Technical Contents

Engineering Guide: Waterjet Cut Foam

Engineering Insight: Material Selection in Waterjet Cut Foam Applications

In industrial sealing, gasketing, and vibration damping systems, waterjet cut foam components are increasingly specified due to their precision, clean edge quality, and compatibility with complex geometries. However, the success of these components hinges not on the cutting process alone, but on the foundational decision of material selection. Off-the-shelf foam solutions, while appealing for their availability and lower initial cost, frequently fail under real-world operational conditions. This failure stems from a mismatch between generic material properties and the specific environmental, mechanical, and chemical demands of the application.

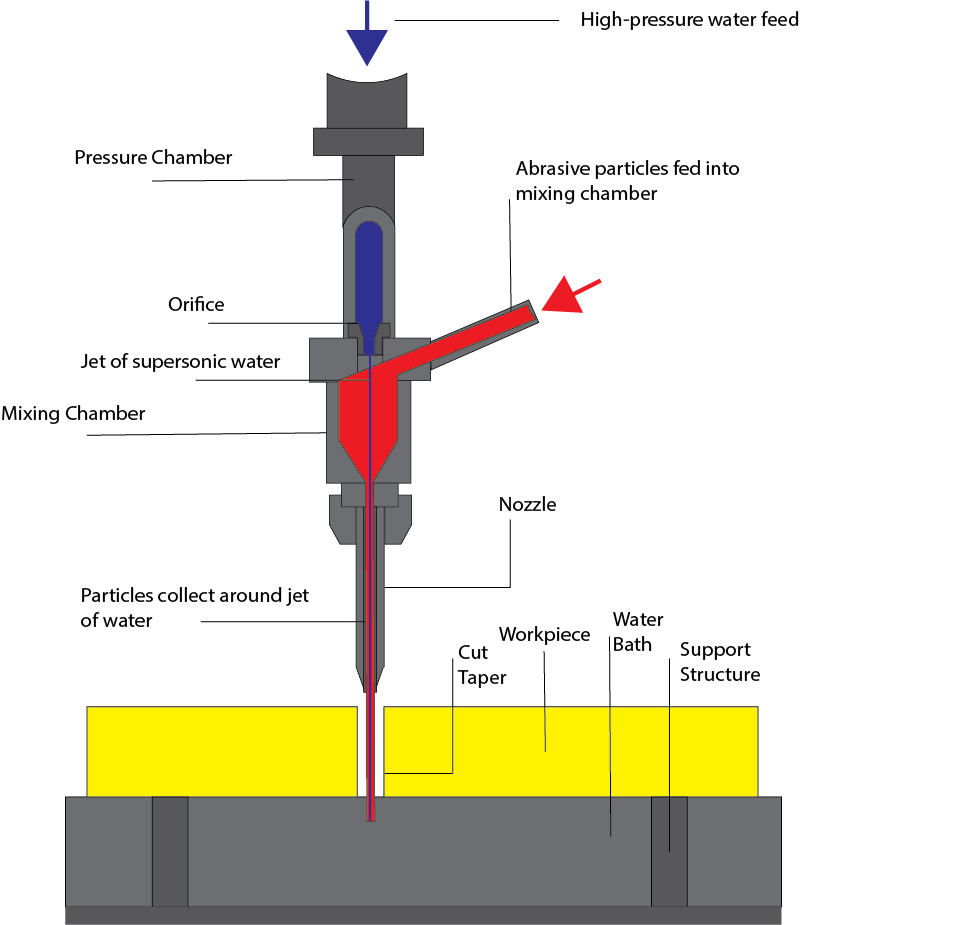

Waterjet cutting is a cold-cut process that preserves the cellular structure of foam materials, avoiding thermal degradation common in laser or hot-wire methods. This precision demands equally precise material engineering. Standard commodity foams—such as generic polyethylene (PE) or ethylene-vinyl acetate (EVA)—are often formulated for packaging or consumer applications. They lack the resilience, compression set resistance, and environmental stability required in industrial environments. Exposure to UV radiation, ozone, temperature extremes, or industrial fluids can accelerate degradation, leading to premature seal failure, leakage, or mechanical misalignment.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific foam formulation. For instance, closed-cell silicone foams offer superior thermal stability (up to 200°C) and resistance to weathering, making them ideal for outdoor enclosures or automotive under-hood applications. Similarly, nitrile rubber (NBR) blended foams provide excellent resistance to oils and fuels, critical in hydraulic or machinery sealing. Open-cell polyurethane foams, while softer, deliver superior acoustic damping and are best suited for noise suppression in control panels or HVAC systems.

