Technical Contents

Engineering Guide: Thin Rubber Tubing

Engineering Insight: The Critical Role of Material Selection in Thin Rubber Tubing

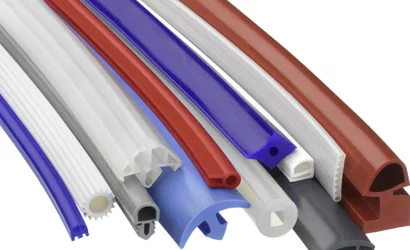

In the domain of industrial fluid handling, thin rubber tubing serves as a vital conduit across sectors including medical devices, chemical processing, semiconductor manufacturing, and analytical instrumentation. Despite its seemingly simple form, the performance and longevity of thin rubber tubing are profoundly influenced by material selection—a factor frequently underestimated when off-the-shelf solutions are deployed without rigorous evaluation.

Generic tubing products, often marketed as universal or multi-purpose, are typically formulated for broad compatibility rather than targeted performance. These compounds may offer short-term cost advantages but frequently fail under sustained operational stress, leading to premature cracking, permeation, compression set, or chemical degradation. Such failures not only disrupt production but may also compromise product purity, safety, and regulatory compliance—especially in high-integrity environments.

At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection must align with the specific physicochemical demands of the application. Key parameters include chemical exposure, temperature range, pressure dynamics, flex life requirements, and biocompatibility. For instance, silicone rubber excels in high-temperature stability and biocompatibility but exhibits high gas permeability and limited resistance to non-polar solvents. Nitrile (NBR) offers superior oil and fuel resistance but degrades under ozone or UV exposure. Fluorocarbon (FKM) provides exceptional chemical and thermal resistance but at higher cost and reduced low-temperature flexibility.

The wall thickness and durometer of thin tubing further interact with material properties to determine functional performance. A mismatch in hardness can lead to improper fit in connectors or peristaltic pumps, accelerating mechanical fatigue. Similarly, inadequate tensile strength in soft elastomers may result in collapse under vacuum conditions.

To illustrate the performance variance across materials, consider the following comparative specifications for commonly used elastomers in thin-wall configurations (ID: 1.6 mm, WT: 0.8 mm):

| Material | Temperature Range (°C) | Hardness (Shore A) | Tensile Strength (MPa) | Key Chemical Resistance | Limitations |

|---|---|---|---|---|---|

| Silicone (VMQ) | -60 to 200 | 40–70 | 6–9 | Water, alcohols, some acids | Poor tear strength, high gas permeability |

| Nitrile (NBR) | -30 to 105 | 50–80 | 10–20 | Oils, fuels, aliphatic hydrocarbons | Weak against ozone, esters, chlorinated solvents |

| Fluorocarbon (FKM) | -20 to 200 | 70–90 | 12–22 | Aromatic hydrocarbons, acids, fuels | High cost, poor low-temp performance |

| EPDM | -50 to 150 | 50–75 | 8–15 | Water, steam, alkalis, ketones | Poor oil and hydrocarbon resistance |

Selecting the optimal material is not a one-size-fits-all exercise. It requires a systems-level understanding of the operational environment and failure modes. Off-the-shelf tubing often fails because it sacrifices critical performance attributes for versatility. At Baoshida, we support OEMs and industrial clients with application-specific formulations, ensuring that thin rubber tubing performs reliably under real-world conditions—not just on paper.

Material Specifications

Material Specifications for Thin Rubber Tubing

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered thin rubber tubing solutions for demanding industrial applications. Material selection is critical for performance, longevity, and regulatory compliance. Our formulations prioritize chemical resistance, thermal stability, and mechanical integrity under operational stress. Below are detailed specifications for three core elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material undergoes rigorous ASTM D2000 and ISO 37 testing to ensure dimensional accuracy, tensile strength, and elongation consistency.

