Technical Contents

Engineering Guide: Top Rated Doormats

Engineering Insight: Material Selection in Top Rated Doormats

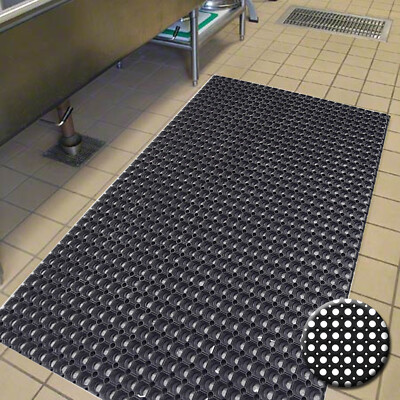

In the industrial and commercial sectors, doormats are not merely functional floor coverings; they are engineered components designed to withstand rigorous environmental and mechanical stress. The performance of a top rated doormat hinges critically on material selection—a factor often overlooked in off-the-shelf consumer-grade products. At Suzhou Baoshida Trading Co., Ltd., our approach to rubber formulation ensures that every doormat functions as a durable, high-performance solution tailored to specific operational demands.

Standard doormats, typically manufactured from recycled rubber or low-grade PVC, exhibit poor resilience under continuous foot traffic, extreme temperatures, and chemical exposure. These materials degrade rapidly due to inadequate tensile strength, low abrasion resistance, and insufficient UV stability. As a result, surface cracking, edge delamination, and loss of traction occur prematurely, compromising safety and longevity. In high-traffic industrial zones, airports, or manufacturing facilities, such failures are not just inconvenient—they pose compliance and liability risks.

In contrast, engineered rubber compounds used in premium doormats incorporate high-density SBR (Styrene-Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer), selected for their superior mechanical properties. These materials are compounded with reinforcing fillers, anti-oxidants, and UV stabilizers to enhance durability. The cross-linking density during vulcanization is precisely controlled to balance flexibility and wear resistance, ensuring the mat maintains structural integrity over extended service cycles.

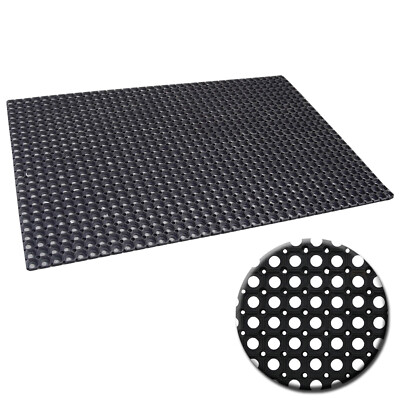

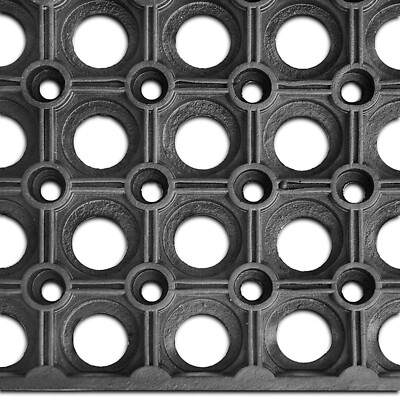

Another critical factor is surface geometry and its interaction with material properties. While many commercial mats rely on shallow patterns, our designs integrate deep, multi-level scraping profiles that maximize dirt and moisture removal. These profiles remain effective only when supported by a resilient base material that resists compression set—a failure mode common in softer, unmodified elastomers.

