Technical Contents

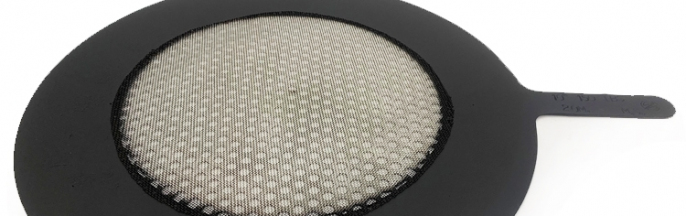

Engineering Guide: Temporary Strainers

Engineering Insight: Material Selection for Temporary Strainers

Temporary strainers serve as critical safeguards during plant commissioning and maintenance shutdowns, intercepting debris before it damages sensitive downstream equipment. Yet their transient nature often leads to misguided material choices, resulting in catastrophic failures that compromise project timelines and safety. Standard commercial rubber compounds—typically off-the-shelf NBR or EPDM—are frequently deployed despite lacking the resilience required for these high-stress applications. Understanding why these generic solutions fail is paramount to preventing operational disruptions.

The primary failure mechanism stems from underestimating the extreme thermal and chemical environment. Temporary strainers endure repeated steam blows (exceeding 150°C), exposure to aggressive chemical cleaning agents like caustic soda or hydrochloric acid, and severe vibration during blowdown procedures. Standard NBR degrades rapidly above 135°C, losing elasticity and developing microcracks that allow particulate bypass. Similarly, conventional EPDM exhibits poor resistance to non-polar solvents and oils commonly present in hydrocarbon processing streams. Off-the-shelf compounds also lack reinforcement for dynamic stress, leading to extrusion, tearing, or complete disintegration under pressure surges. These failures manifest as unfiltered debris entering turbines or pumps, necessitating costly recommissioning cycles and risking multi-million-dollar equipment damage.

Material science must address three non-negotiable criteria: thermal stability, chemical inertness, and mechanical endurance. Generic elastomers prioritize cost over performance, omitting critical additives like peroxide curing systems for steam resistance or specialized fillers for tear strength. Engineered compounds, conversely, integrate synergistic formulations—such as hydrogenated nitrile (HNBR) with ceramic-reinforced matrices or custom peroxide-cured EPDM blends—to withstand thermal cycling from -40°C to 180°C while resisting 10% HCl, 20% NaOH, and hydrocarbon solvents. Crucially, tensile strength and elongation at break must be optimized to absorb mechanical shock without permanent deformation.

The performance gap between standard and engineered materials is quantifiable:

| Property | Standard NBR Compound | Engineered HNBR Compound | Test Standard |

|---|---|---|---|

| Max Continuous Temp | 135°C | 180°C | ASTM D2240 |

| Tensile Strength | 15 MPa | 28 MPa | ASTM D412 |

| Elongation at Break | 250% | 450% | ASTM D412 |

| Volume Swell in 10% HCl | 28% | 8% | ASTM D471 |

| Compression Set (22h/150°C) | 45% | 18% | ASTM D395 |

Selecting substandard materials incurs hidden costs far exceeding initial savings. A single strainer failure during steam blow can trigger weeks of downtime, with turbine blade repairs averaging $500,000. Precision-engineered elastomers eliminate this risk by maintaining integrity across the full operational spectrum. At Suzhou Baoshida, our OEM-grade temporary strainers utilize proprietary rubber formulations validated against API 598 and ISO 5208 protocols, ensuring zero particulate leakage under 1.5x design pressure. Partnering with specialists who prioritize application-specific material science—not catalog availability—is not an expense but a strategic safeguard for asset integrity and project velocity.

Material Specifications

Material selection is a critical factor in the performance and longevity of temporary strainers used in industrial filtration systems. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber components engineered for demanding environments. Our temporary strainers are commonly fabricated using three elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on temperature range, chemical exposure, pressure conditions, and service life requirements.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures and aggressive chemicals. It performs reliably in continuous service up to 200°C and demonstrates excellent stability when exposed to oils, fuels, aromatic hydrocarbons, and many acids. This makes Viton the preferred choice for temporary strainers deployed in petrochemical, aerospace, and high-temperature processing applications. While Viton has a higher initial cost compared to other elastomers, its durability in harsh environments often results in lower total cost of ownership.

Nitrile rubber, also known as Buna-N, is one of the most widely used elastomers in industrial sealing and filtration due to its outstanding resistance to petroleum-based oils and fuels. It operates effectively within a temperature range of -30°C to 120°C, making it suitable for general-purpose applications in hydraulic systems, fuel lines, and oil refining. Nitrile offers good abrasion resistance and mechanical strength, providing reliable performance under moderate pressure. Its cost-effectiveness and broad compatibility with hydrocarbon media make it a practical selection for temporary strainers in standard industrial settings.

