Technical Contents

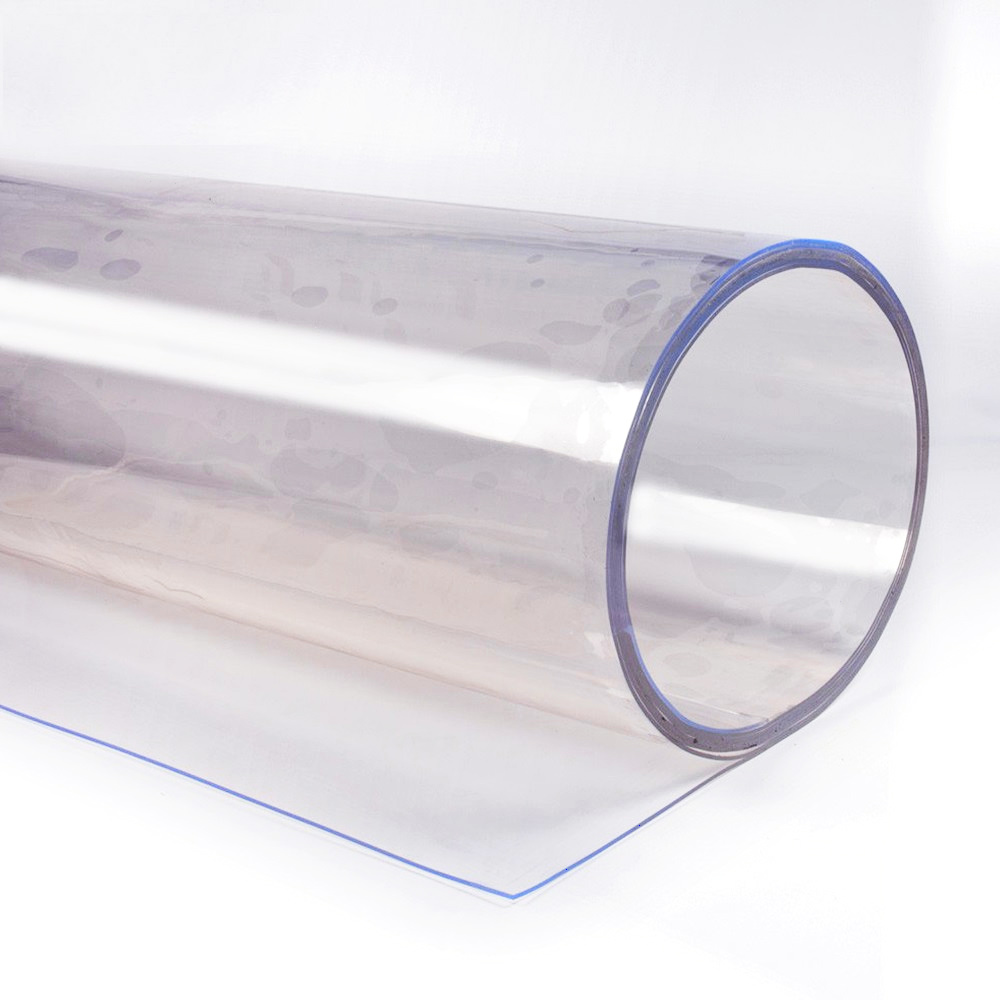

Engineering Guide: Translucent Pvc Sheet

Engineering Insight: The Critical Role of Material Selection in Translucent PVC Sheet Applications

In industrial environments where performance, durability, and optical clarity converge, the selection of translucent PVC sheet material is not a matter of convenience—it is a precision engineering decision. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf PVC solutions frequently fail to meet the rigorous demands of specialized applications due to unoptimized formulations, inconsistent additive packages, and inadequate performance under thermal, chemical, or mechanical stress. Understanding the engineered parameters behind translucent PVC sheets is essential to ensuring long-term reliability and operational safety.

Translucent PVC sheets are commonly deployed in applications requiring light diffusion with structural integrity—such as machine guards, cleanroom partitions, protective enclosures, and architectural glazing. While standard-grade PVC may appear visually adequate, it often lacks the tailored formulation needed to resist yellowing under UV exposure, maintain clarity in high-humidity environments, or sustain mechanical load over time. These shortcomings arise because commodity-grade sheets prioritize cost over performance, using recycled content, unbalanced plasticizer ratios, or insufficient stabilizer systems.

The failure of generic PVC sheets manifests in several critical ways. Plasticizer migration leads to embrittlement and cracking, particularly in dynamic or elevated-temperature environments. Poor UV stabilization results in rapid discoloration and loss of light transmission, compromising both aesthetics and functionality. Additionally, inconsistent sheet thickness and optical distortion in mass-produced variants degrade performance in precision applications.

