Technical Contents

Engineering Guide: Vibration Reducing

Engineering Insight: Vibration Reduction Through Precision Material Selection

Vibration transmission in industrial machinery represents a critical failure vector, directly impacting equipment lifespan, operational precision, and safety compliance. While vibration isolation mounts are ubiquitous, generic off-the-shelf rubber solutions frequently underperform or fail catastrophically in demanding applications. This stems from a fundamental oversight: vibration dynamics are system-specific, requiring material properties engineered to match exact resonant frequencies, load profiles, and environmental conditions. Standard compounds prioritize cost and ease of manufacture over the nuanced physics of energy dissipation, leading to premature fatigue, resonance amplification, or thermal runaway.

The core challenge lies in balancing dynamic modulus, damping coefficient, and resilience across operational extremes. A mount optimized for static compression may exhibit inadequate hysteresis at operational frequencies, converting kinetic energy into heat instead of dissipating it. Conversely, overly rigid compounds transmit damaging harmonics. Temperature fluctuations further destabilize generic formulations; a -40°C to +70°C range common in commodity rubber becomes inadequate in foundries or arctic machinery, causing embrittlement or softening that alters isolation characteristics. Chemical exposure—oils, ozone, or cleaning agents—accelerates degradation in non-formulated elastomers, compromising structural integrity within months.

Suzhou Baoshida Trading Co., Ltd. addresses these failures through OEM-grade compound engineering. We analyze spectral vibration data, load spectra, and environmental stressors to tailor polymer matrices, filler systems, and curing protocols. Below illustrates key differentiators between standard and engineered solutions:

| Critical Property | Standard Off-the-Shelf Rubber | Baoshida Engineered Compound |

|---|---|---|

| Damping Coefficient (tan δ) | 0.15–0.25 (narrow frequency) | 0.35–0.60 (broadband tunable) |

| Dynamic Modulus Stability | ±35% over -30°C to +80°C | ±8% over -55°C to +120°C |

| Compression Set (ASTM D395) | 25–40% after 70h @ 70°C | <12% after 168h @ 100°C |

| Fluid Resistance (IRMOG) | Severe swelling in oils | <5% volume change in ISO 1817 |

| Resonant Frequency Shift | >15% under thermal cycling | <3% under thermal cycling |

Off-the-shelf mounts often fail due to resonant frequency drift during operation. A compressor mount rated for 10Hz may shift to 8Hz after thermal expansion, aligning with harmonic frequencies and amplifying vibration—a phenomenon impossible to predict with generic data sheets. Similarly, poor compression set resistance causes permanent deformation under continuous load, reducing isolation efficiency by up to 50% within 12 months. These failures cascade into bearing wear, seal leakage, and unplanned downtime exceeding material savings by 20x.

At Suzhou Baoshida, we reject one-size-fits-all approaches. Our compounds integrate high-purity polymers, nano-reinforced fillers, and custom curatives to lock performance across the operational envelope. This precision prevents resonance capture, maintains damping efficacy under thermal stress, and resists chemical attack—ensuring vibration energy is predictably dissipated, not merely deferred. For OEMs, this translates to extended service intervals, reduced warranty claims, and compliance with ISO 10814 vibration standards. Consult our engineering team with your spectral analysis data; we will deliver a compound specification, not a catalog part number.

Material Specifications

Vibration reduction in industrial applications demands precision-engineered rubber components capable of withstanding dynamic mechanical stresses, temperature extremes, and exposure to aggressive media. At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are formulated to deliver consistent damping performance, structural resilience, and long-term reliability under continuous vibrational loads. The selection of base elastomer is critical in determining the functional lifespan and operational efficiency of vibration isolation components such as mounts, bushings, and dampers. Among the most effective materials for these applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering a distinct balance of chemical resistance, thermal stability, and mechanical behavior.

Viton rubber is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of chemicals. With a continuous service temperature range up to 230°C, Viton is ideal for high-performance environments such as automotive turbocharger mounts, aerospace systems, and industrial machinery exposed to aggressive lubricants and exhaust gases. Its inherent stiffness provides moderate damping characteristics, making it suitable for applications where dimensional stability under thermal and chemical stress is paramount. However, due to its higher hardness and lower resilience compared to other elastomers, Viton is typically selected when environmental resistance outweighs the need for high flexibility.

