Technical Contents

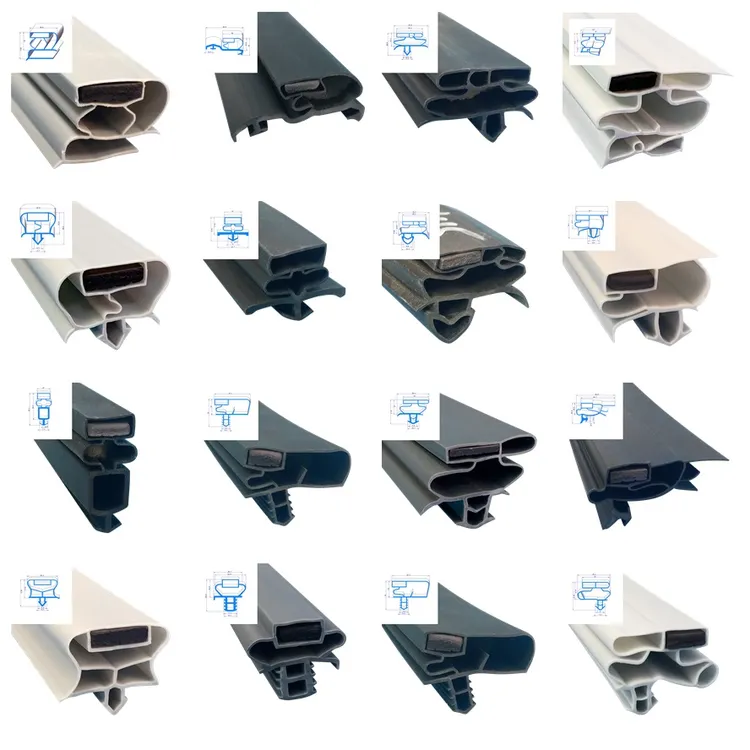

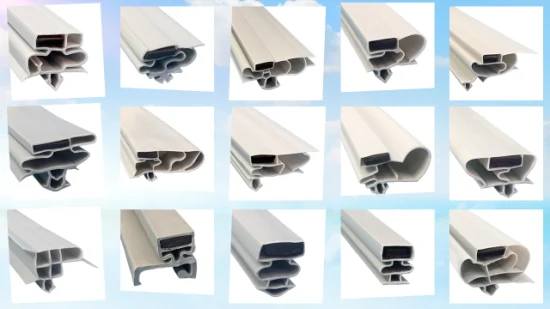

Engineering Guide: Universal Refrigerator Door Seal

Engineering Insight: The Critical Role of Material Selection in Universal Refrigerator Door Seals

In the precision-driven domain of refrigeration system integrity, the universal refrigerator door seal is far more than a passive gasket—it is a dynamically stressed component subjected to continuous compression, thermal cycling, and exposure to environmental contaminants. While many manufacturers default to off-the-shelf elastomeric solutions for cost or convenience, such an approach frequently results in premature seal degradation, compromised thermal efficiency, and increased energy consumption. The root cause lies in inadequate material selection that fails to account for the complex operational profile of modern refrigeration units.

A universal seal must perform reliably across diverse temperature ranges, typically from -40°C to +80°C, while maintaining consistent compression set resistance and elastic recovery. Standard rubber compounds such as low-grade EPDM or recycled NBR may appear functionally adequate in initial testing but often exhibit rapid hardening, cracking, or permanent deformation under sustained thermal and mechanical stress. These failures directly impact door closure integrity, leading to air leakage, frost accumulation, and compressor overwork—issues that cascade into higher maintenance costs and shortened appliance lifespan.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material formulations tailored to the specific thermodynamic and mechanical demands of each application. Our proprietary EPDM blends incorporate high saturation levels, optimized cure systems, and UV stabilizers to ensure long-term resilience against ozone, moisture, and temperature extremes. The molecular architecture is calibrated to balance durometer (Shore A) hardness with flexibility, ensuring a consistent sealing force without excessive door closure effort.

Off-the-shelf seals often neglect critical performance parameters such as compression deflection load, stress relaxation, and aging resistance. In contrast, precision-engineered seals integrate material science with dimensional accuracy to deliver repeatable performance across thousands of door cycles. Moreover, universal compatibility should not imply generic construction; true universality is achieved through intelligent design that accommodates dimensional variance while preserving material-specific performance.

