Technical Contents

Engineering Guide: Water Jet Foam Cutting

Engineering Insight: Material Selection in Water Jet Foam Cutting

Water jet cutting of elastomeric foams presents unique engineering challenges often misattributed to machine performance. The critical failure point lies not in the cutting system but in inappropriate material selection. Off-the-shelf foam solutions frequently exhibit catastrophic delamination, edge fraying, or dimensional instability during high-pressure water jet processing due to unaddressed viscoelastic properties. Generic foams lack the tailored cellular architecture and polymer matrix resilience required to withstand transient hydrodynamic forces exceeding 3,000 bar. When subjected to supersonic water abrasives, non-engineered foams experience rapid cell wall collapse at cut interfaces, generating micro-tears that propagate into macroscopic defects. This manifests as inconsistent kerf widths, surface pitting, and post-cut dimensional drift—issues erroneously blamed on nozzle calibration or pump pressure.

The root cause is the absence of material-specific formulation protocols. Industrial water jet cutting demands foams with precise density gradients, closed-cell dominance, and crosslink density optimized for instantaneous energy dissipation. Off-the-shelf variants typically prioritize cost-driven physical properties like compression set or tensile strength, ignoring dynamic response to impulsive loading. For instance, standard polyurethane foams with open-cell content >15% absorb water during cutting, causing swelling-induced distortion before the cut completes. Similarly, inconsistent cell size distribution creates non-uniform resistance to the jet stream, resulting in wavy edges at traverse speeds above 200 mm/s. These failures escalate scrap rates by 30–45% in high-tolerance applications like automotive sealing or medical device components.

Suzhou Baoshida addresses this through OEM-formulated elastomer systems where material science precedes machining. Our foams integrate controlled cell nucleation agents and dynamic crosslinkers that maintain structural integrity under hydrodynamic shear. The table below details critical parameters distinguishing engineered solutions from generic alternatives:

| Parameter | OEM-Engineered Foam | Off-the-Shelf Foam | Failure Consequence in Water Jet Cutting |

|---|---|---|---|

| Density Range (kg/m³) | 25–45 (±2%) | 15–60 (±15%) | Inconsistent jet penetration depth |

| Closed-Cell Content | ≥92% | 65–85% | Water ingress, edge delamination |

| Cell Size Uniformity | ±50 µm | ±200 µm | Kerf waviness at >150 mm/s traverse |

| Dynamic Modulus @ 10 Hz | 1.8–2.2 MPa | 0.7–3.5 MPa | Vibration-induced microfractures |

Material selection must align with the water jet’s operational envelope. Foams designed for die-cutting or molding cannot be retrofitted for water jet processes without reformulation. At Baoshida, we co-engineer foam chemistry with cutting parameters—adjusting polymer backbone flexibility to match jet pressure decay profiles and embedding sacrificial additives that stabilize cell walls during abrasive impact. This eliminates the trial-and-error approach plaguing generic material adoption. For mission-critical applications requiring ±0.1 mm tolerances, material is not a consumable variable but the foundational engineering control point. Partnering with a rubber specialist during foam development—not procurement—ensures cut quality, yield, and functional performance meet OEM specifications. Precision begins with the polymer, not the nozzle.

Material Specifications

Water jet cutting technology offers a high-precision, cold-cutting solution ideal for industrial rubber components where thermal distortion, mechanical stress, or dimensional inaccuracies are unacceptable. At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering engineered rubber solutions tailored for demanding applications across automotive, aerospace, medical, and industrial sectors. Our expertise in water jet foam cutting ensures clean, burr-free edges with tight tolerances, particularly critical when processing elastomeric materials such as Viton, Nitrile, and Silicone. These materials exhibit distinct chemical, thermal, and mechanical behaviors, necessitating a thorough understanding of their properties to optimize cutting parameters and end-use performance.

Viton (FKM) is a fluorocarbon-based synthetic rubber renowned for its exceptional resistance to high temperatures, aggressive chemicals, and oils. It maintains structural integrity in continuous service up to 200°C and can withstand short-term exposure to temperatures as high as 250°C. This makes Viton an ideal choice for sealing applications in extreme environments, such as engine compartments or chemical processing equipment. When processed via water jet cutting, Viton demonstrates excellent dimensional stability, allowing for intricate profiles without deformation.

Nitrile rubber (NBR) is a copolymer of acrylonitrile and butadiene, offering superior resistance to aliphatic hydrocarbons, oils, and fuels. Its performance under compression and abrasion makes it a preferred material for gaskets, seals, and hoses in automotive and hydraulic systems. Nitrile is typically serviceable from -30°C to 100°C, with formulations available for enhanced low-temperature flexibility. Water jet cutting of Nitrile ensures precise edge definition without the risk of melt or compression damage common in die-cutting methods.