Silicone rubber excels in extreme temperature applications, with continuous service capability from -60°C to 230°C. It maintains flexibility at low temperatures and resists hardening or cracking under thermal cycling. While silicone demonstrates good resistance to ozone, UV radiation, and water, it has limited resistance to petroleum-based fluids and lower mechanical strength compared to Viton and Nitrile. Therefore, it is best suited for applications involving steam lines, food-grade processes, or environments requiring long-term weather resistance.

The following table summarizes key physical and chemical properties of these materials to assist in material selection for temporary strainers.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 70–90 | 60–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Acids | Good to Excellent | Fair | Fair |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Very Good | Good | Good |

| Common Applications | Petrochemical, aerospace | Hydraulic, automotive | Food processing, HVAC |

Material selection must be aligned with the operational parameters of the system in which the temporary strainer will be deployed. Suzhou Baoshida Trading Co., Ltd. provides technical support to ensure optimal material pairing for performance, safety, and compliance.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Temporary Strainers

Suzhou Baoshida Trading Co., Ltd. leverages integrated engineering expertise to deliver mission-critical temporary strainers for industrial fluid systems. Our core strength lies in the seamless collaboration between five dedicated mould engineers and two specialized rubber formula engineers, ensuring every component meets exacting operational demands. This synergy enables us to solve complex challenges in high-pressure, high-temperature environments where failure is not an option.

Our mould engineering team utilizes advanced CAD/CAM systems and finite element analysis (FEA) to design precision tooling that guarantees dimensional stability and repeatable part geometry. Each mould undergoes rigorous simulation for flow dynamics, cooling efficiency, and stress distribution, minimizing defects and optimizing cycle times. Concurrently, our formula engineers develop bespoke elastomeric compounds tailored to the specific chemical exposure, temperature fluctuations, and mechanical loads encountered in temporary strainer applications. We prioritize low compression set properties to maintain sealing integrity after prolonged compression, alongside exceptional resistance to oils, solvents, and hydraulic fluids.

This dual-engineering approach is foundational to our OEM partnership model. Clients provide operational parameters—we translate them into validated material and tooling specifications. Our formula engineers conduct accelerated aging tests, dynamic sealing simulations, and media compatibility trials to ensure compounds withstand real-world conditions. Mould engineers then refine cavity designs for optimal material flow and part ejection, eliminating flash or knit lines that could compromise filtration performance. The result is a strainer that consistently prevents debris ingress during pipeline maintenance without leakage or premature degradation.

Critical material performance metrics for our standard NBR-based temporary strainer compounds are summarized below. All specifications align with ASTM D2000 classification systems and undergo 100% lot traceability.

| Material Property | Specification | Test Standard |

|---|---|---|

| Durometer Hardness | 70 ± 5 Shore A | ASTM D2240 |

| Tensile Strength | ≥ 15 MPa | ASTM D412 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Compression Set (22h/100°C) | ≤ 25% | ASTM D395 Method B |

| Temperature Range | -30°C to +120°C | ISO 188 |

| Fluid Resistance (IRM 903) | Volume Swell ≤ 25% | ASTM D471 |

OEM projects follow a structured phase-gate process: requirement analysis, material validation, tooling qualification, and PPAP documentation. We maintain full control over raw material sourcing—partnering with Tier-1 polymer suppliers—and implement in-house rheometry, DSC, and mechanical testing to verify compound consistency. This end-to-end accountability ensures temporary strainers perform reliably under transient system stresses, directly supporting our clients’ uptime objectives. For custom applications, we co-engineer solutions with clients through iterative prototyping, reducing time-to-market while eliminating field failure risks. Suzhou Baoshida transforms rubber science into industrial reliability—one engineered strainer at a time.

Customization Process

Drawing Analysis

The customization process for temporary strainers begins with a comprehensive drawing analysis, serving as the foundation for all subsequent development stages. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a detailed review of client-provided technical drawings, focusing on dimensional accuracy, tolerance specifications, flange configurations, and interface compatibility with existing pipeline systems. This phase ensures that the physical geometry of the strainer aligns with operational requirements in oil & gas, petrochemical, and power generation applications. We verify critical parameters such as screen mesh size, flow path diameter, and end connection types (e.g., butt-weld, socket weld, or threaded). Any discrepancies or potential design inefficiencies are flagged and discussed with the client for optimization prior to material selection.

Formulation Development

Following drawing validation, our rubber formula engineers initiate the material formulation phase. Temporary strainers are exposed to aggressive media, fluctuating temperatures, and mechanical stress during commissioning phases, necessitating elastomers with superior chemical resistance and mechanical integrity. Based on the operating environment—such as exposure to hydrocarbons, chlorinated solvents, or high-temperature steam—we select from a range of polymers including Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Fluoroelastomer (FKM), or Chloroprene (CR). The compound is then engineered to meet specific Shore A hardness (typically 60–80), tensile strength, elongation at break, and compression set requirements. Additives are incorporated to enhance ozone resistance, thermal stability, or flame retardancy as needed. All formulations comply with ASTM D2000 standards and are traceable through our quality management system.

