Technical Contents

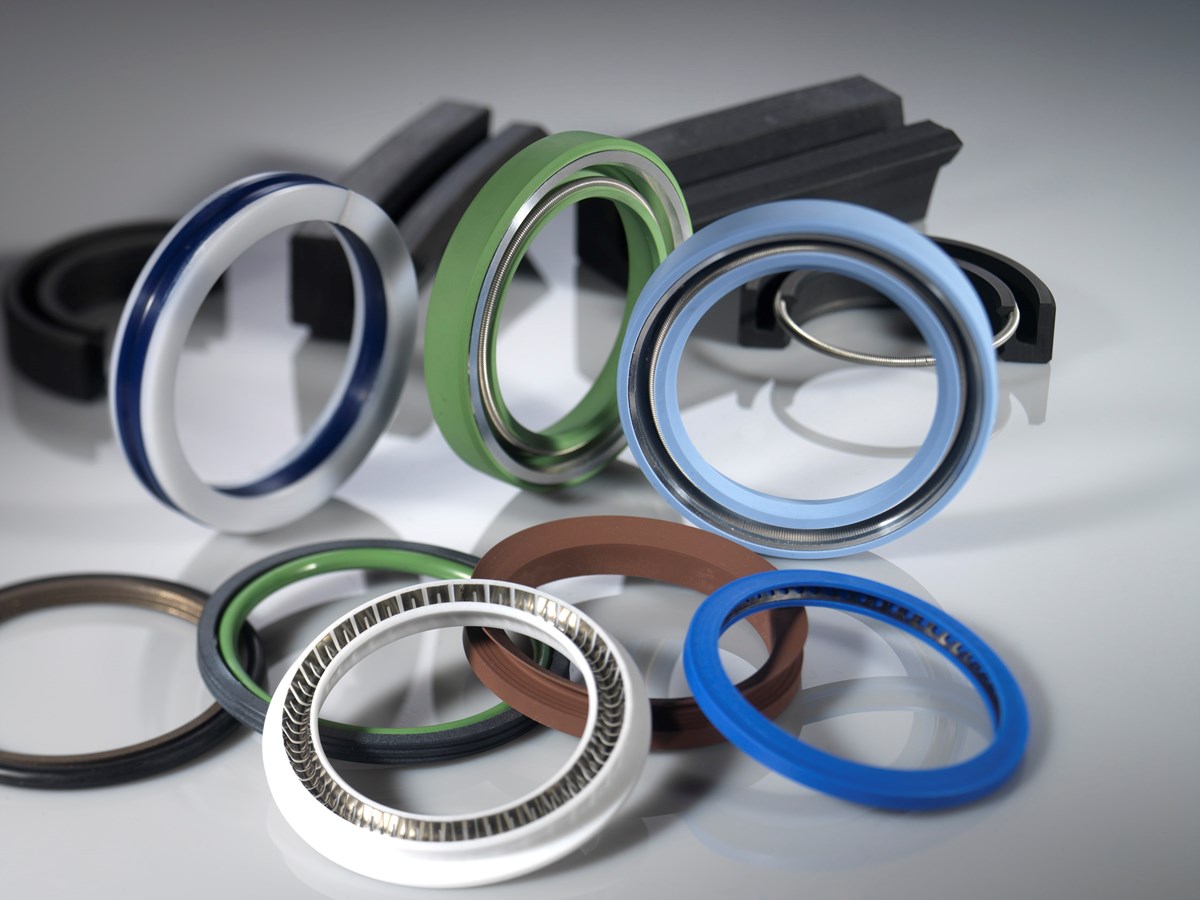

Engineering Guide: Types Of Shaft Seals

Engineering Insight Material Selection in Shaft Seal Performance

Shaft seals represent a critical interface in rotating machinery, where material selection directly dictates operational lifespan and system integrity. Off-the-shelf seals frequently fail due to generic material formulations that ignore application-specific stressors. These compromises arise from manufacturers prioritizing cost and broad compatibility over precision engineering, leading to premature degradation under real-world conditions. Understanding the interplay between elastomer chemistry, environmental exposure, and mechanical demands is non-negotiable for reliability.

Standardized seals often utilize base polymers like Nitrile Butadiene Rubber (NBR) with minimal additive customization. While adequate for benign environments, they catastrophically underperform when exposed to aggressive fluids, extreme temperatures, or dynamic loads. For instance, NBR seals rapidly swell and lose tensile strength in phosphate ester hydraulic fluids, while standard FKM compounds crack under prolonged exposure to hot water or steam. Surface abrasion accelerates when seal hardness mismatches shaft roughness, and compression set occurs if the material’s glass transition temperature (Tg) aligns with operating ranges. These failure modes manifest as leakage, increased friction, or complete seal extrusion—resulting in unplanned downtime, contamination, and safety hazards.