At the core of a reliable solution lies a balanced formulation engineered for the intended service environment. Our translucent PVC sheets are formulated with high-purity virgin resin, non-migrating plasticizers, and advanced UV inhibitors to ensure long-term clarity and mechanical stability. We control the polymerization process and additive integration to achieve consistent optical diffusion without sacrificing impact resistance or chemical resilience.

The table below outlines the key performance specifications of our engineered translucent PVC sheet compared to a typical off-the-shelf alternative.

| Property | Engineered Translucent PVC (Baoshida) | Standard Off-the-Shelf PVC |

|---|---|---|

| Light Transmission (%) | 80–85 | 70–75 |

| Tensile Strength (MPa) | ≥50 | 35–40 |

| Elongation at Break (%) | ≥250 | 180–200 |

| Heat Distortion Temperature (°C) | 75 | 60 |

| UV Resistance (1,000 hrs QUV) | Minimal yellowing (ΔYI < 5) | Significant yellowing (ΔYI > 15) |

| Plasticizer Retention (1,000 hrs at 70°C) | >95% | <80% |

| Sheet Thickness Tolerance | ±0.1 mm | ±0.3 mm |

Material selection must be driven by application-specific performance criteria, not visual similarity or initial cost. In industrial rubber and polymer solutions, the margin between success and failure is often defined at the molecular level. Suzhou Baoshida Trading Co., Ltd. provides engineered translucent PVC sheets designed to outperform generic alternatives in real-world operational conditions—ensuring safety, efficiency, and longevity.

Material Specifications

Material Specifications for Translucent PVC Sheet Applications

Translucent PVC sheet represents a specialized thermoplastic solution distinct from elastomeric compounds like Viton, Nitrile, or Silicone. As an Industrial Rubber Solutions provider, Suzhou Baoshida Trading Co., Ltd. clarifies this critical material classification to prevent specification errors in B2B manufacturing. Translucent PVC sheets derive optical properties from rigid polyvinyl chloride formulations with minimal additives, whereas Viton, Nitrile, and Silicone are elastomers inherently opaque due to reinforcing fillers and curing systems. Confusing these categories risks functional failure in applications requiring visual monitoring, such as fluid containment windows or protective barriers.

Translucent PVC sheets achieve 85–90% light transmission through precise control of plasticizer content, polymer molecular weight, and absence of light-scattering pigments. Standard industrial grades maintain Shore A hardness of 70–85, with continuous service temperatures from -10°C to 60°C. Critical performance parameters include tensile strength (≥15 MPa), elongation at break (≥250%), and haze values below 5% per ASTM D1003. Ultraviolet stabilizers are essential for outdoor use to prevent yellowing, while anti-static variants incorporate conductive additives without compromising clarity. Unlike elastomers, PVC sheets exhibit minimal compression set but lack resilience for dynamic sealing—making them unsuitable for gasketing despite superficial visual similarities.

The following table contrasts translucent PVC with common elastomers to eliminate material misapplication. Viton, Nitrile, and Silicone cannot achieve true translucency due to carbon black or silica reinforcement, limiting their use in sight-glass applications.

| Material Type | Transparency Range | Hardness (Shore A) | Temperature Range (°C) | Key Limitations for Translucent Applications |

|---|---|---|---|---|

| Translucent PVC | 85–90% | 70–85 | -10 to +60 | Plasticizer migration above 60°C; UV degradation without stabilizers |

| Viton (FKM) | Opaque | 60–90 | -20 to +230 | Carbon black reinforcement blocks light transmission; high cost |

| Nitrile (NBR) | Opaque | 50–95 | -30 to +120 | Inherent opacity from fillers; poor ozone resistance |

| Silicone (VMQ) | Translucent* | 30–80 | -60 to +200 | Haze >40% due to filler scattering; limited structural rigidity |

*Note: Silicone achieves only milky translucency (50–70% transmission) and requires costly optical-grade processing. It remains inferior to PVC for clarity-critical industrial sheets.

Suzhou Baoshida emphasizes that genuine translucent PVC sheets require ISO 9001-certified extrusion with laser-guided thickness control (±0.1 mm tolerance). Custom formulations address chemical resistance needs—e.g., adding chlorinated polyethylene for hydrocarbon exposure—while preserving optical properties. Always validate sheet specifications against ASTM D4286 for translucency and ISO 188 for thermal aging. For elastomer applications requiring visibility, consider polycarbonate or acrylic alternatives; elastomeric seals paired with PVC viewing windows deliver optimal system performance. Our OEM team provides material compatibility testing to ensure seamless integration into your manufacturing process.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering division is the cornerstone of our industrial rubber solutions, delivering precision and innovation in every translucent PVC sheet we manufacture. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we integrate material science with advanced tooling design to meet the exacting demands of global OEMs. Our multidisciplinary approach ensures that both the chemical composition and physical structure of our products are optimized for performance, durability, and consistency.

