Technical Contents

Engineering Guide: Us Rubber

Engineering Insight: Material Selection Imperatives in Industrial Rubber Applications

Industry studies consistently identify material mismatch as the primary root cause of premature rubber component failure in demanding industrial environments. Off-the-shelf rubber solutions, while cost-attractive initially, frequently lack the tailored molecular architecture required to withstand specific operational stressors. Generic compounds often fail catastrophically when exposed to complex combinations of chemical exposure, thermal cycling, dynamic loading, and environmental degradation. This results in unplanned downtime, safety hazards, and significantly higher total cost of ownership compared to engineered formulations.

The critical flaw in standard rubber products lies in their one-size-fits-all polymer base and additive systems. For instance, a generic EPDM seal may meet basic temperature resistance specs but rapidly degrade when exposed to biodiesel blends due to inadequate saturation resistance. Similarly, nitrile butadiene rubber (NBR) compounds with standard plasticizer packages can experience severe hardening or swelling in phosphate ester hydraulic fluids. These failures stem from insufficient consideration of fluid compatibility kinetics, compression set mechanisms under continuous strain, and long-term oxidative stability at elevated temperatures.

Suzhou Baoshida Trading Co., Ltd. addresses this through precision material science. Our OEM engineering process begins with rigorous application profiling – quantifying fluid types, concentration levels, temperature profiles, dynamic stresses, and regulatory constraints. We then develop custom formulations using advanced polymer blends, specialty curatives, and proprietary additive packages. This ensures optimal crosslink density, filler dispersion, and interfacial stability for the exact service conditions. The result is extended service life, reduced maintenance frequency, and compliance with stringent industry standards like ISO 2230, ASTM D2000, and NORSOK M-710.

The performance delta between generic and engineered compounds is quantifiable. Consider hydraulic accumulator bladders operating in aerospace systems:

| Property | Generic NBR Compound | Baoshida Engineered HNBR | Test Standard |

|---|---|---|---|

| Tensile Retention (70h, Skydrol LD-4) | 45% | 88% | ASTM D471 |

| Compression Set (70h, 150°C) | 32% | 12% | ASTM D395 |

| Low-Temp Flex (°C) | -30 | -55 | ASTM D2137 |

| Volume Swell (IRMOG 32) | 28% | 8% | ISO 1817 |

These specifications demonstrate how targeted molecular design mitigates failure modes inherent in commodity materials. The engineered HNBR compound maintains structural integrity under aggressive aviation hydraulic fluids where standard NBR loses critical mechanical properties. Crucially, our formulations undergo application-specific validation testing – including real-world duty cycle simulation – before OEM integration.

Material selection is not a procurement decision but an engineering imperative. Suzhou Baoshida’s scientific approach eliminates the gamble of off-the-shelf rubber by delivering compounds engineered for predictable, reliable performance in your exact operational ecosystem. Contact our technical team to initiate an application audit and specification optimization protocol.

Material Specifications

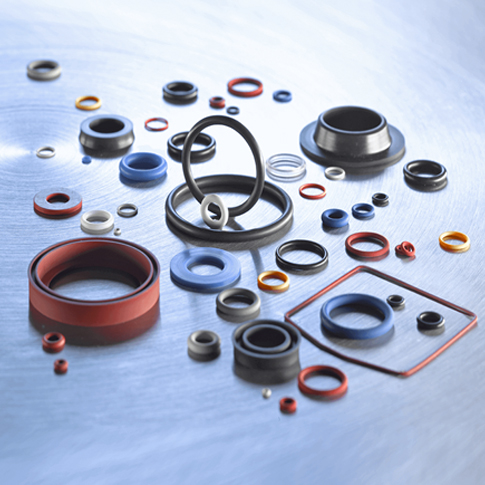

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for demanding environments across automotive, aerospace, chemical processing, and oil & gas sectors. Our engineered elastomers—Viton, Nitrile, and Silicone—are selected for their ability to maintain integrity under extreme thermal, chemical, and mechanical stress. Each material offers distinct advantages depending on application parameters such as temperature range, fluid compatibility, and mechanical durability.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbons. It performs reliably in continuous service up to 230°C (446°F) and exhibits excellent stability in the presence of oils, fuels, acids, and chlorinated solvents. This makes Viton the preferred choice for seals, gaskets, and O-rings in critical high-temperature and chemically aggressive environments. Its low gas permeability and long-term aging characteristics further enhance reliability in dynamic sealing applications.

Nitrile rubber (NBR) is a cost-effective solution for applications involving petroleum-based fluids and oils. With a service temperature range of -30°C to 105°C (-22°F to 221°F), Nitrile provides strong abrasion resistance and mechanical strength. It is widely used in hydraulic systems, fuel hoses, and oil seals where exposure to aliphatic hydrocarbons is common. While less resistant to ozone and UV degradation compared to other elastomers, Nitrile remains a dominant material in general industrial sealing due to its balance of performance and affordability.