The core deficiency of catalog seals lies in their static material profiles. Real applications demand dynamic property balancing: low-temperature flexibility without sacrificing heat resistance, chemical inertness without compromising resilience, and wear resistance without excessive friction. Achieving this requires iterative formulation adjustments—such as peroxide curing for better heat stability, specialized fillers for abrasion resistance, or fluorine-content tuning in FKM for acid compatibility. Without this granular control, seals operate outside their engineered parameters, accelerating fatigue.

Consider the performance divergence across common elastomers under identical stressors:

| Material | Temperature Range (°C) | Pressure Limit (MPa) | Key Chemical Vulnerabilities |

|---|---|---|---|

| Standard NBR | -30 to +100 | 1.5 | Ozone, phosphate esters, polar solvents |

| Custom FKM (High-Fluorine) | -20 to +230 | 5.0 | Hot water/steam, amines, low-molecular-weight acids |

| Peroxide-Cured EPDM | -50 to +150 | 3.0 | Petroleum oils, concentrated acids |

This table underscores why material homogeneity fails. A standard FKM seal may resist jet fuel but disintegrate in a bioreactor’s alkaline wash cycle, while a peroxide-cured EPDM variant withstands sterilization yet swells in hydraulic oil. Off-the-shelf solutions lack the molecular tailoring to navigate such trade-offs.

At Suzhou Baoshida, we reject one-size-fits-all methodologies. Our engineering process begins with fluid compatibility mapping, thermal profiling, and dynamic load simulation to define exact material requirements. We then formulate bespoke compounds—adjusting polymer backbone saturation, crosslink density, and additive packages—to align with the client’s operational envelope. This eliminates the guesswork inherent in catalog selections, transforming seals from failure points into engineered assets. Material selection isn’t a cost center; it’s the foundation of rotational system longevity. Precision demands partnership, not procurement.

Material Specifications

Shaft seals are critical components in mechanical systems, designed to prevent leakage of fluids while maintaining operational integrity under dynamic conditions. The performance of these seals is significantly influenced by the elastomeric material used, which must be selected based on chemical compatibility, temperature range, mechanical strength, and environmental exposure. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered for demanding industrial applications. Our expertise includes the formulation and supply of shaft seals made from three primary elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on the operational parameters of the application.

Viton (fluoroelastomer) is widely recognized for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 200°C and intermittent exposure tolerance to 230°C, Viton is ideal for aerospace, automotive, and chemical processing industries where reliability under extreme conditions is non-negotiable. Its low gas permeability and excellent aging characteristics further enhance long-term sealing performance, although it exhibits lower flexibility at sub-zero temperatures compared to other elastomers.

Nitrile rubber, or Buna-N, remains one of the most commonly used materials for shaft seals due to its excellent resistance to petroleum-based oils and fuels, coupled with good abrasion resistance and mechanical durability. Operating effectively within a temperature range of -30°C to +100°C, NBR provides a cost-effective solution for hydraulic systems, gearboxes, and industrial machinery exposed to mineral oils and greases. However, its performance degrades in the presence of polar solvents, ozone, and high-temperature environments beyond its threshold.

Silicone rubber offers superior thermal stability and low-temperature flexibility, functioning reliably from -60°C to +200°C. It demonstrates excellent resistance to oxidation and UV radiation, making it suitable for outdoor and high-heat applications such as food processing, medical devices, and electrical insulation. However, silicone has relatively poor resistance to petroleum-based fluids and lower tensile strength compared to Viton and Nitrile, limiting its use in high-pressure dynamic sealing scenarios.

Selection of the appropriate material is paramount to ensuring seal longevity and system efficiency. Below is a comparative overview of key physical and chemical properties for these three elastomers.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 230 intermittent) | -30 to 100 | -60 to 200 |

| Fluid Resistance (Oils/Fuels) | Excellent | Excellent | Poor |

| Chemical Resistance | Excellent | Fair | Good (limited) |

| Ozone & UV Resistance | Excellent | Good | Excellent |

| Tensile Strength | High | High | Moderate |

| Compression Set Resistance | Excellent | Good | Good |

| Low-Temperature Flexibility | Limited | Good | Excellent |

| Cost Level | High | Low to Medium | Medium |

Understanding these material characteristics enables engineers to make informed decisions when specifying shaft seals for precision applications. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and industrial partners with material selection guidance, custom formulation, and rigorous quality control to ensure optimal seal performance across diverse operating environments.

