Technical Contents

Engineering Guide: Truck Bed Matt

Engineering Insight: Material Selection in Truck Bed Mat Design

In the industrial transportation sector, the integrity and longevity of truck bed mats are directly tied to material selection. Off-the-shelf solutions often fail under real-world operational stress due to inadequate polymer composition, insufficient resistance to environmental exposure, and poor mechanical performance. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber formulations that meet the dynamic demands of heavy-duty logistics, construction, and municipal fleets.

Standard truck bed mats, typically fabricated from generic recycled rubber or thermoplastic elastomers, lack the resilience required for sustained load-bearing and impact absorption. These materials degrade rapidly when exposed to UV radiation, ozone, diesel fuel, hydraulic fluids, and extreme temperature fluctuations—conditions common in commercial and industrial environments. Cracking, delamination, and surface abrasion are frequent failure modes, compromising cargo security and increasing maintenance costs.

In contrast, purpose-built rubber compounds such as vulcanized styrene-butadiene rubber (SBR), nitrile rubber (NBR), and ethylene propylene diene monomer (EPDM) offer superior performance. These materials are selected based on specific service conditions. For instance, EPDM provides exceptional weather and ozone resistance, making it ideal for open-bed applications in outdoor storage or long-haul transport. NBR, with its high resistance to oils and hydrocarbons, is optimal for utility and service vehicles frequently exposed to lubricants and fuels.

The failure of generic mats often stems from an oversimplified approach to material design—prioritizing cost over function. Industrial-grade truck bed mats require a balance of tensile strength, elongation at break, compression set resistance, and coefficient of friction. These parameters are not interchangeable; each contributes to the mat’s ability to retain shape, resist displacement, and protect both cargo and truck bed surfaces.

Moreover, proper compounding includes reinforcing fillers (such as carbon black or silica), anti-aging agents, and cross-linking accelerators that enhance durability. The curing process—time, temperature, and pressure—must be precisely controlled to achieve optimal cross-link density, ensuring the final product maintains structural integrity under repeated dynamic loading.

Below is a comparison of key material properties relevant to high-performance truck bed mats:

| Material | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) | Temperature Range (°C) | Key Resistance Properties |

|---|---|---|---|---|---|

| Recycled Rubber | 6–10 | 150–250 | 50–65 | -20 to +70 | Moderate abrasion, low chemical |

| SBR (Vulcanized) | 18–25 | 350–500 | 60–75 | -30 to +100 | Good abrasion, moderate oil |

| NBR | 15–22 | 300–450 | 65–80 | -30 to +120 | Excellent oil, fuel, wear |

| EPDM | 17–24 | 400–600 | 55–70 | -40 to +130 | Outstanding ozone, UV, weather |

Custom formulation allows for hybrid compounds that merge the best attributes of multiple base polymers. Suzhou Baoshida Trading Co., Ltd. leverages OEM-level material science to deliver truck bed mats that exceed field performance expectations, reducing lifecycle costs and enhancing operational safety. Material selection is not a commodity decision—it is a precision engineering requirement.

Material Specifications

Material Specifications for Industrial Truck Bed Matting Systems

Optimal material selection for truck bed matting is critical to withstand dynamic operational stresses including abrasion, chemical exposure, temperature extremes, and mechanical impact. At Suzhou Baoshida Trading Co., Ltd., we engineer solutions using three primary elastomers—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each validated against ASTM D2000 and ISO 37 standards for industrial durability. These materials undergo rigorous OEM testing for tensile strength, elongation, and compression set to ensure compliance with heavy-duty fleet requirements.

Viton (FKM) Specifications

Viton excels in extreme chemical resistance, particularly against diesel fuels, hydraulic oils, and solvents common in transportation environments. Its fluoropolymer structure delivers continuous service temperatures from -20°C to +250°C, with intermittent peaks up to 300°C. Typical formulations achieve 15-20 MPa tensile strength (ASTM D412) and 70-80 Shore A hardness, minimizing swelling in hydrocarbon exposure. This material is ideal for specialized applications involving aggressive chemical transport but carries higher raw material costs.

Nitrile (NBR) Specifications

Nitrile remains the industry standard for cost-effective abrasion and oil resistance. With acrylonitrile content tuned between 34-45%, it balances flexibility and resilience, operating reliably from -30°C to +120°C. Standard grades exhibit 25-35 MPa tensile strength and 50-70 Shore A hardness, providing optimal grip for cargo while resisting tearing from sharp edges. Its superior resistance to petroleum-based fluids makes it suitable for 90% of general freight applications, with formulations optimized for UV stability via carbon black reinforcement.

