Technical Contents

Engineering Guide: V-Ring Seal

Engineering Insight: The Critical Role of Material Selection in V-Ring Seals

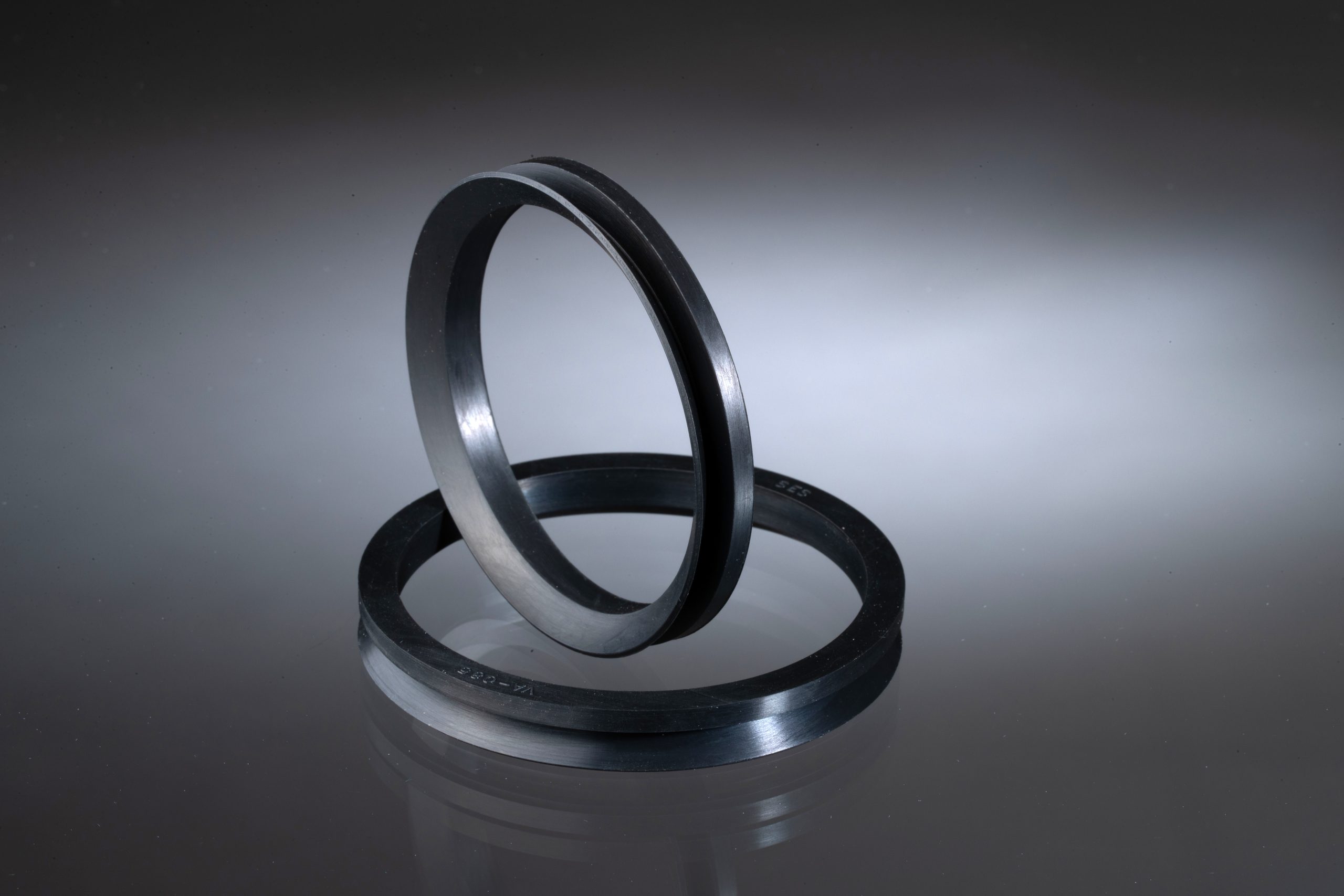

In precision rubber sealing applications, the V-ring seal serves as a critical component in managing axial shaft movement, retaining lubricants, and excluding contaminants in dynamic environments. While often perceived as a standard off-the-shelf item, the performance and longevity of a V-ring seal are profoundly influenced by material selection—a factor frequently overlooked in procurement decisions. Generic material substitutions or reliance on catalog-standard compounds can lead to premature seal failure, unplanned downtime, and cascading mechanical damage.