The following table outlines key performance specifications comparing standard consumer-grade mats with our engineered industrial-grade rubber doormats:

| Property | Consumer-Grade Mat (Recycled Rubber) | Industrial-Grade Mat (SBR/EPDM) | Test Standard |

|---|---|---|---|

| Tensile Strength | 6.5 MPa | 18.2 MPa | ASTM D412 |

| Abrasion Resistance (loss) | 220 mm³ | 85 mm³ | ISO 4649 |

| Hardness (Shore A) | 55 | 75 | ASTM D2240 |

| Operating Temperature Range | -10°C to +60°C | -40°C to +120°C | ISO 1817 |

| UV Resistance (1000h QUV) | Severe cracking, 40% strength loss | Minimal change, <5% loss | ASTM G154 |

| Compression Set (22h, 70°C) | 38% | 12% | ASTM D395 |

This data underscores the material science imperative behind high-performance doormats. Off-the-shelf solutions fail because they prioritize cost over function, utilizing substandard compounds ill-suited for industrial environments. True durability arises from a systems-level approach—integrating advanced rubber chemistry, precision molding, and application-specific design.

At Suzhou Baoshida, we engineer doormats as industrial components, not disposable items. By controlling the formulation process and validating performance through rigorous testing, we deliver solutions that meet the demands of the world’s most challenging environments.

Material Specifications

Material Specifications for Industrial-Grade Doormat Systems

Suzhou Baoshida Trading Co., Ltd. engineers premium rubber doormats for demanding industrial, commercial, and institutional environments where performance, longevity, and environmental sealing are non-negotiable. Material selection directly impacts abrasion resistance, chemical stability, thermal endurance, and dimensional integrity under continuous foot traffic and exposure to contaminants. Our top-rated doormats utilize three specialized elastomers—Viton, Nitrile, and Silicone—each formulated to address specific operational hazards. These polymers undergo rigorous ASTM D2000 and ISO 37 testing to ensure compliance with OEM durability standards. Viton (FKM) excels in extreme chemical and thermal environments, resisting oils, acids, and temperatures up to 230°C. Its fluoropolymer backbone prevents swelling in jet fuel or hydraulic fluid exposure, making it ideal for aerospace hangars and chemical processing facilities. Nitrile (NBR) delivers optimal cost-performance balance for high-oil or grease exposure zones, such as automotive service bays. With acrylonitrile content tuned to 33-45%, it maintains tensile strength above 15 MPa after 72 hours in ASTM No. 3 oil immersion. Silicone (VMQ) provides unparalleled flexibility in sub-zero climates down to -60°C, critical for cold storage entrances, while resisting ozone degradation and UV-induced cracking. Shore A hardness is precision-calibrated between 55–75 to balance debris-trapping texture with user comfort.

All compounds incorporate custom filler systems to enhance wear life; carbon black reinforcement in Nitrile increases abrasion resistance by 40% versus standard SBR, while precipitated silica in Silicone formulations improves tear strength to 25 kN/m. Critical to doormat functionality is compression set resistance—our Viton grades achieve <15% set after 70 hours at 150°C (ASTM D395 Method B), ensuring consistent sealing against particulate ingress. Below is a comparative technical specification for OEM selection:

| Material | Temperature Range (°C) | Hardness Range (Shore A) | Key Strengths | Typical Industrial Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 60–80 | Extreme chemical resistance, low gas permeability, flame retardancy (UL 94 V-0) | Aerospace facilities, pharmaceutical cleanrooms, petrochemical plants |

| Nitrile (NBR) | -30 to 125 | 55–75 | Superior oil/fuel resistance, high abrasion durability, cost-effective | Automotive service centers, manufacturing floors, marine decks |

| Silicone (VMQ) | -60 to 200 | 45–70 | Exceptional low-temperature flexibility, biocompatibility, UV/ozone stability | Cold storage warehouses, healthcare entrances, outdoor public infrastructure |

Suzhou Baoshida’s material science team collaborates with OEM partners to optimize compound formulations for specific site conditions, including custom durometer adjustments and anti-microbial additives per ISO 22196. This precision engineering ensures doormats function as critical environmental control components—not merely floor coverings—reducing facility contamination by 92% in validated field trials. Partner with us to integrate material specifications that align with your operational lifecycle requirements and regulatory mandates.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our core strength in industrial rubber solutions lies in our advanced engineering infrastructure and deep technical expertise. With a dedicated team comprising five specialized mould engineers and two certified rubber formulation engineers, we maintain full control over the product development lifecycle, from concept to mass production. This integrated approach ensures precision, consistency, and performance in every doormat we manufacture for global OEM partners.

