Technical Contents

Engineering Guide: Tpo Rubber Roof

Engineering Insight: Material Selection in TPO Rubber Roof Systems

Thermoplastic polyolefin (TPO) rubber roofing has emerged as a dominant solution in commercial and industrial building envelopes due to its durability, UV resistance, and energy efficiency. However, despite its widespread adoption, premature failures in TPO roofing systems remain a persistent issue—often rooted not in the inherent limitations of the material, but in inadequate material selection and specification practices. At Suzhou Baoshida Trading Co., Ltd., we emphasize that successful TPO roof performance is not a function of generic product availability, but of engineered compatibility with environmental, structural, and operational demands.

Off-the-shelf TPO roofing membranes are frequently marketed as universal solutions, yet they rarely account for regional climate variations, building load dynamics, or long-term exposure to chemical and mechanical stressors. For instance, standard-grade TPO formulations may exhibit acceptable initial tensile strength but degrade rapidly under continuous thermal cycling or prolonged UV exposure, particularly in high-temperature zones such as southern China or desert regions. Additionally, many commercially available membranes utilize lower-grade fillers and plasticizers to reduce costs, compromising long-term flexibility and leading to embrittlement within 5–7 years.

Critical performance parameters such as puncture resistance, seam integrity, and dimensional stability are directly influenced by polymer architecture and additive packages. High-performance TPO systems employ ethylene-propylene rubber (EPR) as the primary elastomeric phase, combined with controlled polypropylene (PP) crystallinity to balance flexibility and strength. Furthermore, stabilizers such as hindered phenols and UV absorbers must be precisely dosed to ensure oxidative resistance over decades, not just years.

Another frequently overlooked factor is substrate compatibility. TPO membranes adhered to steel, concrete, or existing bituminous layers require tailored adhesion promoters and underlayment systems. Using a single adhesive formulation across substrates leads to delamination and moisture ingress. Similarly, mechanical fastening systems must be engineered for wind uplift resistance based on local building codes and roof geometry—standard fastener patterns often fail under dynamic loading.

At the core of reliable TPO roofing is a systems-based approach: material selection cannot be isolated from installation methodology, environmental exposure, and lifecycle expectations. Custom-formulated TPO compounds, developed in collaboration with experienced industrial rubber engineers, ensure that every component of the roofing assembly functions cohesively under real-world conditions.

Below is a comparison of standard-grade versus engineered-grade TPO membrane specifications:

| Property | Standard-Grade TPO | Engineered-Grade TPO (Baoshida OEM) |

|---|---|---|

| Tensile Strength (MPa) | ≥ 9.0 | ≥ 14.5 |

| Elongation at Break (%) | ≥ 300 | ≥ 550 |

| Tear Resistance (kN/m) | ≥ 1.5 | ≥ 3.2 |

| Heat Aging (115°C, 672h) | Strength Retention ≥ 70% | Strength Retention ≥ 90% |

| UV Exposure Resistance (3000h) | Moderate chalking | No chalking, minimal gloss loss |

| Low-Temperature Flexibility | -20°C | -40°C |

| Seam Peel Strength (N/mm) | ≥ 1.0 | ≥ 2.5 |

Material selection is not a cost-driven compromise—it is an engineering imperative. Suzhou Baoshida Trading Co., Ltd. partners with OEMs and contractors to deliver TPO rubber roof solutions that are scientifically validated, regionally optimized, and built for longevity.

Material Specifications

Material Specifications for TPO Roofing System Components

Thermoplastic Olefin (TPO) roofing membranes represent a dominant single-ply solution in commercial construction, yet critical sealing and flashing elements often require elastomeric materials to ensure system integrity. At Suzhou Baoshida Trading Co., Ltd., we supply precision-formulated Viton, Nitrile (NBR), and Silicone compounds engineered for compatibility with TPO substrates and demanding environmental exposure. These materials address key failure points including seam adhesion, penetration sealing, and edge termination under thermal cycling, UV radiation, and chemical exposure. Selection must prioritize long-term elasticity retention, adhesion stability, and resistance to plasticizer migration from adjacent layers.

