Technical Contents

Engineering Guide: Trim Lok Edge Trim

Engineering Insight: Material Selection in trim lok edge trim Applications

In industrial sealing and edge protection systems, the trim lok edge trim is a critical component designed to ensure structural integrity, environmental resistance, and long-term performance. While many manufacturers offer off-the-shelf trim lok solutions, these generic products frequently fail under real-world operational stress. The root cause lies not in design, but in improper material selection—a factor often overlooked in procurement decisions driven by cost and availability.

The performance of a trim lok edge trim is directly tied to its elastomeric composition. Standard rubber compounds such as natural rubber (NR) or basic SBR may appear suitable for light-duty applications, but they lack the resilience required in demanding environments involving UV exposure, temperature extremes, chemical contact, or mechanical abrasion. For instance, exposure to ozone or industrial solvents can cause micro-cracking in non-resistant materials, leading to premature seal failure and costly system downtime.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific formulation. Our engineered rubber compounds—including EPDM, Nitrile (NBR), and silicone—are selected based on rigorous environmental profiling. EPDM, for example, offers superior resistance to weathering and ozone, making it ideal for exterior automotive or construction applications. Nitrile rubber provides excellent oil and fuel resistance, critical in machinery and transportation sectors. Silicone formulations maintain flexibility across extreme temperatures (-60°C to +230°C), suitable for aerospace or high-heat industrial enclosures.

Off-the-shelf trims often use lower-grade polymers with minimal additive optimization. These materials may meet basic dimensional tolerances but fail under sustained stress due to poor compression set resistance, inadequate tensile strength, or insufficient elongation properties. In contrast, precision-formulated compounds undergo accelerated aging and dynamic fatigue testing to ensure performance consistency over the product lifecycle.

Another overlooked factor is durometer selection. A mismatch in hardness can result in inadequate sealing force or excessive compression, leading to deformation or difficulty in installation. Our technical team evaluates load requirements and substrate dynamics to recommend optimal Shore A hardness values tailored to each application.

Material compatibility with adjacent components—such as metals, adhesives, or painted surfaces—is equally critical. Incompatible elastomers can induce galvanic corrosion or adhesive degradation over time. Our approach integrates full system analysis to prevent such interfacial failures.

Below is a comparative overview of common rubber materials used in trim lok edge trim manufacturing:

| Material | Temperature Range (°C) | Key Resistance Properties | Typical Applications |

|---|---|---|---|

| EPDM | -50 to +150 | Ozone, UV, weathering, water | Exterior seals, construction, HVAC |

| NBR | -30 to +120 | Oil, fuel, grease, abrasion | Automotive, machinery, hydraulics |

| Silicone | -60 to +230 | Extreme heat, cold, oxidation | Aerospace, electronics, medical |

| SBR | -20 to +100 | Wear, moderate weathering | General industrial, low-cost trims |

| Natural Rubber | -40 to +80 | High elasticity, tear strength | Vibration dampening, flexible joints |

Material selection is not a commodity decision—it is an engineering imperative. At Suzhou Baoshida, we partner with OEMs to transition from reactive replacement to proactive performance engineering, ensuring that every trim lok edge trim we supply is as resilient as the systems it protects.

Material Specifications

Material Specifications for Trim Lok Edge Trim Seals

Material selection for Trim Lok edge trim seals directly impacts performance longevity and operational safety in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., we engineer solutions using Viton, Nitrile, and Silicone compounds, each optimized for specific environmental stressors. These elastomers undergo rigorous testing per ASTM D2000 and ISO 37 standards to ensure dimensional stability, compression set resistance, and fluid compatibility. Understanding their intrinsic properties is critical for OEM integration into automotive, aerospace, and heavy machinery systems where edge sealing integrity prevents catastrophic failure.

Viton (FKM) fluorocarbon rubber delivers exceptional resistance to high temperatures, aggressive chemicals, and non-flammable hydraulic fluids. Its molecular structure, featuring carbon-fluorine bonds, sustains continuous service at 200°C with intermittent peaks to 230°C. Viton excels in fuel and oil exposure scenarios but exhibits higher compression set values above 150°C compared to alternatives. This material is indispensable for engine compartment seals subject to biodiesel or jet fuel contact.

