Technical Contents

Engineering Guide: Tpe Thermoplastic

Engineering Insight: TPE Thermoplastic Material Selection Imperatives

Industrial applications demand thermoplastic elastomers (TPEs) that consistently perform under rigorous mechanical, thermal, and chemical stresses. While off-the-shelf TPE compounds offer apparent cost savings, their generic formulations frequently fail to meet the specific, often extreme, requirements of precision engineering components. This failure stems from inadequate consideration of the operational environment during material selection, leading to premature part degradation, system downtime, and significant financial losses. Standard TPEs are typically optimized for broad consumer markets, prioritizing processability and initial aesthetics over long-term resilience in demanding industrial settings. Critical factors such as continuous exposure to specific oils, elevated temperatures beyond 100°C, dynamic fatigue cycles, or stringent regulatory compliance (e.g., FDA, UL) are often overlooked in generic grades. Consequently, components like seals, gaskets, or flexible couplings experience accelerated compression set, excessive swelling, loss of tensile strength, or catastrophic cracking, directly impacting equipment reliability and safety.

Material selection must transcend basic hardness (Shore A) or initial cost metrics. A rigorous engineering assessment is essential, evaluating the compound against the exact service conditions. Key parameters include resistance to specific fluid exposures (hydrocarbons, glycols, acids), long-term thermal stability (both upper and lower limits), dynamic flex life under load, compression set retention after prolonged stress, and electrical properties if applicable. The interplay between these factors is complex; for instance, a TPE exhibiting excellent oil resistance at 80°C may suffer rapid deterioration at 110°C. Generic compounds lack the tailored polymer architecture and specialized additive packages required to balance these competing demands effectively. Failure to specify these parameters during sourcing inevitably results in mismatched material performance.

The following table highlights critical performance gaps between standard off-the-shelf TPEs and engineered solutions designed for industrial reliability:

| Property | Standard TPE (Off-the-Shelf) | Engineered TPE (Industrial Grade) | Critical Threshold (Example Application) |

|---|---|---|---|

| Compression Set (70°C, 22h) | 35-45% | ≤ 15% | < 25% for static seals (ISO 360) |

| Oil Swell (IRM 903, 70°C) | 40-60% | ≤ 20% | < 30% for hydraulic seals (SAE J204) |

| Continuous Use Temp | 80-90°C | 110-135°C | > 100°C for under-hood automotive |

| Tensile Retention (1000h, 100°C) | 40-60% | ≥ 85% | > 75% for dynamic couplings |

| Flex Crack Growth (DIN 53504) | High Propagation | Negligible Propagation | Zero growth for high-cycle applications |

Suzhou Baoshida Trading Co., Ltd. addresses this critical gap through our OEM partnership model. We collaborate deeply during the design phase, leveraging our material science expertise to formulate TPE compounds precisely aligned with your application’s mechanical, environmental, and regulatory constraints. Our process involves comprehensive application analysis, iterative compound development, and rigorous validation testing against real-world conditions – not just baseline specs. This proactive engineering approach eliminates the costly trial-and-error of generic materials, ensuring optimal part longevity, system uptime, and total cost of ownership. Trust in engineered performance, not commodity specifications, for mission-critical industrial rubber solutions.