Silicone (VMQ) Specifications

Silicone offers unmatched thermal stability across -60°C to +230°C ranges, critical for arctic or desert logistics operations. While inherently lower in tensile strength (8-12 MPa), its 40-60 Shore A hardness ensures flexibility without permanent set. Key advantages include non-stick properties for frozen or sticky cargo and compliance with FDA 21 CFR 177.2600 for food transport. However, it requires reinforcement for high-abrasion scenarios and exhibits moderate resistance to hydrocarbons.

The comparative analysis below details critical performance parameters for informed material selection:

| Material Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 15-20 | 25-35 | 8-12 |

| Hardness (Shore A) | 70-80 | 50-70 | 40-60 |

| Fuel/Oil Resistance | Excellent | Very Good | Fair |

| Abrasion Resistance | Good | Excellent | Moderate |

| Compression Set (%) | ≤20 (200°C/70h) | ≤25 (100°C/70h) | ≤20 (200°C/70h) |

| OEM Customization Range | Chemical-specific | Acrylonitrile % | Reinforcement type |

Suzhou Baoshida prioritizes application-specific formulation adjustments. NBR dominates standard fleet deployments due to its abrasion resilience and cost efficiency, while Viton serves niche chemical transport needs. Silicone is reserved for extreme thermal environments where flexibility retention is non-negotiable. All compounds undergo 1,000-hour accelerated aging tests per SAE J2236 to validate service life projections. Partner with our engineering team to refine material properties against your operational profile—ensuring optimal mat longevity, safety compliance, and total cost of ownership.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Rubber Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance truck bed mats. With a dedicated team of five specialized mould engineers and two advanced formula engineers, we maintain full in-house control over the entire product development lifecycle. This integrated approach ensures technical precision, material integrity, and rapid time-to-market for custom OEM solutions.

Our mould engineers possess extensive experience in designing complex rubber compression and transfer moulds tailored to the dimensional, load-bearing, and environmental demands of truck bed applications. Utilizing advanced CAD/CAM software and precision CNC machining, they develop robust tooling systems that ensure consistent part geometry, surface texture fidelity, and long-term durability under dynamic stress conditions. Each mould design undergoes rigorous simulation for material flow, shrinkage compensation, and thermal distribution, minimizing defects and optimizing cycle times for high-volume production.

Complementing this expertise are our two dedicated rubber formula engineers, who specialize in elastomer compounding for extreme mechanical and environmental resilience. They formulate custom rubber blends using SBR, EPDM, and NR-based systems, engineered to deliver targeted properties such as abrasion resistance, UV stability, low-temperature flexibility, and anti-slip performance—critical for truck bed mat functionality. Each formulation is developed with a focus on balancing mechanical strength, elongation at break, and compression set, while also meeting OEM-specific requirements for odor, color stability, and recyclability.

Our OEM capabilities are built on a foundation of technical collaboration. We work directly with automotive and aftermarket partners to translate performance specifications into engineered products. From initial concept and 3D prototyping to material validation and production ramp-up, we provide full technical documentation, including material data sheets, mould flow analysis reports, and quality control protocols. This end-to-end support ensures seamless integration into our clients’ supply chains and brand standards.

The synergy between our mould and formula engineering teams enables rapid iteration and problem-solving, particularly in addressing challenges such as part warpage, flash control, or material degradation under prolonged exposure to oils, ozone, and temperature extremes. This cross-functional collaboration is central to delivering reliable, high-quality rubber components that exceed industry benchmarks.

Below is a summary of typical technical specifications achievable for our truck bed mat products:

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–75 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Abrasion Resistance (Taber, CS-17) | ASTM D1044 | ≤120 mg loss |

| Operating Temperature Range | — | -40°C to +100°C |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Specific Gravity | ASTM D297 | 1.25–1.35 |

Through disciplined engineering and material science, Suzhou Baoshida delivers technically superior rubber solutions that meet the rigorous demands of modern commercial vehicle applications.

Customization Process

Customization Process for Industrial Truck Bed Mats

Suzhou Baoshida Trading Co., Ltd. employs a rigorously defined engineering workflow to transform client specifications into high-performance rubber truck bed mats. This process ensures dimensional accuracy, material resilience, and compliance with demanding operational environments. Our methodology eliminates guesswork through systematic validation at each development phase.

