Technical Contents

Engineering Guide: Vinyl Clad Weatherstrip

Engineering Insight: The Critical Role of Material Selection in Vinyl Clad Weatherstrip Performance

In the domain of industrial sealing solutions, vinyl clad weatherstrip serves as a vital component across automotive, construction, and transportation sectors. Its primary function—providing a durable, flexible, and weather-resistant seal—relies heavily on precise material engineering. While off-the-shelf variants are often marketed as cost-effective alternatives, they frequently fail to meet the mechanical, thermal, and environmental demands of real-world applications. This failure stems from inadequate material selection, underscoring the necessity for engineered customization.

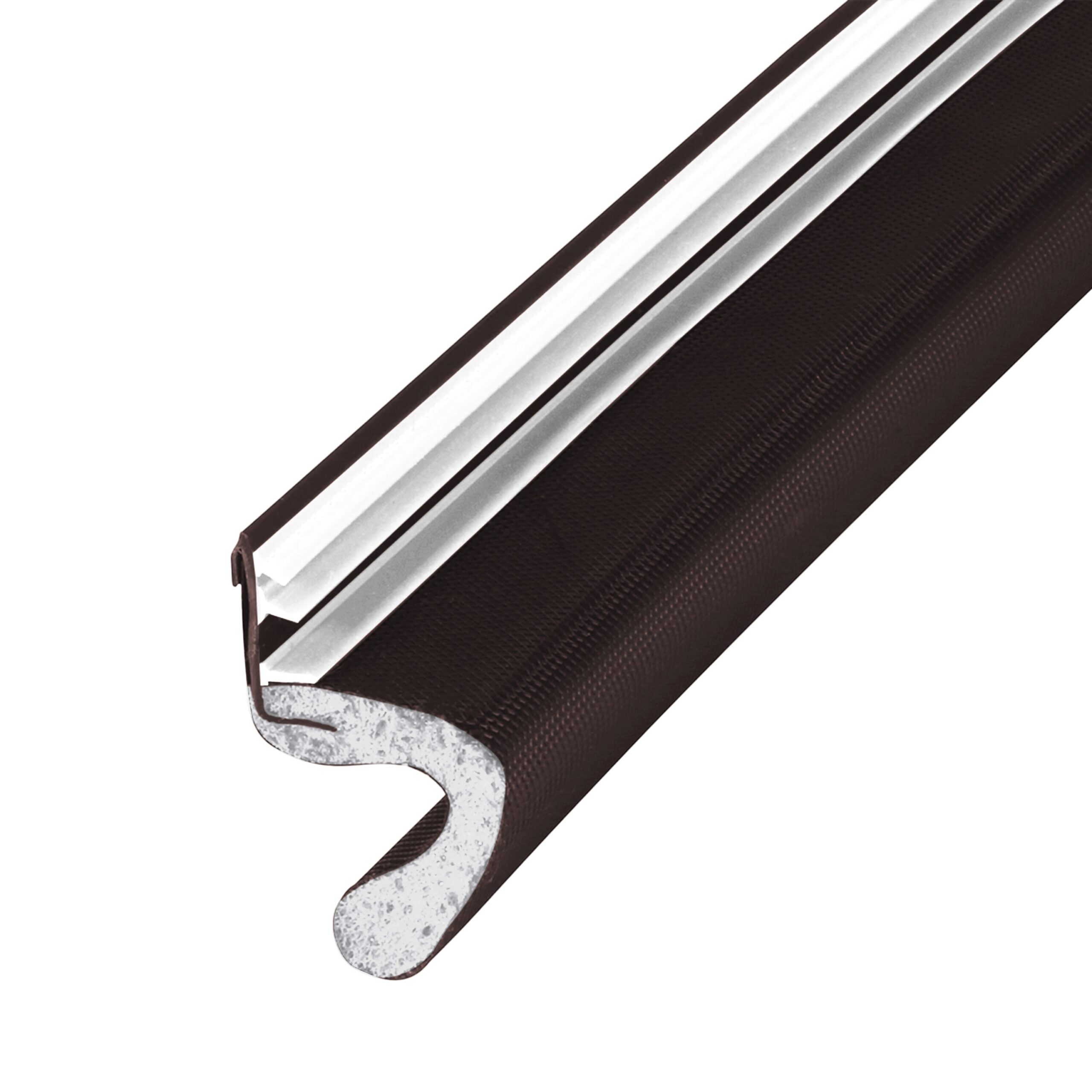

Vinyl cladding, typically composed of polyvinyl chloride (PVC), offers excellent resistance to UV degradation, moisture, and surface abrasion. However, the performance of the final product is not determined by the cladding alone but by the synergy between the vinyl layer and the underlying rubber substrate. Common off-the-shelf solutions often utilize generic EPDM or low-grade sponge rubber cores paired with plasticized PVC that lacks long-term stability. These combinations may perform acceptably during initial installation but degrade rapidly under cyclic compression, thermal fluctuation, or prolonged exposure to ozone and hydrocarbons.

A critical failure mode in substandard weatherstrips is delamination—the separation of the vinyl skin from the rubber core. This occurs due to poor interfacial adhesion, often a result of insufficient surface treatment or incompatible polymer formulations. Additionally, many commercial-grade vinyl compounds utilize high levels of plasticizers to enhance flexibility. Over time, these additives migrate out of the matrix, leading to embrittlement, loss of sealing force, and surface cracking.