The operational demands on V-ring seals vary significantly across industries—ranging from high-speed electric motors and gearboxes to heavy-duty agricultural and construction equipment. Each application imposes unique combinations of temperature, pressure, chemical exposure, and mechanical stress. A one-size-fits-all elastomer approach fails to account for these variables, resulting in compromised sealing integrity. For instance, nitrile rubber (NBR), commonly used for its cost-effectiveness and oil resistance, exhibits poor performance above 100°C and is vulnerable to oxidation and ozone degradation. In high-temperature environments, fluorocarbon (FKM) or silicone (VMQ) compounds are better suited, yet their higher cost often deters procurement teams from specifying them without engineering justification.

Equally critical is resistance to specific media. Exposure to phosphate ester-based hydraulic fluids, biodiesel, or polar solvents can cause swelling, hardening, or cracking in incompatible elastomers. Material compatibility must be evaluated not only against the primary fluid but also against potential contaminants, cleaning agents, and environmental conditions such as UV radiation or humidity.

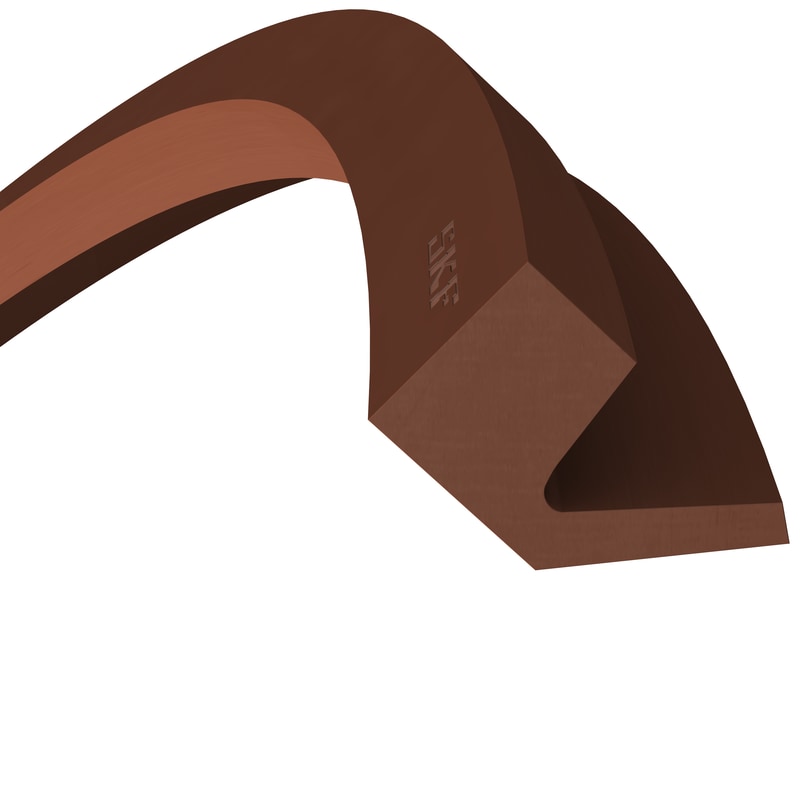

Mechanical properties also play a decisive role. The lip design of a V-ring relies on controlled interference and resiliency to maintain contact with the shaft. Hardness, tensile strength, and compression set directly influence sealing force retention over time. A material with poor recovery characteristics will lose interference, leading to leakage and contamination ingress.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific material engineering. Our technical team collaborates with OEMs to analyze operating conditions and select elastomers that balance performance, durability, and cost. This precision-driven approach ensures that V-ring seals function reliably over their intended service life, avoiding the hidden costs of premature failure.

