Technical Contents

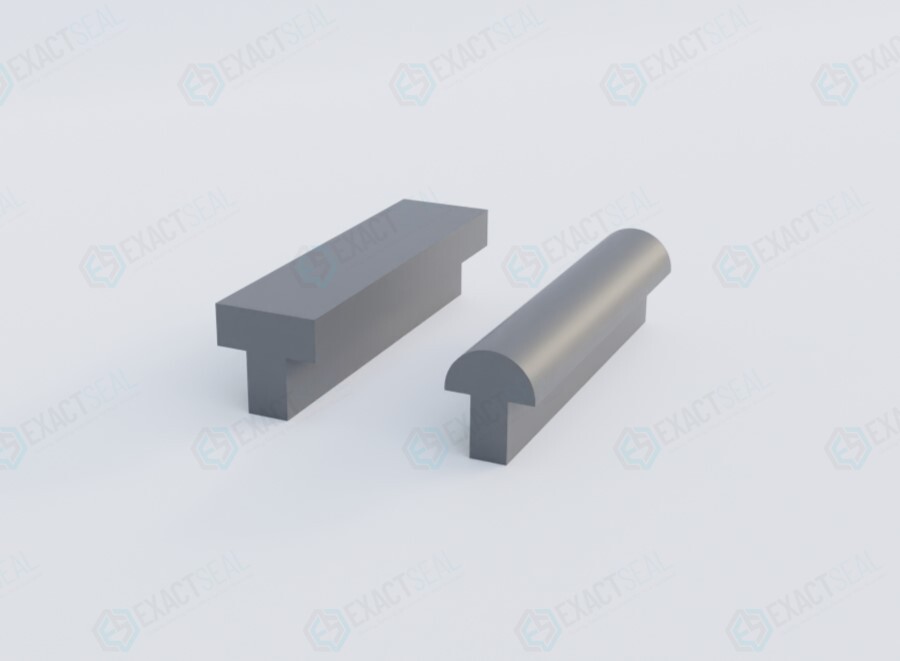

Engineering Guide: T Shaped Rubber Gasket

Engineering Insight: T-Shaped Rubber Gasket – The Critical Role of Material Selection

In precision sealing applications, the T-shaped rubber gasket serves as a critical interface between mating components, ensuring leak-free performance under dynamic mechanical and environmental conditions. While its geometry provides inherent advantages—such as self-centering and resistance to lateral displacement—the long-term reliability of a T-shaped gasket is fundamentally determined by material selection. Off-the-shelf rubber gaskets, often marketed as universal solutions, frequently fail in demanding industrial environments due to mismatched elastomer properties. These failures manifest as compression set, chemical degradation, thermal expansion mismatch, or extrusion under pressure—issues that are preventable through engineered material specification.

The T-shape design introduces unique stress distribution characteristics. The crossbar of the “T” is subjected to compressive loading during installation, while the stem must maintain elastic recovery and dimensional stability. Standard gaskets, typically fabricated from generic NBR or EPDM compounds, may initially appear cost-effective but lack the tailored performance required for sustained sealing integrity. For example, in high-temperature hydraulic systems, off-the-shelf NBR gaskets degrade rapidly above 100°C, leading to hardening and loss of sealing force. Similarly, in ozone-rich environments, non-formulated SBR-based gaskets exhibit surface cracking due to poor weather resistance.

Material selection must align with operational parameters: temperature range, fluid compatibility, pressure load, and dynamic movement. At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific elastomer engineering. Fluorocarbon (FKM) compounds deliver superior resistance to oils, fuels, and elevated temperatures up to 250°C, making them ideal for automotive and aerospace applications. For aqueous and steam environments, peroxide-cured EPDM offers extended service life and resilience. In food and pharmaceutical systems, silicone (VMQ) meets FDA and USP Class VI requirements while maintaining flexibility across a wide thermal range.