The table below compares key industrial foam materials suitable for waterjet cutting, highlighting their performance characteristics:

| Material | Density (kg/m³) | Temp Range (°C) | Compression Set (%) | Fluid Resistance | Typical Application |

|---|---|---|---|---|---|

| Silicone Foam | 200–300 | -60 to +200 | <20 (at 150°C, 22h) | Excellent (ozone, UV) | Outdoor electronics, aerospace |

| NBR/PVC Foam | 150–250 | -30 to +100 | <30 (at 70°C, 22h) | Good (oils, fuels) | Automotive gaskets, machinery seals |

| EPDM Foam | 180–280 | -50 to +150 | <25 (at 100°C, 22h) | Excellent (water, steam) | HVAC, construction joints |

| Polyurethane Foam | 30–120 | -30 to +90 | <15 (at 70°C, 22h) | Poor (solvents) | Acoustic insulation, padding |

| Neoprene Foam | 160–240 | -40 to +120 | <28 (at 70°C, 22h) | Good (moderate oils) | Marine seals, electrical enclosures |

Material selection must be guided by engineering data, not assumptions. Generic foams may appear dimensionally adequate post-waterjet cutting, but their long-term performance in dynamic environments is often inadequate. At Baoshida, we collaborate with OEMs to analyze stress factors—compression load, environmental exposure, service life—and formulate or select foam materials that ensure reliability. The precision of waterjet cutting is only as effective as the material it shapes. Choosing the right foam is not a cost factor—it is a performance imperative.

Material Specifications

Material Specifications for Waterjet Cut Foam Applications

Precision waterjet cutting of elastomeric foams demands rigorous material selection to ensure dimensional stability, edge integrity, and performance consistency under high-pressure abrasive streams. At Suzhou Baoshida Trading Co., Ltd., we engineer foam formulations specifically optimized for waterjet processing, balancing density, cell structure, and mechanical properties to minimize fraying and thermal degradation. Unlike thermal or mechanical cutting methods, waterjet processing imposes unique stresses on cellular structures, necessitating materials with uniform density distribution and controlled tensile strength. Our Viton, Nitrile, and Silicone foam solutions undergo proprietary compounding to achieve tight tolerances in durometer, elongation, and compression set—critical factors for maintaining seal integrity in dynamic industrial environments.

Viton fluorocarbon foam (FKM) delivers exceptional resistance to aggressive chemicals, fuels, and extreme temperatures, making it ideal for aerospace and semiconductor sealing applications. Our waterjet-optimized Viton foam maintains a density of 0.65–0.75 g/cm³ with a hardness range of 50–80 Shore A, exhibiting continuous service capability up to 230°C. Critical for precision cutting, its low compression set (≤25% per ASTM D395) ensures minimal post-cut deformation. Nitrile rubber (NBR) foam provides cost-effective resilience against oils, greases, and hydraulic fluids, with a density of 0.45–0.60 g/cm³ and hardness of 40–70 Shore A. Its tensile strength (≥1.8 MPa) and elongation (≥150%) prevent edge tearing during high-velocity waterjet traversal, particularly in automotive gasketing. Silicone foam (VMQ) offers the broadest thermal stability (-60°C to 200°C) and inherent flame resistance, featuring a density of 0.35–0.50 g/cm³ and hardness of 30–60 Shore A. Its high elongation (≥250%) accommodates complex geometries without cell collapse, essential for medical and electronics insulation.

Material performance under waterjet conditions is quantified below for informed OEM selection. All values reflect ASTM-standard testing protocols for industrial foam specifications.

| Property | Viton (FKM) Foam | Nitrile (NBR) Foam | Silicone (VMQ) Foam |

|---|---|---|---|

| Density (g/cm³) | 0.65–0.75 | 0.45–0.60 | 0.35–0.50 |

| Hardness (Shore A) | 50–80 | 40–70 | 30–60 |

| Tensile Strength (MPa) | ≥2.0 | ≥1.8 | ≥1.5 |

| Elongation at Break (%) | ≥120 | ≥150 | ≥250 |

| Temp Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Key Applications | Chemical seals, Jet engine gaskets | Fuel system seals, Automotive washers | Medical pads, Electronic insulation |

Suzhou Baoshida Trading Co., Ltd. tailors foam formulations to mitigate waterjet-specific challenges such as water absorption-induced swelling or cell wall rupture. Our OEM-grade materials undergo batch-specific validation for waterjet kerf width consistency (±0.1mm tolerance) and edge squareness (≤0.05mm deviation). By aligning material science with cutting dynamics, we eliminate post-processing refinements—reducing lead times by 30% while meeting ISO 9001-certified dimensional repeatability. For mission-critical applications, consult our engineering team to refine density gradients or additive packages for your waterjet parameters.