The following table outlines key material specifications for high-performance refrigerator door seals compared to standard commercial alternatives:

| Property | High-Performance EPDM (Baoshida) | Standard Off-the-Shelf EPDM |

|---|---|---|

| Temperature Range (°C) | -50 to +100 | -30 to +70 |

| Shore A Hardness | 60 ± 5 | 55 ± 8 |

| Compression Set (22 hrs, 70°C) | ≤ 15% | ≤ 35% |

| Tensile Strength (MPa) | ≥ 9.0 | ≥ 5.0 |

| Elongation at Break (%) | ≥ 400 | ≥ 250 |

| Ozone Resistance (100 pphm, 20%) | No cracking after 96 hrs | Cracking within 24–48 hrs |

| Accelerated Aging (7 days, 100°C) | Retains > 80% original strength | Retains < 60% original strength |

Material selection is not a commodity decision—it is a foundational engineering imperative. At Baoshida, we reject one-size-fits-all compromises in favor of scientifically validated elastomer systems designed for enduring performance. For OEMs and industrial partners, this precision translates into reduced field failures, improved energy compliance, and enhanced brand reliability.

Material Specifications

Material Specifications for Universal Refrigerator Door Seals

Selecting the optimal elastomer for refrigerator door seals demands rigorous evaluation of thermal stability, chemical resistance, and mechanical performance. At Suzhou Baoshida Trading Co., Ltd., we prioritize materials that maintain sealing integrity across 15+ years of operational cycles while resisting degradation from refrigerants, cleaning agents, and temperature fluctuations. The three primary compounds employed in precision universal seals are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each engineered for distinct operational profiles.

Viton fluoroelastomers excel in extreme chemical environments, particularly where exposure to hydrocarbon-based refrigerants (e.g., R-134a) or industrial solvents occurs. With a continuous service temperature range of -20°C to +230°C, Viton maintains elastic recovery under prolonged compression, exhibiting compression set values below 25% after 70 hours at 150°C. Its molecular structure provides exceptional resistance to ozone and UV degradation, though material costs are 3–5× higher than alternatives. Viton seals are standard in commercial refrigeration units handling aggressive media.

Nitrile rubber (NBR) remains the industry workhorse for household and light-commercial refrigerators due to its balance of oil resistance and cost efficiency. Formulated with 33–36% acrylonitrile content, it achieves optimal resistance to mineral oils and common refrigerants while operating reliably from -40°C to +120°C. Critical for door seals, NBR demonstrates Shore A hardness of 65–75 and tensile strength ≥15 MPa, ensuring consistent compression force retention. However, its susceptibility to ozone cracking necessitates protective waxes in the compound formulation for outdoor-facing units.

Silicone (VMQ) dominates applications requiring ultra-low temperature flexibility or food-grade compliance. With a service range spanning -60°C to +200°C, it prevents seal hardening in freezer compartments where temperatures drop below -30°C. Silicone’s inert composition meets FDA 21 CFR 177.2600 for direct food contact, making it ideal for medical and pharmaceutical refrigeration. While tensile strength (6–8 MPa) is lower than NBR, its compression set remains under 20% after 22 hours at 150°C, ensuring long-term sealing force.

Material performance is quantified below for direct comparison under standardized test conditions (ASTM D2000).

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Shore A Hardness | 70–80 | 65–75 | 55–65 |

| Tensile Strength (MPa) | ≥12 | ≥15 | 6–8 |

| Elongation at Break (%) | ≥200 | ≥250 | 300–400 |

| Compression Set (70°C/24h) | ≤25% | ≤20% | ≤15% |

| Key Resistance | Refrigerants, Ozone | Oils, Water | Extreme Cold, Food Safety |

OEM selection hinges on operational priorities: NBR for cost-sensitive mass production, Silicone for sub-zero reliability, and Viton for chemical-intensive environments. Suzhou Baoshida validates all compounds through 50,000-cycle door durability testing per ISO 8318, ensuring zero leakage under 0.5 mm deflection. Material certifications (FDA, RoHS, REACH) are provided with batch-specific traceability.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering division is built on a foundation of technical precision and material science expertise, specifically tailored for the development of universal refrigerator door seals. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM solutions from concept to mass production. This multidisciplinary structure ensures that both the physical geometry of the seal and the chemical composition of the rubber are optimized in parallel, resulting in superior performance, durability, and sealing efficiency.