Material Specifications

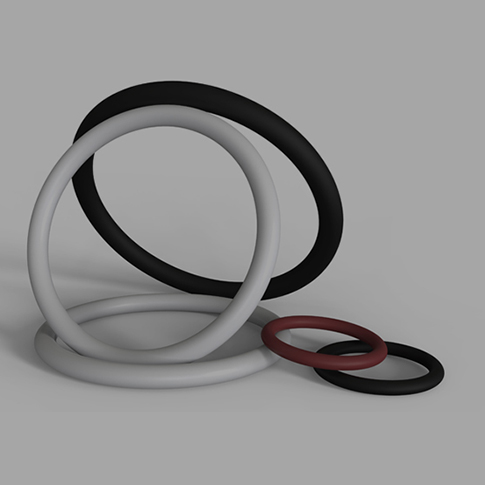

TPE thermoplastics represent a critical class of elastomeric materials engineered for high-performance industrial applications, combining the processability of thermoplastics with the resilience and flexibility of traditional rubber. At Suzhou Baoshida Trading Co., Ltd., we specialize in advanced rubber formulations tailored to meet stringent OEM requirements across automotive, aerospace, medical, and industrial sealing sectors. Among the most widely specified elastomers in our portfolio are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct chemical, thermal, and mechanical properties suitable for targeted operational environments.

Viton exhibits exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals, making it ideal for demanding applications such as fuel system seals, engine gaskets, and chemical processing equipment. With continuous service capabilities up to 230°C and short-term excursions beyond 300°C, Viton maintains structural integrity under extreme thermal cycling. Its low gas permeability and excellent aging characteristics further enhance reliability in critical sealing roles.

Nitrile rubber, a cost-effective solution for oil and fuel resistance, is widely used in hydraulic systems, O-rings, and fuel hoses. It demonstrates strong abrasion resistance and tensile strength, with operational stability in temperatures ranging from -30°C to 120°C. While not as thermally stable as Viton, Nitrile offers superior performance in aliphatic hydrocarbon environments and remains a preferred choice for general-purpose industrial sealing where exposure to petroleum-based fluids is prevalent.

Silicone rubber excels in extreme temperature applications, functioning reliably from -60°C to 200°C, with specialty grades enduring even higher peaks. Its biocompatibility, UV resistance, and low compression set make it ideal for medical devices, food processing seals, and outdoor electrical insulation. Although lower in mechanical strength compared to Viton or Nitrile, Silicone provides outstanding flexibility and resistance to ozone and weathering, ensuring long-term performance in dynamic and environmentally exposed conditions.

The selection of the appropriate elastomer depends on a precise balance of chemical exposure, thermal profile, mechanical loading, and regulatory compliance. Suzhou Baoshida Trading Co., Ltd. supports OEMs with rigorous material testing, custom compounding, and full traceability to ensure optimal performance and compliance with international standards.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fuel/Oil Resistance | Excellent | Good to Excellent | Poor |

| Ozone/Weathering Resistance | Excellent | Good | Excellent |

| Compression Set (22h, 150°C) | Low | Moderate | Low to Moderate |

| Biocompatibility | Limited | No | Yes (medical grades) |

| Common Applications | Aerospace seals, fuel systems | Hydraulic seals, gaskets | Medical devices, outdoor seals |

Manufacturing Capabilities

Engineering Capability: Precision TPE Thermoplastic Solutions

Suzhou Baoshida Trading Co., Ltd. delivers advanced thermoplastic elastomer (TPE) manufacturing through a dedicated core of specialized engineering expertise. Our strength lies in the integrated synergy between 5 certified Mold Engineers and 2 senior Rubber Formula Engineers, ensuring every TPE component meets exacting industrial performance and manufacturability standards. This dual-discipline approach is fundamental to our OEM service model, eliminating the traditional disconnect between material science and mold design prevalent in the industry.

Our Formula Engineers possess deep proficiency in TPE polymer chemistry, focusing on custom compounding for targeted mechanical properties, thermal stability, chemical resistance, and processing behavior. They meticulously develop formulations balancing Shore hardness, tensile strength, elongation, and compression set to satisfy specific application demands, whether for automotive seals, medical device components, or industrial gaskets. Concurrently, our Mold Engineers apply advanced CAD/CAM tools and mold-flow analysis to optimize cavity design, gating systems, cooling channels, and ejection mechanisms specifically for TPE’s unique viscosity and shrinkage characteristics. This parallel development process guarantees that the material formulation and the mold geometry are intrinsically compatible, minimizing trial-and-error cycles and accelerating time-to-market for client projects.