At Suzhou Baoshida Trading Co., Ltd., we approach vinyl clad weatherstrip design through a systems-based engineering methodology. Our material selection process evaluates the entire operational profile: temperature range, compression set requirements, exposure to chemicals or UV radiation, and expected service life. For high-performance applications, we specify semi-rigid, low-plasticizer PVC formulations co-extruded with high-density, peroxide-cured EPDM rubber. This ensures dimensional stability, superior adhesion, and sustained resilience under repeated deformation.

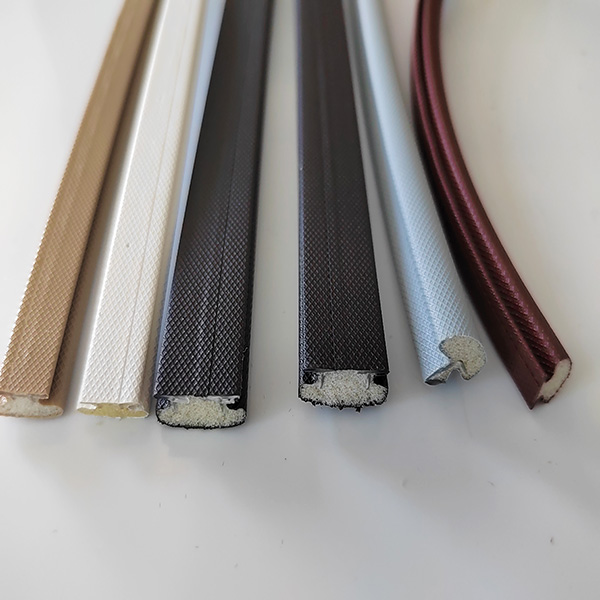

Customization extends beyond base polymers. Additives such as UV stabilizers, anti-oxidants, and flame retardants are precisely dosed based on end-use conditions. Surface textures and gloss levels are also tailored—not merely for aesthetics, but to optimize friction characteristics and water shedding.

The table below outlines typical specifications for engineered versus standard vinyl clad weatherstrip:

| Property | Engineered Solution (Baoshida) | Standard Off-the-Shelf Product |

|---|---|---|

| Base Rubber | Peroxide-cured EPDM, high density | SBR/EPDM blend, low crosslink density |

| Vinyl Type | Low-plasticizer, UV-stabilized PVC | General-purpose plasticized PVC |

| Adhesion Strength (peel test) | ≥ 8 N/cm | 3–5 N/cm |

| Compression Set (22h, 70°C) | ≤ 20% | 35–50% |

| Operating Temperature Range | -40°C to +120°C | -20°C to +80°C |

| UV Resistance (QUV, 1000h) | No cracking, <10% gloss loss | Chalking, >50% gloss loss |

| Service Life (simulated) | 15+ years | 5–7 years |

Material selection is not a commodity decision—it is a precision engineering imperative. Off-the-shelf weatherstrips sacrifice longevity and reliability for upfront cost savings. In contrast, engineered solutions from Suzhou Baoshida ensure sustained performance, reduced maintenance cycles, and compliance with OEM specifications. For mission-critical sealing applications, the right materials are not optional—they are foundational.