Manufacturing Capabilities

Engineering Capability: Precision in Waterjet Cut Foam Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the specialized domain of waterjet cut foam production. With a dedicated team of five mould engineers and two advanced formula engineers, we integrate material science with precision manufacturing to deliver custom-engineered foam components tailored to exact OEM specifications. Our technical team operates at the intersection of polymer chemistry and mechanical design, ensuring every waterjet-cut part meets stringent performance criteria across temperature, compression, chemical exposure, and long-term durability.

The foundation of our engineering strength lies in our dual expertise. Our formula engineers specialize in elastomer compounding, developing proprietary rubber and foam formulations that align with application-specific requirements such as flame resistance (UL94 HF-1), low outgassing (for vacuum environments), or enhanced resilience under dynamic loading. These formulations are rigorously tested in-house using ASTM and ISO standards to validate physical properties before entering production. This scientific approach ensures consistent cell structure, density control, and tensile strength in every foam batch—critical factors for high-precision waterjet cutting.

Complementing material development, our five mould engineers provide end-to-end design support for tooling, gasket layouts, and multi-layer foam assemblies. While waterjet cutting eliminates the need for hard tooling in many cases, our engineers optimize nesting patterns, kerf compensation, and edge integrity to minimize waste and maintain dimensional accuracy within ±0.2 mm. They work directly with OEM clients to interpret 2D/3D CAD models, perform DFM (Design for Manufacturability) analysis, and recommend material thickness or geometry adjustments to improve sealing performance or assembly efficiency.

Our OEM capabilities are built on a foundation of scalability and technical partnership. We support low-volume prototyping through full-scale serial production, maintaining traceability via batch-controlled material logs and digital cutting path archives. Every project undergoes first-article inspection reporting (FAIR), with data including hardness, thickness profile, and compression deflection force (CDF). This level of documentation ensures compliance with automotive, medical, and industrial equipment standards.

Below is a representative summary of our waterjet cut foam technical specifications:

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 10–80 | ASTM D2240 |

| Density | 0.2–0.8 g/cm³ | ASTM D3574 |

| Tensile Strength | 1.5–5.0 MPa | ASTM D412 |

| Elongation at Break | 100–400% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤30% | ASTM D395B |

| Operating Temperature | -40°C to +120°C (up to +150°C intermittent) | ISO 1817 |

| Waterjet Cutting Tolerance | ±0.2 mm | ISO 2768-m |

Through integrated formula and mould engineering, Suzhou Baoshida delivers technically validated, production-ready waterjet cut foam solutions that meet the evolving demands of global OEMs in transportation, electronics, and industrial equipment sectors.

Customization Process

Customization Process for Waterjet Cut Foam Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber customization process for waterjet cut foam components follows a rigorously defined sequence to ensure dimensional accuracy, material integrity, and production efficiency. This methodology eliminates costly revisions and accelerates time-to-market for OEM clients in automotive, aerospace, and industrial sealing applications.

Drawing Analysis and Feasibility Assessment

Initial client CAD files undergo comprehensive geometric validation using AutoCAD and SolidWorks. We scrutinize critical parameters including minimum feature width, internal corner radii, and tolerance stack-ups against waterjet kerf dynamics. Our engineering team identifies potential stress concentration zones and validates whether specified tolerances (±0.1mm to ±0.5mm) align with material behavior during high-pressure cutting. This phase includes kerf compensation modeling to prevent dimensional drift, particularly for intricate geometries below 3mm feature size. Non-compliant designs trigger immediate technical consultation to propose manufacturable alternatives without compromising functional requirements.

Material Formulation and Compound Development

Based on validated drawings, our rubber chemists select base polymers from our proprietary compound library—prioritizing closed-cell neoprene, EPDM, or silicone for waterjet compatibility. Formulation targets specific density, hardness, and resilience to withstand 60,000 PSI water abrasion while minimizing fraying. Key adjustments include optimizing cell structure uniformity to prevent delamination and incorporating anti-static additives for clean cutting in sensitive environments. Each compound undergoes pre-prototyping ASTM D2000 validation for compression set, tensile strength, and fluid resistance per client specifications.