This integrated engineering workflow directly enables our robust OEM capabilities. We partner with clients from initial concept through full-scale production, providing comprehensive technical support for material selection, prototype validation, and process optimization. Our engineers conduct rigorous in-house testing to verify dimensional accuracy, material consistency, and functional performance against client specifications under simulated operational conditions. Suzhou Baoshida maintains strict ISO 9001-aligned quality control protocols throughout the manufacturing process, ensuring batch-to-batch repeatability and compliance with international standards. Clients benefit from a single-source responsibility model where material science and precision molding expertise converge to solve complex engineering challenges.

The following table outlines key technical specifications achievable with our engineered TPE compounds, reflecting the precision enabled by our dual-engineer team:

| Property | Typical Range | Test Method |

|---|---|---|

| Shore Hardness (A) | 30A – 95A | ASTM D2240 |

| Density (g/cm³) | 0.90 – 1.20 | ASTM D792 |

| Tensile Strength (MPa) | 5.0 – 18.0 | ASTM D412 |

| Elongation at Break (%) | 150 – 800 | ASTM D412 |

| Compression Set (%) | ≤ 25 (22h, 70°C) | ASTM D395 |

| Melt Flow Index (g/10min) | 2.0 – 30.0 (190°C/2.16kg) | ASTM D1238 |

Suzhou Baoshida’s commitment to engineering excellence ensures that every TPE solution is not merely manufactured but scientifically engineered. Our team’s combined expertise in material formulation and precision molding delivers OEM partners with reliable, high-performance components that meet the most stringent industrial requirements, backed by rigorous quality assurance and responsive technical collaboration. This capability forms the cornerstone of our value proposition in the global TPE thermoplastic market.

Customization Process

TPE Thermoplastic Customization Process: From Design to Production

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet exacting performance and dimensional standards, particularly in the development of TPE (Thermoplastic Elastomer) components. Our systematic customization process ensures precision, repeatability, and material efficiency across all production phases. The journey begins with Drawing Analysis, where technical blueprints are evaluated for geometric complexity, tolerance requirements, and functional conditions such as stress exposure, temperature range, and chemical resistance. This initial assessment allows us to identify critical dimensions and potential molding challenges, ensuring that the final product aligns with both design intent and operational demands.

Following drawing validation, we proceed to Formulation Design. TPEs offer a broad spectrum of mechanical and thermal properties, but optimal performance requires tailored compounding. Our rubber formula engineers analyze the application environment—whether it involves dynamic flexing, sealing under pressure, or exposure to oils and UV radiation—and select the appropriate base polymer (e.g., SEBS, TPO, or TPV). Additives such as plasticizers, fillers, stabilizers, and reinforcing agents are then precisely blended to achieve target hardness, tensile strength, elongation, and compression set. This stage is critical for balancing processability with end-use functionality, particularly in demanding industrial sectors like automotive, medical devices, and consumer electronics.

Once the formulation is finalized, Prototyping commences using injection molding or extrusion techniques, depending on the part geometry. Small-batch samples are produced under near-production conditions to validate flow behavior, dimensional stability, and surface finish. These prototypes undergo rigorous testing, including durometer measurement, tensile testing, and environmental aging, to confirm compliance with OEM specifications. Client feedback is integrated at this stage, allowing for iterative refinement before tooling investment.

Upon approval, we transition to Mass Production using high-precision molds and automated processing lines. Our manufacturing facilities support scalability from medium to high volumes with strict in-line quality control, including real-time dimensional monitoring and batch traceability. Throughout production, material consistency is maintained through controlled drying, temperature profiling, and screw residence time optimization.

