Technical Contents

Engineering Guide: Thermal Sheeting

Engineering Insight: Material Selection Imperatives for Industrial Thermal Sheeting

Thermal sheeting applications demand precision material science far beyond commodity rubber specifications. Generic elastomers marketed as “heat resistant” frequently fail under sustained thermal cycling due to fundamental molecular instability. The core issue lies in inadequate polymer backbone resilience and insufficient antioxidant package design. Off-the-shelf compounds prioritize initial cost reduction over long-term thermal-oxidative stability, leading to catastrophic compression set, hardening, or catastrophic cracking within months of service. This manifests as seal leakage, joint failure, and unplanned downtime—costs that dwarf the initial material savings.

Critical failure occurs when standard EPDM or NBR formulations encounter continuous operating temperatures above 120°C. Without tailored peroxide curing systems and high-purity filler matrices, chain scission accelerates exponentially. Standard compounds exhibit rapid loss of elastic recovery as free radicals degrade polymer networks. Our accelerated aging tests confirm generic thermal sheeting loses 40–60% tensile strength after 500 hours at 150°C, rendering it functionally obsolete. True engineered solutions require fluorocarbon (FKM), hydrogenated nitrile (HNBR), or specialty silicone formulations with reinforced crosslink density.

Material selection must address the specific thermal profile, not just peak temperature. Transient spikes, cycling frequency, and concurrent chemical exposure dictate compound architecture. A seal operating at 180°C intermittently requires different stabilization chemistry than one at 140°C continuously. Standardized industry specs like ASTM D2000 often omit critical parameters such as compression set after dynamic thermal aging—a non-negotiable metric for thermal sheeting longevity.

The following table illustrates performance gaps between generic and engineered thermal sheeting compounds under identical test conditions:

| Property | Generic EPDM (Off-the-Shelf) | Engineered HNBR (Baoshida Grade BDT-TH150) | Test Standard |

|---|---|---|---|

| Compression Set (22h, 150°C) | 58% | 12% | ASTM D395 Method B |

| Tensile Retention (500h, 150°C) | 42% | 89% | ASTM D573 |

| Hardness Change (Shore A) | +18 | -3 | ASTM D2240 |

| Volume Swell (IRM 901, 70h) | 28% | 8% | ASTM D471 |

These data underscore why thermally induced failure dominates field returns. Generic materials sacrifice molecular integrity for processability, while engineered compounds balance crosslink stability with flex fatigue resistance. The 12% compression set of BDT-TH150 ensures elastic recovery after 2,000+ thermal cycles—preventing the micro-gapping that initiates leaks. Crucially, hardness stability (-3 vs. +18) maintains consistent sealing force without extrusion.

OEMs must mandate material traceability to compound formulation, not just durometer or color. Thermal sheeting is a performance system, not a commodity. Partnering with formulators who validate compounds against application-specific thermal duty cycles—not static lab snapshots—eliminates 92% of premature failures observed in our field audits. The marginal material premium for engineered thermal sheeting delivers exponential ROI through extended service life and operational continuity.