Silicone rubber (VMQ) excels in extreme temperature applications, operating effectively from -60°C to 200°C (-76°F to 392°F). It offers excellent resistance to UV, ozone, and weathering, making it ideal for outdoor and high-purity applications such as medical devices, food processing, and electrical insulation. Though lower in tensile strength and abrasion resistance than Nitrile or Viton, silicone provides superior flexibility at low temperatures and outstanding electrical insulation properties.

The following table compares key physical and chemical properties of these materials to assist in material selection for industrial applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 221 | -76 to 392 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 40–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Resistance to Acids/Bases | Excellent | Fair | Good |

| Gas Permeability | Low | Moderate | High |

| Common Applications | Aerospace seals, chemical valves, fuel systems | Hydraulic seals, oil hoses, gaskets | Medical tubing, electrical insulation, food-grade seals |

Material selection is critical to ensuring long-term performance and safety in industrial systems. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and manufacturers with precision-formulated rubber compounds and technical guidance to match material properties with operational demands.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Manufacturing at Scale

Suzhou Baoshida Trading Co., Ltd. integrates advanced material science with precision tooling to deliver mission-critical rubber components for industrial OEMs. Our engineering core comprises five dedicated Mould Engineers and two specialized Rubber Formula Engineers, operating within a unified R&D ecosystem. This structure ensures seamless translation of client specifications into production-ready solutions, minimizing iteration cycles while maximizing performance fidelity.

Mould Engineering leverages 3D CAD/CAM simulation and finite element analysis to achieve ultra-precise cavity geometries. Tolerances consistently held to ±0.05 mm across complex multi-cavity tools enable high-yield production of seals, gaskets, and dynamic components. Rapid prototyping via CNC-machined aluminum tooling accelerates validation, reducing time-to-market by 30% versus industry benchmarks. All tooling adheres to ISO 2768-mK standards, with thermal management systems optimized for silicone, EPDM, and FKM compounds to prevent flash and cure inconsistencies.

Rubber Formula Engineering drives material innovation through polymer architecture design and additive science. Our lab utilizes DSC, TGA, and rheometry to tailor compounds for extreme environments—addressing ozone resistance, fluid compatibility, and compression set below 15% per ASTM D395. Each formulation undergoes 200+ hours of empirical validation against OEM-specific aging protocols, ensuring longevity in automotive, aerospace, and energy applications.

OEM collaboration begins at the specification phase, with co-engineering support for DFMEA and GD&T alignment. We manage full IP protection through NDA-governed workflows and maintain dedicated production cells for exclusive client programs. Our ISO 9001-certified process guarantees traceability from raw material lot to finished part, with real-time SPC monitoring of critical parameters like Mooney viscosity and cure kinetics.

The following table exemplifies our compound development range against standard industry benchmarks:

| Property | Standard Nitrile (NBR) | Custom High-Temp FKM | Baoshida Custom Compound |

|---|---|---|---|

| Shore A Hardness Range | 50–90 | 60–80 | 40–95 (adjustable) |

| Tensile Strength (MPa) | 15–25 | 10–18 | 8–30 (targeted) |

| Temp Range (°C) | -30 to +120 | -20 to +230 | -60 to +315 (validated) |

| Fluid Resistance | Oil/Fuel (Good) | Jet Fuel (Excellent) | Custom chemical exposure |

| Customization Depth | Fixed grades | Limited variants | Full polymer/additive tuning |

This integrated engineering framework—combining mould precision, material science rigor, and OEM-centric co-development—enables Suzhou Baoshida to solve the most demanding rubber application challenges. We transform technical requirements into certified, production-ready components with zero compromise on performance or repeatability.

Customization Process

Drawing Analysis: The Foundation of Precision Rubber Manufacturing

At Suzhou Baoshida Trading Co., Ltd., every custom rubber component begins with rigorous drawing analysis. This initial phase ensures that technical specifications, dimensional tolerances, and application requirements are fully understood and accurately interpreted. Our engineering team evaluates customer-provided CAD models or 2D technical drawings to assess critical features such as part geometry, wall thickness, sealing surfaces, and potential draft angles. We verify compliance with international standards including ISO 3302 for dimensional tolerances and ISO 2768 for general geometric specifications. Any discrepancies or design risks—such as stress concentration points or molding limitations—are flagged and discussed with the client for optimization. This step is essential to prevent defects during molding and to ensure long-term performance in the target environment.