The following table outlines typical TPE formulation ranges and achievable properties based on application class:

| Property | General Purpose | High Flex Life | Oil-Resistant | High-Temp Stable |

|---|---|---|---|---|

| Hardness (Shore A) | 60–90 | 70–85 | 70–95 | 80–95 |

| Tensile Strength (MPa) | 8–12 | 10–14 | 9–13 | 10–12 |

| Elongation at Break (%) | 400–600 | 500–700 | 400–550 | 350–500 |

| Heat Resistance (°C) | 100 (short-term) | 100 | 110 | 135 |

| Oil Resistance (IRM 903, 70°C, 70h) | Swell >50% | Swell >50% | Swell <30% | Swell <35% |

This structured approach—Drawing Analysis, Formulation, Prototyping, and Mass Production—ensures that every TPE component delivered by Suzhou Baoshida meets the highest standards of industrial performance and reliability.

Contact Engineering Team

Precision TPE Solutions Engineered for Industrial Performance

Suzhou Baoshida Trading Co., Ltd. delivers next-generation thermoplastic elastomer (TPE) formulations engineered to meet the rigorous demands of modern industrial manufacturing. Our TPE compounds bridge the gap between conventional rubber elasticity and thermoplastic processability, enabling high-efficiency production cycles without sacrificing mechanical integrity or environmental resilience. As your dedicated OEM partner, we prioritize material science precision—optimizing hardness, tensile strength, and chemical resistance to align with your specific application requirements. Whether for automotive seals, medical device components, or consumer electronics housings, our formulations undergo stringent QC validation to ensure repeatability across injection molding, extrusion, and overmolding processes.

Critical TPE Performance Specifications

| Property | Test Method | Typical Range | Industrial Relevance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 30–95 | Sealing force, tactile feedback control |

| Tensile Strength (MPa) | ASTM D412 | 8–30 | Structural durability under load |

| Elongation at Break (%) | ASTM D412 | 200–1200 | Flex fatigue resistance |

| Compression Set (%) | ASTM D395 | <25 (70°C, 22h) | Long-term sealing integrity |

| Operating Temperature (°C) | ISO 188 | -50 to +135 | Thermal stability in extreme environments |

| Specific Gravity | ASTM D792 | 0.95–1.20 | Weight-sensitive design optimization |

These metrics reflect our baseline industrial-grade TPE portfolio. However, true value emerges through customization: we adjust polymer architecture to achieve flame retardancy (UL94 V-0), medical biocompatibility (ISO 10993), or enhanced adhesion to engineering plastics like PC/ABS. Our in-house compounding facility in Suzhou operates under ISO 9001 protocols, guaranteeing lot-to-lot consistency and traceability from raw material sourcing to finished compound delivery. Unlike commodity suppliers, we integrate application engineering support—providing mold flow analysis, DFM guidance, and accelerated aging data to de-risk your scale-up phase.

Your Path to Optimized TPE Integration

Material selection is merely the starting point. Suzhou Baoshida functions as an extension of your R&D team, collaborating from prototype validation through full-volume production. We eliminate supply chain vulnerabilities through strategic raw material hedging and dual-source manufacturing capabilities, ensuring uninterrupted delivery even amid volatile petrochemical markets. For complex multi-material assemblies, our adhesion-promoting TPE grades eliminate secondary bonding steps—reducing assembly costs by up to 18% while enhancing product lifespan.

Initiate Your Custom TPE Partnership Today

To transform your material challenges into competitive advantages, contact Mr. Boyce, our Senior Technical Account Manager, for a precision-engineered solution assessment. With 14 years of OEM partnership experience across automotive Tier-1 suppliers and medical device innovators, Mr. Boyce will coordinate a cross-functional review of your performance targets, regulatory constraints, and cost-in-use parameters. Expect actionable data—not generic brochures—within 48 hours of engagement.

Direct Technical Consultation

Mr. Boyce

Senior OEM Solutions Manager

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Subject Line: TPE Technical Collaboration Request [Your Company Name]

Specify your application’s critical requirements in your initial inquiry to accelerate sample validation. We maintain active material libraries for rapid prototyping and welcome confidential disclosure agreements to safeguard your IP. Partner with engineering rigor, not just supply.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).