Technical Contents

Engineering Guide: U Shaped Molding

Engineering Insight: Material Selection in U-Shaped Molding

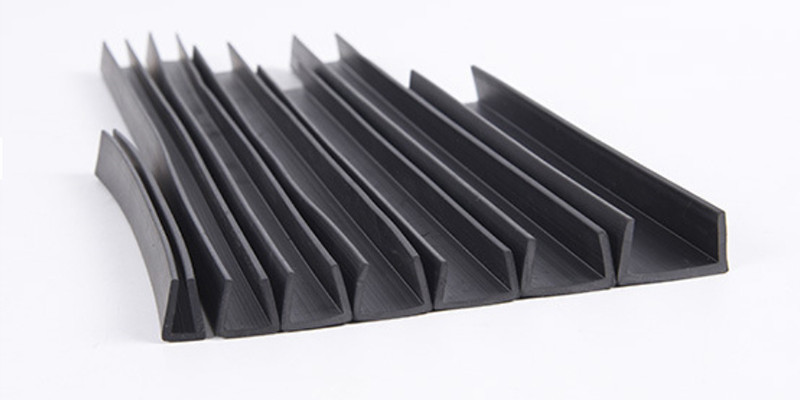

U-shaped rubber moldings are widely used across industrial, automotive, and construction sectors for sealing, dampening, and protective applications. While their geometry appears simple, the performance of these components is highly dependent on precise material selection during the molding process. Off-the-shelf solutions often fail to meet operational demands due to a one-size-fits-all approach that neglects environmental stressors, mechanical loading, and chemical exposure specific to each application.

At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration—it is a foundational engineering decision. The U-shape introduces unique stress concentrations at the base and legs, particularly under compression or repeated flexing. Standard rubber profiles may initially fit the dimensional requirements but degrade prematurely when exposed to temperature extremes, UV radiation, ozone, or fluids such as oils, coolants, or solvents.

Common off-the-shelf profiles are typically manufactured from generic EPDM or SBR compounds optimized for cost, not performance. These materials may exhibit poor resistance to petroleum-based fluids or lose elasticity at low temperatures. In dynamic sealing applications, such deficiencies lead to compression set, cracking, or extrusion—resulting in system failure and unplanned downtime.

Custom U-shaped moldings require a tailored compound formulation. For example, Nitrile (NBR) is preferred in fuel-handling environments due to its excellent oil resistance. Silicone (VMQ) is selected for applications involving extreme temperatures (-60°C to +200°C), while Fluorocarbon (FKM) provides superior chemical and thermal stability in aggressive industrial settings. Even within a single material family, variations in polymer structure, filler content, and curing systems can significantly alter performance.

Our engineering team conducts a full application analysis before recommending a material, evaluating factors such as operating temperature range, media exposure, required lifespan, and mechanical stress. This ensures that the final molded part maintains dimensional stability, sealing force, and resilience throughout its service life.

The following table outlines common rubber materials used in custom U-shaped moldings and their key performance characteristics:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Resistance Properties |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 (up to +120 intermittent) | 10–20 | 250–400 | Oil, fuel, water, abrasion |

| EPDM | -50 to +150 | 8–18 | 200–400 | Ozone, UV, steam, weathering |

| VMQ (Silicone) | -60 to +200 | 5–10 | 200–350 | Extreme heat, cold, oxidation |

| FKM (Fluorocarbon) | -20 to +250 | 12–18 | 150–250 | Chemicals, oil, high heat |

| SBR (Styrene-Butadiene) | -40 to +100 | 15–25 | 300–600 | Water, abrasion, low-cost option |

Selecting the correct material ensures that U-shaped moldings perform reliably under real-world conditions. At Baoshida, we integrate material science with precision molding to deliver custom solutions that outperform generic alternatives—every time.

