Technical Contents

Engineering Guide: Vinyl Tpe

Engineering Insight: Vinyl TPE Material Selection Imperative

Material selection for vinyl thermoplastic elastomers (TPE), specifically thermoplastic vulcanizates (TPV) with polyvinyl chloride (PVC) compatibility, is a non-negotiable engineering parameter in industrial applications. Generic off-the-shelf vinyl TPE compounds frequently fail to meet the rigorous demands of automotive seals, fluid handling systems, or electrical insulation due to unaddressed application-specific stressors. These standard grades prioritize cost and processability over performance resilience, leading to premature degradation under thermal cycling, chemical exposure, or dynamic mechanical loads. The consequence is not merely part replacement but systemic downtime, warranty liabilities, and compromised safety margins.

Vinyl TPE’s core value lies in its dual-phase morphology: a dynamically vulcanized rubber phase (typically EPDM) dispersed within a thermoplastic matrix (PP/PVC blend). This structure delivers elastomeric recovery with thermoplastic processability. However, off-the-shelf formulations often utilize suboptimal rubber-to-plastic ratios, insufficient oil saturation, or inadequate crosslink density. For instance, a standard grade may exhibit acceptable initial compression set but catastrophically harden after 500 hours at 125°C due to oil migration or polymer phase separation. Similarly, inadequate filler dispersion in commodity grades accelerates crack propagation under repeated flexing, a critical flaw in vibration-damping components.

The failure root cause is invariably misalignment between bulk material properties and localized operational physics. A gasket exposed to biodiesel requires precise resistance to ester-based swelling, yet generic vinyl TPE lacks tailored antioxidant packages. An automotive interior trim component must maintain low-temperature flexibility down to -40°C while resisting plasticizer leaching from adjacent PVC—demands unmet by standardized Shore 70A compounds. These gaps manifest as seal leakage, electrical tracking, or catastrophic brittle fracture, directly traceable to unoptimized molecular architecture.

Suzhou Baoshida Trading Co., Ltd. addresses this through application-driven formulation engineering. We correlate OEM use-case data—temperature profiles, fluid chemistries, stress cycles—with polymer science to adjust critical variables:

Rubber phase crosslink density for compression set retention

Plasticizer type and concentration for low-temperature performance

Filler surface treatment to inhibit moisture-induced degradation

Stabilizer systems calibrated to specific chemical exposures

The following table illustrates why standard grades fail and how engineered solutions mitigate risk:

| Critical Property | Standard Vinyl TPE Grade | Baoshida Engineered Grade | Failure Consequence (Standard) |

|---|---|---|---|

| Compression Set (22h/125°C) | 45-55% | ≤25% | Seal leakage after thermal aging |

| Tensile Strength (MPa) | 8-10 | 12-15 | Fracture under assembly stress |

| Fluid Resistance (Biodiesel) | Swell >25% | Swell <8% | Dimensional instability, seal failure |

| Low-Temp Flexibility (°C) | -25 | -45 | Brittle cracking in cold climates |

| Abrasion Loss (mg) | 120-150 | 60-80 | Premature wear in dynamic seals |

Material selection is not a procurement decision but an engineering control point. Off-the-shelf vinyl TPE sacrifices longevity for initial cost savings, ultimately inflating total cost of ownership. Precision formulation—anchored in application physics—ensures functional integrity across the product lifecycle. Partnering with a specialist OEM like Suzhou Baoshida transforms material from a commodity risk into a reliability advantage.

Material Specifications

Vinyl TPE, or thermoplastic elastomer with vinyl-based polymer segments, represents a class of advanced elastomeric materials engineered for high-performance industrial applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering precision-formulated rubber compounds tailored to meet the rigorous demands of automotive, aerospace, fluid handling, and industrial sealing systems. Our core material offerings—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are optimized for compatibility, durability, and thermal stability, ensuring reliable performance under extreme operational conditions.

