Technical Contents

Engineering Guide: Teflon Backup Rings

Engineering Insight: Teflon Backup Rings

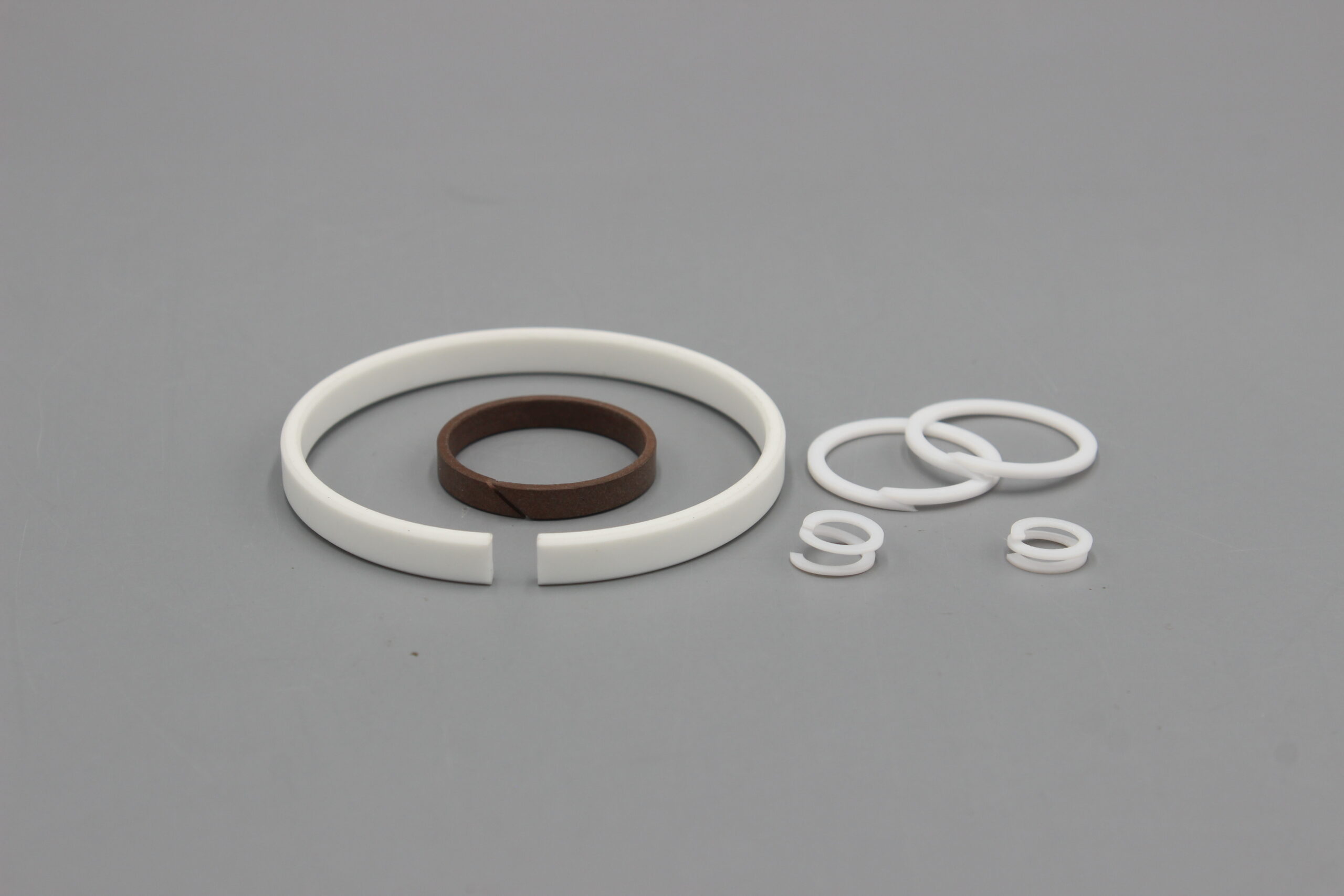

Backup rings serve as critical mechanical barriers in dynamic sealing systems, preventing primary elastomeric seals from extruding into clearance gaps under high pressure. While often perceived as simple spacers, their material composition directly dictates system integrity. Off-the-shelf Teflon (PTFE) backup rings frequently fail due to inadequate material engineering for specific operational profiles. Generic solutions prioritize cost over precision, neglecting the interplay between thermal dynamics, chemical exposure, and mechanical stress. This oversight manifests as premature extrusion, spiral failure, or catastrophic seal blowout—especially in applications exceeding 35 MPa or involving aggressive media like aviation hydraulic fluids or sour gas.