Manufacturing Capabilities

Engineering Capability: Precision Shaft Seal Development at Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. delivers engineered shaft seal solutions grounded in rigorous material science and precision manufacturing oversight. Our core strength resides in the integrated expertise of our dedicated engineering teams, directly addressing the complex interplay between elastomer formulation, mold design, and application performance critical for demanding industrial sealing environments. We maintain strict control over the technical pathway from specification to final product validation, ensuring reliability under extreme pressure, temperature, and chemical exposure.

Our technical foundation is built upon two specialized engineering disciplines working in concert. Five certified Mould Engineers possess deep expertise in precision tooling design for complex rubber geometries. They utilize advanced CAD/CAM systems and finite element analysis (FEA) to optimize cavity flow, minimize flash, ensure uniform material distribution, and compensate for elastomer micro-shrinkage. This meticulous approach guarantees dimensional stability within tight tolerances, critical for maintaining seal integrity and minimizing leakage paths in dynamic shaft applications. Complementing this is our team of two dedicated Rubber Formula Engineers. These specialists develop and refine custom elastomer compounds tailored to specific OEM requirements. They systematically evaluate base polymers (including NBR, FKM, EPDM, HNBR, and specialty silicones), filler systems, plasticizers, and cure packages to achieve the precise balance of hardness, compression set resistance, fluid compatibility, low-temperature flexibility, and abrasion resistance demanded by the application. Every compound undergoes rigorous laboratory testing against ASTM and ISO standards before release.

This dual-engineering capability enables Suzhou Baoshida to provide true OEM partnership beyond simple procurement. We collaborate closely with client design teams during the feasibility and prototyping phases, offering material selection guidance, DFM input for manufacturability, and rapid iterative testing. Our engineers specify all raw materials, define critical process parameters for our certified production partners, and implement stringent in-process quality controls. Full traceability from compound batch to finished seal is standard, supported by comprehensive material certifications and performance validation reports. Intellectual property protection for custom formulations and tooling designs is a fundamental aspect of our OEM agreements.

The following table outlines key performance specifications achievable for common precision shaft seal types through our engineered approach:

| Seal Type | Typical Material | Temperature Range (°C) | Pressure Range (Bar) | Key Application Focus | Durometer Range (Shore A) |

|---|---|---|---|---|---|

| Radial Lip Seals | NBR, FKM, HNBR | -40 to +200 (FKM: +230) | Up to 0.5 | Hydraulic pumps, Gearboxes | 60 – 90 |

| Mechanical Face Seals | Carbon/ Ceramic | -20 to +260 | Up to 25 | Agitators, Pumps (high pressure) | N/A (Seal face) |

| Piston Seals | PU, FKM | -30 to +150 (PU) | Up to 500 | Hydraulic cylinders | 70 – 95 |

| Rotary Shaft Seals | EPDM, FKM | -50 to +150 (EPDM) | Up to 0.3 | Food processing, Water pumps | 70 – 85 |

Suzhou Baoshida’s engineering-led methodology transforms shaft seal specification from a commodity purchase into a value-engineered solution. We mitigate field failure risks through scientifically validated materials and precision-manufactured components, directly supporting our OEM partners’ goals for extended equipment life and reduced maintenance costs. Partner with us for seals where engineering precision is non-negotiable.

Customization Process

Drawing Analysis

The foundation of any successful shaft seal customization begins with a rigorous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review of the client-provided technical drawings, focusing on dimensional accuracy, tolerance specifications, and interface geometry with mating components. We assess critical parameters such as shaft diameter, housing bore, sealing lip configuration, and installation depth. Surface finish requirements and dynamic operating conditions—such as shaft runout, misalignment, and rotational speed—are also evaluated to ensure the design supports reliable performance. This stage often involves direct consultation with the client’s engineering department to clarify ambiguities and optimize the design for manufacturability without compromising functionality.

Formulation Development

Once the geometric parameters are confirmed, our rubber formula engineers initiate material formulation tailored to the operational environment. The selection of base polymer—whether NBR, FKM, EPDM, or silicone—is determined by exposure to temperature extremes, chemical media, and pressure conditions. For example, FKM is preferred for high-temperature and aggressive chemical environments, while NBR offers excellent abrasion resistance and cost efficiency in standard industrial applications. Additives such as reinforcing fillers, plasticizers, and aging inhibitors are precisely balanced to enhance wear resistance, compression set performance, and long-term sealing integrity. Each formulation is documented and stored in our proprietary database to ensure consistency across production batches and future reorders.