Material Specifications

Material Specifications for U-Shaped Rubber Moldings

Material selection dictates the functional longevity and performance efficacy of U-shaped rubber moldings in critical sealing applications. At Suzhou Baoshida Trading Co., Ltd., we prioritize precision-engineered compounds validated against OEM operational demands. U-profile geometries impose unique stress distributions at the apex and legs, necessitating elastomers with balanced compression set resistance, thermal stability, and fluid compatibility. Viton fluorocarbon rubber (FKM), Nitrile butadiene rubber (NBR), and high-consistency silicone rubber (VMQ) represent our core material solutions, each engineered for distinct environmental challenges.

Viton excels in aerospace and chemical processing U-seals due to its exceptional resistance to fuels, oils, and acids. Standard FKM grades maintain integrity from -20°C to +200°C, with specialty perfluoroelastomers (FFKM) extending to +327°C. Its low gas permeability ensures reliable vacuum sealing in semiconductor U-channel applications. Nitrile remains the cost-optimized solution for hydraulic and automotive U-moldings, offering robust resistance to aliphatic hydrocarbons and water-based fluids. Standard NBR operates between -40°C and +100°C, with high-acrylonitrile variants improving oil resistance at the expense of low-temperature flexibility. Silicone provides unmatched biocompatibility and extreme temperature resilience for medical and food-grade U-profiles. Platinum-cured VMQ withstands -60°C to +230°C cycles while meeting USP Class VI and FDA 21 CFR 177.2600 requirements, though its tensile strength necessitates design compensation for high-pressure sealing.

Critical comparative parameters are quantified below for engineering validation. All materials comply with ISO 37 tensile testing and ASTM D2000 classification standards.

| Material | ASTM D2000 Line Callout | Temperature Range (°C) | Key Fluid Resistances | Typical Hardness Range (Shore A) | Critical Limitation |

|---|---|---|---|---|---|

| Viton (FKM) | BK 7474 B14 EF14 EF33 EE20 | -20 to +200 (+327 for FFKM) | Jet fuels, brake fluids, mineral oils, acids | 60–90 | Poor resistance to ketones, amines; high compression set above 200°C |

| Nitrile (NBR) | BA 3364 A10 B10 EF11 EF31 | -40 to +100 (+120 for HNBR) | Aliphatic hydrocarbons, water, hydraulic fluids | 50–95 | Swells in ozone, esters, and aromatic solvents; limited thermal stability |

| Silicone (VMQ) | AE 0635 A10 B14 EF11 EF31 | -60 to +230 | Water, alcohols, food oils, weak acids | 30–80 | Low tear strength; permeable to gases; requires post-cure for optimal compression set |

Suzhou Baoshida Trading Co., Ltd. mandates rigorous lot-specific certification for all U-shaped molding compounds. Viton formulations undergo ASTM D471 fluid immersion testing at 150°C for 70 hours to validate volume swell under 15%. NBR compounds are screened for ACN content (33–50%) to balance oil resistance and low-temperature performance per ISO 1817. Silicone batches undergo 24-hour post-curing at 200°C to minimize volatile organic compound (VOC) emissions for sensitive applications. OEMs must specify dynamic or static sealing requirements, as U-profile leg geometry directly influences material stress relaxation behavior. Our engineering team collaborates to cross-reference fluid exposure matrices with Shore A hardness selections, ensuring optimal compression force deflection (CFD) profiles for flange sealing integrity. Material datasheets with full ASTM test reports are provided upon technical inquiry.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our custom rubber molding services, particularly in the production of precision u shaped molding for demanding industrial applications. Our team comprises five dedicated mold engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated solutions from concept to final product. This cross-functional expertise ensures that both the physical tooling and material composition are optimized for performance, durability, and cost-efficiency.

Our mold engineers bring extensive experience in designing and refining molds for complex geometries, including the challenging u shaped profile. Utilizing advanced CAD/CAM software and precision CNC machining, we develop steel and aluminum molds with tight tolerances, balanced flow channels, and optimized venting systems to ensure consistent part quality. Each mold is rigorously tested and fine-tuned during the prototyping phase to eliminate defects such as air traps, flash, or uneven curing—common issues in u shaped cross-sections with variable wall thicknesses.