Material selection must address three non-negotiable factors. First, thermal expansion coefficients must align with mating components; mismatched PTFE grades expand 30–50% more than metals under temperature swings, creating dangerous gaps. Second, crystallinity control is essential—low-crystallinity PTFE lacks the creep resistance to withstand sustained pressure, while over-crystallized variants become brittle below −40°C. Third, filler composition determines chemical resilience; unfilled PTFE degrades rapidly in amine-based lubricants, whereas specialized formulations with carbon/graphite retain structural integrity. Generic rings use recycled or inconsistent resin batches, leading to unpredictable porosity and micro-cracking under cyclic loads.

The consequence of suboptimal material choices is systemic. In a documented case involving offshore hydraulic actuators, off-the-shelf backup rings swelled 18% when exposed to biodegradable ester oils, distorting the primary seal geometry and causing 72-hour downtime per failure. Laboratory analysis revealed 40% lower tensile strength versus OEM-specified grades due to uncontrolled sintering temperatures. Such failures underscore why backup rings cannot be treated as commodity items—they are engineered stress-management components.

Critical material properties for high-reliability backup rings are non-negotiable. The table below contrasts OEM-grade specifications against typical generic alternatives:

| Property | OEM Specification (ASTM D4894) | Generic Alternative | Critical Deviation Impact |

|---|---|---|---|

| Density (g/cm³) | 2.16–2.19 | 2.05–2.12 | Porosity >5% accelerates fluid permeation |

| Tensile Strength (MPa) | ≥25.0 | 18.0–22.0 | 25% higher extrusion risk at 40 MPa |

| Elongation at Break (%) | 300–400 | 150–250 | Brittle fracture in dynamic cycling |

| Hardness (Shore D) | 55–65 | 45–55 | Inadequate support against seal extrusion |

Suzhou Baoshida Trading Co., Ltd. engineers backup rings using virgin PTFE resins with proprietary filler matrices, validated through ISO 3601 groove clearance simulations. Each formulation undergoes pressure-temperature cycling tests replicating 10,000+ operational hours. This precision eliminates the “one-size-fits-all” compromise, ensuring backup rings function as designed pressure containment elements—not failure initiators. For mission-critical applications, collaborative engineering engagement with seal manufacturers is imperative to align material science with real-world physics. Generic alternatives sacrifice longevity for upfront savings; engineered solutions deliver lifecycle cost reduction through zero unplanned downtime.

Material Specifications

Material selection for Teflon backup rings is a critical engineering decision that directly influences seal performance, longevity, and system reliability in dynamic and static sealing applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered for industrial environments where temperature extremes, chemical exposure, and mechanical stress are common. While the primary sealing element may be made from elastomeric materials such as Viton, Nitrile, or Silicone, the Teflon backup ring serves a structural role—preventing extrusion of the seal under high pressure and enhancing resistance to spiral failure in reciprocating motion. The elastomer used in conjunction with the backup ring must therefore be carefully matched to operational conditions.

Viton (FKM) is widely regarded as a high-performance elastomer due to its exceptional resistance to heat, oils, fuels, and a broad range of aggressive chemicals. It performs reliably in temperatures ranging from -20°C to +200°C, with short-term exposure tolerance up to +230°C. This makes Viton ideal for demanding applications in aerospace, automotive fuel systems, and chemical processing equipment. Its low compression set and excellent aging characteristics further enhance service life in critical sealing environments.

Nitrile rubber (NBR) offers a cost-effective solution for applications involving petroleum-based oils and hydraulic fluids. With a functional temperature range of -30°C to +100°C, extendable to +120°C for limited durations, Nitrile is commonly used in industrial hydraulics, pneumatic systems, and general mechanical sealing. While not as chemically resistant as Viton, NBR provides superior abrasion resistance and tensile strength, making it suitable for dynamic applications where mechanical wear is a concern.

Silicone rubber (VMQ) excels in extreme temperature environments, operating effectively from -60°C to +200°C. It demonstrates excellent resistance to ozone and UV radiation, making it well-suited for outdoor and high-temperature air sealing applications. However, due to its relatively low mechanical strength and poor resistance to petroleum-based fluids, Silicone is typically selected for non-lubricated or dry-running systems, such as food processing equipment or medical devices, where compliance with sanitary standards is required.