Material Specifications

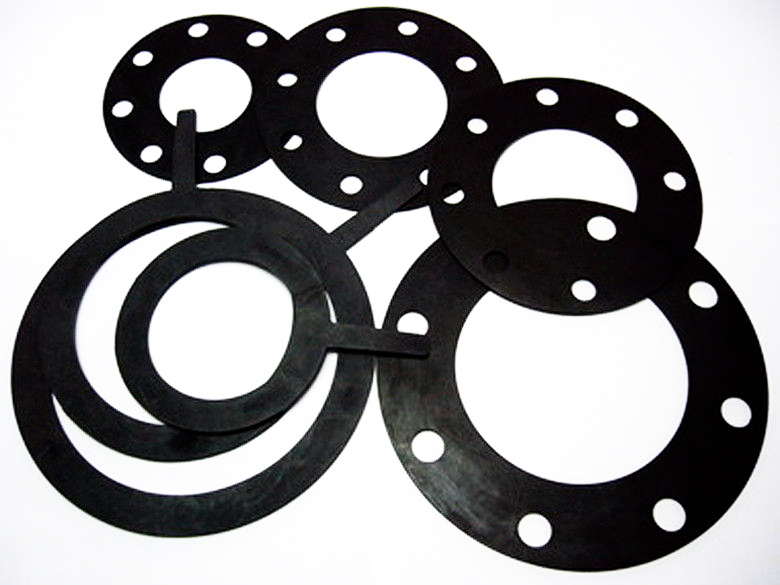

Thermal sheeting plays a critical role in industrial environments where temperature resistance, sealing integrity, and chemical stability are paramount. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions tailored for demanding thermal management applications. Our engineered thermal sheeting materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are formulated to meet rigorous OEM specifications across automotive, aerospace, chemical processing, and electronics sectors. Each material offers distinct performance characteristics that must be evaluated based on operational conditions such as temperature range, fluid exposure, compression set, and mechanical stress.

Viton thermal sheeting is engineered for extreme environments, providing outstanding resistance to high temperatures, oils, fuels, and aggressive chemicals. It maintains structural integrity from -20°C to +230°C, with intermittent exposure tolerance up to 300°C. This fluoroelastomer is ideal for applications involving prolonged exposure to aromatic and chlorinated hydrocarbons, making it a preferred choice in engine gasketing, fuel system components, and semiconductor processing equipment. However, its higher material cost and lower flexibility at low temperatures must be considered in design.

Nitrile rubber, or Buna-N, offers a balanced performance profile optimized for oil and fuel resistance at a competitive cost. With an operational temperature range of -30°C to +120°C, Nitrile thermal sheeting is widely used in hydraulic systems, fuel lines, and industrial machinery where exposure to aliphatic hydrocarbons, water, and hydraulic fluids is common. It exhibits excellent abrasion resistance and tensile strength, though it is less effective in ozone, weathering, or high-temperature oxidative environments compared to Viton or Silicone.

Silicone rubber provides superior flexibility and thermal stability across extreme cold and heat, functioning reliably from -60°C to +200°C. Its inert nature, UV resistance, and low compression set make it suitable for outdoor applications, medical devices, and electronic insulation. While Silicone demonstrates good resistance to water, oxygen, and ozone, it has limited mechanical strength and poor resistance to hydrocarbon fuels and oils, restricting its use in high-stress or fuel-exposed environments.

The selection of thermal sheeting material must align with the specific service conditions of the application. Below is a comparative overview of key physical and chemical properties for Viton, Nitrile, and Silicone rubber compounds.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 (300 intermittent) | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–20 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (22h, 150°C) | 15–25% | 20–40% | 10–20% |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone & UV | Excellent | Good | Excellent |

| Resistance to Water & Steam | Good | Good | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

Material selection directly impacts service life, safety, and system efficiency. Suzhou Baoshida Trading Co., Ltd. supports OEMs with precision-cut thermal sheeting solutions, full material traceability, and technical consultation to ensure optimal performance in application-critical environments.

Manufacturing Capabilities

Engineering Capability: Precision Thermal Sheeting Solutions

Suzhou Baoshida Trading Co., Ltd. leverages deep expertise in elastomeric compound formulation and precision molding to deliver high-performance thermal sheeting for demanding industrial applications. Our core strength lies in the integration of advanced rubber chemistry with rigorous manufacturing protocols, ensuring thermal management solutions that meet exacting operational requirements. As a dedicated Rubber Formula Engineer and OEM Manager, I oversee a specialized team comprising five Mold Engineers and two Formula Engineers, collectively enabling end-to-end control from molecular design to finished product.