Drawing Analysis

Technical drawings undergo comprehensive geometric and tolerance scrutiny using CAD-based analysis tools. We verify load-bearing zones, anti-slip pattern integrity, and mounting interface compatibility against OEM vehicle blueprints. Critical dimensions such as mat thickness (±0.5 mm tolerance), edge chamfer angles, and drainage channel profiles are cross-referenced with stress simulation data. This phase identifies potential molding challenges early, preventing costly revisions during prototyping. Material thickness zones are optimized to balance weight reduction with impact absorption requirements.

Formulation Development

Based on operational parameters from the drawing analysis, our rubber compounding team designs proprietary formulations. Key variables include hardness range, oil/fuel resistance, and temperature stability (-40°C to +120°C). We prioritize wear resistance for abrasive cargo handling while maintaining sufficient flexibility to prevent cracking during installation. All compounds undergo accelerated aging tests per ASTM D573 and fluid immersion validation per ISO 1817. The final formulation is locked only after achieving target mechanical properties across three consecutive lab batches.

Prototyping & Validation

Precision-engineered prototypes are produced using client-approved tooling inserts. Each sample undergoes:

Dimensional inspection via CMM (Coordinate Measuring Machine) against original CAD data

Tensile/tear strength testing per ASTM D412

Real-world slip resistance assessment on wet/dry steel surfaces

Load cycle testing simulating 5+ years of cargo impacts

Prototypes are shipped with full traceability documentation including raw material certificates and test reports. Client feedback triggers iterative refinements until all performance criteria are met.

Mass Production Execution

Upon prototype sign-off, production commences under ISO 9001-certified protocols. Every batch is monitored via statistical process control (SPC) for critical parameters. Final inspection includes 100% visual checks for surface defects and random sampling for physical property verification. Mats are serialized for full traceability from raw material lot to finished product. We maintain buffer stock for JIT delivery while ensuring zero deviation from validated specifications.

Key Material Specifications

| Property | Test Method | Target Value |

|————————-|——————|——————–|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 12 MPa |

| Tear Resistance | ASTM D624 | ≥ 45 kN/m |

| Abrasion Loss | DIN 53516 | ≤ 120 mm³ |

| Oil Resistance (IRM 903)| ASTM D471 | Volume swell ≤ 25% |

| Operating Temperature | – | -40°C to +120°C |

This structured approach guarantees truck bed mats that withstand extreme mechanical stress, chemical exposure, and thermal cycling inherent in commercial transport applications. Suzhou Baoshida’s engineering discipline ensures every mat delivers consistent performance throughout its service life.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Truck Bed Mat Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber manufacturing, specializing in high-performance truck bed mats engineered for durability, safety, and operational efficiency. As a trusted OEM partner in the rubber solutions sector, we combine advanced material science with precision production techniques to deliver products that meet the rigorous demands of commercial transport, logistics, and heavy-duty vehicle applications. Our truck bed mats are formulated using high-density EPDM and SBR rubber compounds, offering exceptional resistance to abrasion, UV exposure, oil, and extreme temperatures. Whether you are a fleet operator, automotive accessory distributor, or OEM vehicle manufacturer, our engineered rubber solutions ensure long-term performance and protection for cargo and chassis alike.

Our production facility in Suzhou integrates automated molding systems and stringent quality control protocols, including tensile strength testing, Shore A hardness verification, and environmental aging simulations. Every truck bed mat is manufactured to exact dimensional tolerances and surface grip profiles, ensuring secure cargo retention and slip resistance under dynamic load conditions. We support both standard configurations and custom tooling projects, enabling clients to specify thickness, texture, color, and reinforcement options such as embedded steel or fabric layers.

For technical collaboration, volume procurement, or custom development projects, we invite direct engagement with our engineering and sales team. Mr. Boyce, our dedicated OEM Manager, oversees all client technical onboarding and product specification alignment. With over 12 years of experience in rubber formulation and industrial supply chain integration, Mr. Boyce ensures seamless communication between design requirements and manufacturing execution. He is available to provide material data sheets, sample kits, mold development timelines, and cost-optimized production plans tailored to your market and volume needs.

