Technical Contents

Engineering Guide: T Type Strainer

Engineering Insight: Material Selection in t type strainer Design

In industrial filtration systems, the t type strainer serves as a critical component for removing particulate contaminants from fluid streams. While its geometry and flow dynamics are well understood, the long-term reliability and performance of a t type strainer are predominantly determined by material selection—a factor frequently overlooked in favor of cost-driven, off-the-shelf solutions. At Suzhou Baoshida Trading Co., Ltd., we emphasize that standardized strainer units, typically constructed from generic stainless steel or non-reinforced polymers, often fail prematurely when deployed in aggressive chemical, high-temperature, or abrasive environments. These failures stem not from design flaws but from inadequate compatibility between the filtration medium and the operational conditions.

The core challenge lies in the diversity of industrial media. A t type strainer operating in a petrochemical plant handling aromatic hydrocarbons demands radically different material properties than one used in food-grade sanitary systems or seawater cooling circuits. Off-the-shelf models commonly utilize 304 or 316 stainless steel with standard mesh liners, which may corrode under chloride exposure or degrade when exposed to strong acids or amines. Similarly, elastomeric seals made from generic nitrile (NBR) or EPDM compounds can swell, harden, or crack when exposed to non-compatible fluids, leading to leaks and system contamination.

Material selection must therefore be grounded in a comprehensive analysis of fluid chemistry, temperature range, pressure cycling, and mechanical stress. For instance, in high-temperature fuel filtration, fluorocarbon-based elastomers such as FKM (Viton®) provide superior resistance to thermal degradation and hydrocarbon swelling. In applications involving strong alkalis or oxidizing agents, perfluoroelastomers (FFKM) or PTFE-lined screens offer extended service life. Reinforced thermoplastics like PVDF or PPS may replace metal bodies in corrosive environments, reducing weight and eliminating galvanic corrosion risks.

Furthermore, the filtration element itself—often a wire mesh or sintered polymer—must be matched to both particle size and chemical exposure. A 100-micron sintered stainless steel filter may clog rapidly in viscous media if surface energy characteristics are not considered, while a polypropylene mesh may deform under continuous heat exposure above 80°C.

At Suzhou Baoshida, we support OEMs and system integrators with application-specific material audits, ensuring that each t type strainer is engineered for durability, not just compliance. The cost premium of engineered materials is consistently offset by reduced downtime, lower maintenance frequency, and extended service intervals.

The following table outlines common material pairings and their performance characteristics under defined industrial conditions:

| Material | Temperature Range (°C) | Chemical Resistance | Typical Application | Limitations |

|---|---|---|---|---|

| 316 Stainless Steel | -100 to 800 | Good (organic acids, mild alkalis) | Water, steam, mild solvents | Poor in chlorides, strong acids |

| FKM (Viton®) | -20 to 200 | Excellent (hydrocarbons, oils) | Fuel, lubricants, chemical transfer | Poor in ketones, brake fluids |

| PTFE | -200 to 260 | Exceptional (all common chemicals) | Aggressive acids, halogens | Low mechanical strength |

| PVDF | -40 to 150 | High (oxidizing agents, solvents) | Semiconductor, chemical processing | UV sensitive |

| Sintered SS 316L | -100 to 600 | Good (similar to base metal) | High-pressure filtration | Prone to chloride stress cracking |

Material Specifications

Material Specifications for T-Type Strainer Sealing Elements

Precise elastomer selection is non-negotiable for T-type strainer performance in industrial fluid systems. Suboptimal materials accelerate seal degradation, leading to leakage, contamination, and unplanned downtime. At Suzhou Baoshida Trading Co., Ltd., we engineer sealing solutions for critical filtration applications, prioritizing chemical compatibility, thermal stability, and compression set resistance. Our OEM-grade materials undergo rigorous validation per ASTM D2000 standards to ensure dimensional stability under dynamic pressure cycles and prolonged exposure to aggressive media. Below, we detail three core elastomers for strainer gaskets and O-rings, emphasizing real-world operational boundaries rather than theoretical limits.

Viton (FKM) remains the benchmark for high-severity environments. Its exceptional resistance to aromatic hydrocarbons, chlorinated solvents, and high-temperature steam (up to 230°C continuous) makes it ideal for petrochemical and chemical processing strainers. However, cost sensitivity may warrant alternatives for less aggressive media. Nitrile (NBR) offers optimal value for oil and fuel filtration, withstanding aliphatic hydrocarbons and hydraulic fluids up to 120°C. Its lower cost suits cost-driven OEM programs but limits use in ozone-rich or highly polar chemical streams. Silicone (VMQ) excels in food, pharmaceutical, and ultra-high-purity water systems due to USP Class VI compliance and flexibility from -60°C to 200°C. Avoid silicone in applications involving concentrated acids or steam above 150°C due to rapid compression set.