The following table summarizes key material properties for Viton, Nitrile, and Silicone elastomers used in conjunction with Teflon backup rings:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +100 | -60 to +200 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Good (petroleum oils, water) | Poor (oils), Good (water, ozone) |

| Compression Set Resistance | Excellent | Good | Good |

| Tensile Strength (MPa) | 10–15 | 15–20 | 5–8 |

| Abrasion Resistance | Moderate | Excellent | Poor |

| Common Applications | Aerospace, chemical seals, fuel systems | Hydraulics, pneumatic seals, industrial machinery | Medical devices, food processing, outdoor seals |

Selecting the appropriate elastomer ensures optimal synergy between the sealing element and the Teflon backup ring, maximizing system integrity under operational stress.

Manufacturing Capabilities

Engineering Capability: Precision Teflon Backup Ring Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages integrated material science and precision molding expertise to deliver Teflon backup rings that mitigate extrusion gaps and enhance seal longevity in high-pressure industrial systems. Our engineering team comprises five dedicated mold engineers and two specialized rubber formula engineers, ensuring seamless alignment between material composition and geometric execution. This dual-discipline approach eliminates traditional handoffs between R&D and production, directly translating client specifications into functionally optimized components.

Our formula engineers focus on PTFE composite development, optimizing filler ratios (e.g., glass fiber, carbon, or graphite) to balance compressive strength, thermal stability, and chemical resistance. Each formulation undergoes rigorous tribological testing to validate performance under dynamic pressure cycles up to 70 MPa and temperatures spanning -200°C to +260°C. Critical to this process is the elimination of micro-voids through controlled sintering profiles, which prevents fluid permeation and maintains dimensional integrity during installation. Concurrently, mold engineers utilize 3D cavity flow analysis to refine gate placement, venting, and cooling channels. This ensures uniform material density across complex cross-sections, minimizing post-mold trimming and achieving concentricity tolerances of ±0.05 mm.

For OEM partnerships, we implement a closed-loop engineering protocol starting with client application data (pressure profiles, media compatibility, and mating seal dimensions). Our team generates GD&T-compliant prototypes within 15 days using rapid tooling, followed by FEA-simulated stress validation. Clients receive comprehensive material traceability reports, including lot-specific tensile strength, elongation at break, and coefficient of friction metrics. This structured workflow reduces time-to-market by 30% compared to industry benchmarks while ensuring AS9100-compliant documentation for aerospace, oil/gas, and semiconductor applications.

The following table outlines standard Teflon backup ring specifications achievable through our engineered process:

| Parameter | Standard Range | Precision Capability | Test Standard |

|---|---|---|---|

| Inner Diameter (ID) | 10–300 mm | ±0.03 mm | ISO 3601-3 |

| Outer Diameter (OD) | 15–320 mm | ±0.04 mm | ISO 3601-3 |

| Cross-Section Width | 1.5–5.0 mm | ±0.02 mm | ISO 3601-1 |

| Max Pressure | 70 MPa | Validated at 1.5x | ASTM D624 |

| Temp Range | -200°C to +260°C | Continuous exposure | ASTM D1239 |

Backed by in-house material compounding and 12 CNC-controlled molding presses, we guarantee repeatability across volumes from 1,000 to 500,000 units. Suzhou Baoshida’s engineering synergy transforms Teflon backup rings from passive components into engineered system safeguards, directly addressing extrusion risks in critical hydraulic and pneumatic assemblies. Clients benefit from reduced field failures through our physics-based design methodology, where every micron of tolerance and molecular interaction is intentionally controlled.

Customization Process

Customization Process for PTFE Backup Rings at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our engineering-driven approach ensures that every custom PTFE backup ring meets exacting performance standards in demanding industrial environments. Our four-stage customization process—Drawing Analysis, Formulation, Prototyping, and Mass Production—integrates material science with precision manufacturing to deliver seals that enhance system reliability and longevity.

The process begins with Drawing Analysis, where our rubber formula engineers conduct a comprehensive review of the customer’s technical drawings and operational requirements. We evaluate critical dimensions, groove compatibility, axial and radial clearance, and installation conditions. This stage also includes an assessment of the mating seal (typically an elastomeric O-ring or hydraulic seal) to ensure the backup ring effectively prevents extrusion under high pressure. Any dimensional deviations or design risks are flagged, and design-for-manufacturability recommendations are provided to optimize sealing performance and assembly efficiency.