Viton fluorocarbon rubber is renowned for its exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbon-based fluids. With continuous service capabilities up to 230°C and intermittent exposure tolerance beyond 260°C, Viton is the preferred choice for applications involving fuel systems, engine seals, and chemical processing equipment. Its low gas permeability and outstanding aging characteristics further enhance long-term reliability in critical environments.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), offers excellent mechanical strength and resistance to oils, fuels, and aliphatic hydrocarbons. It is widely used in hydraulic systems, oil seals, and gaskets where cost-effective performance in moderate temperature ranges (-30°C to 100°C, extendable to 125°C with formulation adjustments) is required. Nitrile’s abrasion resistance and compressive strength make it ideal for dynamic sealing applications subject to mechanical stress.

Silicone rubber (VMQ) provides unmatched flexibility across extreme temperatures, functioning reliably from -60°C to 200°C. While it exhibits lower tensile strength compared to Viton or Nitrile, its superior resistance to ozone, UV radiation, and weathering makes it ideal for outdoor, medical, and high-purity applications. Additionally, silicone demonstrates excellent electrical insulation properties, supporting use in electrical enclosures and high-voltage components.

Each material is available in multiple hardness grades (Shore A 40–90) and can be customized with additives to enhance flame resistance, wear performance, or fluid compatibility. Our formulation team at Suzhou Baoshida ensures strict adherence to ASTM D2000 and ISO 1817 standards, with full traceability and batch consistency.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 125 | -60 to 200 |

| Tensile Strength (MPa) | 12–20 | 15–25 | 6–10 |

| Hardness Range (Shore A) | 50–90 | 40–90 | 40–80 |

| Fluid Resistance (Oil/Fuel) | Excellent | Very Good | Poor |

| Chemical Resistance | Excellent | Moderate | Good (limited acids) |

| Compression Set Resistance | Excellent | Good | Very Good |

| Electrical Insulation | Good | Fair | Excellent |

| UV/Ozone Resistance | Excellent | Moderate | Excellent |

Selection of the appropriate elastomer requires a comprehensive assessment of operational parameters including media exposure, temperature cycling, mechanical load, and regulatory compliance. Our engineering team supports OEMs with material validation, prototyping, and performance testing to ensure optimal integration into end-use systems.

Manufacturing Capabilities

Engineering Capabilities for Precision Vinyl TPE Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers advanced vinyl thermoplastic elastomer (TPE) solutions through integrated engineering expertise and OEM-centric processes. Our dedicated team of five mold engineers and two specialized formula engineers operates as a unified technical unit, ensuring seamless translation from material science to production-ready components. This structure eliminates siloed workflows, enabling rapid iteration and precision tuning for complex industrial applications where chemical resistance, clarity, and flexibility are non-negotiable.

Our formula engineers possess deep mastery of vinyl TPE polymer architecture, including styrene-ethylene-butylene-styrene (SEBS) and styrene-isoprene-styrene (SIS) base systems. They optimize formulations by adjusting polymer ratios, plasticizers, and functional additives to achieve exact Shore A hardness, tensile strength, and low-temperature flexibility per client specifications. Concurrently, mold engineers leverage 3D simulation software to preempt flow imbalances, weld lines, and shrinkage in multi-cavity tooling. This dual-engineering approach ensures first-article success rates exceed 92% across automotive seals, medical device housings, and consumer electronics interfaces.

OEM partnerships benefit from our closed-loop development protocol. We initiate with material compatibility testing against client-specified fluids or environmental conditions, followed by Design for Manufacturing (DFM) reviews that address gate placement, cooling efficiency, and ejection dynamics. Prototyping occurs within 15 business days using in-house 3D-printed molds for validation, reducing time-to-market by 30% versus conventional suppliers. Crucially, our formula engineers remain engaged through production ramp-up, monitoring lot-to-lot consistency via real-time rheology data and adjusting processing parameters to maintain ±0.5 Shore A tolerance.