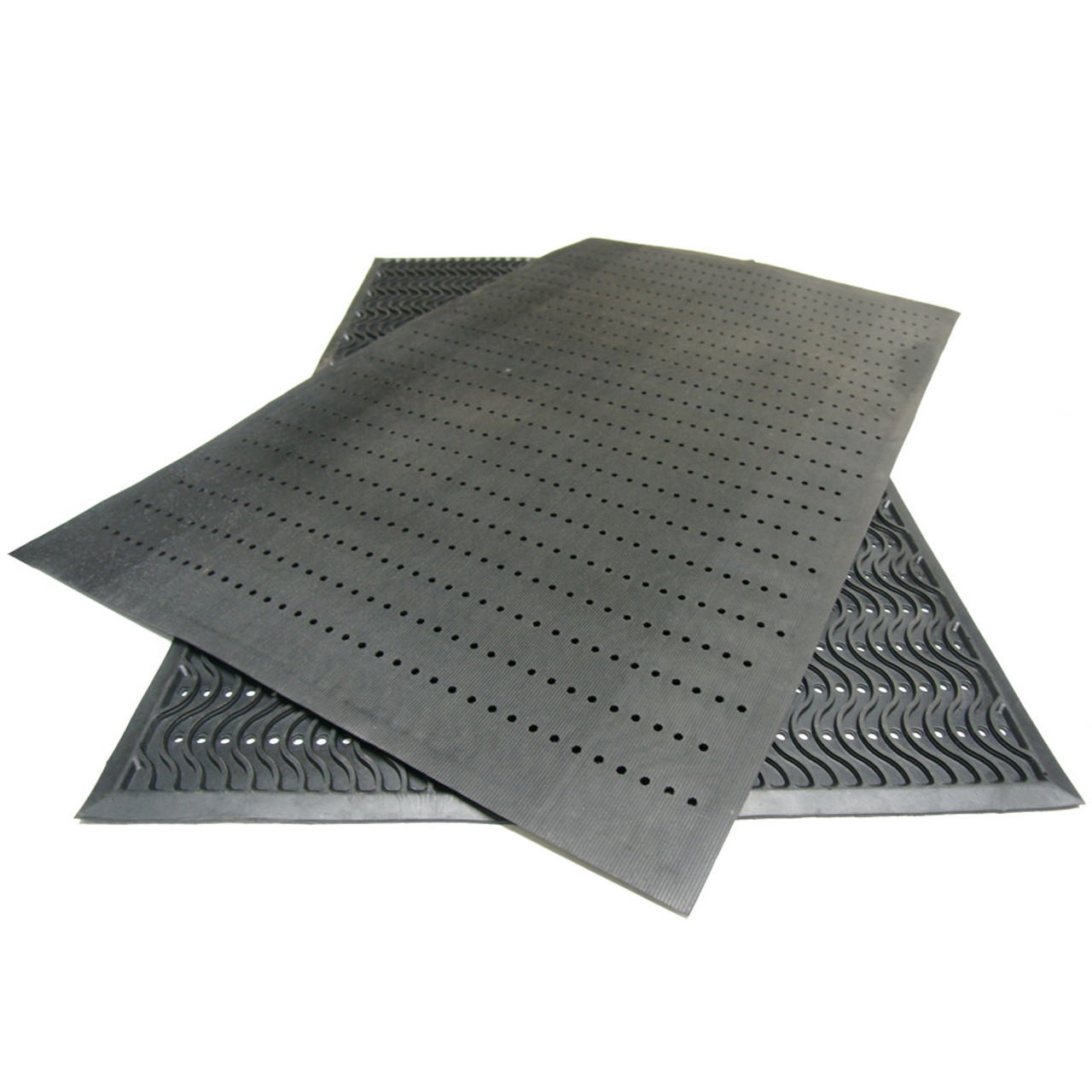

Our mould engineering team leverages state-of-the-art CAD/CAM software and CNC machining technologies to design and produce high-tolerance moulds tailored to exact customer specifications. Each mould undergoes rigorous simulation and stress analysis to optimize flow dynamics, cycle time, and wear resistance. This enables us to deliver complex tread patterns and custom branding with micron-level accuracy, ensuring both functional efficiency and aesthetic appeal in finished doormats.