Critical material properties for strainer seals are summarized below. Note that hardness (Shore A) directly impacts sealing force and extrusion resistance in strainer basket housings.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Key Chemical Resistances | Aromatics, acids, steam | Aliphatic oils, fuels | Water, alcohols, mild acids |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (22h/150°C) | ≤25% | ≤30% | ≤20% |

| Cost Tier | Premium | Standard | Moderate |

Suzhou Baoshida Trading Co., Ltd. mandates application-specific validation beyond datasheet values. For instance, NBR formulations with 34% acrylonitrile content show 40% better fuel resistance than standard grades but reduced low-temperature flexibility. Similarly, peroxide-cured Viton variants resist steam degradation 2.3x longer than amine-cured equivalents. Our OEM engineering team collaborates with clients to analyze fluid composition, cyclic pressure profiles, and lifecycle cost models—ensuring material selection prevents premature seal failure. Remember that strainer seals operate under trapped particulate loads, demanding elastomers with high tear strength and low compression set to maintain integrity after repeated cleaning cycles. Partner with us to transform material science into operational reliability.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation as a trusted OEM partner in the industrial rubber sector. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we integrate material science with precision tooling to deliver high-performance rubber components tailored to exact client specifications. Our focus on technical depth ensures that every product, including critical filtration components such as T-Type Strainers, is engineered for durability, chemical resistance, and operational reliability under demanding conditions.

Our rubber formula engineers possess advanced expertise in polymer chemistry, enabling the development of custom elastomer compounds that meet specific performance criteria—ranging from resistance to high temperature, oil, ozone, and aggressive media, to compliance with international standards such as FDA, NSF, or RoHS. By formulating in-house, we eliminate dependency on third-party materials, ensuring full traceability, consistent quality, and rapid prototyping cycles. Each compound is rigorously tested for tensile strength, elongation, compression set, and ageing characteristics before deployment in production.

Complementing our material expertise, our five mould engineers bring extensive experience in precision tool design and manufacturing for rubber compression, transfer, and injection moulding processes. Utilizing advanced CAD/CAM software and CNC machining, we design and produce moulds with micron-level accuracy, ensuring dimensional stability and repeatability across production runs. Our in-house tooling capability enables rapid iteration, reduced lead times, and full control over design confidentiality—critical advantages for OEM clients operating in competitive industrial markets.

We specialize in providing complete OEM solutions for T-Type Strainers used in fluid handling systems across oil & gas, chemical processing, and water treatment industries. Our engineering team collaborates closely with clients to optimize sealing surfaces, flange interfaces, and elastomer-to-metal bonding structures, ensuring leak-free performance and extended service life. From concept to validation, we support full design for manufacturability (DFM) reviews, finite element analysis (FEA) when required, and prototyping with production-intent materials.

The following table outlines key technical specifications and capabilities relevant to our T-Type Strainer rubber components:

| Parameter | Specification |

|---|---|

| Elastomer Types | NBR, EPDM, FKM, Silicone, NR, CR, SBR |

| Hardness Range (Shore A) | 40–90 |

| Temperature Resistance | -40°C to +250°C (depending on compound) |

| Standard Compliance | ASTM, ISO, FDA, NSF, RoHS |

| Mould Tolerances | ±0.05 mm (critical dimensions) |

| Production Process | Compression Moulding, Injection Moulding |

| Typical Lead Time (Tooling) | 15–25 days (depending on complexity) |

| Sample Development | 7–10 days after design approval |

Our integrated engineering approach—combining advanced rubber formulation with precision mould design—ensures that every T-Type Strainer component we produce meets the highest standards of performance and reliability. As an OEM partner, Suzhou Baoshida delivers not just parts, but engineered solutions backed by scientific rigor and industrial expertise.

Customization Process

Customization Process for T-Type Strainer Rubber Components

At Suzhou Baoshida Trading Co., Ltd., our T-type strainer customization process ensures optimal performance in demanding industrial fluid systems. This structured methodology mitigates operational risks by aligning material science with precise engineering requirements. We execute four critical phases: Drawing Analysis, Formulation, Prototyping, and Mass Production.