Following drawing validation, the Formulation phase commences. Although PTFE (polytetrafluoroethylene) is inherently chemically inert and thermally stable, we tailor the material compound based on application-specific demands. Additives such as glass fiber, carbon, or graphite may be incorporated to improve compressive strength, reduce cold flow, or enhance thermal conductivity. Our engineers select the optimal PTFE variant—whether virgin, filled, or modified—based on pressure ratings, temperature exposure, media compatibility, and dynamic vs. static application profiles. This stage ensures that the final product maintains dimensional stability and mechanical integrity across its service life.

Once the formulation is finalized, we proceed to Prototyping. Using precision CNC machining or compression molding, depending on geometry and volume requirements, we produce functional prototypes for customer validation. Each prototype undergoes rigorous dimensional inspection via coordinate measuring machines (CMM) and is subjected to simulated operational testing, including pressure cycling and thermal exposure. Feedback from this stage is incorporated into final design adjustments, ensuring full compliance with OEM specifications.

Upon prototype approval, the project transitions to Mass Production. Our automated production lines, operating under ISO 9001-certified quality management systems, ensure consistency and scalability. Every batch is subjected to statistical process control (SPC), with traceability maintained through serialized lot numbering. Final inspection includes visual checks, dimensional sampling, and material verification via FTIR spectroscopy.

The table below outlines key technical specifications we evaluate during customization:

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Material Type | Virgin PTFE, Glass-Filled PTFE, Carbon-Filled PTFE | Graphite, Bronze, or Hybrid Fillers |

| Temperature Resistance | -200°C to +260°C | Enhanced thermal stability with fillers |

| Pressure Resistance | Up to 70 MPa (static) | Higher with reinforced formulations |

| Hardness (Shore D) | 50–65 | Adjustable via filler content |

| Tolerance (per ISO 3302) | ±0.1 mm to ±0.5 mm | Tighter tolerances upon request |

| Surface Finish (Ra) | 0.8–3.2 µm | Polished or textured finishes available |

Through this disciplined, science-based workflow, Suzhou Baoshida delivers PTFE backup rings that exceed industrial performance benchmarks, ensuring optimal sealing system integrity under extreme conditions.

Contact Engineering Team

Precision Engineering for Critical Sealing Applications: Partner with Suzhou Baoshida

Teflon backup rings represent a non-negotiable element in high-integrity sealing systems, particularly where extrusion resistance under extreme pressure differentials is paramount. Standard elastomeric seals alone cannot withstand the mechanical stresses encountered in aerospace hydraulics, subsea oilfield equipment, or semiconductor manufacturing processes. At Suzhou Baoshida Trading Co., Ltd., we engineer PTFE (Polytetrafluoroethylene) backup rings to exacting tolerances, ensuring they function as precision mechanical barriers that prevent seal extrusion while maintaining compatibility with dynamic motion and thermal cycling. Our formulations are rigorously validated through finite element analysis and real-world pressure testing, delivering solutions that extend seal life by up to 300% in demanding operational envelopes.

Material science is foundational to our approach. We utilize virgin-grade PTFE compounded with controlled percentages of fillers such as glass fiber or carbon to enhance compressive strength and reduce cold flow, without compromising chemical inertness. Each component undergoes stringent lot traceability per ASTM D2000 and ISO 3601 standards, with dimensional verification using coordinate measuring machines (CMM) to ±0.05mm tolerances. This precision ensures seamless integration with primary seals—whether O-rings,唇 seals, or piston packings—across global flange standards (AS568, ISO 3601, JIS B 2401).