Nitrile rubber, or Buna-N, is one of the most widely used elastomers in vibration control due to its excellent resistance to petroleum-based oils and fuels, coupled with good mechanical strength and damping capacity. Operating effectively within a temperature range of -30°C to 100°C, Nitrile offers a balanced combination of flexibility, abrasion resistance, and energy absorption. It is commonly employed in engine mounts, compressor supports, and industrial equipment where exposure to hydraulic fluids and greases is routine. Its cost-effectiveness and reliable performance in moderate environments make NBR a preferred choice for general-purpose vibration isolation.

Silicone rubber exhibits outstanding thermal stability from -60°C to 200°C and maintains elasticity across extreme temperature cycles. While its tensile strength and abrasion resistance are lower than Nitrile or Viton, Silicone excels in applications requiring high flexibility and consistent performance under thermal cycling. It is frequently used in electronic enclosures, HVAC systems, and precision instruments where low mechanical loading and high damping efficiency are required. Additionally, Silicone demonstrates good resistance to ozone and UV radiation, making it suitable for outdoor or elevated-temperature environments.

The following table compares the key material properties relevant to vibration reduction performance:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 | -60 to 200 |

| Hardness Range (Shore A) | 60–90 | 40–90 | 30–80 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Compression Set Resistance | Excellent | Good | Very Good |

| Oil/Fuel Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Good | Excellent |

| Damping Capacity | Moderate | High | High |

Material selection must align with the specific operational demands of the application, including dynamic load profiles, environmental exposure, and service life expectations. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and testing support to ensure optimal elastomer performance in vibration-critical systems.

Manufacturing Capabilities

Engineering Capabilities for Precision Vibration Reduction Solutions

Suzhou Baoshida Trading Co., Ltd. leverages deep expertise in rubber science and precision manufacturing to deliver engineered vibration reduction solutions for demanding industrial applications. Our core strength resides in a dedicated team of 5 Mold Engineers and 2 Rubber Formula Engineers, operating at the intersection of material innovation and production excellence. This integrated approach ensures that every component—from aerospace dampers to industrial machinery mounts—is optimized for dynamic load management, longevity, and performance consistency under extreme operational conditions.

Our Rubber Formula Engineers specialize in tailoring polymer compounds to achieve precise damping characteristics. Through advanced dynamic mechanical analysis (DMA), we manipulate molecular structures to control the loss modulus (E”) and storage modulus (E’), directly influencing energy dissipation efficiency. Compounds are engineered for specific frequency ranges, temperature stability, and chemical resistance, eliminating trial-and-error in material selection. For instance, our proprietary EPDM formulations achieve a damping loss factor (tan δ) of 0.28–0.35 at 10–50 Hz, critical for isolating low-frequency vibrations in heavy machinery. This scientific rigor ensures solutions meet OEM specifications without compromising durability or environmental resilience.

Complementing material science, our Mold Engineering team employs finite element analysis (FEA) to simulate stress distribution and deformation behavior under cyclic loads. Precision mold design minimizes flash, ensures uniform material flow, and maintains tight tolerances (±0.1 mm) for complex geometries. This synergy between formulation and tooling accelerates prototyping cycles by 40% compared to industry averages, enabling rapid validation of vibration attenuation performance before full-scale production.

As an OEM partner, we manage end-to-end manufacturing with full traceability. Our process begins with collaborative requirement analysis, where we translate vibration spectra, load profiles, and environmental factors into material and structural specifications. We then execute iterative testing using laser vibrometry and shaker tables to validate insertion loss and transmissibility curves against client benchmarks. Every batch undergoes rigorous quality control per ISO 9001 protocols, with material certificates and dynamic test reports provided for full supply chain transparency.

Typical Vibration Reduction Material Specifications

| Material Type | Frequency Range (Hz) | Damping Loss Factor (tan δ) | Temperature Range (°C) | Key Applications |

|---|---|---|---|---|

| Custom EPDM | 10–50 | 0.28–0.35 | -50 to +150 | Industrial pumps, generators |

| High-Damping NBR | 5–100 | 0.32–0.40 | -30 to +120 | Automotive engine mounts |

| Silicone-Hybrid | 1–200 | 0.25–0.30 | -60 to +200 | Aerospace avionics |

| Polyurethane | 20–150 | 0.20–0.25 | -40 to +90 | Conveyor systems, robotics |

Our OEM framework supports low-volume custom projects and high-volume production with identical engineering rigor. By embedding material science and mold precision into every phase—from compound development to final inspection—we deliver vibration reduction solutions that extend equipment lifespan, reduce maintenance costs, and ensure operational stability. Partner with Baoshida to transform vibration challenges into engineered advantages.