Below are key technical specifications for our standard truck bed mat series:

| Property | Value / Range | Test Method |

|---|---|---|

| Material Compound | EPDM/SBR Blend | ASTM D412 |

| Hardness (Shore A) | 65 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 12 MPa | ASTM D412 |

| Elongation at Break | ≥ 280% | ASTM D412 |

| Operating Temperature Range | -40°C to +120°C | ISO 188 |

| Thickness Options | 6 mm, 8 mm, 10 mm, 12 mm | Customizable |

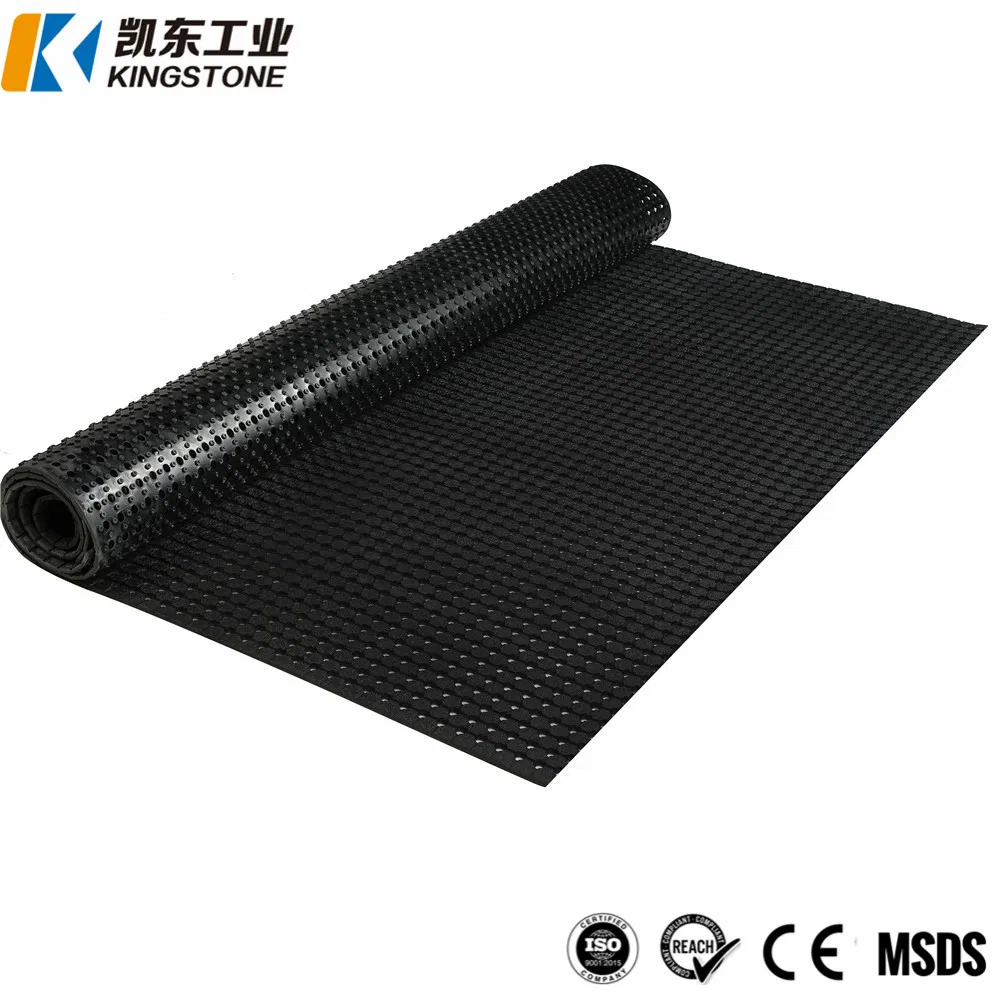

| Surface Texture | Diamond Plate, Linear Rib | Mold-Engineered |

| Fire Resistance | UL94 HB Rated | UL 94 |

| Density | 1.25 g/cm³ | ASTM D792 |

| Custom Color Availability | Black, Gray, Red, Yellow | Pantone Matching System |

To initiate a technical consultation or request a formal quotation, please contact Mr. Boyce directly at [email protected]. We respond to all inquiries within 12 business hours and offer virtual product reviews, material certification packages, and logistics planning support for global distribution. Suzhou Baoshida is committed to engineering excellence and long-term partnership in industrial rubber applications. Let us provide you with a reliable, scalable, and technically superior truck bed mat solution.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).