Technical Contents

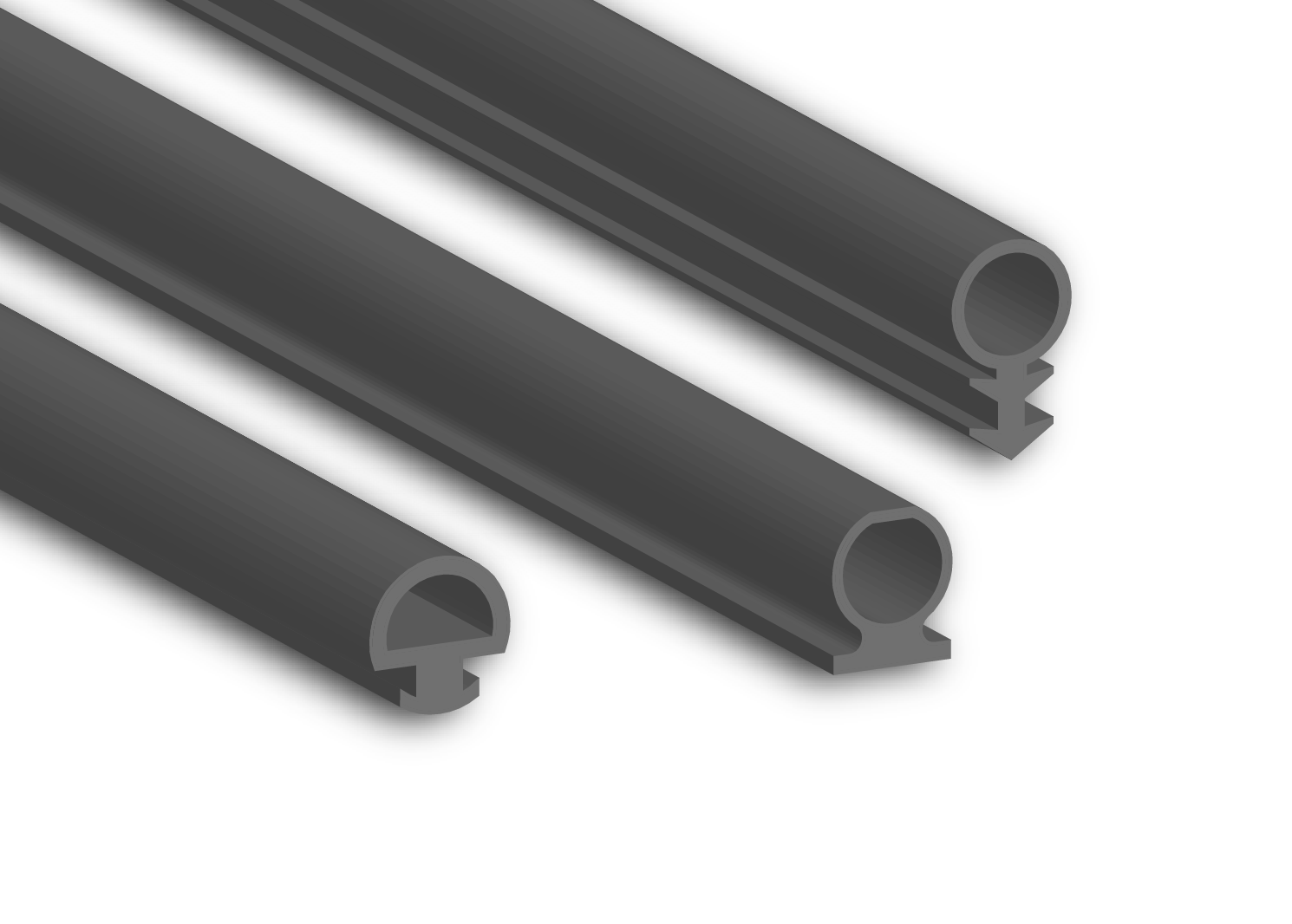

Engineering Guide: Thin Pipe

Engineering Insight: Material Selection in Thin Pipe Applications

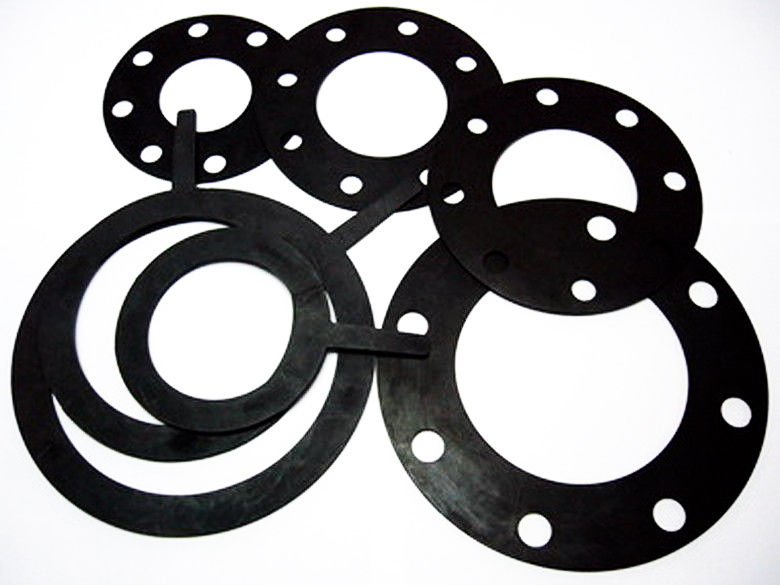

In industrial fluid transfer systems, thin pipe components are subjected to a unique set of mechanical, thermal, and chemical stresses that demand precise engineering solutions. Unlike standard piping, thin wall geometries offer reduced structural mass, which increases flexibility and reduces material cost—but at the expense of reduced tolerance to pressure surges, abrasion, and environmental degradation. This makes material selection not merely a design consideration, but a fundamental determinant of system reliability and service life.

Off-the-shelf rubber pipes often fail in demanding industrial environments due to generic material formulations optimized for cost rather than performance. These standard solutions typically utilize general-purpose elastomers such as natural rubber (NR) or low-grade EPDM, which lack resistance to ozone, UV exposure, or specific industrial fluids like hydraulic oils, solvents, or acidic media. When deployed in applications involving continuous flexing, elevated temperatures, or aggressive media, premature cracking, swelling, or delamination occurs—leading to unplanned downtime and safety risks.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific material engineering. For thin pipe solutions, this involves selecting high-performance elastomers tailored to the operational environment. For instance, fluorocarbon rubber (FKM) offers exceptional resistance to high temperatures and hydrocarbon-based fluids, making it ideal for automotive and aerospace fuel lines. Nitrile rubber (NBR), with its superior oil resistance and mechanical strength, is preferred in hydraulic and industrial machinery applications. For environments requiring broad chemical compatibility and ozone resistance, peroxide-cured EPDM or silicone rubber (VMQ) are deployed—particularly in pharmaceutical or food-grade transfer systems.

The wall thinness exacerbates material limitations. A 1.0 mm wall thickness, while enabling compact routing and weight reduction, provides minimal buffer against permeation or extrusion under pressure. Therefore, compound formulation—including reinforcement fillers, crosslink density, and antioxidant packages—must be optimized to maintain integrity over time.

Below is a comparison of key elastomers used in engineered thin pipe applications:

| Material | Temperature Range (°C) | Key Resistance Properties | Typical Applications |

|---|---|---|---|

| FKM (Fluorocarbon) | -20 to +200 (short peaks to +250) | Fuels, oils, acids, ozone | Automotive fuel lines, chemical seals |

| NBR (Nitrile) | -30 to +120 | Aliphatic hydrocarbons, water, hydraulic fluids | Industrial hydraulics, pneumatic systems |

| EPDM (Peroxide-cured) | -50 to +150 | Steam, water, alkalis, UV, ozone | HVAC, pharmaceutical processing |

| VMQ (Silicone) | -60 to +180 | Extreme cold, heat, biocompatibility | Medical tubing, food-grade transfer |

Material selection must be guided by fluid compatibility charts, dynamic stress modeling, and accelerated aging tests. At Baoshida, we support OEMs with compound testing and custom formulation to ensure thin pipe solutions exceed field performance expectations. Generic alternatives may offer short-term savings, but only engineered materials deliver long-term operational integrity.