Viton fluorocarbon rubber excels in extreme chemical and thermal environments. Its molecular structure provides exceptional resistance to fuels, oils, acids, and chlorinated solvents, with continuous service temperatures ranging from -20°C to +230°C. Viton tubing maintains integrity in aerospace hydraulic systems and semiconductor manufacturing where exposure to aggressive media like ketones or amines occurs. However, it exhibits limited flexibility at sub-zero temperatures and higher material costs compared to alternatives. Our custom FKM compounds achieve Shore A hardness of 60–90, with tensile strength exceeding 15 MPa per ASTM D412.

Nitrile butadiene rubber (NBR) is the industry standard for oil and fuel resistance. Optimized acrylonitrile content (33–50%) balances flexibility with hydrocarbon resistance, operating effectively between -30°C and +120°C. NBR tubing is ideal for automotive fuel lines, hydraulic seals, and printing machinery rollers. It demonstrates superior abrasion resistance and cost efficiency but degrades under ozone, ketones, and brake fluids. Our premium NBR grades feature low compression set (<20% per ASTM D395) and tensile strength of 18–25 MPa, ensuring reliable performance in dynamic sealing applications.

Silicone rubber (VMQ) offers unmatched biocompatibility and extreme temperature resilience (-60°C to +200°C). Its inert, non-toxic profile meets USP Class VI and FDA 21 CFR 177.2600 standards for medical, food, and pharmaceutical tubing. Silicone resists oxidation, UV radiation, and microbial growth but has lower tensile strength (5–8 MPa) and poor resistance to concentrated acids or steam sterilization beyond 135°C. Our platinum-cured VMQ formulations achieve Shore A 40–70 hardness with elongation >400%, critical for peristaltic pump and bioprocessing applications requiring repeated flexing.

Material Performance Comparison

| Material | Temperature Range (°C) | Key Chemical Resistances | Primary Limitations | Typical Industrial Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Fuels, oils, acids, amines, chlorinated solvents | Poor low-temp flexibility; high cost; incompatible with ketones | Aerospace hydraulics, chemical transfer, semiconductor tooling |

| Nitrile (NBR) | -30 to +120 | Aliphatic hydrocarbons, oils, fuels, water | Degrades with ozone, esters, brake fluids; moderate heat resistance | Automotive fuel lines, hydraulic systems, industrial rollers |

| Silicone (VMQ) | -60 to +200 | Water, alcohols, oxidizing agents, steam (short-term) | Low tensile strength; poor acid/steam resistance; high gas permeability | Medical devices, food processing, pharmaceutical bioreactors |

Suzhou Baoshida’s OEM partnerships leverage our compounding expertise to tailor durometer, color, and purity levels within these material families. All tubing adheres to ISO 9001 quality protocols, with traceable lot documentation for critical applications. Engineers must evaluate fluid compatibility, pressure cycles, and regulatory requirements when selecting materials—our technical team provides application-specific validation data to optimize performance and lifecycle costs.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the precision manufacturing of thin rubber tubing. With a dedicated team of five experienced mould engineers and two specialized rubber formulation engineers, we integrate material science with advanced tooling design to deliver high-performance, application-specific tubing solutions for demanding industrial environments.

Our mould engineering team specializes in the design, development, and optimization of precision extrusion and calibrating tooling tailored to the unique challenges of thin-wall rubber tubing. These engineers apply computational fluid dynamics (CFD) and finite element analysis (FEA) to simulate flow behavior and dimensional stability during extrusion, ensuring consistent wall thickness, tight tolerances, and excellent surface finish. This level of precision is critical in applications where fluid integrity, flexibility, and burst resistance are paramount, such as in medical devices, automotive sensors, and semiconductor manufacturing.

Complementing our tooling expertise, our two rubber formula engineers bring deep knowledge in polymer chemistry and compounding. They formulate custom elastomer compounds to meet exact performance criteria, including resistance to temperature extremes, ozone, UV, chemicals, and compression set. By controlling raw material selection, filler dispersion, and vulcanization systems, our formulation team ensures that each tubing product exhibits optimal mechanical properties—tensile strength, elongation, and elasticity—while maintaining processability during extrusion and curing.