Complementing our mold design expertise are our two in-house rubber formula engineers. These specialists focus on material science and compound development, tailoring rubber formulations to meet specific performance requirements such as compression set resistance, temperature stability, chemical exposure, and mechanical strength. Whether the application demands silicone for high-temperature sealing, EPDM for weather resistance, or NBR for oil compatibility, our formula engineers ensure the compound precisely matches the operational environment. This dual capability—mold design and material formulation—allows us to solve complex sealing and damping challenges that off-the-shelf solutions cannot address.

As an OEM manufacturing partner, we operate under strict quality control protocols, including ISO 9001 standards, and support full documentation traceability for materials, molds, and production runs. Our facility is equipped for low to high-volume production, with compression, transfer, and injection molding capabilities suitable for u shaped profiles up to 600 mm in length and ±0.15 mm dimensional tolerance.

The integration of mold engineering and rubber chemistry in-house eliminates external dependencies, accelerates development cycles, and ensures consistent quality across batches. This vertical integration is a key differentiator in serving industries such as automotive, industrial equipment, medical devices, and consumer electronics, where reliability and repeatability are non-negotiable.

Below is a summary of our technical specifications for u shaped molding production:

| Parameter | Capability Range |

|---|---|

| Profile Length | Up to 600 mm |

| Cross-Section Tolerance | ±0.15 mm |

| Material Types | NBR, EPDM, Silicone, CR, SBR, HNBR, FKM |

| Hardness Range (Shore A) | 30–90 |

| Mold Materials | P20, H13, 420 Stainless, Aluminum 7075 |

| Production Processes | Compression, Transfer, Injection Molding |

| Tooling Lead Time | 15–25 days (depending on complexity) |

| Sample Production Lead Time | 3–7 days after mold completion |

| OEM Documentation Support | Full material certs, PPAP, FAIR, 2D/3D CAD |

This combination of engineering depth, material expertise, and OEM-focused manufacturing makes Suzhou Baoshida a trusted partner for technically demanding u shaped rubber molding applications.

Customization Process

Customization Process for U-Shaped Rubber Molding at Suzhou Baoshida Trading Co., Ltd.

The precision manufacturing of custom U-shaped rubber moldings demands a rigorously controlled engineering workflow to ensure dimensional accuracy, material performance, and long-term reliability in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., our OEM-managed process integrates deep materials science with advanced production capabilities, commencing with comprehensive drawing analysis. This initial phase involves meticulous scrutiny of the client’s technical specifications, focusing on critical geometric tolerances, cross-sectional consistency along the U-profile, wall thickness variations, and surface finish requirements. We evaluate potential flow lines, knit lines, and vulcanization challenges inherent to the U-geometry, identifying areas requiring specific mold design considerations or process parameter optimization to prevent defects like flash, incomplete filling, or excessive shrinkage. Material compatibility with the intended operational environment (fluids, temperatures, stress) is cross-referenced against initial client suggestions.

Material formulation constitutes the scientific core of our value proposition. Leveraging our in-house rubber compounding expertise, we develop bespoke elastomer recipes tailored precisely to the U-molding’s functional demands. This involves selecting the optimal base polymer (NBR, EPDM, Silicone, FKM, etc.) and systematically adjusting filler systems, plasticizers, curatives, and specialty additives. Key performance targets include achieving the specified durometer hardness while simultaneously optimizing compression set resistance, tensile strength, elongation, and low-temperature flexibility critical for sealing or cushioning functions within the U-channel structure. Accelerated aging tests against relevant media and temperatures are integral to the formulation validation phase, ensuring long-term service life. The table below outlines typical performance parameters achievable through our custom compound development for common U-molding applications.

| Key Performance Parameter | Typical Range (Customizable) | Critical for U-Molding Function |

|---|---|---|

| Durometer Hardness (Shore A) | 30 – 90 | Sealing force, compression recovery, installation fit |

| Tensile Strength (MPa) | 8 – 25 | Resistance to tearing during assembly/use |

| Elongation at Break (%) | 150 – 600 | Accommodation of deflection without fracture |

| Compression Set (B, 22h, 70°C) | < 25% | Long-term sealing integrity under constant load |

| Operating Temperature Range | -50°C to +250°C (varies by compound) | Performance stability in application environment |