Material Specifications

Material Specifications for Thin Pipe Applications

Selecting the optimal elastomer for thin pipe manufacturing requires rigorous evaluation of operational parameters including temperature exposure, chemical compatibility, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we prioritize material integrity to ensure extruded rubber profiles maintain dimensional stability and functional reliability under demanding industrial conditions. Thin pipe geometries amplify sensitivity to compound formulation, necessitating precise control over polymer selection, filler systems, and vulcanization protocols. Below we detail critical specifications for Viton, Nitrile, and Silicone—three premier materials for fluid conveyance systems where wall thickness constraints demand exceptional resilience.

Viton (FKM) fluorocarbon rubber delivers unparalleled resistance to aggressive chemicals, including hydrocarbons, acids, and high-temperature fuels. Its molecular structure sustains integrity from -20°C to 230°C continuous service, making it indispensable for aerospace hydraulic lines and semiconductor processing equipment. Tensile strength typically exceeds 15 MPa (ASTM D412), with elongation at break around 200%. Viton’s low gas permeability prevents fluid migration in ultra-thin extrusions, though its higher cost necessitates justification through extreme environmental exposure.

Nitrile (NBR) remains the industrial standard for cost-effective oil and fuel resistance. Operating effectively between -40°C and 120°C, it balances mechanical robustness with affordability for automotive fuel lines and hydraulic machinery. Standard formulations achieve 10–18 MPa tensile strength and 250–400% elongation. While vulnerable to ozone and ketones, hydrogenated NBR variants extend temperature tolerance to 150°C. Its compatibility with petroleum-based fluids and ease of extrusion suit high-volume thin pipe production where budget constraints prevail.

Silicone (VMQ) excels in extreme temperature flexibility (-60°C to 200°C) and biocompatibility, critical for pharmaceutical transfer lines and food-grade tubing. With tensile strength of 6–10 MPa and elongation exceeding 500%, it accommodates dynamic flexing without cracking. Silicone’s inert nature resists water, steam, and ozone but exhibits poor resistance to concentrated acids and hydrocarbons. Peroxide-cured variants ensure low compression set for sealing-critical thin-wall applications, though reinforcement additives are essential to offset lower abrasion resistance.

The comparative analysis below summarizes key performance metrics essential for thin pipe engineering decisions. All values reflect standard test methods per ASTM D2000 classification.

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Fluid Resistance | Primary Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 15–20 | 150–250 | Fuels, oils, acids, solvents | Aerospace hydraulics, chemical processing, semiconductor tooling |

| Nitrile (NBR) | -40 to 120 | 10–18 | 250–400 | Petroleum oils, water-based fluids | Automotive fuel systems, industrial hydraulics, printing machinery |

| Silicone (VMQ) | -60 to 200 | 6–10 | 500–700 | Water, steam, alcohols, ozone | Medical devices, food/beverage transfer, high-temp electrical insulation |

Material selection must align with fluid chemistry, pressure cycles, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. validates all formulations through accelerated aging tests and extrusion trials to guarantee thin pipe performance meets OEM specifications. Consult our engineering team for application-specific compound optimization and ISO 9001-certified production support.

Manufacturing Capabilities

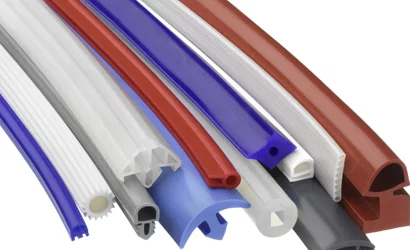

Engineering Capability: Precision-Driven Rubber Solutions for Thin Pipe Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of thin pipe components. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific products that meet the exacting demands of global OEMs. Our integrated engineering approach ensures seamless development from concept to mass production, with a focus on dimensional accuracy, material performance, and long-term reliability.