Our formula engineers possess deep expertise in polymer chemistry, with a focused understanding of plasticizers, stabilizers, and transparency modifiers critical to producing high-clarity translucent PVC sheets. They systematically develop and refine PVC formulations to achieve target properties such as light transmission, UV resistance, flexibility, and thermal stability. Each formulation is validated through rigorous in-house testing, including aging simulations, tensile strength analysis, and haze measurement, ensuring compliance with international standards such as ISO 9001 and RoHS.

Complementing this material expertise, our five mould engineers bring extensive experience in precision tooling design and process optimization. They utilize advanced CAD/CAM software and finite element analysis (FEA) to design extrusion dies and calendering systems tailored to the unique flow characteristics of translucent PVC compounds. This synergy between formulation and tooling enables us to maintain tight tolerances, eliminate optical distortions, and ensure uniform sheet thickness—critical factors in applications requiring visual clarity and dimensional accuracy.

As an OEM-focused manufacturer, we offer end-to-end development support, from concept and material selection to prototyping and mass production. Our engineering team collaborates directly with clients to customize mechanical properties, adjust color fastness, and integrate functional additives such as anti-static or flame-retardant agents. This collaborative model allows for rapid iteration and accelerated time-to-market, particularly for industries such as medical enclosures, protective barriers, display systems, and industrial glazing.

Our production facility is equipped with state-of-the-art extrusion lines and inline quality monitoring systems, enabling real-time adjustments during manufacturing. This closed-loop control system, combined with our engineering team’s oversight, ensures batch-to-batch consistency and minimal defect rates.

Below is a summary of our standard technical specifications for translucent PVC sheets:

| Property | Standard Value | Test Method |

|---|---|---|

| Thickness Range | 0.3 mm – 5.0 mm | ISO 2818 |

| Light Transmission (1mm) | ≥85% | ASTM D1003 |

| Haze | ≤3% | ASTM D1003 |

| Tensile Strength | ≥45 MPa | ISO 37 |

| Elongation at Break | ≥250% | ISO 37 |

| Operating Temperature Range | -10°C to +60°C | ISO 188 |

| Flame Retardancy (Optional) | UL94 V-0 available | UL 94 |

| Plasticizer Content | Adjustable (DINP, DOTP, etc.) | GC-MS |

Through the integration of advanced formulation science and precision engineering, Suzhou Baoshida delivers translucent PVC sheets that meet the highest industrial standards. Our OEM capabilities are built on technical depth, responsive collaboration, and a relentless focus on quality.

Customization Process

Translucent PVC Sheet Customization Process: Precision Engineering from Concept to Volume Production

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions mandate rigorous scientific methodology for translucent PVC sheet customization. This ensures optimal performance in demanding applications like protective glazing, equipment windows, and specialized enclosures where optical clarity, mechanical integrity, and environmental resistance are non-negotiable. Our four-phase OEM process eliminates guesswork, translating client specifications into reliable, high-volume output.

Drawing Analysis: Decoding Performance Requirements

Initial engagement centers on meticulous technical drawing review. We dissect dimensional tolerances, optical specifications (haze, transmission), mechanical load requirements, and environmental exposure parameters (UV, temperature range, chemical contact). Crucially, we assess the interplay between these factors; for instance, extreme flexibility demands may conflict with high light transmission targets. Our engineers identify potential manufacturability conflicts early, proposing scientifically sound material or design refinements. This phase establishes the definitive performance benchmark against which all subsequent stages are measured, preventing costly iterations later.

Formulation: Tailored Polymer Science

Leveraging our core expertise in rubber and plastic compounding, we develop a proprietary PVC formulation. Standard translucent grades often fail under industrial stress. Our chemists precisely calibrate plasticizer types and concentrations to achieve target flexibility without excessive migration or volatility. Stabilizer packages are engineered for specific thermal and UV exposure profiles, while optical modifiers are selected to minimize light scattering. Critical additives like epoxidized soybean oil enhance long-term clarity retention. Every component ratio undergoes computational modeling to predict processing behavior and final properties, ensuring the compound meets the stringent criteria defined in the drawing analysis phase.