Viton (FKM) fluorocarbon rubber delivers unparalleled chemical and thermal resistance, essential for roofs exposed to industrial pollutants, hydrocarbon-based roofing cements, or extreme temperature fluctuations. Its molecular stability prevents degradation from ozone, acid rain, and cleaning solvents, maintaining seal integrity where other elastomers fail. Nitrile (NBR) offers a cost-effective balance for general applications, providing strong resistance to aliphatic oils and moderate UV exposure, though it exhibits reduced performance above 100°C and susceptibility to ozone cracking without protective additives. Silicone excels in extreme UV and high-temperature environments (>200°C), with exceptional flexibility retention down to -60°C, but requires careful formulation to mitigate potential issues with tear strength and adhesion to non-polar TPO surfaces.

The comparative analysis below details critical performance parameters for informed material selection in TPO roofing auxiliary components. All values reflect standard ASTM test methods under controlled laboratory conditions; real-world performance depends on formulation specifics and installation protocols.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Continuous Service Temp Range | -20°C to +230°C | -30°C to +120°C | -60°C to +230°C |

| Tensile Strength (MPa) | 12–18 | 10–20 | 5–10 |

| Elongation at Break (%) | 150–250 | 200–400 | 300–800 |

| Ozone Resistance (100 pphm) | Excellent | Poor to Fair* | Excellent |

| Acid Resistance (10% H₂SO₄) | Excellent | Good | Poor |

| Adhesion to TPO (Peel Strength) | High (requires primer) | Moderate | Variable (surface treatment critical) |

| Typical Application Context | High-pollution zones, chemical plants | Standard commercial roofs, cost-sensitive projects | Desert climates, high-UV exposure, extreme thermal cycling |

*Requires saturation resistance additives for roofing applications.

Material selection directly impacts system longevity and warranty validity. Viton is non-negotiable for roofs adjacent to chemical processing facilities or where solvent exposure is anticipated. Nitrile remains viable for standard urban installations when compounded with ozone inhibitors, though accelerated aging tests are recommended. Silicone’s superior low-temperature flexibility makes it ideal for northern climates, but its lower tear strength necessitates thicker cross-sections in high-stress details. Crucially, all compounds must undergo substrate compatibility testing per ASTM D471 to prevent plasticizer extraction from TPO membranes, which causes embrittlement. Suzhou Baoshida provides OEM-specific formulation tuning and adhesion validation data to ensure seamless integration within your TPO roofing system, minimizing field failures and maximizing service life. Partner with us to optimize material performance against your project’s environmental profile.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for TPO Rubber Roofing Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance TPO (Thermoplastic Polyolefin) rubber roofing materials. Our technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM services from concept to final product. This multidisciplinary structure ensures that both material science and mechanical design are optimized in parallel, reducing development cycles and enhancing product reliability.

Our rubber formula engineers focus on the molecular architecture of TPO compounds, tailoring polymer blends to meet rigorous environmental and mechanical demands. By adjusting ethylene-propylene rubber (EPR) ratios, filler systems, plasticizers, and stabilizers, we achieve superior UV resistance, thermal stability, and low-temperature flexibility—critical for roofing applications exposed to extreme weather. These formulations are validated through accelerated aging tests, tensile analysis, and dynamic mechanical thermal analysis (DMTA), ensuring compliance with international standards such as ASTM D6878 and ISO 12967.