Nitrile (NBR) butadiene-acrylonitrile copolymer provides cost-effective resilience against petroleum-based oils, greases, and water. Acrylonitrile content (34–50%) directly correlates with oil resistance; higher percentages enhance durability but reduce low-temperature flexibility. NBR maintains functionality from -30°C to 120°C continuous, making it ideal for transmission seals and hydraulic systems. Its abrasion resistance and tensile strength exceed silicone but fall short in ozone or ketone environments.

Silicone (VMQ) polymethylvinylsiloxane offers unparalleled flexibility across extreme temperatures (-60°C to 200°C) with minimal compression set. While inherently resistant to ozone and UV degradation, standard silicone lacks mechanical strength for high-pressure applications and swells significantly in hydrocarbons. Reinforced formulations address this limitation for medical or food-grade edge trims requiring biocompatibility and steam sterilization tolerance.

The following comparative analysis details critical performance metrics for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Compression Set (ASTM D395) | 15–25% @ 200°C/70h | 20–35% @ 100°C/22h | 10–20% @ 200°C/22h |

| Fuel Resistance (B) | Excellent | Good | Poor |

| Ozone Resistance | Excellent | Poor | Excellent |

| OEM Customization Range | Wide (perfluoro options) | Moderate (HNBR variants) | Limited (reinforced grades) |

Suzhou Baoshida prioritizes application-specific formulation over generic material supply. Our OEM engineering team adjusts polymer ratios, filler types (e.g., silica vs. carbon black), and cure systems to meet exact compression force-deflection curves and Shore A hardness requirements (50–90 durometer). All compounds comply with RoHS, REACH, and FDA 21 CFR 177.2600 standards where applicable. Partner with us to validate material performance against your operational parameters through accelerated aging and fluid immersion protocols. Precision-engineered Trim Lok seals from Baoshida ensure zero-leakage performance under sustained mechanical stress.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solution Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and manufacturing of high-performance trim lok edge trim products. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific components that meet the rigorous demands of global OEMs.