Our mould engineering team specializes in high-precision tooling for thin-wall rubber extrusion and injection processes. Each engineer brings over a decade of experience in optimizing flow dynamics, minimizing flash, and ensuring uniform wall thickness—critical parameters in thin pipe manufacturing where tolerances are often within ±0.1 mm. Utilizing advanced CAD/CAM software and finite element analysis (FEA), our engineers simulate production conditions to preempt defects such as warping, shrinkage, or delamination. This proactive design methodology reduces prototyping cycles and accelerates time-to-market for our partners.

Complementing our mould expertise is our in-house rubber formulation capability. Our two formula engineers operate a fully equipped polymer laboratory, where they develop and refine custom elastomer compounds tailored to specific environmental and mechanical requirements. Whether the application demands resistance to high temperature, ozone, oil, or repeated flexing, we formulate solutions using NR, EPDM, NBR, silicone, and other specialty rubbers. This vertical integration allows us to control raw material consistency, cure kinetics, and final physical properties—ensuring every batch meets OEM specifications.

We are a certified OEM partner for several Tier-1 industrial equipment manufacturers, providing co-engineering support and private-label production under strict confidentiality agreements. Our facility supports full project lifecycle management, including design validation, tooling approval, process capability studies (CpK ≥ 1.67), and batch traceability. With ISO 9001-certified quality systems and real-time monitoring on production lines, we maintain repeatability and compliance across high-volume runs.

The following table outlines key engineering specifications we support for thin pipe manufacturing:

| Parameter | Capability Range |

|---|---|

| Inner Diameter | 3 mm – 50 mm |

| Wall Thickness | 0.8 mm – 3.0 mm (±0.1 mm tolerance) |

| Length Tolerance | ±0.5 mm per 100 mm |

| Moulding Process | Injection, Compression, Transfer |

| Hardness (Shore A) | 40 – 90 |

| Operating Temperature Range | -40°C to +200°C (material-dependent) |

| Custom Compound Development | Yes (including halogen-free, low-smoke) |

| Lead Time (Prototype Tooling) | 15 – 25 days |

| OEM Branding & Packaging | Full customization available |

Our engineering team works in closed-loop collaboration with clients, offering DFM feedback, material selection guidance, and performance testing reports. This technical depth, combined with scalable manufacturing capacity, positions Suzhou Baoshida as a trusted engineering partner in the global supply chain for precision rubber components.

Customization Process

Customization Process for Precision Thin Pipe Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our thin pipe customization process integrates rigorous engineering protocols to transform client specifications into high-performance industrial rubber components. This methodology ensures dimensional accuracy, material resilience, and compliance with sector-specific standards, particularly for applications demanding ultra-thin walls and consistent fluid dynamics. The four-phase workflow begins with comprehensive drawing analysis. Our engineering team dissects technical schematics to validate critical parameters: inner/outer diameter tolerances (±0.05mm), wall thickness uniformity, bend radius constraints, and surface finish requirements. We cross-reference these against ISO 3601 or SAE J514 standards, identifying potential manufacturability risks such as extrusion instability or vulcanization-induced deformation in sub-millimeter geometries.

Following validation, elastomer formulation is engineered at the molecular level. We prioritize compound selection based on fluid compatibility, temperature range, and mechanical stress profiles. For instance, nitrile rubber (NBR) formulations dominate hydraulic thin pipes requiring oil resistance, while fluorocarbon (FKM) variants address aerospace fuel systems exceeding 200°C. Key variables include polymer backbone saturation, filler dispersion (e.g., silica vs. carbon black), and peroxide curing systems to minimize compression set. The table below illustrates typical property-targeting for critical applications:

| Application Sector | Base Polymer | Tensile Strength (MPa) | Elongation at Break (%) | Compression Set (70h/70°C) | Fluid Resistance Target |

|---|---|---|---|---|---|

| Automotive Brake Lines | HNBR | 28-32 | 450-500 | ≤15% | DOT 4 Glycol Ethers |

| Semiconductor Coolant | EPDM | 22-26 | 400-450 | ≤20% | Ultra-Pure Deionized Water |

| Medical Peristaltic Pumps | Silicone | 10-12 | 600-700 | ≤10% | USP Class VI Biocompatibility |

Prototyping employs precision extrusion and continuous vulcanization (CV) lines calibrated for thin-wall integrity. Initial samples undergo iterative pressure decay testing (ASTM D1418) and dimensional laser scanning to correct micro-voids or eccentricity. Client feedback loops refine surface adhesion for bonding or coating processes, ensuring zero delamination in multi-layer assemblies.