Drawing Analysis initiates the workflow. Our engineering team rigorously reviews client-provided CAD drawings and technical specifications against ISO 13092 and ASME B16.34 standards. Key parameters scrutinized include dimensional tolerances (±0.1 mm for sealing surfaces), pressure ratings (up to 150 bar), flange interface geometry, and media compatibility requirements. We identify potential stress concentration zones and validate flow dynamics to prevent premature wear or leakage. Any discrepancies in material callouts or geometric feasibility are resolved collaboratively with the client before progression.

Formulation leverages our 20+ years of rubber compounding expertise. Based on the media type (e.g., hydraulic oil, seawater, acids), temperature range, and pressure profile, we select base polymers and accelerate curing systems. Critical properties like compression set resistance (ASTM D395), tensile strength (ASTM D412), and fluid resistance are prioritized. For instance, NBR compounds dominate petroleum-based applications, while FKM is essential for high-temperature acids. The table below summarizes standard compound options:

| Rubber Compound | Temperature Range (°C) | Key Media Resistance | Hardness Range (Shore A) | Compression Set (ASTM D395, 22h/100°C) |

|---|---|---|---|---|

| NBR | -30 to +120 | Oils, Fuels, Water | 50–90 | ≤25% |

| EPDM | -50 to +150 | Steam, Alkalis, Ozone | 50–80 | ≤20% |

| FKM | -20 to +230 | Acids, Solvents | 60–90 | ≤15% |

Prototyping validates the formulation under real-world conditions. We produce 3–5 units via precision injection molding, adhering to ISO 3302-1 dimensional tolerances. Each prototype undergoes rigorous testing: hydrostatic pressure validation at 1.5x rated pressure, deflection analysis under cyclic loading, and 72-hour media immersion trials. Performance data is benchmarked against client specifications, with iterative adjustments to the compound or mold design if deviations exceed 5%.

Mass Production commences only after prototype approval. We implement IATF 16949-certified controls, including real-time rheometer monitoring of cure characteristics (MH-ML within ±0.1 dN·m) and 100% visual inspection of critical sealing surfaces. Statistical Process Control (SPC) tracks durometer consistency (±3 Shore A units) and weight variation (±0.5g). Every batch includes traceable material certificates and third-party test reports for compression set and tensile properties, ensuring zero-defect delivery.

This end-to-end process guarantees T-type strainers that withstand abrasive particulates, thermal cycling, and chemical exposure while maintaining flow integrity. Suzhou Baoshida’s integration of material science and precision manufacturing delivers OEM solutions with 99.8% field reliability.