Material Specifications

Material Specifications for Vinyl Clad Weatherstrip

Vinyl clad weatherstrip performance hinges critically on the elastomeric core compound, which must deliver sealing integrity under dynamic compression while resisting environmental degradation. The vinyl cladding provides UV stability, aesthetic finish, and surface lubricity, but the underlying rubber formulation determines functional lifespan. Suzhou Baoshida Trading Co., Ltd. prioritizes precise material selection based on operational parameters, with Viton (FKM), Nitrile (NBR), and Silicone (VMQ) representing optimal solutions for distinct industrial challenges. Each compound exhibits unique chemical resistance, thermal stability, and mechanical behavior that must align with end-use requirements.

Viton fluoroelastomers excel in extreme environments demanding resistance to automotive fluids, jet fuels, and continuous high temperatures. Their saturated backbone structure provides exceptional stability against oxygen, ozone, and aggressive chemicals, making them indispensable for under-hood automotive seals and aerospace applications. Viton maintains sealing force retention above 200°C but requires specialized compounding for low-temperature flexibility. Nitrile rubber offers the best cost-performance balance for general-purpose weatherstripping exposed to petroleum derivatives. Its acrylonitrile content directly correlates with oil resistance, with medium-high ACN grades (40-45%) providing robust sealing against engine oils, greases, and aliphatic hydrocarbons. NBR compounds achieve optimal compression set resistance through controlled polymerization and filler systems, though performance degrades above 120°C. Silicone rubber delivers unmatched thermal range and electrical insulation properties, functioning reliably from -60°C to 230°C. Its inorganic backbone ensures minimal property drift across temperature extremes, ideal for architectural glazing and electronic enclosures. However, silicone exhibits lower tensile strength and abrasion resistance than hydrocarbon rubbers, necessitating careful design for high-stress applications.

The following comparative analysis details critical specifications per ASTM D2000 classification standards. All compounds are formulated for extrusion compatibility with rigid vinyl cladding via co-extrusion processes, ensuring molecular adhesion at the interface.

| Material | Temperature Range (°C) | Key Resistance Properties | Hardness Range (Shore A) | Typical Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +250 | Extreme oil/fuel, ozone, oxidation | 60-90 | Engine compartment seals, fuel system gaskets, aerospace |

| Nitrile (NBR) | -40 to +120 | Petroleum oils, aliphatic hydrocarbons, abrasion | 50-95 | Automotive door/window seals, hydraulic seals, general industrial |

| Silicone (VMQ) | -60 to +230 | Extreme temperature cycling, ozone, UV, dielectric | 30-80 | Architectural glazing, medical device seals, electronic housings |

Material selection requires rigorous evaluation of fluid exposure, thermal cycling magnitude, and mechanical stress profiles. Suzhou Baoshida Trading Co., Ltd. employs advanced rheometry and accelerated aging protocols to validate compound performance against OEM-specific test matrices. Compression set values below 25% after 70 hours at 100°C are mandatory for NBR and Viton formulations in automotive weatherstrip, while silicone compounds must demonstrate Shore A stability within ±5 points across 10,000 thermal cycles. These specifications ensure long-term sealing integrity in demanding industrial environments.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Vinyl Clad Weatherstrip Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the domain of vinyl clad weatherstrip manufacturing. With a dedicated team comprising five specialized mould engineers and two advanced formula engineers, we maintain full in-house control over product development, material science, and production optimization. This integrated technical structure enables us to deliver high-performance, application-specific weatherstrip profiles that meet stringent OEM requirements across automotive, construction, and transportation sectors.

Our mould engineers bring over 70 combined years of experience in precision die design, extrusion tooling, and profile geometry optimization. Each engineer is proficient in CAD/CAM software, including SolidWorks and AutoCAD, ensuring accurate 3D modeling and tolerance analysis down to ±0.1 mm. This precision translates into consistent extrusion performance, minimal scrap rates, and seamless integration with downstream assembly processes at our clients’ facilities. We specialize in complex co-extruded profiles where vinyl cladding must bond perfectly with EPDM or TPE sealing substrates, requiring exact flow dynamics and thermal balance in the die design.