Prototyping and Validation

Following formulation, we produce functional prototypes using precision molding techniques. These prototypes undergo a series of in-house performance tests, including leakage evaluation under simulated operating pressures, thermal cycling, and dynamic rotation testing. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity to drawing specifications. Clients are provided with test reports and physical samples for field evaluation. Feedback from this stage is integrated into final design or material adjustments, ensuring optimal performance prior to scale-up.

Mass Production and Quality Assurance

Upon client approval, the project transitions to mass production. Our automated molding lines, supported by statistical process control (SPC), ensure consistent part quality. Every production batch is subject to rigorous quality checks, including hardness testing, visual inspection, and抽样 dimensional verification. We maintain full traceability through lot numbering and material certification.

The following table outlines typical material options and their performance characteristics for shaft seal applications:

| Material | Temperature Range (°C) | Common Media Resistance | Hardness (Shore A) | Key Applications |

|---|---|---|---|---|

| NBR | -30 to +120 | Oil, water, aliphatic hydrocarbons | 60–90 | Gearboxes, hydraulic systems |

| FKM | -20 to +220 | Fuels, acids, aromatic hydrocarbons | 70–90 | Automotive, aerospace |

| EPDM | -50 to +150 | Water, steam, brake fluids | 50–80 | HVAC, water pumps |

| Silicone | -60 to +200 | Ozone, UV, temperature extremes | 40–80 | Medical, food processing |

This structured approach ensures Suzhou Baoshida delivers precision rubber shaft seals that meet exacting industrial demands.

Contact Engineering Team

Technical Consultation for Precision Shaft Seal Implementation

Selecting optimal shaft seals demands rigorous technical evaluation beyond standard catalog specifications. Improper material selection or dimensional tolerancing directly impacts seal longevity, leading to premature elastomer degradation, leakage failures, and unplanned downtime in dynamic sealing interfaces. At Suzhou Baoshida Trading Co., Ltd., our engineering team specializes in custom compounding and OEM validation for critical shaft applications across automotive, industrial hydraulics, and heavy machinery sectors. We translate operational parameters—such as media compatibility, surface velocity, and thermal cycling—into validated sealing solutions through iterative prototyping and accelerated life testing.

Our OEM partnership model integrates early in your design phase, ensuring seamless manufacturability while meeting stringent international standards. Below represents core technical capabilities applicable to shaft seal projects:

| Parameter Category | Standard Range | Customization Capability |

|---|---|---|

| Material Formulation | NBR, FKM, EPDM, HNBR, ACM | Proprietary blends for extreme pH/temperature |

| Temperature Resistance | -40°C to +230°C (standard) | Up to +300°C with specialty fluorocarbons |

| Pressure Rating | 0.5–25 MPa (static/dynamic) | Validated up to 40 MPa for aerospace OEMs |

| Dimensional Tolerance | ISO 3601-1 Class S (±0.10 mm) | Tight-tolerance machining to ±0.025 mm |

| Surface Finish (Shaft) | Ra 0.2–0.8 µm recommended | Custom lapping protocols for micro-roughness control |

This technical foundation enables us to resolve complex failure modes—such as extrusion under pulsating pressure, chemical swelling in biofuels, or stick-slip phenomena at low temperatures—through material science and precision tooling. Every seal undergoes 100% dimensional inspection via CMM and functional validation on application-specific test rigs before shipment. Our ISO 9001:2015-certified process guarantees repeatability for volumes ranging from 500 to 500,000 units annually, with full traceability from raw material batch to finished component.

Initiate your project with direct engineering support from Mr. Boyce, our dedicated OEM Technical Manager. With 18 years of experience in rubber-to-metal bonding and dynamic seal failure analysis, he will coordinate material selection, DFM feedback, and validation protocols tailored to your operational envelope. Provide your shaft diameter, housing bore, media composition, and cycle requirements for a preliminary technical assessment.

Contact Mr. Boyce immediately at [email protected] with subject line: Shaft Seal Technical Query – [Your Company Name]. Include applicable drawings (ISO 1122-1 format preferred), failure mode descriptions, and target cost-per-unit for expedited review. All technical inquiries receive a validated material recommendation and dimensional feasibility report within 24 business hours. Do not rely on generic seal specifications—partner with engineers who understand the physics of elastomer deformation under shear stress. Suzhou Baoshida delivers precision sealing solutions, not off-the-shelf components. Your next-generation shaft interface begins with this email.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).