Silicone rubber (VMQ) provides outstanding thermal stability across a broad range, from -60°C to 200°C, along with excellent electrical insulation and biocompatibility. It is widely used in medical devices, food-grade applications, and electronic insulation. Silicone’s low surface energy and high elasticity require precise water pressure calibration during jet cutting to prevent edge feathering or deformation. Our optimized cutting protocols ensure clean, consistent results even with thin or complex silicone profiles.

The following table summarizes key material specifications relevant to water jet foam cutting processes:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 200–400 | 200–500 | 300–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Good to excellent (oils, fuels) | Poor (oils, fuels); excellent (water, ozone) |

| Compression Set Resistance | Excellent | Good | Moderate to good |

| Biocompatibility | Limited | No | Yes (medical grade available) |

Selecting the appropriate elastomer depends on operational environment, regulatory requirements, and mechanical demands. Our technical team at Suzhou Baoshida ensures material and process alignment to deliver precision-cut rubber components optimized for performance and reliability.

Manufacturing Capabilities

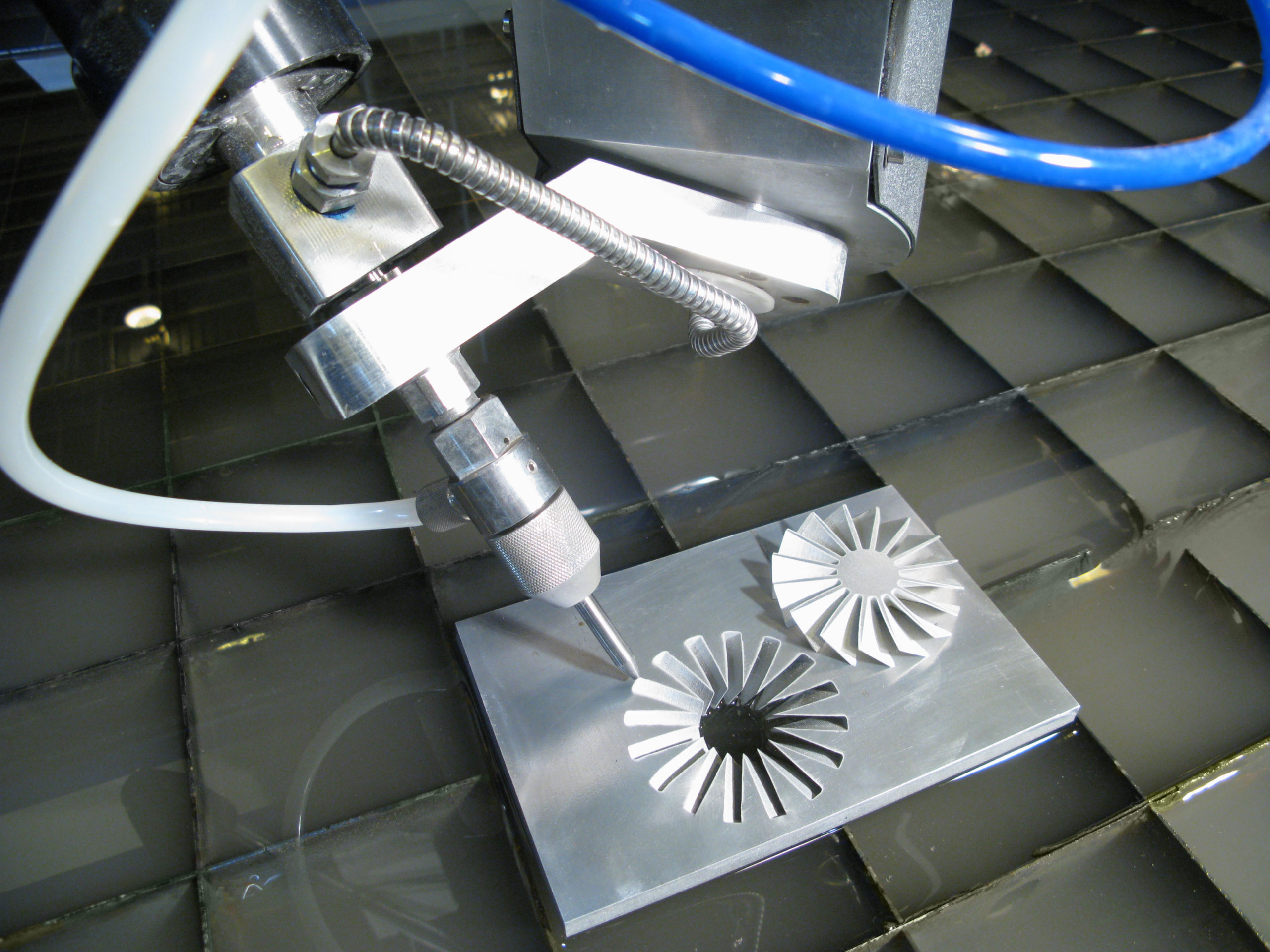

Engineering Capability: Precision Water Jet Foam Cutting for Industrial Rubber Applications