Complementing our tooling expertise, our two formula engineers focus exclusively on rubber compound development and material compatibility. They operate a fully equipped polymer laboratory where they formulate and test EPDM, silicone, and specialty TPE compounds tailored to specific environmental resistance needs—such as UV stability, ozone resistance, low-temperature flexibility (down to -50°C), and compression set performance. Each formulation is rigorously validated through accelerated aging, Shore A hardness testing, and adhesion strength analysis between the rubber core and vinyl cladding layer. This ensures long-term durability and consistent sealing performance under real-world operating conditions.

Our OEM capabilities are built on a foundation of technical collaboration. We engage with client engineering teams early in the design phase, offering DFM (Design for Manufacturability) feedback and prototype validation services. From concept to mass production, we manage tooling, compound selection, process validation (including CPK analysis), and PPAP documentation, ensuring full compliance with IATF 16949 standards. Our facility supports low-volume pilot runs and high-volume production, with annual capacity exceeding 1,200 tons of extruded weatherstrip profiles.

The following table outlines key technical specifications achievable with our current engineering and manufacturing platform:

| Parameter | Standard Capability | High-Performance Option |

|---|---|---|

| Profile Tolerance | ±0.3 mm | ±0.1 mm (laser-guided extrusion) |

| Durometer Range (Shore A) | 40–90 | 30–95 (custom formulations) |

| Operating Temperature Range | -40°C to +120°C | -50°C to +150°C (silicone blend) |

| Adhesion Strength (Peel Test) | ≥8 N/cm | ≥12 N/cm (primed bonding) |

| UV/Ozone Resistance | ASTM D1149 Pass (4000h) | ASTM D1149 Pass (6000h) |

| Production Lead Time (Tooling) | 25–35 days | 18–22 days (express program) |

Through the synergy of advanced tooling, scientific material engineering, and OEM-aligned development protocols, Suzhou Baoshida delivers vinyl clad weatherstrip solutions that combine reliability, precision, and long-term performance.

Customization Process

Suzhou Baoshida Trading Co., Ltd. Technical Guide: Vinyl Clad Weatherstrip Customization Process

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered vinyl clad weatherstrip solutions through a rigorously defined customization pathway. This process ensures optimal performance, durability, and compatibility for demanding OEM applications within the automotive, construction, and appliance sectors. Our methodology transitions seamlessly from initial concept to high-volume production, prioritizing technical accuracy and material science expertise at every stage.

The process commences with Drawing Analysis. Our engineering team conducts a comprehensive review of the client’s CAD drawings and technical specifications. This involves rigorous dimensional verification, tolerance assessment against ISO 2768-mK standards, and critical evaluation of the vinyl-rubber interface geometry. We identify potential manufacturability constraints early, focusing on extrusion die feasibility, co-extrusion bonding zones, and secondary operation requirements. Material compatibility with the intended operating environment (e.g., temperature range, fluid exposure, UV resistance) is cross-referenced against our extensive database during this phase.

Subsequent Formulation leverages Suzhou Baoshida’s proprietary rubber compounding capabilities. Based on the environmental and mechanical requirements derived from the drawing analysis, our rubber formula engineers develop a tailored elastomer compound. This involves precise selection of base polymers (EPDM, TPE, or specialty blends), reinforcing fillers, plasticizers, and critical additives for ozone/weathering resistance. Simultaneously, the vinyl (PVC or TPO) formulation is optimized for adhesion, flexibility, and color stability. Key performance targets, including compression set, low-temperature flexibility, and adhesion strength between layers, are embedded into the compound design. Formulation validation occurs through small-batch laboratory mixing and preliminary physical testing.

Prototyping utilizes client-approved formulations for initial production runs on pilot-scale co-extrusion lines. This phase produces functional samples for dimensional conformance checks against the original drawing using CMM equipment and critical performance validation. Samples undergo accelerated aging tests, dynamic compression testing per ASTM D395, and adhesion peel strength evaluation (ASTM D429 Method B). Client feedback on prototype fit, function, and aesthetics triggers a closed-loop feedback process; minor formulation or process parameter adjustments are implemented swiftly before final sign-off.