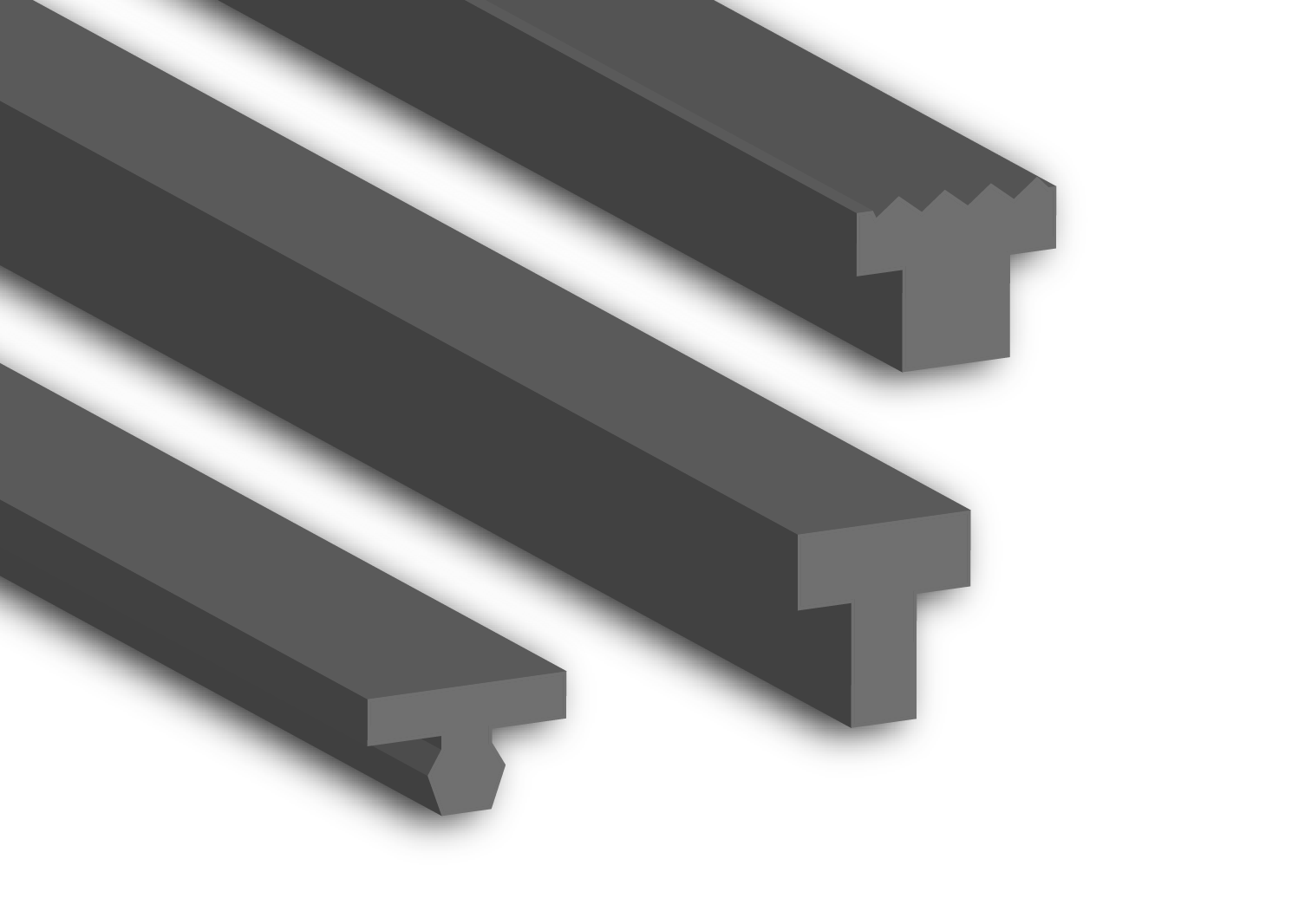

Simultaneously, our five mould engineers specialize in precision tooling design for large-format TPO roofing membranes and profile extrusions. Utilizing advanced CAD/CAM software and finite element analysis (FEA), they optimize flow dynamics, cooling channels, and part ejection systems to ensure dimensional accuracy and consistent surface finish across high-volume production runs. Their expertise extends to both compression and injection moulding processes, allowing flexibility in manufacturing complex geometries and custom profiles for OEM partners.