Our mould engineers possess extensive experience in precision tooling design for thermoplastic vulcanized (TPV) and EPDM rubber profiles. Utilizing advanced CAD/CAM software and CNC machining techniques, they develop high-tolerance moulds capable of producing complex cross-sectional geometries required for airtight refrigeration seals. Each design undergoes rigorous simulation for flow dynamics, shrinkage compensation, and thermal distribution, ensuring dimensional stability and consistent extrusion performance across production runs. This capability allows us to support universal fit applications across multiple OEM refrigerator platforms, minimizing client-specific tooling costs while maintaining tight sealing tolerances.

Complementing our tooling expertise, our two in-house rubber formula engineers specialize in elastomer compounding for low-temperature flexibility, compression set resistance, and ozone durability—critical performance parameters in refrigeration environments. They formulate custom rubber compounds that meet international standards including RoHS, REACH, and FDA compliance for food-safe applications. By controlling the formulation process internally, we ensure batch-to-batch consistency and rapid iteration during the development phase. This vertical integration of material science and mechanical design enables us to solve complex sealing challenges such as energy loss mitigation, frost resistance, and long-term door closure integrity.

We offer full OEM/ODM support, including reverse engineering of existing seals, 3D printing of prototypes, and performance validation through environmental testing chambers that simulate -40°C to 80°C thermal cycling. Clients benefit from reduced development lead times and scalable production readiness, backed by our ISO 9001-certified quality management system.

The table below outlines the standard technical specifications we engineer into our universal refrigerator door seals:

| Parameter | Standard Specification | Test Method |

|---|---|---|

| Material Type | EPDM, TPV, or Custom Compound | ASTM D1418 |

| Hardness (Shore A) | 55 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 7.0 MPa | ASTM D412 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Compression Set (24h @ 70°C) | ≤ 20% | ASTM D395 |

| Low-Temperature Flexibility | Pass at -40°C | ASTM D1329 |

| Ozone Resistance | No Cracking (200 pphm, 20%) | ASTM D1149 |

| Operating Temperature Range | -40°C to +80°C | Internal Validation |

| Color Matching Tolerance | ΔE ≤ 1.5 (Pantone or RAL) | ISO 7724 |

This combination of advanced engineering resources and rigorous material control positions Suzhou Baoshida as a strategic partner for global appliance manufacturers seeking reliable, high-performance universal sealing solutions.

Customization Process

Suzhou Baoshida’s Precision Customization Process for Universal Refrigerator Door Seals

Suzhou Baoshida Trading Co., Ltd. executes a rigorously defined customization pathway for universal refrigerator door seals, ensuring optimal performance, longevity, and compatibility across diverse OEM platforms. Our industrial-grade process eliminates guesswork, translating client specifications into certified production-ready components through four critical, interdependent phases.

The process initiates with comprehensive Drawing Analysis. Our engineering team meticulously dissects provided OEM technical drawings or 3D models, focusing on dimensional tolerances, critical sealing surfaces, compression set requirements, and interface geometries. We scrutinize groove dimensions, lip profiles, and hinge point flex zones to identify potential stress concentrations or material flow challenges during molding. This phase includes a formal gap analysis against international standards like ISO 3302-1 for rubber dimensioning and ISO 188 for thermal aging, ensuring the design is manufacturable within our precision tooling capabilities and meets core functional demands for energy efficiency and moisture barrier integrity.

Subsequent Formulation Development leverages our extensive rubber compound database and in-house laboratory expertise. Based on the thermal profile (-40°C to +70°C typical for refrigeration), chemical exposure (oils, cleaning agents), and required hardness (typically Shore A 55-75), we select the optimal base polymer system. Critical additives are precisely engineered: peroxide curing systems for superior compression set resistance, specialized fillers for tear strength, and proprietary stabilizers for ozone and UV resistance. Every formulation undergoes computational modeling to predict flow behavior and final physical properties before physical mixing.