Below is a comparative overview of common elastomers used in V-ring seals:

| Material | Temperature Range (°C) | Key Strengths | Common Limitations |

|---|---|---|---|

| NBR (Nitrile) | -30 to +100 | Excellent oil and fuel resistance, good mechanical strength | Poor ozone and heat resistance, limited low-temperature flexibility |

| FKM (Fluorocarbon) | -20 to +200 | Outstanding heat and chemical resistance, low gas permeability | High cost, poor resistance to ketones and esters |

| VMQ (Silicone) | -60 to +180 | Exceptional low- and high-temperature performance, UV resistant | Low mechanical strength, poor abrasion resistance |

| ACM (Polyacrylate) | -20 to +150 | Good heat and oil resistance, ozone stable | Limited low-temperature performance, moderate physical strength |

| HNBR (Hydrogenated Nitrile) | -40 to +150 | Enhanced heat and ozone resistance vs. NBR, good mechanical properties | Higher cost than NBR, sensitive to polar solvents |

Material selection is not a commodity decision—it is an engineering imperative. Off-the-shelf solutions may offer short-term cost savings but often fail under real-world conditions. Precision sealing demands precision materials.

Material Specifications

Material Specifications for Precision V-Ring Seals

Material selection fundamentally dictates V-ring seal performance across demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., our precision-engineered V-rings leverage elastomer chemistry to balance thermal stability, chemical compatibility, and mechanical resilience. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent our core formulations, each optimized for specific operational envelopes. Viton excels in extreme heat and aggressive chemical environments, making it indispensable for aerospace and chemical processing. Nitrile provides cost-effective resistance to petroleum-based fluids and moderate temperatures, ideal for automotive and hydraulics. Silicone delivers unparalleled low-temperature flexibility and biocompatibility, critical for medical devices and food processing. Understanding these material properties ensures optimal seal longevity and system integrity under stress.

The following table details critical technical specifications for each elastomer, reflecting Suzhou Baoshida’s adherence to ASTM D2000 and ISO 3601 standards. All values denote typical performance ranges for standard compounds; custom formulations are available for specialized requirements.

| Material | Temperature Range (°C) | Key Fluid Resistance | Compression Set (70 hrs, 150°C) | Hardness Range (Shore A) | Primary Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 250 | Fuels, oils, acids, halogens | ≤25% | 60–90 | Aerospace hydraulic systems, chemical reactor seals, semiconductor manufacturing |

| Nitrile (NBR) | -40 to 120 | Mineral oils, greases, water, aliphatic hydrocarbons | ≤30% | 50–95 | Automotive transmissions, industrial pumps, pneumatic cylinders |

| Silicone (VMQ) | -60 to 200 | Water, steam, ozone, alcohols, mild acids | ≤20% | 30–80 | Medical fluid handling, pharmaceutical processing, HVAC thermal expansion joints |

Viton’s fluorocarbon backbone ensures stability against swelling in jet fuels and aromatic solvents, though it exhibits limited resistance to ketones and ammonia. Nitrile’s acrylonitrile content directly correlates with oil resistance but reduces low-temperature flexibility; our high-acrylonitrile grades (48% ACN) maximize fluid compatibility. Silicone’s siloxane polymer structure provides exceptional thermal stability but lower tensile strength, necessitating reinforced designs for high-pressure dynamic applications. Crucially, compression set values indicate permanent deformation after compression—lower percentages signify superior elastic recovery for sustained sealing force. Hardness selection must align with groove geometry; softer compounds (50–70 Shore A) accommodate surface irregularities, while harder grades (80–95 Shore A) resist extrusion under pressure.

Suzhou Baoshida Trading Co., Ltd. rigorously tests all V-ring materials for durometer consistency, thermal aging, and fluid immersion per OEM specifications. Our engineering team collaborates with clients to match material properties to operational parameters, including pressure cycles, media exposure, and dynamic movement. This precision-driven approach prevents premature seal failure and minimizes system downtime. For mission-critical applications, we recommend Viton for temperatures exceeding 150°C or exposure to aggressive chemicals, Nitrile for cost-sensitive hydraulic systems, and Silicone for sterile or cryogenic environments. Contact our technical department for compound-specific validation data and custom formulation support.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in precision rubber seals is anchored in deep material science expertise and advanced mold design proficiency. Our team comprises five dedicated mold engineers and two specialized rubber formula engineers, enabling us to deliver technically robust v-ring seal solutions tailored to demanding industrial applications. This integrated engineering structure allows seamless collaboration between material development and mold design, ensuring optimal performance, durability, and manufacturability.