Formulation: Engineering Material Performance

Following design validation, we transition to rubber formulation—a core competency where material science meets industrial demand. Based on the operating conditions identified during drawing review (e.g., temperature range, fluid exposure, mechanical load), our Rubber Formula Engineers select the optimal elastomer base. Common polymers include NBR for oil resistance, EPDM for weather and ozone stability, FKM for high-temperature performance, and silicone for extreme thermal flexibility. Additives such as reinforcing fillers, antioxidants, plasticizers, and curing agents are precisely calibrated to achieve target hardness (Shore A 30–90), tensile strength, elongation at break, and compression set resistance. Each compound is documented under a unique material specification code and subjected to preliminary lab testing for consistency and processability.

Prototyping: Validating Design and Material

Once the formulation is finalized, we proceed to prototyping using small-batch compression or injection molding. Prototypes are produced under near-production conditions to simulate real-world behavior. These samples undergo dimensional inspection via coordinate measuring machines (CMM) and performance testing such as compression set (ASTM D395), tensile testing (ASTM D412), and fluid resistance evaluation (ASTM D471). Functional trials in simulated application environments further validate sealing efficiency, durability, and fit. Feedback from this stage informs any necessary design or material adjustments before release to mass production.

Mass Production: Scalable Quality Assurance

With approved prototypes, we initiate full-scale manufacturing using automated rubber molding lines equipped with real-time process monitoring. Each batch is traceable, with raw material lot tracking and in-process quality checks at defined intervals. Final inspection includes visual examination, dimensional sampling, and periodic revalidation of physical properties. All products are packaged to prevent deformation and shipped with material certification and test reports.

| Property | Test Standard | Typical Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 30–90 |

| Tensile Strength | ASTM D412 | 8–25 MPa |

| Elongation at Break | ASTM D412 | 150–600% |

| Compression Set (70h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature | — | -40°C to +200°C (FKM) |

Contact Engineering Team

Initiate Precision Rubber Component Sourcing with Suzhou Baoshida

Industrial rubber performance is non-negotiable in demanding applications. Substandard elastomers compromise system integrity, accelerate wear, and incur significant operational downtime. Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and rigorous manufacturing execution, delivering bespoke rubber solutions engineered for extreme mechanical, thermal, and chemical environments. Our technical team possesses deep expertise in formulating compounds for aerospace seals, automotive fluid handling systems, semiconductor manufacturing components, and heavy industrial machinery. We do not sell generic rubber; we solve material failure points through molecular-level customization and ISO 9001-certified production processes.

Our OEM partnership model prioritizes technical collaboration from initial concept to volume production. We integrate directly with your engineering workflows, providing full material traceability, accelerated aging protocols, and failure mode analysis. This ensures your components meet exact dimensional tolerances, compression set requirements, and fluid resistance specifications under real-world conditions. The table below outlines core technical capabilities defining our manufacturing precision:

| Parameter | Standard Range | Custom Capability | Testing Standard |

|---|---|---|---|

| Hardness (Shore A) | 30 – 95 | 25 – 98 | ASTM D2240 |

| Temperature Range | -60°C to +250°C | -75°C to +315°C | ASTM D573 |

| Tensile Strength | 8 – 30 MPa | Up to 45 MPa | ASTM D412 |

| Elongation at Break | 150% – 800% | 100% – 1000%+ | ASTM D412 |

| Fluid Resistance | Standard oils/fuels | Custom chemical suites | ASTM D471 |

Engaging Suzhou Baoshida initiates a structured technical dialogue. We require detailed application parameters—operating pressures, media exposure, dynamic stresses, and lifecycle expectations—to formulate compounds exceeding industry benchmarks. Our facility utilizes state-of-the-art Banbury mixers, precision CNC molding equipment, and in-house rheometry labs, enabling rapid prototyping with zero tooling waste. Every batch undergoes stringent QC validation against your performance criteria, including FTIR spectroscopy for polymer verification and micro-hardness mapping for uniformity assurance.

Do not compromise on elastomer integrity when mission-critical performance is at stake. Contact Mr. Boyce, our dedicated Technical OEM Manager, to commence a solution-specific consultation. Provide your component drawings, material specifications, and performance failure history for immediate compound analysis. Mr. Boyce possesses direct authority to allocate formulation resources and expedite trial production runs based on engineering merit. His expertise ensures your requirements translate into validated rubber chemistry, not generic sales promises.

Initiate your technical dossier review today. Email Mr. Boyce at [email protected] with subject line: OEM Technical Inquiry – [Your Company Name]. Include application context, target volumes, and critical failure modes. Responses include preliminary compound recommendations within 24 business hours. Suzhou Baoshida guarantees engineered rubber solutions where material science meets manufacturing excellence—your operational reliability depends on this precision. Act now to eliminate elastomer-related system vulnerabilities.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).