Prototyping: Validated Performance Under Real Conditions

Prototype sheets are manufactured using production-intent tooling and processes. Rigorous in-house testing validates optical properties per ASTM D1003, mechanical strength per ISO 527, and thermal stability per ISO 11357. Prototypes undergo accelerated aging tests simulating years of field exposure. Crucially, we conduct application-specific validation – bending cycles for flexible windows, chemical immersion tests for enclosure gaskets, or impact testing for protective barriers. Client feedback on prototype samples is integrated with quantitative data to finalize the formulation and process parameters. Only when all metrics consistently exceed the agreed specification is the design released for production.

Mass Production: Consistent Quality at Scale

Transition to high-volume manufacturing employs tightly controlled extrusion processes with real-time monitoring of melt temperature, line speed, and calendering pressure. Statistical Process Control (SPC) tracks critical parameters like thickness uniformity and optical clarity on every production run. Batch traceability from raw material lots to finished sheets ensures accountability. Final inspection includes 100% visual checks for defects and random sampling for full mechanical and optical retesting against the approved prototype baseline. This systematic approach guarantees every square meter of translucent PVC sheet shipped delivers the precise performance promised.

Key Translucent PVC Sheet Specifications Achievable via Customization

| Parameter | Standard Range | Precision Customization Capability | Test Standard |

|---|---|---|---|

| Thickness | 0.3 mm – 5.0 mm | ±0.02 mm tolerance achievable | ISO 2567 |

| Light Transmission | 80% – 88% | Target-specific optimization | ASTM D1003 |

| Haze | 2% – 8% | <3% achievable for critical optics | ASTM D1003 |

| Tensile Strength | 15 MPa – 25 MPa | Engineered to application load | ISO 527 |

| Elongation at Break | 200% – 400% | Precisely calibrated flexibility | ISO 527 |

| Heat Deflection Temp | 55°C – 70°C @ 0.45MPa | Enhanced stability to 85°C+ | ISO 75 |

This structured engineering pathway minimizes client risk and production downtime, transforming complex translucent PVC requirements into dependable, high-performance industrial components. Suzhou Baoshida’s scientific rigor ensures your specification becomes a reality, consistently.

Contact Engineering Team

For industrial manufacturers seeking high-performance translucent PVC sheet solutions, Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered materials tailored to demanding applications across automotive, construction, electronics, and medical equipment sectors. As a specialized provider within the Industrial Rubber Solutions category, we integrate material science expertise with rigorous quality control to ensure every batch of translucent PVC sheet meets exacting standards for clarity, durability, and chemical resistance.

Our translucent PVC sheets are formulated for optimal light transmission while maintaining mechanical integrity under variable thermal and environmental conditions. Whether used for protective enclosures, sight windows, or flexible barriers, our product line supports customization in thickness, hardness, and UV stabilization. Each sheet undergoes in-line optical inspection and tensile verification to guarantee consistency across large-scale production runs.

To support seamless integration into your manufacturing process, we offer technical data packages including compliance documentation (REACH, RoHS), thermal deflection curves, and flame retardancy ratings upon request. Our engineering team collaborates directly with OEMs to validate material performance against application-specific stress factors such as cyclic flexing, solvent exposure, and long-term weathering.

For immediate technical consultation or custom formulation support, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce specializes in industrial polymer solutions and has over 12 years of experience supporting global clients in material selection, prototyping, and volume supply chain coordination. He is available to provide sample kits, coordinate third-party testing validation, and assist in transitioning from prototype to full production with minimal lead-time disruption.

Reach out via email at [email protected] to initiate a technical dialogue. Include your project specifications, volume requirements, and any regulatory certifications needed. Our response time is within 4 business hours for all qualified inquiries. For urgent requests, indicate “Time-Sensitive: Translucent PVC Project” in the subject line to ensure priority routing.

Below are key technical specifications for our standard translucent PVC sheet offering:

| Property | Test Method | Value |

|---|---|---|

| Thickness Range | ASTM D374 | 0.5 mm – 5.0 mm |

| Light Transmission (1mm) | ASTM D1003 | ≥ 88% |

| Tensile Strength | ASTM D412 | 35 MPa (min) |

| Elongation at Break | ASTM D412 | 280% (min) |

| Hardness (Shore A) | ASTM D2240 | 85 ± 5 |

| Operating Temperature | — | -10°C to +60°C |

| Flame Rating | UL94 | HB |

| Specific Gravity | ASTM D792 | 1.35 |

All values are nominal and subject to batch certification. Custom modifications available upon technical review. Partner with Suzhou Baoshida for engineered transparency you can rely on. Contact Mr. Boyce today to advance your next industrial design with precision-grade translucent PVC sheeting.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).