A standardized approach to material properties ensures consistency and performance predictability. The table below outlines key elastomer characteristics relevant to T-shaped gasket applications.

| Material | Temperature Range (°C) | Hardness (Shore A) | Key Chemical Resistance | Typical Applications |

|---|---|---|---|---|

| NBR | -30 to +100 | 60–90 | Oils, fuels, water | General industrial, hydraulics |

| EPDM | -50 to +150 | 50–80 | Steam, water, alkalis | HVAC, automotive cooling |

| FKM | -20 to +250 | 65–90 | Fuels, acids, oils | Aerospace, chemical processing |

| VMQ | -60 to +200 | 40–80 | Water, oxygen, UV | Medical, food processing |

| CR | -30 to +100 | 50–75 | Ozone, weathering | Outdoor electrical enclosures |

Selecting the correct material is not a secondary consideration—it is the foundation of sealing performance. Generic gaskets compromise system reliability, increase maintenance frequency, and elevate total cost of ownership. At Suzhou Baoshida, we integrate material science with precision molding to deliver T-shaped gaskets engineered for exact operational demands, ensuring optimal performance, longevity, and safety in critical sealing applications.

Material Specifications

Material Specifications for T-Shaped Rubber Gaskets

Precision-engineered T-shaped rubber gaskets require meticulous material selection to ensure optimal sealing performance under dynamic operational stresses. The T-profile geometry—featuring a stem for compression and a head for load distribution—demands elastomers with balanced tensile strength, resilience, and resistance to extrusion. At Suzhou Baoshida Trading Co., Ltd., we rigorously qualify Viton (FKM), Nitrile (NBR), and Silicone (VMQ) formulations against ASTM D2000 and ISO 3601 standards for critical industrial applications. Material choice directly impacts compatibility with media, temperature stability, and service life, particularly in high-pressure or chemically aggressive environments where seal integrity is non-negotiable.

Viton (FKM)

Viton excels in extreme chemical resistance, maintaining integrity against fuels, acids, chlorinated hydrocarbons, and high-temperature steam up to 230°C continuous exposure. Its low compression set (≤20% per ASTM D395 at 200°C/70h) ensures long-term sealing force retention in aerospace and chemical processing systems. Standard hardness ranges from 60 to 90 Shore A, with tensile strength of 15–20 MPa. While premium-priced, Viton’s thermal stability up to 300°C intermittent makes it indispensable for critical OEM applications where failure is unacceptable.

Nitrile (NBR)

Nitrile remains the industrial standard for cost-effective resistance to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. Operating effectively from -40°C to 120°C (short-term to 150°C), it offers robust tensile strength (10–25 MPa) and elongation (200–500%). Hardness spans 40–90 Shore A, allowing customization for dynamic or static seals. Its moderate compression set (25–35% at 100°C/70h) suits automotive and machinery applications, though it degrades in ozone, ketones, and brake fluids. NBR’s balance of performance and economy drives >60% of T-gasket deployments in general manufacturing.

Silicone (VMQ)

Silicone provides unparalleled temperature resilience from -60°C to 200°C continuous, with brief excursions to 230°C. It exhibits excellent resistance to ozone, UV, and water vapor but limited oil/fuel compatibility. With tensile strength of 6–10 MPa and elongation exceeding 400%, it accommodates significant thermal cycling. Hardness typically ranges 30–80 Shore A. Low compression set (15–25% at 150°C/70h) and FDA compliance make it ideal for food processing, medical devices, and extreme-climate electronics.

The following comparative analysis details critical performance parameters for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -40 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 6–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 400–700 |

| Hardness Range (Shore A) | 60–90 | 40–90 | 30–80 |

| Compression Set (%)* | ≤20 | 25–35 | 15–25 |

| Key Chemical Resistance | Acids, fuels, steam | Petroleum oils, water | Ozone, water, steam |

| Limitations | Cost, poor brake fluid resistance | Poor ketone/aromatic resistance | Poor oil/fuel resistance |

*ASTM D395, 22h at max service temperature

Material selection for T-shaped gaskets must align with specific application stressors. Suzhou Baoshida Trading Co., Ltd. leverages OEM engineering partnerships to validate material suitability through accelerated aging, fluid immersion, and compression stress relaxation testing. Our technical team provides full formulation traceability and batch-specific certification to ensure compliance with ISO 9001 and IATF 16949 standards, guaranteeing dimensional stability and leak-free performance in your critical sealing interfaces.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in precision rubber seal manufacturing. Specializing in complex profiles such as the T-shaped rubber gasket, we combine advanced material science with precision tooling to deliver consistently reliable sealing solutions for industrial OEMs. Our team comprises five dedicated mould engineers and two full-time rubber formulation engineers, enabling vertical integration from concept to production. This internal expertise ensures rapid prototyping, tight tolerance control, and long-term performance validation under real-world operating conditions.