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions through integrated material science and advanced manufacturing expertise. Our dedicated team comprises five certified Mold Engineers and two specialized Rubber Formula Engineers, ensuring end-to-end control from compound development to final part production. This synergy enables precise adaptation of rubber formulations to water jet cutting parameters, optimizing edge quality and dimensional stability for demanding industrial applications.

Our Formula Engineers develop custom elastomer compounds with tailored hardness (40–90 Shore A), density, and cell structure to minimize fraying and thermal distortion during high-pressure water jet processing. Concurrently, Mold Engineers design tooling and nesting layouts that maximize material yield while maintaining critical tolerances. This dual-engineering approach eliminates inter-departmental delays, accelerating prototyping by 30% compared to industry benchmarks. All processes adhere to ISO 9001:2015 standards, with full traceability from raw material certificates to cutting parameter logs.

As an OEM manufacturing partner, we implement closed-loop feedback systems where cutting performance data directly informs compound refinement. For instance, edge integrity issues in closed-cell neoprene batches trigger immediate formulation adjustments to enhance cohesion under 60,000 PSI water streams. Our facility supports low-volume prototyping (1–50 units) and high-volume production (50,000+ units) with identical process validation protocols, ensuring seamless scale-up. Clients receive comprehensive PPAP documentation, including material test reports, cutting path simulations, and first-article inspection data.

Key technical specifications for our water jet foam cutting capability are detailed below:

| Parameter | Value | Standard Compliance | Material Impact | Application Note |

|---|---|---|---|---|

| Thickness Range | 1.5 mm – 100 mm | ISO 2286-2 | Optimized for EPDM, Neoprene, Silicone | Max 50 mm for cellular TPE |

| Tolerance | ±0.1 mm (≤25 mm thickness) | ISO 2768-mK | Reduced burr formation in nitrile | Tighter tolerances achievable via secondary calibration |

| Cutting Speed | 10–500 mm/min | ASTM D624 | Higher speeds for open-cell foams | Slower speeds for dense sponge rubber |

| Pressure Range | 30,000–60,000 PSI | ISO 15848-1 | Lower pressure for fragile microcellular | Prevents delamination in laminated stock |

| Edge Quality | Ra ≤ 3.2 µm | ISO 4287 | Critical for sealing surfaces | Validated via optical profilometry |

This technical infrastructure ensures consistent production of gaskets, insulation layers, and vibration dampeners where dimensional accuracy directly impacts system performance. Our engineers collaborate with clients during DFM reviews to identify cost-saving opportunities, such as optimizing part orientation to reduce waterjet path length by 15–25%. By unifying rubber chemistry expertise with precision cutting technology, Suzhou Baoshida provides OEMs with a single-source solution for mission-critical foam components. All projects include lifetime process validation records, enabling rapid troubleshooting and continuous improvement throughout the product lifecycle.

Customization Process

Customization Process for Water Jet Foam Cutting in Industrial Rubber Applications

At Suzhou Baoshida Trading Co., Ltd., our approach to custom water jet foam cutting integrates precision engineering with advanced rubber formulation science. This ensures optimal performance, dimensional accuracy, and material compatibility for industrial clients across automotive, electronics, and sealing sectors. Our four-phase customization process—Drawing Analysis, Formulation, Prototyping, and Mass Production—delivers tailored rubber foam components that meet exact functional and environmental demands.

The process begins with Drawing Analysis, where our engineering team reviews technical specifications, including geometric complexity, tolerance requirements (typically ±0.1 mm to ±0.5 mm), and application conditions. Critical parameters such as compression set resistance, flame retardancy, or chemical exposure are identified. We assess whether the design is optimized for water jet cutting, which excels in intricate profiles without tool wear or thermal degradation. Compatibility with water pressure (typically 3,000–4,000 bar) and kerf width (0.1–0.3 mm) is evaluated to prevent deformation or edge damage.

Next, Formulation is conducted in-house using proprietary elastomer blends. Based on the operational environment, we select base polymers such as EPDM, silicone, or neoprene, then modify them with additives for density control, UV resistance, or low outgassing. Closed-cell foam structures are preferred for water jet cutting due to their consistent cell matrix and minimal water absorption during processing. The formulated compound is cured and batch-tested for tensile strength, elongation at break, and hardness (Shore A 15–60) before proceeding.