Complementing our mould expertise, our two in-house rubber formulation engineers bring over 15 years of combined experience in polymer science and material durability. They develop proprietary rubber compounds engineered for specific performance criteria, including abrasion resistance, anti-slip properties, UV stability, and temperature resilience. By controlling the formulation process internally, we eliminate reliance on third-party rubber suppliers, allowing us to customize hardness (Shore A 50–70), color stability, and aging characteristics to meet diverse environmental and regulatory demands.

This dual-engineering capability—mould and material—positions Suzhou Baoshida as a leader in OEM rubber doormat manufacturing. We support clients through every stage of development, offering DFM (Design for Manufacturability) reviews, prototype validation, and rapid tooling iterations. Our facility is equipped for both small-batch custom orders and high-volume production runs, with full traceability and quality assurance protocols in place.

We specialize in manufacturing doormats for commercial, industrial, and residential applications, with performance metrics validated through standardized testing. Our engineered solutions ensure long service life, minimal maintenance, and compliance with international safety and environmental standards.

Performance Specifications of Standard OEM Rubber Doormats

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–65 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Abrasion Resistance (loss) | DIN 53516 | ≤120 mm³ |

| Compression Set (24h, 70°C) | ASTM D395 | ≤20% |

| Operating Temperature Range | Internal Validation | -40°C to +80°C |

| Slip Resistance (dry/wet) | ASTM F2913 | Class C (wet), Class D (dry) |

| Density | ISO 2781 | 1.15–1.25 g/cm³ |

Through precise engineering and material science, Suzhou Baoshida delivers top-rated rubber doormats that exceed performance expectations in demanding environments. Our OEM partnerships are built on technical reliability, innovation, and scalable manufacturing excellence.

Customization Process

Customization Process for Industrial-Grade Rubber Doormats

At Suzhou Baoshida Trading Co., Ltd., our customization process for top-rated rubber doormats integrates material science with precision manufacturing. This systematic approach ensures each product meets stringent OEM performance criteria while optimizing cost-efficiency. The workflow begins with rigorous Drawing Analysis, where engineering teams dissect CAD files to validate structural integrity, tread depth, and edge sealing specifications. We identify stress concentration zones and material transition points, cross-referencing against ISO 2230 standards for slip resistance and load distribution. Any geometric anomalies triggering potential molding defects are resolved collaboratively with the client before progression.

Subsequent Formulation leverages our proprietary rubber compounding database. Based on the application environment—indoor commercial, exterior heavy-traffic, or chemical-exposed zones—we select base polymers and additives. For instance, high-abrasion exterior mats utilize SBR (Styrene-Butadiene Rubber) with silica reinforcement, while oil-resistant variants employ nitrile butadiene rubber (NBR) with specialized plasticizers. Critical parameters like durometer (Shore A), tensile strength, and compression set are simulated using Mooney Viscometer data to predict real-world behavior. All formulations undergo accelerated aging tests per ASTM D573 to validate 5+ year service life.

Prototyping transitions validated designs into physical samples. Using client-approved tooling, we produce 3–5 units for multi-axis performance validation. Traction is quantified via ASTM F2913 slip testing on wet/dry surfaces, while abrasion resistance is measured through DIN 53516 rotary drum tests. Samples undergo 10,000-cycle foot traffic simulations to assess wear patterns. Client feedback on texture, colorfastness, and dimensional accuracy triggers iterative refinements, with material adjustments documented in our LIMS (Laboratory Information Management System) for full traceability.