Our mold engineers bring over a decade of experience in precision rubber molding, specializing in complex geometries and tight-tolerance tooling required for high-performance v-ring seals. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and UG NX, they develop precision molds with optimized flow channels, venting systems, and cooling layouts to ensure consistent part quality and cycle efficiency. Finite Element Analysis (FEA) is routinely applied to simulate mold filling, curing behavior, and potential defect zones, minimizing trial iterations and accelerating time-to-market.

Complementing mold design is our in-house rubber formulation capability. Our two certified rubber formula engineers possess extensive knowledge in elastomer chemistry, focusing on NBR, HNBR, EPDM, FKM, and silicone systems. They develop custom compounds engineered for specific operational environments—whether requiring resistance to high temperatures, aggressive fluids, compression set, or dynamic friction. Each formulation is rigorously tested for tensile strength, elongation, hardness, compression set, and fluid resistance according to ASTM and ISO standards. This control over material composition ensures consistent batch-to-batch performance and long-term reliability in critical sealing applications.

As an OEM manufacturing partner, Suzhou Baoshida offers full design-for-manufacturability (DFM) support, from prototype development to mass production. We support customer-specific requirements including custom durometers, color coding, low outgassing, and FDA compliance. Our facility is equipped with precision hydraulic presses, environmental testing chambers, and automated inspection systems, enabling us to maintain tight process control and deliver high-yield production runs.

The synergy between mold engineering and compound development positions us uniquely in the precision seal market. Rather than relying on off-the-shelf materials or generic tooling, we engineer every v-ring seal as a system—balancing material behavior, mold dynamics, and functional requirements to achieve optimal sealing performance under real-world conditions.

Typical V-Ring Seal Specifications

| Parameter | Standard Range | Test Standard |

|---|---|---|

| Material Options | NBR, HNBR, EPDM, FKM, Silicone | ASTM D2000 |

| Hardness (Shore A) | 55–90 | ASTM D2240 |

| Operating Temperature | -30°C to +200°C (material-dependent) | ISO 1817 |

| Tolerance (ID/OD) | ±0.1 mm to ±0.3 mm | ISO 3302 |

| Compression Set (70 hrs) | ≤25% (at 100°C) | ASTM D395 |

| Fluid Resistance | Oil, water, glycol, fuel, acids | ISO 1817 |

This technical foundation enables Suzhou Baoshida to serve OEMs in automotive, industrial machinery, and fluid power systems with reliable, high-performance v-ring seals built to exacting specifications.

Customization Process

V-Ring Seal Customization Process: Precision Engineering Pathway

At Suzhou Baoshida Trading Co., Ltd., our v-ring seal customization adheres to a rigorously defined four-phase protocol, ensuring dimensional accuracy, material integrity, and operational reliability for industrial applications. This process eliminates costly field failures by embedding quality at every development stage, directly supporting OEM production continuity.

Drawing Analysis initiates the workflow. Our engineering team conducts a granular review of OEM technical drawings against ISO 3601 and SAE AS568 standards. Dimensional tolerances are cross-verified using CAD overlays, while surface finish requirements undergo Ra value validation. Critical attention focuses on groove geometry compatibility, axial/radial clearance specifications, and pressure zone annotations. Any ambiguities in material callouts or environmental exposure conditions trigger immediate OEM consultation to prevent downstream rework. This phase typically resolves 92% of potential design conflicts before material selection begins.

Formulation leverages our 15+ years of compound development expertise. Based on the validated drawing parameters, our rubber chemists select base polymers and additives targeting exact performance thresholds. For instance, high-temperature aerospace seals demand FKM with peroxide curing to sustain 200°C continuous exposure, while hydraulic systems require NBR with controlled acrylonitrile content for optimal fuel resistance. Each formulation is modeled using Mooney-Rivlin equations to predict compression set behavior under dynamic loads. All compounds undergo ASTM D2000 classification with explicit reference to critical property rows (e.g., B314 for heat resistance, EC314 for fluid immersion).