Our mould engineers utilize 3D CAD/CAM software and CNC precision machining to develop high-accuracy steel or aluminum tooling tailored to the geometric demands of T-shaped gaskets. These gaskets require balanced cross-sectional symmetry and consistent leg thickness to ensure uniform compression and sealing force distribution. Our in-house tooling process allows for iterative design validation, minimizing lead time and eliminating dependency on external toolmakers. Each mould is subject to dimensional inspection and flow analysis to optimize material fill and reduce flash, ensuring high yield rates during high-volume production.

Complementing our tooling strength is our rubber formulation capability. Our two formula engineers specialize in custom elastomer development, focusing on performance attributes such as compression set resistance, temperature stability, and chemical compatibility. For T-shaped gaskets used in dynamic or harsh environments—such as automotive cooling systems, industrial pumps, or HVAC units—we formulate compounds based on EPDM, NBR, silicone, and FKM to meet specific OEM requirements. Each formulation undergoes rigorous testing for tensile strength, elongation, hardness, and aging resistance per ASTM and ISO standards.

We operate as a full-service OEM partner, providing end-to-end support from initial design consultation to serial production and quality documentation. Our facility supports small-batch prototyping and scalable manufacturing, accommodating both domestic and international supply chain needs. With ISO 9001-certified processes and real-time process monitoring, we maintain batch traceability and consistent part quality across production runs.

The following table outlines typical technical specifications for our standard T-shaped rubber gaskets:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Cross-sectional Diameter | 3.0 mm – 12.0 mm | ISO 3302 |

| Hardness (Shore A) | 50 – 80 ±5 | ASTM D2240 |

| Tensile Strength | ≥7 MPa (NBR/EPDM) | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Compression Set (70°C, 22h) | ≤25% | ASTM D395 |

| Temperature Range | -40°C to +150°C (varies by material) | Material Specific |

| Tolerance (Dimensional) | ±0.15 mm (critical dimensions) | ISO 3302-1 |

Our engineering-first approach ensures that every T-shaped rubber gasket meets the functional and environmental demands of modern industrial applications. By integrating material science with precision manufacturing, Suzhou Baoshida delivers OEM-grade performance with supply chain efficiency.