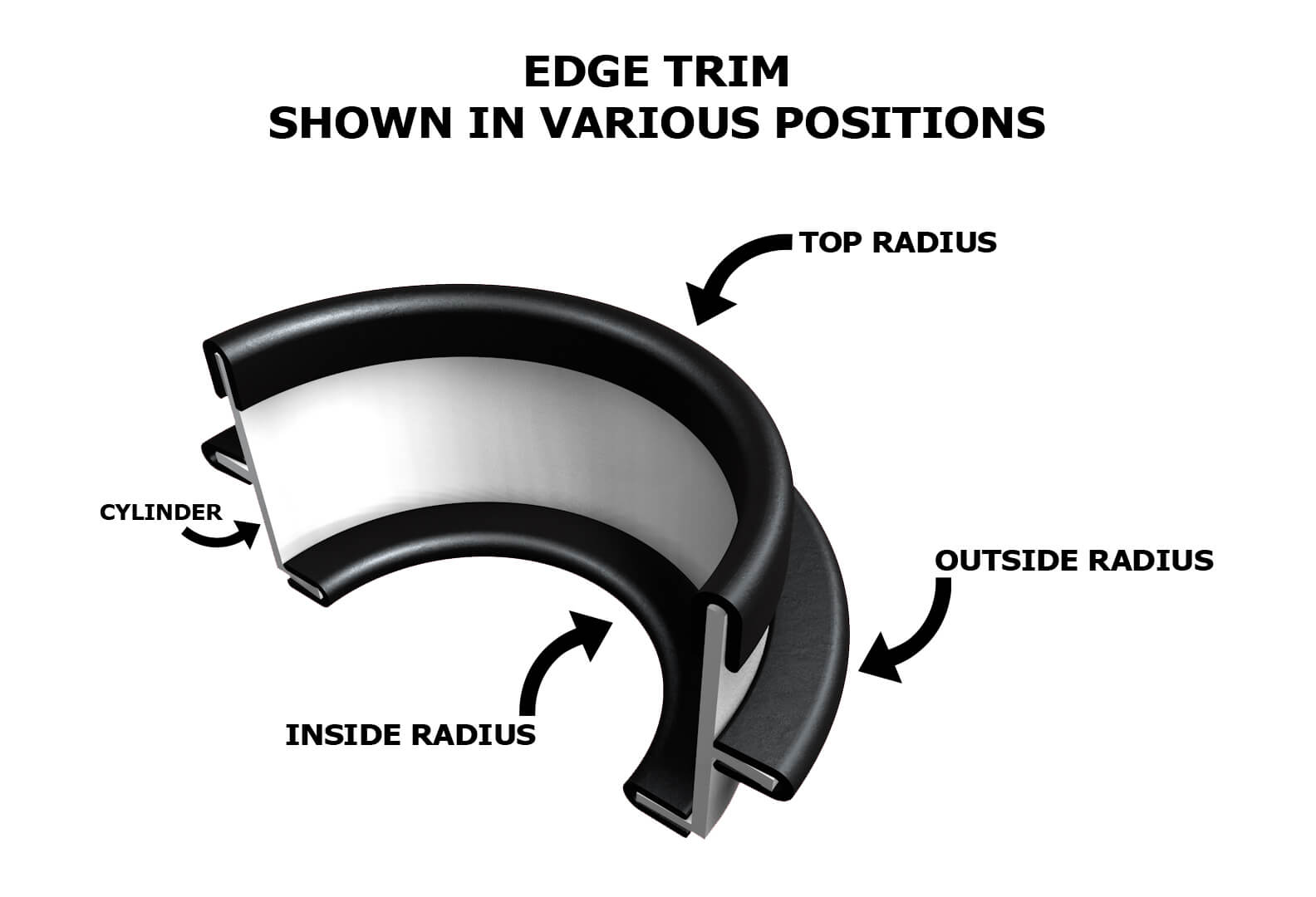

Our mould engineering team brings over two decades of collective experience in precision tooling for rubber extrusion and compression molding. Each engineer is trained in CAD/CAM software, including SolidWorks and AutoCAD, enabling rapid prototyping, tolerance analysis, and design validation. This ensures that every trim lok profile is developed with exacting dimensional accuracy, optimized flow characteristics, and long-term durability under dynamic stress. The team works closely with clients during the initial design phase to refine cross-sectional geometry, sealing interfaces, and installation tolerances, ensuring seamless integration into final assemblies.

Complementing our mould expertise is our in-house rubber formulation capability. Our two senior formula engineers specialize in compounding elastomers for targeted performance attributes such as weather resistance, UV stability, compression set, and low-temperature flexibility. Utilizing a fully equipped R&D lab, we develop custom rubber compounds based on EPDM, silicone, neoprene, and other specialty polymers. This vertical integration allows us to tailor material properties precisely to the operational environment—whether it’s automotive door seals exposed to extreme thermal cycling or industrial enclosures requiring resistance to ozone and chemical exposure.

Our OEM capabilities are built on a foundation of technical collaboration and process control. We support full turnkey solutions—from concept and material selection to tooling, production, and quality assurance. Every project follows a structured APQP process, with detailed FMEA documentation, first-article inspection reports (FAIR), and PPAP submissions available upon request. Our facility maintains ISO 9001 certification, ensuring consistent adherence to international quality standards.

The synergy between our mould and formula engineering teams enables rapid iteration and problem-solving, reducing time-to-market and minimizing design risks. Clients benefit from a single-source partner who controls both the physical form and material science behind each trim lok edge trim component.

Below is a representative specification profile for a standard EPDM-based trim lok edge trim designed for automotive applications:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 9 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs at 70°C) | ASTM D395 | ≤ 20% |

| Temperature Range | — | -40°C to +120°C |

| Specific Gravity | ASTM D297 | 1.45 ± 0.05 |

| Color | Visual Match | Black, Custom RAL Available |

This technical depth, combined with scalable manufacturing capacity, positions Suzhou Baoshida as a trusted engineering partner for OEMs requiring robust, customized edge trim solutions.

Customization Process

Customization Process for Trim Lok Edge Trim Solutions

At Suzhou Baoshida Trading Co., Ltd., our Trim Lok edge trim customization follows a rigorously controlled engineering sequence to ensure dimensional accuracy, material resilience, and seamless OEM integration. This process eliminates design-to-production gaps while adhering to global automotive and industrial standards.