We support full OEM collaboration, offering private-label development, co-engineering services, and rapid prototyping. Clients benefit from our end-to-end control over formulation, tooling, and process validation, minimizing third-party dependencies and safeguarding intellectual property. Our facility is equipped with state-of-the-art twin-screw compounding lines, hydraulic presses, and inline quality monitoring systems to ensure batch-to-batch consistency.

The integration of formulation and mould engineering enables us to solve complex challenges—such as reducing weld-line visibility, improving seam strength, or enhancing reflectivity—through coordinated material and design adjustments. This holistic approach differentiates our TPO roofing solutions in performance-critical markets across construction, transportation, and industrial infrastructure.

Key Technical Specifications of Custom TPO Roofing Compounds

| Property | Test Method | Typical Value |

|---|---|---|

| Tensile Strength | ASTM D412 | ≥12.0 MPa |

| Elongation at Break | ASTM D412 | ≥450% |

| Heat Aging (115°C, 240h) | ASTM D573 | Retention ≥80% |

| Low-Temperature Flexibility | ASTM D2136 | Pass at -40°C |

| UV Resistance (3000h QUV) | ASTM G154 | ΔE < 3.0 |

| Tear Strength | ASTM D624 | ≥40 kN/m |

| Flame Spread (UL 790) | ASTM E108 | Class A |

Through rigorous engineering and deep material expertise, Suzhou Baoshida delivers TPO rubber roofing solutions that combine durability, process efficiency, and OEM scalability.

Customization Process

TPO Rubber Roof Customization Process: Precision Engineering for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our TPO rubber roof customization process integrates rigorous scientific methodology with industrial-scale execution to meet exact OEM specifications. This structured workflow ensures material performance aligns with environmental demands, structural requirements, and longevity expectations critical for commercial roofing systems.

The process initiates with Drawing Analysis, where engineering teams dissect client-provided technical schematics against ASTM D6878 and EN 13956 standards. We validate dimensional tolerances, seam configurations, and substrate compatibility, identifying potential stress points or chemical exposure risks. Critical parameters such as membrane thickness (±0.1mm), reinforcement layer placement, and edge detailing undergo computational stress modeling to preempt field failures. This phase concludes with a formal deviation report, ensuring design integrity before material development commences.

Formulation follows, leveraging our proprietary polymer science expertise. Our lab engineers adjust base resin ratios (polypropylene/EPDM), UV stabilizers, and flame retardants to achieve target properties. For instance, enhanced UV resistance requires precise hindered amine light stabilizer (HALS) dosing at 0.8–1.2 phr, while low-temperature flexibility demands EPDM copolymer optimization. Every compound is validated via DSC for crystallinity control and rheometry for extrusion stability. Client-specific requirements—such as heightened chemical resistance for industrial zones—trigger iterative adjustments, documented in our ISO 9001-certified formulation logs.

Prototyping transforms the validated formula into physical samples. Using client-specified tooling, we produce 1m² test membranes for accelerated aging (QUV ASTM G154), tensile testing (ASTM D412), and peel strength validation. Critical performance metrics undergo third-party verification, including hydrolysis resistance at 80°C/95% RH for 500 hours. Clients receive a comprehensive test dossier; non-conformities trigger immediate reformulation without delaying mass production timelines.

Mass Production deploys the approved prototype at scale under stringent SPC protocols. Our Suzhou facility utilizes 2.4m wide extrusion lines with laser-guided thickness control (±0.05mm). Real-time monitoring tracks melt viscosity, cooling rates, and surface finish. Each production lot includes embedded RFID tags for full traceability—from raw material batches to finished rolls—ensuring compliance with LEED v4.1 and FM 4473 certification frameworks. Final inspection includes 100% visual scanning and random destructive testing against the prototype baseline.