Customization Process

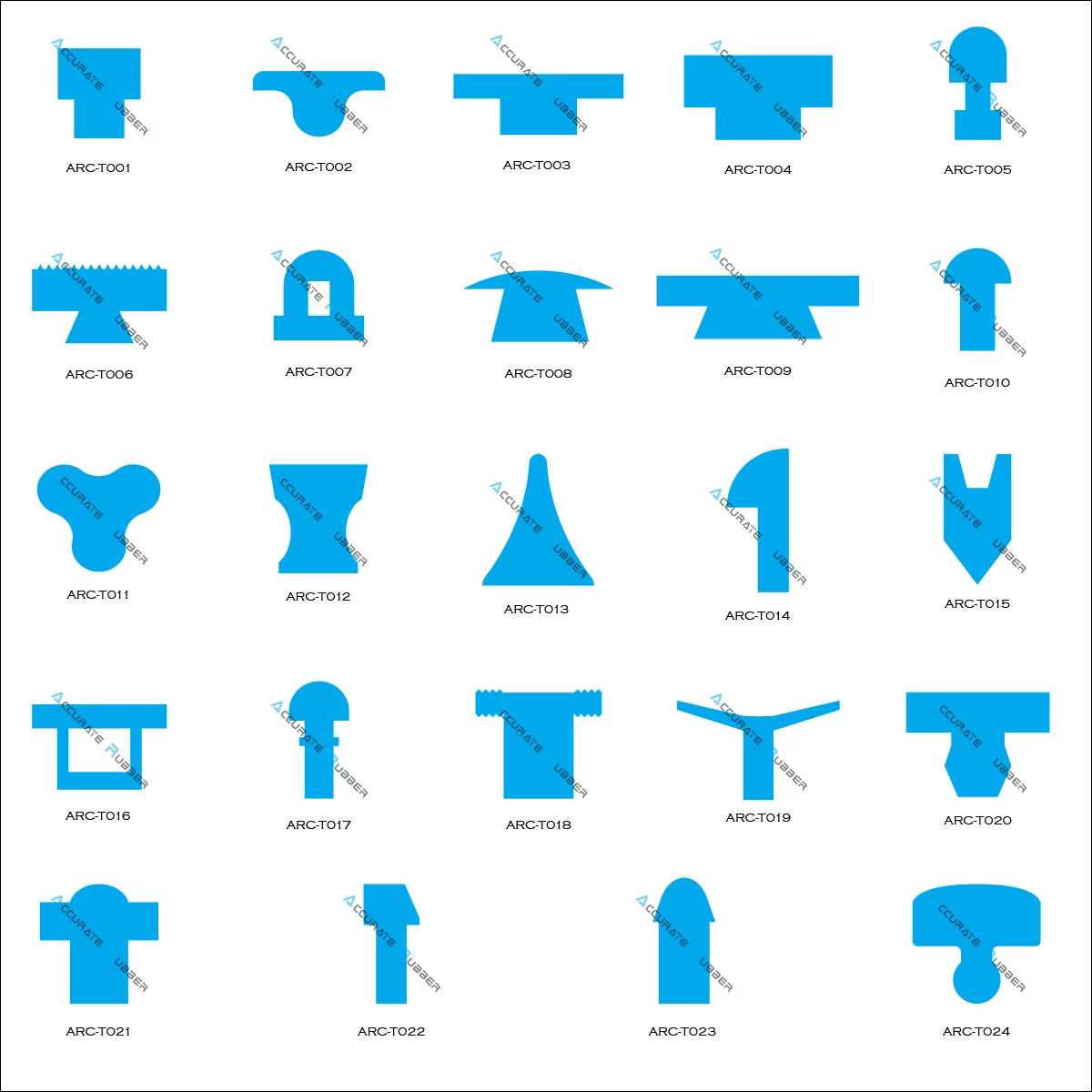

T-Shaped Rubber Gasket Customization Process: Precision Engineering from Concept to Volume Supply

At Suzhou Baoshida Trading Co., Ltd., our T-shaped rubber gasket customization follows a rigorously controlled four-stage workflow, ensuring dimensional accuracy, material integrity, and functional reliability for demanding industrial applications. This process leverages our ISO 9001:2015 certified systems and 15+ years of OEM partnership experience in precision rubber seals.

Drawing Analysis initiates every project. Our engineering team conducts a comprehensive GD&T (Geometric Dimensioning and Tolerancing) review of client-provided CAD files or technical drawings, focusing on critical features inherent to T-shaped profiles: cross-section symmetry, leg depth consistency, and sealing surface radii. We validate draft angles for mold release feasibility, identify potential undercuts risking flash formation, and assess tolerances against ISO 3302-1 E2 extrusion standards. Material compatibility notes and environmental exposure requirements are cross-referenced against our proprietary polymer database. This phase concludes with a formal Design for Manufacturability (DFM) report, highlighting actionable recommendations to optimize performance and yield.

Formulation Development is executed by our in-house rubber chemists. Based on application-specific demands—such as fluid media (hydraulic oil, coolant, refrigerant), temperature range (-50°C to +150°C), and compression set resistance—we select base polymers (NBR, EPDM, FKM, or specialty blends) and engineer compound recipes. Critical parameters like Shore A hardness, tensile strength, and elongation at break are precisely targeted. Each formulation undergoes accelerated aging tests per ASTM D2000 and fluid immersion validation to guarantee long-term sealing integrity. Material certifications (e.g., FDA, NSF, UL) are integrated as required.

Prototyping & Validation utilizes CNC-machined prototype molds for rapid iteration. We produce 10–15 sample gaskets per iteration, subjected to:

3D optical scanning against nominal CAD geometry (deviation tolerance ≤ ±0.05mm)

Compression set testing per ASTM D395 Method B (target <25% at 100°C/24h)

Functional pressure decay testing under simulated operational conditions

Client feedback on fit, assembly, and initial performance drives refinements until all KPIs are met.