Prototyping and Validation

Once the formulation is finalized, a functional prototype is manufactured using precision molding techniques. This prototype undergoes rigorous testing to validate dimensional conformity, sealing performance, and structural integrity under simulated service conditions. Hydrostatic testing, burst pressure evaluation, and dynamic flow testing are conducted to ensure reliability during short-term installation in piping systems. Client feedback is integrated at this stage, allowing for design or material refinements before tooling approval.

Mass Production

After successful prototype validation, the project transitions to mass production. Our facility in Suzhou operates under ISO 9001-certified processes, ensuring consistency across batches. CNC-controlled molding machines, automated inspection systems, and real-time process monitoring guarantee repeatability and adherence to tight tolerances. Each batch undergoes first-article inspection and periodic quality audits.

The following table outlines typical material specifications for custom temporary strainer components:

| Property | NBR | EPDM | FKM | CR |

|---|---|---|---|---|

| Temperature Range (°C) | -30 to +125 | -50 to +150 | -20 to +200 | -40 to +120 |

| Hardness (Shore A) | 70 ± 5 | 75 ± 5 | 75 ± 5 | 70 ± 5 |

| Tensile Strength (MPa) | ≥20 | ≥18 | ≥15 | ≥17 |

| Elongation at Break (%) | ≥300 | ≥250 | ≥200 | ≥280 |

| Fluid Resistance | Excellent (oils, fuels) | Excellent (steam, water, alkalis) | Outstanding (aromatics, acids) | Good (ozone, weathering) |

All custom temporary strainers are delivered with material test reports, dimensional inspection certificates, and packaging suitable for international logistics.

Contact Engineering Team

Contact Suzhou Baoshida for Engineered Temporary Strainer Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber engineering, delivering precision temporary strainers that ensure operational integrity during critical pipeline commissioning, maintenance, and hydrotesting phases. Our strainers are not generic components but scientifically formulated elastomeric solutions engineered to withstand aggressive chemical exposure, extreme temperatures, and high-pressure differentials inherent in oil and gas, petrochemical, and power generation infrastructure. Unlike standard mesh alternatives, our temporary strainers integrate advanced rubber compounds with reinforced structural designs, preventing debris migration while maintaining flow efficiency and eliminating costly system contamination risks. This technical superiority stems from our in-house R&D capabilities, rigorous ASTM and ISO 13073 validation protocols, and deep OEM collaboration experience with Tier-1 industrial equipment manufacturers.

The performance of temporary strainers hinges on material science precision. Generic solutions often fail under dynamic service conditions, leading to catastrophic particulate ingress or premature degradation. Suzhou Baoshida addresses this through proprietary compound formulations tailored to your specific media, temperature, and pressure profiles. Below are key specifications for our standard temporary strainer elastomers, validated per ASTM D2000 classification systems:

| Material Type | Durometer (Shore A) | Temperature Range (°C) | Key Media Resistance | Pressure Rating (Bar) |

|---|---|---|---|---|

| Hydrogenated NBR (HNBR) | 70 ±5 | -40 to +150 | Hydraulic fluids, sour gas, aliphatic hydrocarbons | 150 |

| Peroxide-Cured EPDM | 65 ±5 | -50 to +160 | Steam, caustics, polar solvents, oxidizing agents | 120 |

| Fluorocarbon (FKM/Viton®) | 75 ±5 | -20 to +230 | Aromatic hydrocarbons, acids, fuels, chlorinated solvents | 200 |

These specifications reflect our commitment to quantifiable performance. Each compound undergoes accelerated aging tests per ASTM D573 and fluid immersion analysis per ISO 1817 to guarantee dimensional stability and sealing integrity under real-world stressors. Our OEM-managed production ensures traceability from raw material sourcing to final assembly, with certifications including ISO 9001:2015 and API Q1 compliance.

Partnering with Suzhou Baoshida eliminates the guesswork in temporary strainer selection. We do not sell off-the-shelf products; we co-engineer solutions based on your P&ID schematics, fluid dynamics data, and failure mode analysis. Our technical team, led by Mr. Boyce, specializes in translating complex operational requirements into optimized elastomeric configurations—whether for sour service pipelines requiring H₂S resistance or cryogenic LNG applications demanding low-temperature flexibility. This collaborative approach minimizes downtime during critical path activities and prevents multi-million-dollar contamination incidents.

To secure a strainer solution calibrated to your exact engineering parameters, contact Mr. Boyce directly. Submit your project specifications—including fluid composition, operating temperature/pressure, pipe dimensions, and duration of service—for a validated material recommendation and dimensional drawing within 72 hours. Mr. Boyce will coordinate our formulation chemists and OEM production team to deliver certified strainers with documented test reports, ensuring seamless integration into your maintenance protocols. Do not compromise system integrity with inadequate temporary filtration. Initiate the engineering dialogue today:

Mr. Boyce

OEM Technical Manager | Rubber Formula Engineering

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Precision elastomeric solutions for critical industrial infrastructure

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).