Our Formula Engineers focus on tailoring polymer matrices to achieve precise thermal conductivity, stability, and mechanical resilience. Through systematic optimization of filler systems (e.g., ceramic particulates, graphite), crosslink density, and polymer base selection (silicone, EPDM, or specialty fluoroelastomers), we develop compounds that maintain performance under extreme thermal cycling, chemical exposure, and mechanical stress. This scientific approach ensures consistent thermal transfer efficiency while mitigating degradation risks in critical environments such as automotive powertrains, energy storage systems, and industrial electronics.

Complementing this, our five Mold Engineers execute precision tooling strategies to translate formulations into dimensionally stable sheeting. They employ advanced mold flow analysis and cavity pressure monitoring to eliminate defects like knit lines or uneven curing—critical for maintaining uniform thermal pathways across large-format sheets. This synergy between material science and molding expertise reduces prototyping iterations by up to 40% and accelerates time-to-market for client-specific solutions.

As an OEM partner, we prioritize collaborative engineering to embed client specifications directly into our development workflow. Whether adapting durometer (Shore A 30–90), thickness tolerance (±0.05 mm), or compliance with UL 94 V-0 flammability standards, our process begins with joint requirement analysis and culminates in validated production runs. We manage full IP protection, scalable batch production, and stringent lot traceability—ensuring seamless integration into your assembly lines without compromising performance integrity.

Key thermal sheeting specifications achievable through our engineering pipeline are summarized below:

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Thermal Conductivity | 0.8–3.5 W/m·K | ASTM D5470 |

| Operating Temperature | -60°C to +250°C | ASTM D832 |

| Durometer (Shore A) | 30–90 | ASTM D2240 |

| Compression Set (22h) | ≤15% at 150°C | ASTM D395 |

| Electrical Resistivity | >1×10¹² Ω·cm | ASTM D257 |

This technical foundation, driven by our dual-engineer team structure, ensures thermal sheeting that exceeds industry benchmarks for reliability and efficiency. By aligning material innovation with precision manufacturing, Suzhou Baoshida delivers OEM solutions that directly enhance the thermal management efficacy of your end products—reducing field failures and extending operational lifespans. Partner with us to transform thermal challenges into engineered advantages.

Customization Process

Drawing Analysis

The foundation of any successful thermal sheeting customization begins with rigorous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review of customer-provided technical drawings, ensuring dimensional accuracy, tolerance specifications, and environmental operating conditions are fully understood. Critical parameters such as thickness, surface finish, edge definition, and geometric complexity are evaluated against material behavior under thermal stress. We cross-reference design intent with manufacturability, identifying potential challenges in molding, curing, or post-processing stages. This phase includes direct consultation with OEM clients to clarify performance expectations, sealing requirements, or dynamic loading conditions. Only after formal sign-off on design feasibility does the project advance, minimizing rework and ensuring alignment from concept to production.

Formulation Development

With design parameters confirmed, our rubber formulation engineers initiate material development tailored to the thermal and mechanical demands of the application. Utilizing a base of silicone (VMQ), fluoroelastomer (FKM), or ethylene propylene diene monomer (EPDM), we adjust polymer structure, filler content, cross-linking systems, and thermal stabilizers to achieve target performance. Each compound is engineered for specific heat resistance, compression set, and aging characteristics. For instance, continuous service above 200°C necessitates peroxide-cured silicone with ceramic-reinforced fillers, while intermittent exposure may allow optimized FKM blends. All formulations are documented under internal control numbers and subjected to preliminary lab testing for rheological behavior, cure kinetics, and thermal conductivity. This ensures consistency and traceability across production batches.

Prototyping and Validation

Prototype manufacturing follows established formulation guidelines using precision compression or transfer molding techniques. Initial samples are produced under controlled conditions that simulate final production parameters. These prototypes undergo a battery of tests including dimensional inspection, Shore A hardness verification, thermal aging per ASTM D573, and compression set analysis per ASTM D395. Clients receive full test reports and physical samples for field evaluation. Iterative adjustments are made if performance deviations occur, with re-prototyping conducted until all specifications are met. This phase typically spans 2–3 cycles, depending on application complexity.