Prototyping follows successful formulation, utilizing precision steel molds crafted to the validated design. Short production runs generate physical samples under near-mass-production conditions. These prototypes undergo rigorous dimensional inspection using calibrated CMMs and optical comparators to verify conformity to the original drawing, particularly critical internal and external radii of the U-profile. Simultaneously, physical properties are tested per ASTM/ISO standards to confirm the formulated compound meets all performance criteria. Client feedback on prototype fit, form, and function within their assembly is actively solicited and incorporated.

Upon prototype approval, seamless transition to mass production occurs under strict OEM management protocols. Our ISO-certified facilities employ automated injection or compression molding lines with real-time process monitoring (temperature, pressure, cure time). Statistical Process Control (SPC) is implemented for critical dimensions, ensuring batch-to-batch consistency. Comprehensive First Article Inspection Reports (FAIR) and Certificate of Conformance (CoC), including full material traceability, accompany all production shipments, guaranteeing the U-shaped moldings meet the exacting standards required for integration into our clients’ high-performance systems.

Contact Engineering Team

For precision-engineered U-shaped rubber moldings tailored to your industrial application, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in custom rubber component manufacturing. With advanced compounding capabilities, in-house tooling design, and rigorous quality control protocols, we deliver U-shaped profiles that meet exact dimensional, material, and performance criteria. Whether your project demands high-temperature resistance, chemical stability, or dynamic sealing performance, our engineering team collaborates directly with OEMs and Tier suppliers to develop optimized rubber solutions.

Our U-shaped moldings are commonly deployed in automotive sealing systems, industrial machinery, construction gaskets, and electrical enclosures where reliable compression set resistance and environmental sealing are critical. We process a full range of elastomers including EPDM, Nitrile (NBR), Silicone (VMQ), Fluorocarbon (FKM), and Neoprene (CR), ensuring compatibility with oils, ozone, UV exposure, and extreme thermal cycles. Each molding is produced using precision steel molds, high-tonnage hydraulic presses, and vulcanization processes calibrated to achieve consistent cross-link density and physical properties.

We specialize in low to mid-volume custom runs, rapid prototyping, and long-term production contracts with JIT delivery options. Our facility adheres to ISO 9001 standards, and all critical dimensions and material certifications are documented per customer requirements. From initial concept to final inspection, Suzhou Baoshida ensures technical accuracy, supply chain transparency, and on-time fulfillment.

Below is a representative specification profile for a standard U-shaped rubber molding. All parameters can be modified based on your engineering drawings or performance demands.

| Property | Value |

|---|---|

| Profile Shape | U-Channel (Customizable inner/outer radius, leg height, base width) |

| Standard Materials | EPDM, NBR, VMQ, FKM, CR, SBR |

| Hardness Range (Shore A) | 40 to 90 ±5 |

| Temperature Resistance | -40°C to +250°C (material-dependent) |

| Tolerance (per ASTM D3182) | ±0.2 mm (critical dimensions), ±0.5 mm (non-critical) |

| Production Method | Compression Molding, Transfer Molding |

| Post-Curing | Available upon request |

| Color Options | Black, Red, Blue, Green, Custom (Pantone matching) |

| Packaging | Anti-rust paper, vacuum sealed, carton with desiccant |

To initiate a project or request a quotation for custom U-shaped rubber moldings, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads technical client engagement and brings over 12 years of experience in rubber formulation, failure analysis, and industrial sealing solutions. He will review your application requirements, material specifications, and environmental stress factors to recommend the optimal compound and manufacturing approach.

Direct technical inquiries and RFQs to:

[email protected]

Include drawings, material callouts, annual volumes, and performance expectations for fastest response. We support CAD formats (DWG, STEP, PDF) and conduct DFM reviews within 48 hours of submission. Partner with Suzhou Baoshida for engineered rubber components built to perform—where precision meets performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).