The table below summarizes key customization tiers for TPO roofing membranes:

| Performance Tier | Base Polymer Composition | UV Resistance (kWh/m²) | Tear Strength (kN/m) | Operating Temperature Range (°C) |

|---|---|---|---|---|

| Standard | 65% PP / 35% EPDM | 5,000 | 18.5 | -40 to +115 |

| Enhanced | 60% PP / 40% EPDM + 1.0% HALS | 12,000 | 24.0 | -45 to +120 |

| Extreme | 55% PP / 45% EPDM + 1.5% HALS + Nanoclay | 20,000 | 30.5 | -50 to +125 |

This end-to-end process eliminates guesswork, transforming client drawings into certified, field-proven roofing solutions. Suzhou Baoshida guarantees seamless transition from prototype to production, backed by 15+ years of OEM partnership in industrial rubber manufacturing. All custom formulations include lifetime performance warranties aligned with regional climate databases.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced TPO Rubber Roofing Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber solutions, delivering high-performance materials tailored for demanding construction and roofing applications. Our expertise in thermoplastic olefin (TPO) rubber roofing systems ensures long-term durability, UV resistance, and superior waterproofing characteristics essential for modern commercial and industrial buildings. As a trusted OEM partner, we combine precision engineering with rigorous quality control to meet international standards, including ASTM D6878 and ISO 9001 certifications. Whether you are developing large-scale roofing projects or require customized membrane formulations, our technical team provides end-to-end support from material selection to production optimization.

Our TPO rubber roofing compounds are engineered for exceptional weatherability, maintaining structural integrity under extreme temperature fluctuations and prolonged solar exposure. With inherent resistance to ozone, algae, and chemical degradation, our formulations extend service life while minimizing maintenance costs. We supply raw compounds, pre-fabricated sheets, and co-extruded membranes compatible with mechanical fastening, fully adhered, and ballasted installation methods. Each product batch undergoes comprehensive testing for tensile strength, elongation at break, low-temperature flexibility, and heat aging performance to ensure consistency and compliance.

For architects, engineers, and industrial manufacturers seeking reliable supply chains and technical collaboration, Suzhou Baoshida offers scalable production capacity and global logistics support. We specialize in custom compounding to meet regional building codes and performance requirements, including fire ratings (FM 4470, UL 790) and energy efficiency standards (ENERGY STAR® compliant). Our R&D team works closely with clients to adjust formulation parameters such as filler content, polymer blend ratios, and stabilizer packages, ensuring optimal balance between cost-efficiency and performance.

Partnering with Suzhou Baoshida means gaining access to a vertically integrated supply chain, advanced testing laboratories, and over a decade of experience serving leading roofing manufacturers across Europe, North America, and Southeast Asia. We prioritize transparency, technical accuracy, and responsive service to support your project timelines and quality benchmarks.

For immediate technical consultation or material sampling, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer, directly at [email protected]. Mr. Boyce leads formulation development and client engineering integration, ensuring that every TPO solution is precisely aligned with your performance and production needs. We respond to all inquiries within 24 hours during business days.

TPO Rubber Roofing Material Specifications

| Property | Test Method | Typical Value |

|---|---|---|

| Tensile Strength | ASTM D412 | ≥12.0 MPa |

| Elongation at Break | ASTM D412 | ≥500% |

| Tear Resistance | ASTM D624 | ≥40 kN/m |

| Low Temperature Flexibility | ASTM D1938 | Pass at -40°C |

| Heat Aging Resistance (115°C, 672h) | ASTM D573 | Tensile Retention ≥80% |

| UV Resistance (3000h Xenon Arc) | ASTM G155 | No cracking, minimal color shift |

| Flame Spread (UL 790) | UL 790 | Class A Rated |

| Water Absorption (7 days) | ASTM D570 | ≤0.5% |

Reach out today to integrate high-performance TPO rubber roofing materials into your next project.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).