Key vinyl TPE performance metrics achievable through our engineered solutions include:

| Property | Typical Range | Test Standard | Industrial Relevance |

|---|---|---|---|

| Shore A Hardness | 35–95 | ASTM D2240 | Sealing force optimization |

| Tensile Strength | 5–18 MPa | ISO 37 | Durability in dynamic flexing |

| Elongation at Break | 300–800% | ISO 37 | Impact resistance |

| Heat Resistance | -50°C to +100°C | ASTM D573 | Automotive under-hood stability |

| Specific Gravity | 0.95–1.15 | ASTM D792 | Weight-sensitive assemblies |

| Oil Resistance (IRMOG) | Class 1–2 | ISO 1817 | Fuel/oil exposure in machinery |

We prioritize traceability through batch-specific certificates of conformance (CoC) documenting raw material lot numbers, cure profiles, and physical test results. This granular data empowers OEMs to meet stringent regulatory requirements in medical (ISO 10993) and automotive (TS 16949) sectors. Suzhou Baoshida’s engineering model transforms vinyl TPE from a commodity material into a precision-engineered asset, where your specifications become our blueprint for zero-defect manufacturing. Partner with us to convert material challenges into competitive advantage through science-driven execution.

Customization Process

Vinyl TPE Customization Process: From Design to Mass Production

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered for precision, durability, and performance. When it comes to customizing vinyl thermoplastic elastomer (TPE) compounds, we follow a rigorous four-phase process that ensures material compatibility, dimensional accuracy, and compliance with OEM specifications. This structured approach bridges design intent with scalable manufacturing.

The process begins with Drawing Analysis, where our technical team evaluates client-provided CAD models, 2D technical drawings, and performance requirements. We assess critical parameters such as part geometry, wall thickness, tolerance bands, and intended operating environment (temperature range, chemical exposure, mechanical stress). This phase ensures manufacturability and identifies potential risks in molding or material behavior early in the development cycle.

Following drawing validation, our formulation engineers initiate the Material Development stage. Vinyl TPE is a hybrid polymer system combining the processability of thermoplastics with the elasticity of rubber. Our team tailors the compound by adjusting the vinyl-to-rubber ratio, selecting appropriate plasticizers, reinforcing fillers, and stabilizers to meet specific Shore hardness, tensile strength, and weather resistance targets. Additives for UV resistance, flame retardancy, or antimicrobial properties are incorporated as needed. Each formulation is documented and archived for full traceability.

Once the compound is finalized, we proceed to Prototyping. Using injection molding or extrusion techniques on pilot-scale equipment, we produce sample parts for functional testing. These prototypes undergo rigorous evaluation, including dimensional inspection, compression set analysis, thermal cycling, and adhesion testing if overmolding is involved. Feedback from this stage informs minor adjustments in formulation or processing parameters, ensuring optimal performance before scale-up.

Upon client approval of the prototype, we transition to Mass Production. Our manufacturing partners utilize high-precision molding systems with real-time process monitoring to maintain consistency across batches. Every production run is accompanied by a full material certification, including hardness, density, and mechanical property reports. We support both Just-in-Time (JIT) delivery and bulk shipping, tailored to the client’s supply chain model.

Throughout the process, Suzhou Baoshida maintains strict quality control in accordance with ISO 9001 standards, ensuring that every vinyl TPE component meets the highest industrial benchmarks.

Typical Vinyl TPE Technical Specifications

| Property | Test Method | Typical Value Range |

|---|---|---|

| Shore Hardness (A) | ASTM D2240 | 50–95 |

| Tensile Strength | ASTM D412 | 8–18 MPa |

| Elongation at Break | ASTM D412 | 300–700% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤30% |

| Operating Temperature Range | — | -40°C to +120°C |

| Specific Gravity | ASTM D792 | 0.98–1.25 |

| Molding Shrinkage | ASTM D955 | 1.0–1.8% |

This systematic customization workflow enables Suzhou Baoshida to deliver high-performance vinyl TPE solutions optimized for automotive seals, industrial gaskets, consumer appliance components, and medical device housings.