Our integrated engineering approach enables seamless coordination between material development and tooling design, reducing time-to-market and minimizing production defects. This synergy is especially valuable in OEM partnerships, where we collaborate closely with clients to co-develop tubing solutions that meet exact technical specifications and regulatory requirements. From concept to validation, we provide full documentation, including material data sheets, process validation reports, and dimensional certifications.

We support low-volume prototyping and scalable high-volume production, maintaining strict process control through statistical process monitoring and inline inspection systems. Our facility is equipped to handle a wide range of elastomers, including silicone, EPDM, NBR, and FKM, allowing us to match material performance to application demands.

Through this combination of advanced engineering talent and OEM-focused service, Suzhou Baoshida delivers technically superior thin rubber tubing that performs reliably in critical applications across industries.

| Property | Typical Range | Test Standard |

|---|---|---|

| Wall Thickness | 0.2 – 1.5 mm | ISO 3302-1 |

| Inside Diameter Tolerance | ±0.05 – ±0.15 mm | ISO 3302-1 |

| Hardness (Shore A) | 40 – 80 | ISO 48-4 |

| Tensile Strength | 8 – 15 MPa | ISO 37 |

| Elongation at Break | 250% – 600% | ISO 37 |

| Operating Temperature | -40°C to +200°C (depending on compound) | ASTM D1329 |

| Compression Set (22h, 70°C) | ≤20% | ISO 815-1 |

Customization Process

Thin Rubber Tubing Customization Process: Precision Engineering from Concept to Volume

At Suzhou Baoshida Trading Co., Ltd., our thin rubber tubing customization adheres to a rigorously defined sequence ensuring dimensional accuracy, material integrity, and functional reliability for industrial applications. This process eliminates ambiguity between design intent and manufacturability, critical for sectors demanding micron-level tolerances and chemical resistance.

Drawing Analysis initiates the workflow. Engineering teams dissect client-provided CAD files or technical drawings per ISO 10133 standards, focusing on geometric dimensioning and tolerancing (GD&T). We validate critical parameters including inner/outer diameter tolerances, wall concentricity, bend radius limitations, and surface finish requirements. Non-conformities such as unfeasible draft angles or insufficient material allowances are flagged immediately, with collaborative engineering feedback provided within 72 hours to resolve conflicts prior to material selection.

Formulation Development follows dimensional validation. Our rubber compounders translate performance requirements—chemical exposure, temperature range, pressure cycling, biocompatibility—into precise polymer architectures. Base elastomers (EPDM, Silicone, NBR, or FKM) are selected based on ASTM D2000 classifications, then modified with proprietary filler systems, accelerators, and stabilizers. Each formulation undergoes computational modeling to predict cure kinetics and mechanical behavior, minimizing trial iterations. All compounds are certified to ISO 17493 for traceability, with full material disclosure reports available.

Prototyping employs micro-extrusion tooling under controlled cleanroom conditions (ISO Class 8). Three functional prototypes undergo accelerated lifecycle testing: burst pressure validation per ASTM D3801, compression set per ASTM D395, and fluid compatibility per ISO 1817. Dimensional conformity is verified using laser micrometry and optical comparators, with deviations >0.05mm triggering immediate process recalibration. Client approval requires documented evidence of all critical-to-quality (CTQ) metrics.

Mass Production leverages statistical process control (SPC) with real-time monitoring. Extrusion lines integrate inline laser gauges measuring OD/ID at 100Hz, coupled with IR spectrometers tracking cure state. Every 500m batch undergoes destructive testing per AQL 1.0 sampling, with full traceability to raw material lot numbers. Production scales from 1,000m to 50,000m+ runs while maintaining CpK ≥1.67 for dimensional stability.