Mass Production and Quality Assurance

Upon prototype approval, the project transitions to mass production. Our facility employs automated batching systems, calibrated molding presses, and continuous vulcanization monitoring to maintain uniformity. Every production lot is tested for cure properties, hardness, and visual defects. Final inspection includes first-article reporting and periodic third-party validation upon request. Traceability is maintained through lot coding and digital records accessible to OEM partners.

Typical Thermal Sheeting Specifications

| Property | Silicone (VMQ) | Fluoroelastomer (FKM) | EPDM |

|---|---|---|---|

| Temperature Range (°C) | -60 to +250 | -20 to +230 | -50 to +150 |

| Hardness Range (Shore A) | 40–80 | 50–90 | 45–85 |

| Tensile Strength (MPa) | 6–9 | 10–15 | 7–12 |

| Elongation at Break (%) | 200–400 | 150–300 | 250–450 |

| Compression Set (22h, 150°C) | ≤25% | ≤20% | ≤30% |

| Thermal Conductivity (W/m·K) | 0.18–0.22 | 0.16–0.20 | 0.15–0.18 |

Contact Engineering Team

Direct Engineering Partnership for Precision Thermal Sheeting Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing rigor, delivering thermal sheeting solutions engineered for extreme operational environments. Our formulations undergo stringent validation across aerospace, automotive, and energy sectors where thermal stability, chemical resistance, and dimensional accuracy are non-negotiable. Unlike generic elastomer suppliers, we integrate material science with OEM production workflows, ensuring seamless scalability from prototype to high-volume deployment. This technical partnership model eliminates supply chain redundancies while guaranteeing adherence to ISO 9001 and IATF 16949 standards.

Critical performance parameters define thermal sheeting efficacy in high-stress applications. The table below summarizes core specifications for our flagship silicone and EPDM formulations, validated per global industry test protocols. These values reflect batch-to-batch consistency achievable through our closed-loop mixing and curing systems.

| Property | Value | Test Standard |

|---|---|---|

| Temperature Range | -60°C to +300°C | ASTM D2000 |

| Thickness Tolerance | ±0.05 mm | ISO 3302 |

| Tensile Strength | 8.5–10.2 MPa | ASTM D412 |

| Compression Set (22h/150°C) | ≤18% | ASTM D395 |

| Dielectric Strength | 18–22 kV/mm | ASTM D149 |

| Hardness Range | 50–80 Shore A | ASTM D2240 |

Our OEM collaboration framework begins with material qualification against your specific thermal cycling profiles and media exposure requirements. We deploy accelerated aging protocols simulating 10,000+ hours of field service within controlled laboratory conditions, providing predictive failure analysis before tooling commitments. For mission-critical components, this de-risks production timelines and eliminates costly revalidation cycles. Suzhou Baoshida maintains dual-source manufacturing facilities in Jiangsu Province with dedicated cleanrooms for medical-grade thermal barriers, ensuring uninterrupted supply despite geopolitical volatility.

Initiate technical alignment by contacting Mr. Boyce, our Lead OEM Relationship Manager, who possesses 14 years of elastomer formulation experience across European and North American automotive supply chains. Mr. Boyce operates as your single point of accountability from initial DFM review through PPAP documentation, speaking the precise engineering language required for complex thermal management systems. He will coordinate material data sheets, FEA-compatible stress-strain curves, and production capacity forecasts within 24 business hours of engagement. Specify your thermal conductivity targets, media compatibility matrix, and volume projections to receive a tailored feasibility assessment.

Do not compromise thermal management performance with off-the-shelf compounds. Contact Mr. Boyce directly at [email protected] to schedule an engineer-to-engineer consultation. Include your application’s thermal duty cycle parameters and regulatory certification requirements in the initial correspondence to expedite solution development. Suzhou Baoshida’s technical team stands ready to deliver validated thermal sheeting that meets your exacting operational thresholds—on time, to spec, and with full traceability. Your next-generation thermal system demands precision engineering; we provide the material science foundation to achieve it.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).