Drawing Analysis

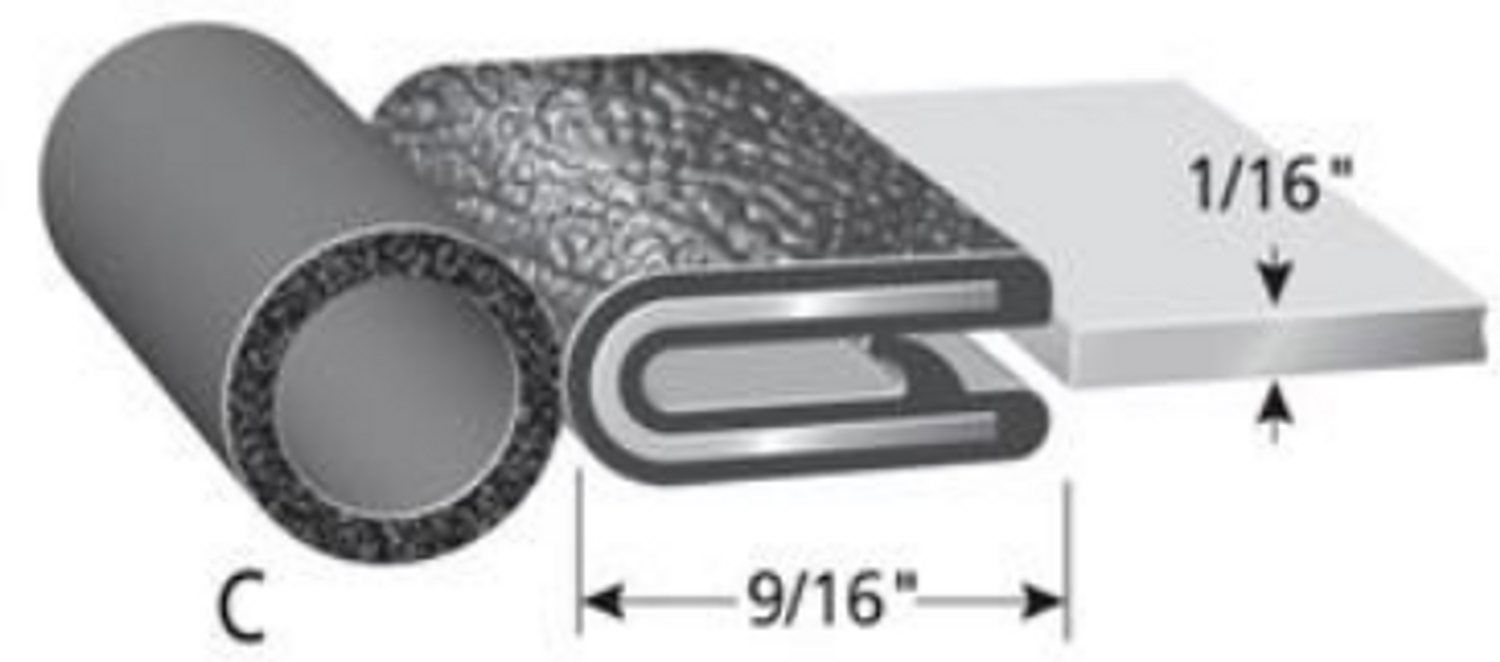

Initial technical scrutiny focuses on client CAD files and GD&T specifications. We validate critical parameters including cross-sectional tolerances (±0.1mm), insertion force requirements, and environmental exposure conditions. Finite element analysis (FEA) identifies stress concentration zones, particularly at interlocking profiles and curvature transitions. Any deviations from manufacturable geometries—such as undercuts exceeding 0.5mm draft angles or wall thickness below 1.2mm—are flagged for collaborative redesign. This phase concludes with a formal Design for Manufacturability (DFM) report approved by both engineering teams.