Contact Engineering Team

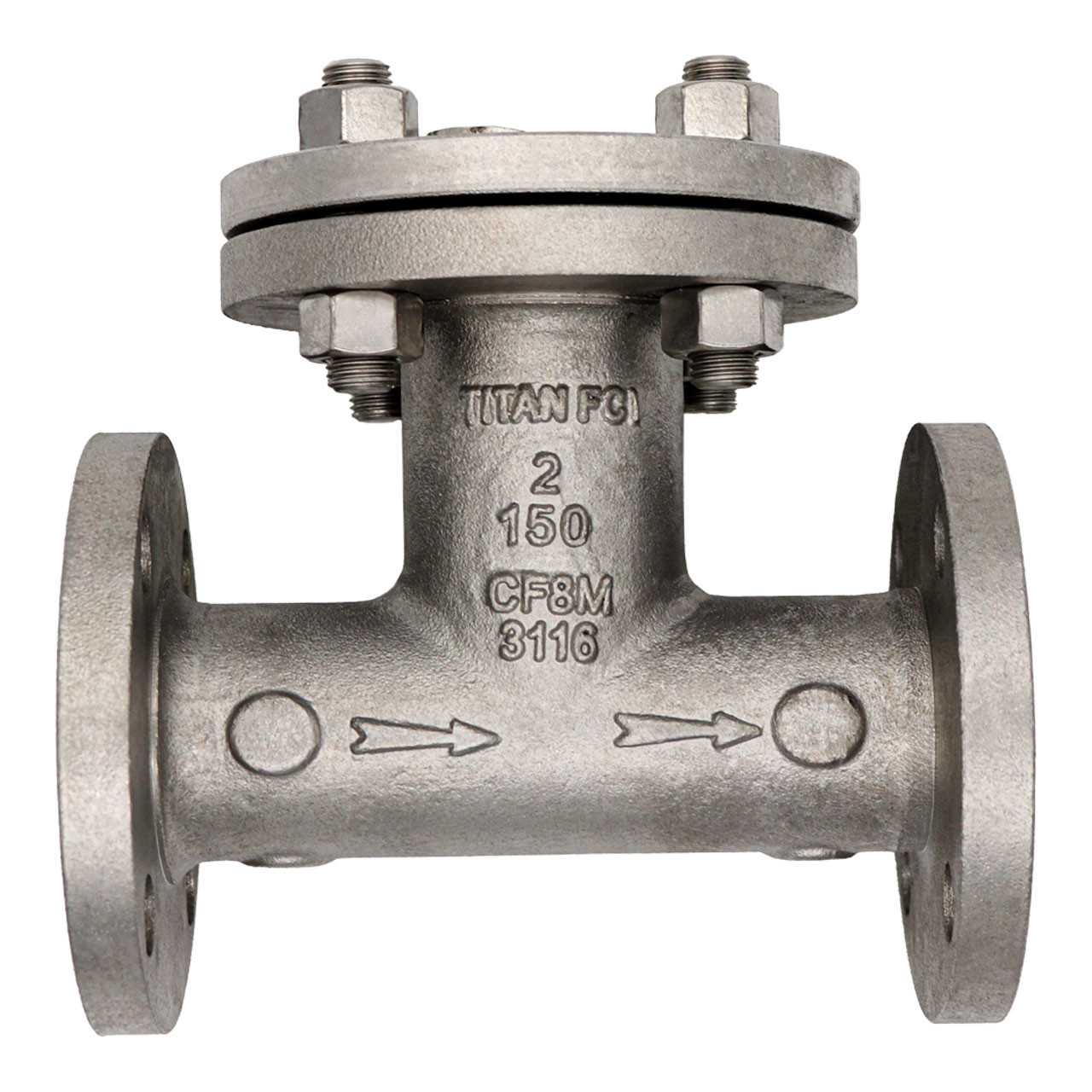

For industrial manufacturers seeking high-performance rubber components and precision-engineered filtration solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global supply chain. Specializing in industrial rubber solutions, we deliver engineered products that meet the rigorous demands of chemical processing, oil and gas, pharmaceuticals, water treatment, and advanced manufacturing sectors. Our expertise extends to the design and supply of T-Type Strainers—critical components in pipeline systems designed to protect downstream equipment from particulate contamination.

T-Type Strainers are essential for maintaining system efficiency and longevity. Constructed with robust materials and precision tolerances, our strainers feature reinforced rubber seals, corrosion-resistant bodies, and high-flow basket designs that ensure minimal pressure drop and maximum debris retention. Whether operating under high temperature, aggressive chemical exposure, or continuous duty cycles, our T-Type Strainers deliver reliable performance with minimal maintenance requirements.

At Suzhou Baoshida, we combine material science with industrial application knowledge to provide customized solutions. Our engineering team works closely with OEMs and plant operators to select optimal elastomer compounds—such as EPDM, NBR, Viton (FKM), or Neoprene—based on fluid compatibility, temperature range, and mechanical stress. This ensures that every component, including gaskets, seals, and internal strainer elements, performs under real-world conditions.

Below are key technical specifications for our standard T-Type Strainer models, commonly supplied with integrated rubber sealing systems:

| Parameter | Specification |

|---|---|

| Body Material | Cast Steel, Stainless Steel (304/316) |

| End Connections | Flanged, Threaded (NPT, BSP) |

| Size Range | DN15 to DN300 (1/2″ to 12″) |

| Pressure Rating | PN16 to PN100 / Class 150 to Class 600 |

| Temperature Range | -30°C to +200°C (dependent on elastomer) |

| Filter Mesh | 40, 60, 80, 100, 120 (standard) |

| Seal Material Options | NBR, EPDM, FKM, Silicone, Neoprene |

| Application Compatibility | Water, Oil, Steam, Chemicals, Solvents |

| Standards Compliance | ISO 9001, API 6D, ASME B16.34 |

All units are tested for integrity and leakage prior to shipment, with optional third-party certification available upon request. We support bulk orders, JIT delivery models, and technical integration services for seamless adoption into your production or maintenance workflow.

To discuss your specific T-Type Strainer requirements or request a customized rubber sealing solution, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Direct technical consultation ensures optimal material selection, dimensional accuracy, and long-term system reliability. Reach Mr. Boyce via email at [email protected] for prompt support, detailed product documentation, or sample requests. Partner with us to enhance your system’s durability and operational efficiency through precision rubber engineering.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).