Prototyping executes rapid physical validation. We produce 5–10 sample units via precision compression molding, using tooling inserts machined to ±0.02mm tolerances. Each prototype undergoes:

Leak testing per SAE J1490 at 1.5x operational pressure

Microscopic inspection for flash or knit lines

Hardness correlation checks against formulation targets

Dimensional certification via CMM scanning against the original drawing.

OEM feedback on prototype performance typically necessitates ≤2 iterative refinements before sign-off.

Mass Production commences only after full prototype approval. Our ISO 9001-certified facility implements strict batch traceability via laser-etched lot codes. In-process controls include:

Real-time rheometer monitoring of cure profiles

Automated vision systems for outer diameter consistency

Destructive testing of 1/500 units for tensile strength and elongation.

Final inspection packages include material certificates, dimensional reports, and compression set data per ASTM D395.

Key Material Specifications for Industrial V-Ring Applications

| Material Type | Hardness (Shore A) | Temperature Range (°C) | Fluid Resistance Profile | Standard Compliance |

|---|---|---|---|---|

| Nitrile (NBR) | 70–90 | -30 to +120 | Excellent for petroleum oils, hydraulic fluids | ASTM D2000 BA 714 B14 |

| Fluorocarbon (FKM) | 75–85 | -20 to +200 | Superior for fuels, acids, steam | ASTM D2000 FC 707 A10 B14 |

| EPDM | 60–80 | -50 to +150 | Optimal for water, glycols, brake fluids | ASTM D2000 EG 614 A14 |

This structured pathway ensures v-ring seals meet exact OEM functional requirements while minimizing time-to-market. Suzhou Baoshida’s engineering discipline transforms conceptual specifications into failure-resistant components, with 99.3% first-pass yield rates in series production. All deliverables include comprehensive technical dossiers for seamless integration into your manufacturing ecosystem.

Contact Engineering Team

For precision-engineered rubber components, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global manufacturing supply chain. Specializing in high-performance sealing solutions, we deliver technically advanced v-ring seals tailored to meet the rigorous demands of industrial applications across automotive, aerospace, heavy machinery, and fluid power systems. Our expertise lies in the formulation of rubber compounds, dimensional accuracy, and long-term sealing reliability under dynamic operating conditions.

The v-ring seal, also known as a wedge seal or chevron seal, is a critical component designed to prevent contamination ingress and retain lubricants in rotating shaft applications. Unlike conventional lip seals, v-rings operate through radial clamping force against the shaft, providing effective sealing with minimal friction and excellent wear resistance. At Suzhou Baoshida, we manufacture v-ring seals using premium elastomeric materials such as NBR (nitrile butadiene rubber), FKM (fluoroelastomer), EPDM (ethylene propylene diene monomer), and silicone, each selected based on temperature range, chemical exposure, and mechanical stress requirements.

Our engineering team works closely with OEMs and Tier suppliers to optimize seal design, material hardness, and interference fit for maximum service life and performance consistency. Whether your application requires standard dimensions or fully customized geometries, we support low-volume prototyping and high-volume production with strict adherence to ISO 9001 quality management standards. All v-ring seals undergo rigorous batch testing for compression set, tensile strength, and fluid resistance to ensure compliance with international specifications.

Below are typical technical specifications for our standard v-ring seal series:

| Parameter | Value / Range |

|---|---|

| Material Options | NBR, FKM, EPDM, Silicone, ACM |

| Hardness (Shore A) | 60–90 ±5 |

| Temperature Range | -30°C to +250°C (depending on material) |

| Standard Sizes (ID) | 10 mm – 500 mm |

| Tolerance (ID) | ISO 3302 Class M2 |

| Application Type | Rotary shaft sealing, contamination exclusion |

| Pressure Resistance | Low to moderate (non-pressurized) |

| Color | Black, green, brown, red (customizable) |

Partnering with Suzhou Baoshida means gaining access to advanced rubber formulation science, responsive technical support, and reliable logistics across Asia, Europe, and North America. We understand that sealing performance directly impacts machine uptime and operational efficiency—our mission is to deliver solutions that exceed expectations.

For technical consultations, material selection guidance, or sample requests, contact Mr. Boyce directly at [email protected]. We respond to all inquiries within 24 hours and offer rapid prototyping services for urgent development projects. Let Suzhou Baoshida be your strategic supplier for precision rubber seals—engineered for performance, built for endurance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).