Critical Performance Specifications for PTFE Backup Rings

| Parameter | Standard Value Range | Testing Method |

|---|---|---|

| Inner Diameter Tolerance | ±0.05 mm to ±0.15 mm | ISO 3302-1 |

| Outer Diameter Tolerance | ±0.08 mm to ±0.20 mm | ISO 3302-1 |

| Hardness (Shore D) | 55–75 | ASTM D2240 |

| Continuous Temp Range | -200°C to +260°C | ASTM D883 |

| Max Pressure Resistance | 70 MPa (10,150 PSI) | ISO 14310-3 |

| Chemical Resistance | Inert to >95% industrial fluids | ASTM D471 |

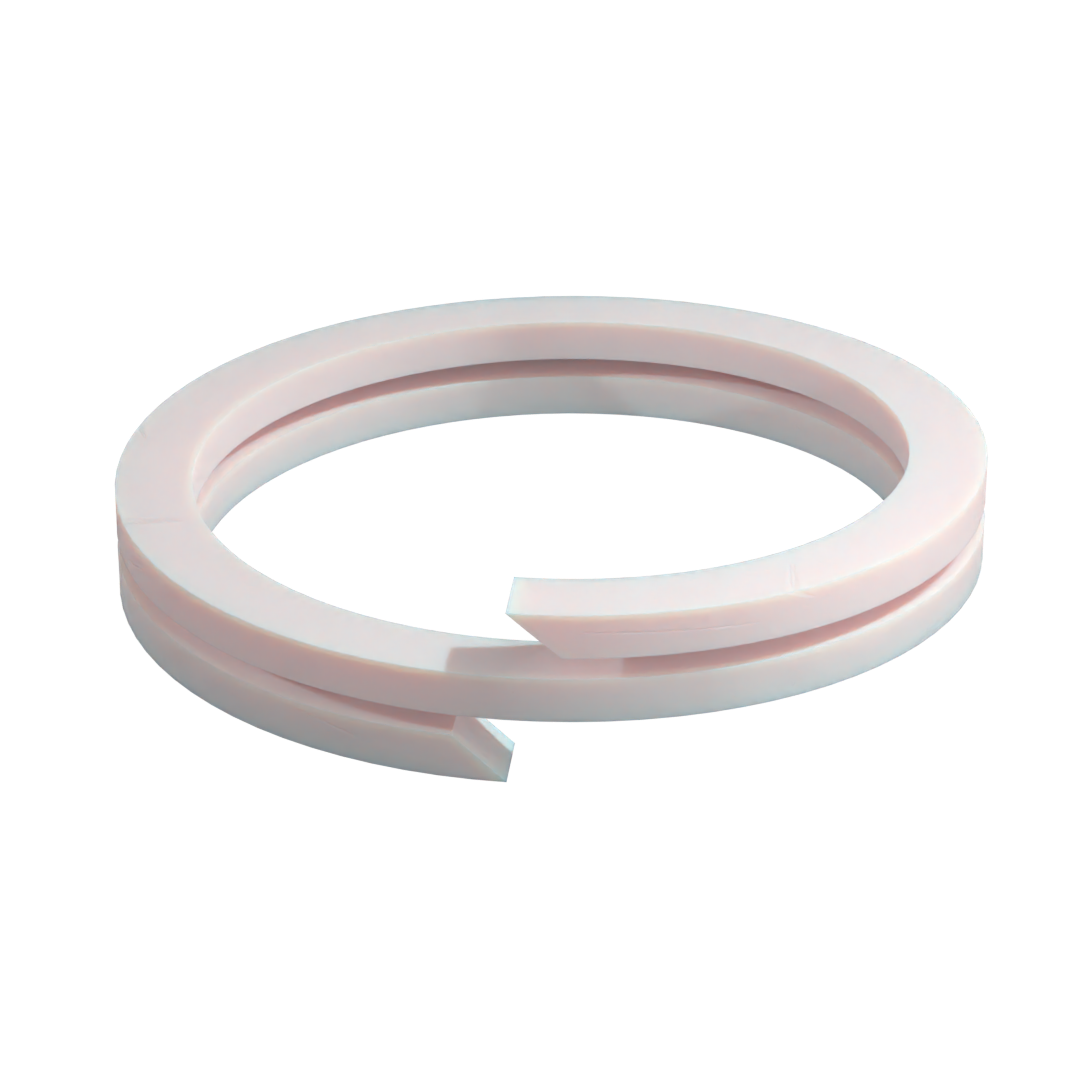

These specifications are not theoretical benchmarks but production realities enforced through our ISO 9001-certified manufacturing process. We specialize in rapid prototyping for custom geometries—including stepped, beveled, and spiral-cut designs—and support OEM production scalability from 100 to 1,000,000 units with consistent batch-to-batch repeatability.

Initiate Your Technical Dialogue with Suzhou Baoshida

Do not compromise sealing integrity through generic component sourcing. Our engineering team, led by Mr. Boyce, possesses 18 years of specialized expertise in polymer tribology and dynamic sealing failure analysis. We provide comprehensive material compatibility assessments, GD&T optimization for groove design, and accelerated life testing protocols tailored to your specific media, pressure, and temperature profiles. For immediate technical consultation or to request a formal quotation with full material certification, contact Mr. Boyce directly at [email protected]. Include your application’s critical parameters—system pressure, media composition, stroke length, and cycle rate—to enable our team to deliver a validated solution within 72 hours. Suzhou Baoshida operates as your dedicated engineering partner, not merely a supplier, ensuring your sealing systems achieve uncompromised reliability in the world’s most challenging industrial environments. Precision sealing demands precision partnership—contact us to elevate your engineering outcomes.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).