Contact Engineering Team

Technical Partnership for Vinyl TPE Manufacturing Excellence

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing scalability. As your dedicated Rubber Formula Engineer and OEM Manager, we recognize that vinyl thermoplastic elastomer (TPE) applications demand uncompromising precision in material behavior under dynamic operational conditions. Our engineering team specializes in formulating vinyl TPE compounds that balance Shore hardness consistency, tensile resilience, and chemical resistance for mission-critical components across automotive sealing, medical device housings, and consumer electronics. Generic material datasheets cannot address the nuanced interplay between processing parameters, end-use environmental stressors, and lifecycle performance. We provide OEMs with application-specific compound validation, ensuring your production lines achieve zero-defect throughput while meeting ISO 10993 or UL 94 flammability benchmarks.

The table below summarizes core performance metrics achievable with our proprietary vinyl TPE formulations. These values represent baseline capabilities; actual specifications are dynamically optimized during our joint development phase to align with your dimensional tolerances, regulatory framework, and cost targets.

| Property | Test Standard | Typical Range | Industrial Significance |

|---|---|---|---|

| Shore Hardness (A) | ASTM D2240 | 40–90 | Sealing force consistency in dynamic joints |

| Tensile Strength (MPa) | ASTM D412 | 8.0–15.0 | Resistance to mechanical fatigue |

| Elongation at Break (%) | ASTM D412 | 300–800 | Flexural durability in thin-wall parts |

| Oil Resistance (IRM 903) | ASTM D471 | ΔVolume: +5% to +25% | Long-term stability in lubricant exposure |

| Heat Aging (100°C/72h) | ASTM D573 | ΔTensile: ≤ -20% | Predictable performance in thermal cycling |

Initiating collaboration with Suzhou Baoshida eliminates the guesswork in vinyl TPE adoption. Our technical service engineers conduct on-site processing audits to diagnose extrusion or injection molding anomalies—such as melt fracture at high screw speeds or post-molding shrinkage—that degrade part functionality. We then recalibrate filler dispersion, plasticizer compatibility, and thermal stabilizer packages within 72 hours of sample receipt. This rapid iteration cycle reduces your time-to-market by up to 37% compared to standard supplier workflows. Furthermore, our Suzhou-based pilot production facility replicates your exact tooling parameters, generating validation batches for accelerated life testing under simulated field conditions.

For OEMs requiring seamless scale-up from prototype to high-volume manufacturing, our vertically integrated supply chain guarantees uninterrupted material continuity. We maintain strategic reserves of critical base polymers and additives across three bonded warehouses in Jiangsu Province, mitigating global logistics volatility. All compounds undergo rigorous QC protocols per IATF 16949, with full traceability from raw material lot to finished pellet.

Contact Mr. Boyce, OEM Director, to commence a technical consultation. Detail your application’s environmental stressors, production throughput requirements, and compliance mandates. Mr. Boyce will coordinate our formulation chemists and process engineers to deliver a customized vinyl TPE solution within five business days. Direct all technical inquiries and sample requests to [email protected]. Specify your target annual volume and existing pain points in current material performance. Suzhou Baoshida commits to engineering not just a compound, but a validated manufacturing advantage.

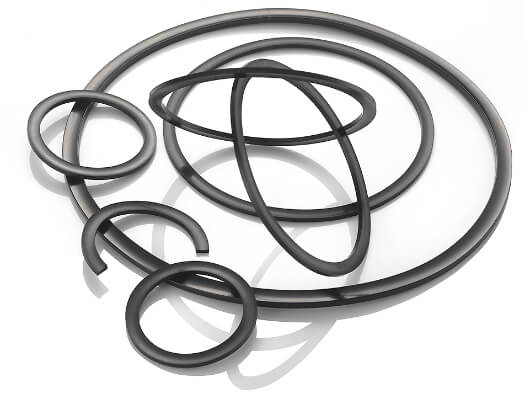

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).