Prototyping follows, where small-batch samples are cut using CNC-controlled water jet systems. This phase validates dimensional accuracy, edge quality, and material behavior under high-pressure water streams. We conduct functional tests including compression deflection, aging under elevated temperatures (e.g., 70°C for 72 hours), and adhesion performance if bonding is required. Client feedback is incorporated for design or material refinements, ensuring the prototype meets all performance benchmarks.

Upon approval, we transition to Mass Production, leveraging automated water jet lines with multi-axis cutting heads for high throughput and repeatability. Each batch undergoes 100% visual inspection and statistical sampling for dimensional verification. Traceability is maintained through batch coding and material certificates (e.g., RoHS, UL94 HF-1).

Our integrated process ensures that every custom foam component delivers consistent performance, longevity, and compliance with industrial standards.

| Parameter | Standard Range | Notes |

|---|---|---|

| Cutting Tolerance | ±0.1 mm to ±0.5 mm | Depends on foam density and thickness |

| Water Pressure | 3,000 – 4,000 bar | Adjustable based on material hardness |

| Kerf Width | 0.1 – 0.3 mm | Minimizes material loss |

| Foam Hardness (Shore A) | 15 – 60 | Customizable per application |

| Maximum Cutting Area | 1,500 mm × 3,000 mm | Per single sheet |

| Lead Time (Prototype) | 7–10 days | Includes testing and review |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Water Jet Foam Cutting Solutions

Achieving dimensional accuracy and material integrity in rubber foam components demands specialized water jet cutting expertise. Standard cutting methods often induce thermal degradation, edge deformation, or inconsistent kerf widths, compromising performance in critical sealing, insulation, and vibration damping applications. Suzhou Baoshida Trading Co., Ltd. addresses these challenges through engineered water jet processes calibrated for elastomeric foams. Our systems operate within rigorously controlled pressure gradients and abrasive flow rates, preserving the cellular structure of EPDM, silicone, neoprene, and polyurethane foams while delivering micron-level tolerances. This precision ensures optimal compression set resistance, fatigue life, and functional reliability in end-use environments ranging from automotive HVAC systems to medical device housings.

Our technical team implements ISO 9001-certified protocols for every water jet operation, integrating material science insights with fluid dynamics optimization. Unlike generic cutting services, we adjust standoff distance, traverse speed, and garnet mesh size based on polymer density, durometer, and cross-linking stability. This prevents delamination in multi-layered composites and maintains consistent edge quality across production runs exceeding 10,000 units. The result is reduced scrap rates, accelerated time-to-assembly, and compliance with ASTM D3574 and ISO 1856 foam testing standards.

The following table details our water jet cutting specifications for industrial rubber foams:

| Parameter | Specification | Industrial Relevance |

|---|---|---|

| Pressure Range | 30,000–60,000 PSI | Eliminates melt zones in low-density foams (≤30 pcf) |

| Positional Accuracy | ±0.05 mm | Critical for sealing surfaces in aerospace gaskets |

| Kerf Width Tolerance | +0.02 / -0.00 mm | Ensures consistent compression force in dynamic seals |

| Max Workpiece Thickness | 150 mm | Accommodates thick insulation blocks for construction |

| Material Compatibility | EPDM, Silicone, CR, PU, EVA | Validated for FDA 21 CFR 177.2600 and UL 94 HB foams |

| Lead Time (Prototype) | 72 hours | Accelerates OEM validation cycles |

Mr. Boyce, our dedicated OEM Manager and Rubber Formulation Specialist, possesses 14 years of experience optimizing water jet parameters for complex elastomeric geometries. He leads cross-functional collaboration between your engineering team and our manufacturing unit to resolve material-specific challenges—such as mitigating water absorption in hydrophilic foams or preventing cell collapse in ultra-low-density materials. Mr. Boyce does not function as a conventional sales representative; he provides actionable technical analysis of your CAD files, material certifications, and performance requirements to configure cutting protocols that align with your assembly line specifications.

Initiate your project with validated technical support. Contact Mr. Boyce directly via email at [email protected] with your component drawings, material grade specifications, and target tolerance thresholds. Include the subject line: Water Jet Foam Cutting Inquiry – [Your Company Name]. Mr. Boyce will respond within 24 business hours with a process capability report, including predicted edge quality metrics and a dimensional conformance plan. For time-sensitive prototyping needs, reference your required delivery date in the initial correspondence to prioritize resource allocation. Suzhou Baoshida operates from our ISO 13485-certified facility in Suzhou Industrial Park, providing full traceability from raw material lot numbers to final cut-part certification. Partner with us to transform foam cutting from a production bottleneck into a value-added engineering asset.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).