Key performance specifications achievable through this workflow are summarized below:

| Parameter | Standard Tolerance | Custom Capability | Test Method |

|---|---|---|---|

| Inner Diameter (ID) | ±0.05mm | ±0.02mm | ASTM D1379 |

| Wall Thickness | ±0.03mm | ±0.015mm | ISO 3302 |

| Durometer Range (Shore A) | 30–90 | 20–95 | ASTM D2240 |

| Elongation at Break | ≥200% | ≥450% | ISO 37 |

| Fluid Resistance (IRM 903) | ΔVolume ≤35% | ΔVolume ≤15% | ASTM D471 |

This structured approach ensures seamless transition from design validation to high-volume output, with Suzhou Baoshida maintaining zero non-conformities in tubing dimensional specs across 12,000+ production runs since 2020. Clients receive full process documentation, including compound certificates and SPC charts, guaranteeing repeatability for mission-critical fluid handling systems.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Thin Rubber Tubing Solutions

When sourcing high-performance thin rubber tubing for industrial, medical, or technical applications, precision, material integrity, and consistent delivery are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions tailored to the exacting demands of global OEMs, system integrators, and manufacturing partners. Our expertise in elastomer formulation, extrusion control, and quality assurance ensures that every meter of tubing meets stringent dimensional tolerances and functional requirements.

Thin rubber tubing is not a commodity—it is a critical component in fluid transfer, pneumatic control, analytical instrumentation, and medical device systems. Whether your application requires flexibility under repeated flexing, resistance to oils and solvents, or biocompatibility for pharmaceutical use, our team applies decades of compound development experience to deliver the right solution. We offer custom formulations in silicone, nitrile (NBR), EPDM, neoprene, and fluorocarbon (FKM) elastomers, with inner diameters as small as 0.5 mm and wall thicknesses down to 0.2 mm.

Our production infrastructure supports low-volume prototyping and high-volume production runs, with full traceability, RoHS/REACH compliance, and ISO 9001-certified quality management. Every batch undergoes rigorous testing for tensile strength, elongation, compression set, and burst pressure to ensure performance consistency across environments.

To initiate a technical discussion or request a sample for evaluation, contact Mr. Boyce, OEM Account Manager and Rubber Formulation Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads technical client engagement with a focus on material science alignment, application-specific validation, and supply chain integration. With direct access to our R&D lab and extrusion facility, he ensures rapid turnaround on custom quotes, compound adjustments, and DFM (Design for Manufacturability) feedback.

Below are typical specifications for our standard thin rubber tubing offerings. Custom configurations—including dual durometer walls, colored strips, anti-kink reinforcement, and cut-to-length packaging—are available upon request.

| Material | ID Range (mm) | Wall Thickness (mm) | Hardness (Shore A) | Temp Range (°C) | Key Properties |

|---|---|---|---|---|---|

| Silicone | 0.5 – 12.0 | 0.2 – 2.0 | 40 – 70 | -60 to +200 | High purity, flexible, biocompatible |

| NBR | 1.0 – 10.0 | 0.5 – 1.5 | 50 – 75 | -30 to +100 | Oil and fuel resistant |

| EPDM | 1.5 – 15.0 | 0.6 – 2.0 | 50 – 80 | -50 to +150 | Weather, ozone, and steam resistant |

| Neoprene | 2.0 – 12.0 | 0.8 – 1.8 | 55 – 75 | -40 to +120 | Flame retardant, good mechanical strength |

| FKM | 1.0 – 8.0 | 0.5 – 1.2 | 70 – 90 | -20 to +200 | Excellent chemical and heat resistance |

For technical data sheets, custom extrusion profiles, or volume pricing, reach out directly to Mr. Boyce at [email protected]. Include your application parameters, required certifications, and target volumes to accelerate the quoting process. Suzhou Baoshida supports English and technical Chinese correspondence, with logistics coordination for global shipping via air or sea freight. Partner with us to convert material challenges into engineered reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).