Customization Process

Drawing Analysis: The Foundation of Precision Vibration Reduction

The customization process for industrial rubber components designed to reduce vibration begins with rigorous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we treat technical drawings as the blueprint for performance, durability, and compatibility. Every dimension, tolerance, and surface finish specification is scrutinized to ensure the final product meets the mechanical and environmental demands of its intended application. Our engineering team evaluates load distribution, compression set requirements, dynamic stress points, and interface geometry. This step also includes assessing material thickness, cavity design, and potential stress concentrators that could compromise vibration damping efficiency. We collaborate closely with OEMs to validate design intent, ensuring that the rubber component will function optimally within the larger mechanical system. Finite element analysis (FEA) is often employed during this phase to simulate dynamic behavior under operational conditions, allowing for early-stage optimization.

Rubber Formulation: Engineering for Dynamic Performance

Once the design parameters are confirmed, we proceed to rubber formulation—a critical phase where material science meets application-specific demands. Vibration-reducing rubber components must balance elasticity, damping capacity, and long-term resilience. Our in-house polymer chemists develop custom elastomer blends using natural rubber (NR), nitrile (NBR), ethylene propylene diene monomer (EPDM), or silicone (VMQ), depending on temperature range, chemical exposure, and dynamic modulus requirements. Additives such as reinforcing fillers, plasticizers, and anti-aging agents are precisely calibrated to enhance energy absorption and fatigue resistance. The Shore hardness, typically ranging between 40 and 80 A, is tailored to match the frequency and amplitude of expected vibrations. Special considerations are given to low-temperature flexibility and resistance to ozone or oil, ensuring operational stability across diverse industrial environments.

Prototyping: Validating Design and Material Synergy

Following formulation, we produce functional prototypes using precision molding techniques such as compression, transfer, or injection molding. These prototypes are subjected to a battery of tests including dynamic stiffness evaluation, harmonic response analysis, and accelerated aging. Performance data is compared against OEM specifications to verify damping efficiency and structural integrity. Prototyping allows for iterative refinement—minor geometry adjustments or compound modifications can be implemented before committing to full-scale production. Client feedback is integrated at this stage to ensure alignment with real-world operating conditions.

Mass Production: Consistency at Scale

Upon approval, we transition to mass production using automated molding lines and strict quality control protocols. Each batch undergoes real-time monitoring for cure time, hardness, and dimensional accuracy. Our ISO-certified manufacturing partners ensure repeatability and traceability across production runs.

| Property | Typical Range | Test Standard |

|---|---|---|

| Shore A Hardness | 40–80 | ASTM D2240 |

| Tensile Strength | 8–20 MPa | ASTM D412 |

| Elongation at Break | 200–500% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature | -40°C to +120°C | ISO 1817 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Vibration Reduction Solutions

Achieving optimal vibration isolation in demanding industrial environments requires more than standardized rubber components; it demands engineered material science tailored to your specific dynamic loads, frequency spectra, and operational constraints. At Suzhou Baoshida Trading Co., Ltd., our core competency lies in translating complex vibration challenges into high-performance elastomeric solutions through rigorous formula development and precision manufacturing. We understand that ineffective damping leads to accelerated equipment wear, compromised measurement accuracy, increased noise pollution, and ultimately, unplanned downtime costing your operation significant revenue. Our team of specialized Rubber Formula Engineers operates at the intersection of polymer chemistry and mechanical dynamics, ensuring every compound we produce delivers quantifiable attenuation across your critical frequency bands.

The efficacy of a vibration isolator is intrinsically linked to its material properties under real-world conditions. Generic rubber mounts often fail to address the nuanced interplay between hardness, resilience, temperature stability, and damping characteristics required for superior performance. Suzhou Baoshida’s formulations are systematically optimized, moving beyond simple hardness (durometer) specifications to target precise loss factors and dynamic moduli. This scientific approach guarantees consistent energy dissipation, whether isolating sensitive semiconductor manufacturing equipment from sub-micron floor vibrations or stabilizing heavy-duty industrial compressors operating continuously under extreme thermal cycling. Our commitment to precision extends through every stage, from computational material modeling and accelerated life testing to ISO 9001-certified production and stringent batch traceability.