Upon successful prototype validation, Mass Production initiates under stringent Suzhou Baoshida quality management protocols (IATF 16949 certified). Full-scale co-extrusion lines operate with real-time monitoring of critical parameters: melt temperatures, line speeds, cooling profiles, and dimensional tolerances via laser gauging. In-process quality checks occur at defined intervals, including continuous durometer measurement and visual inspection for surface defects. Final inspection adheres to AQL 1.0 standards, with comprehensive batch testing reports provided. Our integrated supply chain ensures consistent raw material sourcing and on-time delivery to OEM assembly lines.

Critical performance specifications for standard vinyl clad weatherstrip formulations are summarized below. All values are achievable targets subject to specific client requirements and environmental conditions.

| Specification Parameter | Typical Range (Rubber Core) | Test Standard | Typical Range (Vinyl Clad) | Test Standard |

|---|---|---|---|---|

| Hardness (Shore A) | 55 – 85 | ASTM D2240 | 70 – 95 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 7.0 | ASTM D412 | ≥ 12.0 | ASTM D638 |

| Elongation at Break (%) | ≥ 250 | ASTM D412 | ≥ 200 | ASTM D638 |

| Compression Set (70°C, 22h) | ≤ 35% | ASTM D395 B | N/A | – |

| Adhesion Peel Strength (N/mm) | ≥ 3.0 | ASTM D429 B | ≥ 3.0 | ASTM D429 B |

Note: Ranges represent common industry targets; Suzhou Baoshida formulates to exact client specifications beyond standard parameters.

Contact Engineering Team

For manufacturers and OEMs seeking high-performance vinyl clad weatherstrip solutions, Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber components tailored to industrial and automotive sealing applications. Our expertise in rubber compounding, extrusion, and material integration ensures that every vinyl clad weatherstrip meets stringent durability, compression set resistance, and environmental sealing requirements. As a trusted partner in the industrial rubber supply chain, we combine advanced manufacturing capabilities with rigorous quality control to support clients across automotive, construction, and transportation sectors.

Vinyl clad weatherstrip is a critical sealing component designed to provide weather resistance, noise reduction, and energy efficiency in dynamic and static joints. Our formulations utilize EPDM rubber for superior ozone, UV, and thermal resistance, bonded seamlessly with flexible PVC (vinyl) cladding to enhance abrasion resistance and aesthetic finish. This dual-material construction ensures long-term performance under extreme temperature cycles, moisture exposure, and mechanical stress. Whether for door perimeters, window channels, or panel interfaces, our weatherstrip profiles are engineered for optimal sealing force, compression recovery, and dimensional stability.

We offer full customization of profile geometry, durometer (40–80 Shore A), and bonding strength between rubber and vinyl layers. Our production lines support co-extrusion, splicing, and 3D forming to meet complex OEM design specifications. In addition to standard black EPDM with gray or black vinyl cladding, we provide color-matched and low-temperature formulations down to -50°C for specialized applications.

Technical specifications for our standard vinyl clad weatherstrip are detailed below:

| Property | Specification |

|---|---|

| Base Material | EPDM Rubber |

| Cladding Material | Flexible PVC (Vinyl) |

| Hardness (Shore A) | 40–80 ±5 |

| Temperature Range | -50°C to +135°C |

| Tensile Strength | ≥8.0 MPa |

| Elongation at Break | ≥250% |

| Compression Set (22h @ 100°C) | ≤30% |

| Bonding Strength (Rubber-Vinyl) | ≥80 N/cm |

| Color Options | Black, Gray, Custom (RAL/Pantone) |

| Standard Compliance | RoHS, REACH, ISO 9001:2015 |

All products undergo in-line dimensional inspection, adhesion testing, and environmental aging validation to ensure compliance with international standards and OEM technical dossiers. Suzhou Baoshida maintains a rapid prototyping workflow, enabling sample delivery within 10–15 business days upon receipt of technical drawings or physical templates.

For technical collaboration, material data sheets, or custom quoting, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Direct inquiries to [email protected]. Include application details, performance requirements, and volume forecasts to expedite engineering review. We support English and Mandarin correspondence and offer factory audits, virtual production walkthroughs, and logistics coordination for global supply chain integration. Partner with us to elevate your sealing performance with scientifically optimized vinyl clad weatherstrip solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).