Formulation Development

Material selection is derived from operational demands. Our rubber compounding lab tailors polymer matrices to balance compression set resistance, UV stability, and chemical compatibility. Key formulation variables include polymer type, filler reinforcement, and cure system kinetics. Below are standard specifications for common edge trim applications:

| Material Type | Hardness Range (Shore A) | Temperature Range (°C) | Key Properties | Common Applications |

|---|---|---|---|---|

| EPDM | 50–85 | -50 to +150 | Ozone resistance, low water absorption | Automotive door seals, HVAC ducts |

| NBR | 45–75 | -30 to +120 | Fuel/oil resistance, abrasion durability | Engine compartment trims |

| Silicone | 30–70 | -60 to +230 | Extreme temp stability, biocompatibility | Appliance gaskets, medical enclosures |

| TPE | 40–90 | -40 to +135 | High elasticity, paint adhesion | Interior trim, consumer electronics |

Prototyping and Validation

Precision extrusion or injection molding produces functional prototypes using production-intent tooling. We conduct ASTM D2000-compliant testing: 72-hour compression set at 70°C, 10,000-cycle fatigue testing, and adhesion strength measurements (≥1.5 kN/m). Dimensional verification via CMM ensures profile conformity within ISO 2768-mK tolerances. Client validation includes fitment trials on actual assemblies, with iterative adjustments until all performance metrics are certified.

Mass Production Execution

Upon prototype sign-off, we initiate serial production under IATF 16949 protocols. Real-time process monitoring tracks critical control points: extrusion line speed (±0.5m/min), vulcanization temperature (±2°C), and surface finish Ra values (≤3.2μm). Each batch undergoes first-article inspection and quarterly material requalification. Logistics coordination ensures JIT/JIS delivery with traceability via QR-coded batch identifiers, maintaining zero-defect shipment records across 120+ OEM programs.

This closed-loop methodology guarantees Trim Lok edge trims that withstand 15,000+ door cycles, -40°C cold-crack resistance, and 10-year service life—proven through accelerated aging per SAE J2236. Suzhou Baoshida’s engineering ownership from drawing to dock minimizes time-to-market while exceeding Tier-1 durability benchmarks.

Contact Engineering Team

For industrial manufacturers seeking high-performance sealing and edge protection solutions, Trim Lok edge trim represents a critical component in ensuring durability, safety, and operational efficiency across a wide range of applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber solutions tailored to meet the rigorous demands of modern industrial environments. Our Trim Lok edge trim products are manufactured using advanced compounding techniques and high-grade elastomeric materials, ensuring consistent performance under extreme temperatures, abrasion, and mechanical stress.

We understand that every industrial application presents unique challenges. Whether you are working in material handling, conveyor systems, automated manufacturing, or heavy machinery, the integrity of edge sealing directly impacts equipment longevity and workplace safety. Our engineering team works closely with OEMs and maintenance departments to customize Trim Lok profiles based on specific dimensional, durometer, and environmental requirements. From standard formulations to custom compounds resistant to oil, ozone, UV exposure, or extreme temperature fluctuations, Suzhou Baoshida delivers reliable, long-term solutions.

Our Trim Lok edge trims are designed for seamless integration, offering excellent adhesion, impact resistance, and noise dampening properties. They are widely used in applications requiring edge protection on metal sheets, conveyor belts, access panels, and protective guards. The product line supports multiple installation methods, including adhesive backing, mechanical fastening, and extrusion mounting, ensuring compatibility with existing production processes.

To support our clients in making informed material decisions, we provide detailed technical specifications and performance data. Below is a representative specification table for our standard Trim Lok edge trim product line:

| Property | Value | Test Method |

|---|---|---|

| Material | EPDM / NBR / Natural Rubber | ASTM D1418 |

| Hardness (Shore A) | 50–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥10 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Operating Temperature | -40°C to +100°C (up to +135°C intermittent) | ASTM D1329 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Color Options | Black, Gray, Red, Blue, Yellow | Customizable |

| Standard Lengths | 1m, 2m, 3m, or continuous rolls | Custom cuts available |

For project-specific inquiries, technical consultations, or sample requests, we invite you to contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With extensive experience in industrial rubber applications and global supply chain coordination, Mr. Boyce serves as a dedicated technical liaison between our engineering team and your production requirements. He ensures rapid response, accurate technical interpretation, and seamless integration of our Trim Lok edge trims into your manufacturing process.

Reach out today via email at [email protected] to discuss your application needs, request material data sheets, or obtain a quotation. At Suzhou Baoshida, we are committed to delivering engineered rubber solutions that enhance performance, reduce downtime, and support your operational excellence. Partner with us to achieve precision, reliability, and long-term value in every component.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).