Critical Material Properties for Vibration Reduction

| Material Property | Performance Range | Application Relevance |

|---|---|---|

| Durometer (Shore A) | 30A – 90A | Balances load support with deflection for target frequencies |

| Temperature Resistance | -50°C to +150°C (standard compounds) | Maintains damping efficacy across operational extremes |

| Damping Coefficient (Tan δ) | 0.15 – 0.45 (at 10Hz, 23°C) | Directly correlates with vibration energy absorption |

| Compression Set (70h/100°C) | < 25% | Ensures long-term dimensional stability and preload |

| Dynamic Modulus (10Hz) | 2.5 MPa – 15.0 MPa | Critical for calculating isolator stiffness and resonance |

| Oil/Fuel Resistance | ASTM D471 compliant (custom grades) | Essential for automotive, marine, and industrial fluid exposure |

Partnering with Suzhou Baoshida means accessing deep technical collaboration, not just component supply. Our OEM management process is designed for seamless integration into your engineering and procurement workflows. We initiate every engagement with a detailed application review, analyzing your vibration spectra, load profiles, environmental factors, and lifecycle requirements. This enables us to propose the most effective compound formulation and geometry—whether standard cylindrical mounts, custom shear springs, or complex multi-layer isolators—ensuring maximum transmission loss tailored to your system. We support low-volume prototyping through high-volume production with rigorous quality control, including dynamic testing reports validating performance against your specifications.

Initiate the engineering dialogue to resolve your vibration challenges definitively. Contact Mr. Boyce, our dedicated OEM Manager, who possesses comprehensive authority over technical specifications, production scheduling, and supply chain coordination for global industrial clients. Mr. Boyce ensures your project receives direct access to our formula engineering team and prioritized manufacturing capacity. Provide him with your application details, target isolation efficiency, and performance criteria to receive a technically grounded proposal within 24 hours. Do not settle for off-the-shelf compromises when precision-engineered vibration reduction is essential for your equipment’s longevity and performance. Reach out immediately to commence the path toward quantifiable operational improvement.

Email Mr. Boyce directly at [email protected] to schedule a technical consultation. Include your specific vibration attenuation requirements, operating environment parameters, and preferred material certifications for the most efficient solution development. Suzhou Baoshida Trading Co., Ltd. stands ready to deliver the scientifically validated rubber solutions your critical machinery demands.

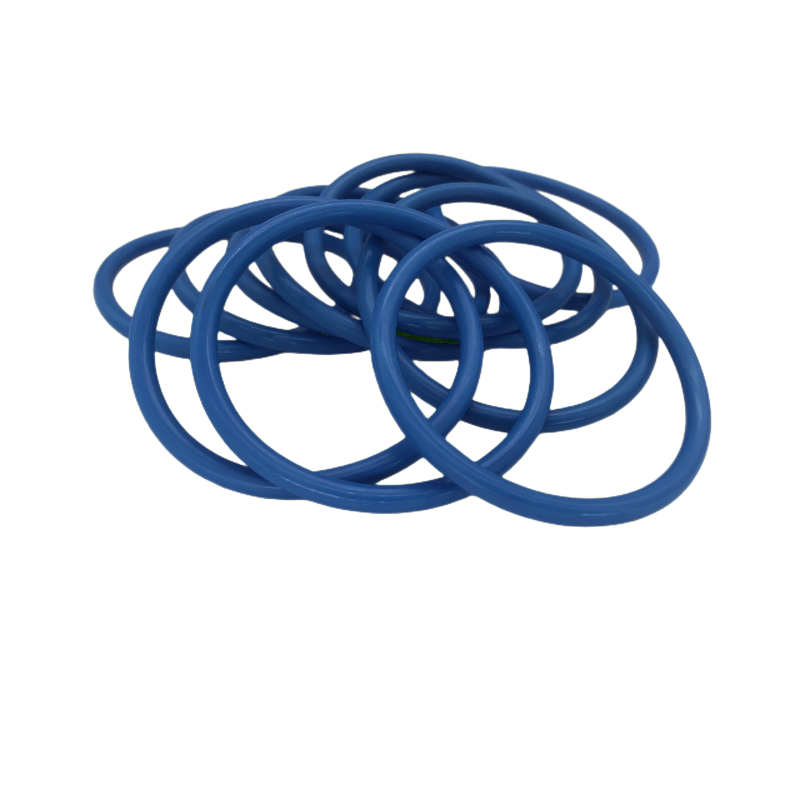

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).