Prototyping & Validation employs rapid tooling techniques to produce functional samples within 10-15 working days. These prototypes undergo stringent in-house testing per ASTM D2000 and ISO 16269 standards, including compression deflection force measurement, thermal cycling between -40°C and +80°C, accelerated aging for 1000+ hours, and vacuum integrity checks. We collaborate closely with the client to conduct real-world door closure force tests and condensation validation on representative refrigerator units. Iterative refinements to the compound or profile geometry occur only if empirical data indicates necessary adjustments, minimizing development cycles.

Upon client sign-off, seamless transition to Certified Mass Production occurs within our ISO 9001:2015 certified facility. Production utilizes multi-cavity precision steel molds with automated rubber injection molding presses, maintaining strict environmental controls. Statistical Process Control (SPC) monitors key parameters like cure time, temperature, and compound viscosity in real-time. Every production batch undergoes 100% visual inspection and抽样 physical testing per AQL 1.0 standards, with full material traceability from raw compound to finished seal. Final certification packages include comprehensive test reports and dimensional conformance data, ensuring consistent delivery of seals meeting the universal performance benchmark.

Material Specification Comparison for Universal Refrigerator Seals

| Material Type | Key Properties | Primary Application Fit |

|---|---|---|

| High-Performance EPDM | Shore A 60±5, Compression Set ≤20% (70°C/22h), Temp Range -45°C to +120°C, Excellent Ozone Resistance | Standard & commercial refrigeration, optimal balance of cost and performance |

| Silicone (VMQ) | Shore A 55±5, Compression Set ≤15% (70°C/22h), Temp Range -60°C to +200°C, Superior Low-Temp Flex | Ultra-low temperature freezers (-40°C and below), medical-grade units |

| Thermoplastic Elastomer (TPE) | Shore A 50±5, Compression Set ≤25% (70°C/22h), Temp Range -30°C to +100°C, Faster Cycle Times | Cost-sensitive residential applications, simplified recycling streams |

Contact Engineering Team

Contact Suzhou Baoshada Trading Co., Ltd. for Precision Universal Refrigerator Door Seals

When sourcing high-performance universal refrigerator door seals for OEM integration or industrial refrigeration systems, precision, durability, and material consistency are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber sealing solutions that meet stringent global standards for thermal efficiency, compression recovery, and long-term environmental resistance. Our universal refrigerator door seals are designed to deliver consistent performance across a broad range of commercial and domestic cooling units, ensuring optimal energy retention and operational reliability.

We invite manufacturers, procurement managers, and engineering teams to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, to discuss customized sealing solutions tailored to your production requirements. With over a decade of experience in rubber compounding and industrial seal design, Mr. Boyce leads technical consultations to align material properties—such as Shore A hardness, elongation at break, and low-temperature flexibility—with your specific application demands. Whether you require EPDM, silicone, or custom-blended thermoset rubber formulations, our team ensures every seal meets exact dimensional tolerances and performance benchmarks.

Our manufacturing process integrates advanced extrusion techniques, precision die-cutting, and rigorous quality control protocols, including tensile testing, aging resistance evaluation, and ozone exposure validation. All seals are produced in ISO-certified facilities with full traceability, ensuring compliance with international safety and environmental regulations.

To streamline integration into your production workflow, we provide comprehensive technical documentation, including material data sheets (MDS), dimensional drawings, and performance test reports. We also support rapid prototyping and small-batch trials to validate fit, form, and function before full-scale rollout.

Below are the standard technical specifications for our universal refrigerator door seal series:

| Property | Value | Test Standard |

|---|---|---|

| Material | EPDM Rubber (Custom Formulations Available) | ASTM D2000 |

| Hardness (Shore A) | 60 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 9.0 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ASTM D412 |

| Compression Set (22 hrs, 70°C) | ≤ 25% | ASTM D395 |

| Operating Temperature Range | -40°C to +120°C | ISO 1817 |

| Ozone Resistance | Excellent (No Cracking at 50 pphm, 20%) | ASTM D1149 |

| Flame Rating | UL94 HB | UL 94 |

| Standard Length | 2.0 m, 2.2 m, or Custom Cut | ISO 1817 |

For technical inquiries, sample requests, or volume quotation discussions, please contact Mr. Boyce directly at [email protected]. We respond to all inquiries within 12 business hours and offer multilingual support for clients in North America, Europe, and Southeast Asia. Partner with Suzhou Baoshida Trading Co., Ltd. to ensure your refrigeration systems are equipped with seals engineered for precision, longevity, and superior sealing integrity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).