Mass production activation requires formal sign-off on prototype validation dossiers, including full material traceability (mill certificates, lot numbers) and process capability indices (CpK ≥1.67). Our Suzhou facility utilizes IoT-monitored extrusion presses with real-time die swell compensation algorithms, maintaining ±0.03mm wall consistency at throughput rates of 15m/min. Every production batch undergoes 100% visual inspection via automated optical comparators and statistical burst pressure validation per ISO 1402. This closed-loop system guarantees that thin pipe assemblies meet the exacting demands of hydraulic, pneumatic, and fluid transfer systems without compromise.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Thin Pipe Rubber Solutions

When sourcing high-performance thin pipe components for industrial applications, precision, material integrity, and supplier reliability are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions tailored to the demanding requirements of sectors including automotive, aerospace, medical devices, and advanced manufacturing. Our thin pipe products are designed to deliver consistent performance under dynamic pressure, thermal fluctuation, and chemical exposure, ensuring long-term operational stability.

Our technical team, led by Mr. Boyce, brings over 15 years of experience in rubber compounding, extrusion process optimization, and OEM collaboration. We understand that thin wall rubber tubing presents unique challenges—dimensional control, burst strength, and material homogeneity are critical. That’s why we employ precision extrusion techniques combined with rigorous QC protocols, including laser gauging, tensile testing, and accelerated aging cycles, to guarantee every meter of pipe meets exacting specifications.

We offer customization across a range of elastomers, including silicone, EPDM, NBR, and fluororubber (FKM), enabling compatibility with oils, acids, steam, and high-temperature environments. Whether you require medical-grade biocompatible tubing or fuel-resistant hoses for industrial machinery, our formulation database and in-house testing lab allow rapid prototyping and scalable production.

Below are representative technical specifications for our standard thin pipe series. All parameters can be adjusted based on OEM requirements and application conditions.

| Parameter | Material (Silicone) | Material (NBR) | Material (FKM) | Units |

|---|---|---|---|---|

| Inner Diameter Range | 1.0 – 12.0 | 1.5 – 10.0 | 2.0 – 8.0 | mm |

| Wall Thickness Tolerance | ±0.05 | ±0.08 | ±0.10 | mm |

| Hardness (Shore A) | 40 – 70 | 50 – 80 | 60 – 85 | Shore A |

| Tensile Strength | ≥8.0 | ≥12.0 | ≥10.0 | MPa |

| Elongation at Break | ≥300 | ≥250 | ≥200 | % |

| Operating Temperature | -60 to +200 | -30 to +120 | -20 to +230 | °C |

| Volume Resistivity | >1×10¹⁴ | >1×10¹² | >1×10¹³ | Ω·cm |

| Biocompatibility (USP Class VI) | Yes | No | No | — |

For application-specific inquiries or custom formulation development, direct engagement with our technical lead is recommended. Mr. Boyce oversees all OEM projects and provides end-to-end support—from initial material selection and DFM analysis to production scaling and documentation (including IMDS, RoHS, and REACH compliance).

To initiate a technical consultation or request sample batches, contact Mr. Boyce directly at [email protected]. Include your application context, performance requirements, and target volumes to enable a rapid, data-driven response. We respond to all qualified technical inquiries within 12 business hours.

Suzhou Baoshida Trading Co., Ltd. operates under ISO 9001-certified processes and maintains strategic partnerships with extrusion facilities in Jiangsu and Guangdong, ensuring supply chain resilience and on-time delivery. Partner with us to solve your most demanding thin pipe challenges with engineered rubber integrity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).