Mass Production commences only after formal client sign-off on prototypes. We deploy multi-cavity production molds with automated feed systems, maintaining extrusion tolerances per ISO 3302-1 E1. Real-time Statistical Process Control (SPC) monitors key variables: cure time, temperature uniformity, and durometer consistency. Every production lot undergoes 100% visual inspection and batch-level physical testing. Traceable documentation, including material COAs and SPC charts, accompanies shipments to ensure full compliance and audit readiness.

Critical Material Specifications for T-Gaskets

| Property | Test Standard | Typical Range (NBR Example) | Target for Critical Seals |

|————————|—————|—————————–|—————————|

| Hardness (Shore A) | ASTM D2240 | 60–90 | 70 ± 5 |

| Tensile Strength | ASTM D412 | ≥10 MPa | ≥14 MPa |

| Elongation at Break | ASTM D412 | ≥200% | ≥250% |

| Compression Set (22h) | ASTM D395 B | ≤35% | ≤22% |

| Fluid Resistance (IRM 903) | ASTM D471 | Volume swell ≤25% | ≤15% |

This systematic approach minimizes time-to-market while ensuring Suzhou Baoshida’s T-gaskets deliver leak-free performance in automotive, HVAC, and industrial machinery applications. All stages incorporate client collaboration, with transparent milestone reporting from engineering kickoff to volume shipment.

Contact Engineering Team

Contact Suzhou Baoshida for Custom T-Shaped Rubber Gaskets

Suzhou Baoshida Trading Co., Ltd. is a trusted OEM partner in the precision rubber seals industry, delivering high-performance T-shaped rubber gaskets tailored to exact industrial specifications. Our engineering team combines advanced material science with rigorous quality control to produce seals that ensure leak-proof performance in demanding environments. Whether you require gaskets for hydraulic systems, pneumatic equipment, or industrial enclosures, our T-shaped profiles offer superior sealing efficiency, dimensional stability, and long-term durability.

We specialize in custom formulation and precision molding of T-shaped rubber gaskets using a wide range of elastomers, including NBR, EPDM, silicone, FKM (Viton), and neoprene. Each product is manufactured under ISO 9001-certified processes, ensuring consistency, repeatability, and compliance with international standards. Our in-house testing laboratory validates compression set, tensile strength, hardness, and fluid resistance to guarantee performance under operational stress.

For engineers and procurement managers seeking a reliable supply chain partner, Suzhou Baoshida offers end-to-end support—from material selection and prototype development to volume production and global logistics. We understand that every application presents unique challenges, whether it’s extreme temperature exposure, chemical resistance, or dynamic mechanical loads. Our technical team collaborates directly with clients to optimize gasket design, material compatibility, and cost-efficiency without compromising performance.

To initiate a technical consultation or request a quotation, contact Mr. Boyce, OEM Manager, directly at [email protected]. Mr. Boyce brings over 12 years of experience in rubber component manufacturing and serves as the primary liaison for international clients requiring customized sealing solutions. He will coordinate your technical inquiry, provide material data sheets, and facilitate sample delivery within 7–10 business days.

Below are standard specifications for our T-shaped rubber gaskets. Custom dimensions and materials are available upon request.

| Parameter | Standard Options |

|---|---|

| Cross-Section Shape | T-shaped (symmetrical and asymmetrical profiles) |

| Material Types | NBR, EPDM, Silicone, FKM, Neoprene, CR |

| Hardness Range (Shore A) | 40° to 90° |

| Temperature Resistance | -40°C to +230°C (depending on material) |

| Standard Lengths | Cut lengths, continuous rings, coiled strips |

| Tolerance (ISO 3302) | Rubber Class M2 or tighter upon request |

| Color Options | Black, red, green, blue, custom color matching |

| Certifications | ISO 9001, RoHS, FDA (for silicone upon request) |

Partnering with Suzhou Baoshida means gaining access to precision-engineered rubber components backed by responsive technical support and scalable manufacturing capacity. We serve industries including automotive, aerospace, medical devices, and industrial automation, where reliability is non-negotiable.

For immediate assistance with your T-shaped rubber gasket requirements, email Mr. Boyce at [email protected]. Include your technical drawings, material specifications, and volume expectations to accelerate the quoting process. We respond to all inquiries within 24 business hours.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).