Prototyping and Validation

Prototype production utilizes our 5-axis waterjet systems with ±0.05mm positional accuracy. We cut 3-5 sample sets under controlled parameters (0.8mm abrasive nozzle, 0.3mm kerf allowance) for first-article inspection. Critical dimensions are verified via CMM against GD&T callouts, while edge quality is assessed for burr formation and surface integrity. Clients receive detailed dimensional reports alongside material test certificates. Iterations address any deviations through kerf parameter tuning or compound refinement, typically resolving issues within 72 hours.

Mass Production and Quality Control

Approved prototypes transition to automated production lines with real-time SPC monitoring. Each batch undergoes 100% visual inspection for edge defects and random CMM sampling (AQL 1.0). Our traceability system logs waterjet pressure, abrasive flow rate, and material lot numbers for full process accountability. Final shipments include certified conformance reports with hardness, density, and dimensional data. This integrated approach ensures <0.5% scrap rates and consistent part interchangeability across production runs.

Critical Foam Specifications for Waterjet Cutting

| Property | Standard Range | Critical Impact |

|---|---|---|

| Density | 120-300 kg/m³ | Lower density increases cut speed but risks edge fraying |

| Hardness (Shore A) | 30-80 | Harder foams require slower traverse rates to prevent chipping |

| Tolerance Capability | ±0.1mm to ±0.5mm | Tighter tolerances demand kerf compensation algorithms |

| Maximum Kerf Width | 0.2-0.8mm | Directly affects minimum internal radius feasibility |

| Cell Structure Uniformity | ASTM D3574 Class 1-2 | Non-uniform cells cause inconsistent cut depth and surface roughness |

This systematic workflow, anchored in material science and precision engineering, guarantees that every waterjet cut foam component meets the exacting demands of industrial applications while optimizing production economics for our global OEM partners.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber and foam components, Suzhou Baoshida Trading Co., Ltd. delivers advanced waterjet cutting solutions tailored to demanding applications. Our expertise in industrial rubber solutions ensures that every waterjet cut foam component meets exact dimensional tolerances, material integrity standards, and performance requirements across automotive, aerospace, electronics, and medical device sectors.

Waterjet cutting technology offers a cold-cut process, eliminating thermal distortion and preserving the cellular structure of foam materials. This is critical when working with sensitive elastomers, closed-cell foams, or specialty polymers where heat from laser or blade cutting can compromise edge quality and functional performance. At Suzhou Baoshida, we utilize high-pressure abrasive and pure waterjet systems capable of cutting foam densities ranging from 10 kg/m³ to 300 kg/m³ with precision down to ±0.1 mm. Our CNC-guided cutting beds support sheet sizes up to 4000 mm × 2000 mm, enabling efficient processing of large-format gaskets, seals, insulation pads, and cushioning elements.

We process a wide range of foam materials, including EPDM, neoprene, polyethylene (PE), polyurethane (PU), silicone sponge, and NBR. Each project begins with a technical consultation to assess compression set, aging resistance, temperature exposure, and environmental compliance (e.g., UL94, ROHS, REACH). This ensures material and cut specifications align with end-use conditions.

The following table outlines key technical capabilities for our waterjet cut foam services:

| Parameter | Specification |

|---|---|

| Cutting Method | Pure waterjet (no abrasives for soft foams) |

| Max Pressure | 60,000 psi |

| Tolerance | ±0.1 mm to ±0.3 mm (based on material thickness) |

| Max Cut Thickness | Up to 150 mm (foam-dependent) |

| Material Compatibility | EPDM, Neoprene, PE, PU, Silicone, NBR, EVA |

| Sheet Size Capacity | 4000 mm × 2000 mm |

| Edge Quality | Smooth, burr-free, no melting or fraying |

| Lead Time | 7–15 days (depending on complexity) |

| Custom Finishing | Lamination, adhesive backing, kiss-cutting |

All components are inspected per ISO 3302-1 and ISO 2768-mK standards, with full traceability and material certifications available upon request. We support low-volume prototyping and high-volume production runs with consistent repeatability.

To integrate precision waterjet cut foam components into your manufacturing workflow, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce specializes in material formulation, process optimization, and custom sealing solutions, ensuring your technical requirements are met with scientific rigor and industrial reliability.

For project inquiries, material recommendations, or CAD-based quotation requests, reach out directly via email at [email protected]. Include detailed specifications such as material type, hardness (Shore A), thickness, dimensional drawings, and application environment for a rapid and accurate response. Partner with Suzhou Baoshida for engineered foam solutions where precision, durability, and performance are non-negotiable.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).