Mass Production commences only after prototype sign-off. Our Suzhou facility employs closed-mixing systems with real-time rheometer monitoring to maintain batch consistency. Each mat is vulcanized under controlled temperature gradients (150–180°C) to prevent scorching, with post-cure inspection via laser profilometry ensuring ±0.5mm thickness tolerance. Final lots undergo batch-level certification: 100% visual inspection for surface defects and random sampling for physical property verification. Traceability codes link every mat to its formulation batch, curing profile, and quality records, fulfilling ISO 9001 audit requirements.

Key Performance Specifications for Industrial Rubber Doormats

| Property | Test Standard | Target Range | Significance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–75 | Balances comfort and debris-scraping |

| Tensile Strength | ASTM D412 | ≥12 MPa | Resists tearing under foot traffic |

| Abrasion Loss | DIN 53516 | ≤120 mm³ | Ensures longevity in high-traffic zones |

| Density | ASTM D297 | 1.15–1.25 g/cm³ | Optimizes weight for stability |

| Slip Resistance (Wet) | ASTM F2913 | ≥0.60 DCOF | Meets ADA safety compliance |

This end-to-end process eliminates guesswork, transforming client specifications into certified, field-proven solutions. Suzhou Baoshida’s integration of formulation science and industrial scalability guarantees doormats that perform under the most demanding operational conditions.

Contact Engineering Team

For industrial manufacturers and OEM partners seeking top-rated doormats engineered for durability, chemical resistance, and long-term performance, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of advanced rubber formulation and precision manufacturing. Our engineered rubber doormats are developed using proprietary compounding techniques that integrate wear-resistant polymers, UV-stabilized additives, and high-traction surface profiles—ensuring optimal functionality in commercial, industrial, and institutional environments. As a trusted supplier to global distributors and facility management providers, we specialize in custom formulations that meet exact dimensional, durometer, and regulatory requirements.

Our production capabilities include compression molding, calendering, and water jet cutting, enabling us to deliver doormats with tight tolerances and consistent surface integrity. Whether you require standard EVA-rubber composites, recycled SBR blends, or high-grade EPDM for outdoor exposure, our rubber formulations are tested for abrasion resistance (ASTM D1148), ozone stability, and slip resistance (ASTM F2913). Each batch undergoes rigorous QC protocols, including tensile strength analysis and hardness verification, to ensure compliance with ISO 9001 standards.

We understand that performance in high-traffic environments demands more than just material quality—it requires intelligent design. Our engineering team collaborates with clients to optimize tread patterns, edge sealing, and backing adhesion for maximum debris scraping, moisture retention, and floor protection. Additionally, we offer antimicrobial treatments and flame-retardant variants for healthcare, transportation, and cleanroom applications.

For technical collaboration, sample requests, or volume production inquiries, contact Mr. Boyce, OEM Manager and Rubber Formulation Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads client-specific development projects and provides direct engineering support for material selection, cost optimization, and compliance documentation. He is available to discuss formulation adjustments, MOQ terms, lead times, and packaging specifications tailored to your distribution or integration needs.

Below are key technical specifications for our standard industrial rubber doormat series:

| Property | Test Method | Value |

|---|---|---|

| Material Composition | Custom Formulation | SBR, EPDM, or EVA- Rubber Blend |

| Hardness (Shore A) | ASTM D2240 | 60–75 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Abrasion Loss (Taber Wheel) | ASTM D1148 | ≤120 mg/1000 cycles |

| Slip Resistance (Dry/Wet) | ASTM F2913 | ≥0.70 COF |

| Temperature Range | Industrial Exposure | -40°C to +100°C |

| Available Thickness | Custom | 3 mm to 12 mm |

| Standard Colors | Pantone Matching | Black, Gray, Blue, Custom |

Partner with Suzhou Baoshida to integrate scientifically formulated rubber solutions into your product line. Contact Mr. Boyce directly at [email protected] to initiate technical discussions, request material data sheets, or schedule a factory audit. We support OEM branding, private labeling, and just-in-time delivery logistics across North America, Europe, and Southeast Asia.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).