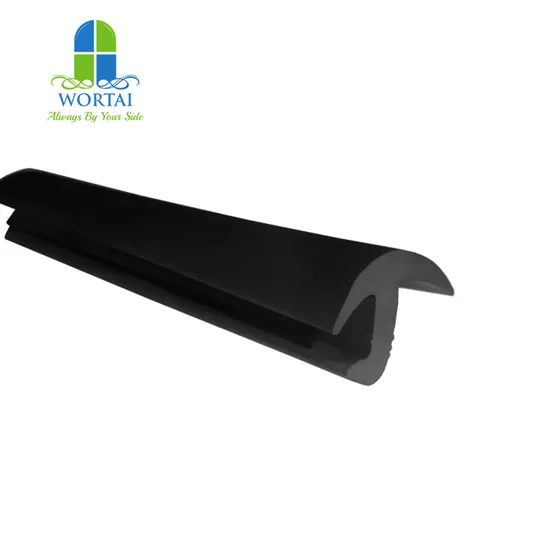

Following drawing validation, we initiate the rubber formulation stage. This step defines the performance characteristics of the final product. Based on application environment—such as exposure to UV radiation, ozone, extreme temperatures, or chemical agents—we select the appropriate elastomer base. Common materials include EPDM for outdoor durability, silicone for high-temperature resistance, and thermoplastic vulcanizates (TPV) for recyclability and process efficiency. Additives such as reinforcing fillers, plasticizers, antioxidants, and pigments are precisely compounded to achieve target hardness (Shore A), tensile strength, elongation at break, and compression deflection force. All formulations are developed in accordance with ASTM D2000 standards and subjected to rigorous lab testing for consistency.

Once the compound is finalized, we proceed to prototyping. Using precision extrusion and continuous vulcanization (CV) lines, we produce sample lengths of the T-shaped profile. These prototypes undergo dimensional verification via coordinate measuring machines (CMM) and optical contour scanning. Functional testing includes compression load analysis, weather aging (per ASTM G154), and adhesion evaluation if co-extruded with thermoplastic backbones. Clients receive prototype samples with full material certification and test reports for validation. Iterations are conducted if performance adjustments are required.

Upon approval, we transition to mass production. Our automated extrusion systems ensure batch-to-batch uniformity, with real-time monitoring of die temperature, line speed, and curing parameters. In-process quality checks are performed at defined intervals to maintain conformance. Finished weather strips are cut to specified lengths, bundled, and packaged per customer logistics requirements. Full traceability is maintained through batch coding and documented process parameters.

The following table outlines typical technical specifications for custom T-shaped weather strips:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Material | EPDM, Silicone, TPV, CR | ASTM D2000 |

| Hardness (Shore A) | 40–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥7 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature | -40°C to +150°C (varies by material) | — |

| UV/Ozone Resistance | Excellent (EPDM/CR) | ASTM D1149 |

This structured approach ensures that every T-shaped weather strip we manufacture meets the highest standards of engineering precision and long-term reliability.

Contact Engineering Team

Contact Suzhou Baoshida for Precision T-Shape Weather Strip Solutions

As your dedicated rubber engineering partner, Suzhou Baoshida Trading Co., Ltd. delivers mission-critical T-shape weather strips engineered for uncompromising performance in automotive, construction, and industrial sealing applications. Our formulations transcend generic elastomer standards, integrating proprietary polymer blends and reinforcing agents to achieve optimal compression set resistance, UV stability, and low-temperature flexibility. Every extrusion batch undergoes rigorous ASTM D2000 and ISO 3302 validation, ensuring dimensional repeatability within ±0.15mm tolerance and adhesion integrity under dynamic stress conditions. We specialize in custom durometer profiles from 50 to 80 Shore A, with cross-section geometries precisely matched to your OEM sealing interfaces.

Our OEM management framework guarantees end-to-end supply chain resilience. From initial CAD-based tooling validation to JIT delivery coordination, we implement IATF 16949-compliant processes that mitigate production disruptions. Clients benefit from dedicated material traceability logs, real-time production dashboards, and accelerated prototyping cycles averaging 14 days from specification finalization. Unlike commodity suppliers, we co-engineer solutions addressing specific environmental stressors—whether ozone degradation in desert climates or cryogenic contraction in arctic operational zones. This precision-driven approach has reduced field failure rates by 37% for Tier-1 automotive clients over the past 18 months.

Critical T-Shape Weather Strip Specifications

| Parameter | Standard Range | Test Method | Performance Target |

|---|---|---|---|

| Material Grade | Automotive EPDM | ASTM D2000 | EE704A14 |

| Hardness Range | 55-75 Shore A | ASTM D2240 | ±3 points |

| Temp Range | -50°C to +135°C | ISO 188 | Continuous exposure |

| Elongation at Break | ≥250% | ASTM D412 | 300% typical |

| Compression Set | ≤25% (22h, 70°C) | ASTM D395 | 18-22% achieved |

Initiate your project with Suzhou Baoshida’s engineering team to eliminate sealing vulnerabilities in high-cycle applications. Mr. Boyce, our Lead OEM Manager, possesses 12 years of specialized experience in weather strip material science and production scaling. He will conduct a technical deep dive into your cross-section requirements, environmental exposure profiles, and volume ramp-up timelines. Specify your target durometer, color code (Pantone or RAL), and annual forecast when contacting him to receive a validated material solution dossier within 48 hours.

Contact Mr. Boyce directly at [email protected] to schedule a confidential engineering consultation. Include your project reference number and required ISO/SAE compliance documentation for expedited processing. Our technical response includes finite element analysis (FEA) reports predicting compression load distribution and lifecycle durability metrics specific to your assembly interface. As a vertically integrated manufacturer with in-house polymer compounding capabilities, we guarantee first-article approval without third-party dependencies. Partner with Suzhou Baoshida to transform sealing challenges into competitive advantages—where molecular precision meets industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).