Technical Contents

Engineering Guide: Weather Stipping Door

Engineering Insight: Material Selection in Weather Stripping for Doors

The performance and longevity of weather stripping for doors are fundamentally determined by material selection. In industrial and commercial applications, off-the-shelf weather stripping solutions often fail prematurely due to inadequate material properties for the specific environmental and mechanical demands of the installation. These generic products, typically formulated for residential use, lack the resilience required in high-cycle, extreme-temperature, or chemically aggressive environments. Understanding the engineering parameters behind elastomer selection is essential to ensure sealing integrity, energy efficiency, and operational reliability.

Thermoplastic rubber (TPR), ethylene propylene diene monomer (EPDM), silicone, and neoprene are common elastomers used in door weather stripping. Each material exhibits distinct physical and chemical characteristics that influence compression set resistance, UV stability, low-temperature flexibility, and resistance to ozone and weathering. For instance, EPDM demonstrates superior resistance to UV radiation and ozone, making it ideal for exterior applications exposed to direct sunlight. However, its poor resistance to hydrocarbon-based oils limits its use in industrial environments with chemical exposure. Conversely, neoprene offers balanced resistance to oils, weathering, and flame, but may exhibit higher compression set over time, leading to seal degradation.

Silicone excels in extreme temperature ranges (from -60°C to over 200°C) and maintains flexibility under thermal cycling, but its mechanical strength and abrasion resistance are lower than those of TPR or EPDM. TPR provides excellent extrudability and cost-effective processing, yet it may degrade under prolonged UV exposure unless specially formulated. Selecting the wrong compound results in premature cracking, hardening, or compression set—leading to air infiltration, energy loss, and compromised building envelope performance.

Custom-engineered weather stripping from Suzhou Baoshida Trading Co., Ltd. addresses these challenges through application-specific material formulation. We analyze door cycle frequency, environmental exposure, compression load requirements, and regulatory standards to tailor the elastomer composition. This precision engineering ensures optimal sealing force, long-term resilience, and compliance with industrial durability benchmarks.

The following table outlines key material properties for common weather stripping elastomers used in door applications:

| Material | Temperature Range (°C) | UV Resistance | Compression Set (%) | Ozone Resistance | Chemical Resistance |

|---|---|---|---|---|---|

| EPDM | -50 to 150 | Excellent | Low to Moderate | Excellent | Poor to Fair |

| Silicone | -60 to 200+ | Good | Low | Good | Fair |

| Neoprene | -40 to 120 | Moderate | Moderate | Moderate | Good |

| TPR | -30 to 100 | Fair | Moderate | Poor | Poor to Fair |

Material selection is not a one-size-fits-all decision. Off-the-shelf weather stripping often fails because it prioritizes cost and availability over performance engineering. At Suzhou Baoshida, we deliver industrial rubber solutions that are scientifically formulated to meet the precise demands of commercial and industrial door systems, ensuring long-term sealing performance and system integrity.

Material Specifications

Material Specifications for Industrial Weather Stripping Door Seals

Weather stripping for doors demands rigorous material selection to ensure longevity, sealing integrity, and resilience against environmental stressors. At Suzhou Baoshida Trading Co., Ltd., we prioritize precision-engineered rubber compounds tailored to operational demands. This section details critical specifications for three industry-standard elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material exhibits distinct chemical, thermal, and mechanical properties directly impacting performance in sealing applications.

Viton (FKM) excels in extreme environments requiring resistance to high temperatures, ozone, and aggressive chemicals like fuels, oils, and acids. Its fluorocarbon structure delivers continuous service up to 200°C with intermittent peaks at 230°C. Viton maintains sealing force under prolonged compression, evidenced by a low compression set (typically <25% at 150°C after 70 hours per ASTM D395). However, its high raw material cost and processing complexity necessitate careful cost-benefit analysis for high-value applications such as automotive engine compartments or chemical processing facilities.

Nitrile (NBR) remains the cost-effective solution for general-purpose weather stripping where exposure to petroleum-based fluids and moderate temperatures (-40°C to 120°C) is expected. With acrylonitrile content optimized at 33–36%, it achieves balanced oil resistance and low-temperature flexibility. NBR compounds offer excellent abrasion resistance and tensile strength (15–25 MPa), facilitating durable extrusion profiles. Its primary limitation is poor resistance to ozone and polar solvents, requiring stabilizers for outdoor UV exposure. NBR dominates mass-market door seals due to processing efficiency and scrap recyclability.

Silicone (VMQ) provides unparalleled thermal stability from -60°C to 200°C and exceptional resistance to UV, ozone, and weathering. Its inert composition meets stringent food and medical standards (e.g., FDA 21 CFR 177.2600), making it ideal for cleanroom or healthcare environments. Silicone’s high gas permeability and lower tensile strength (6–10 MPa) necessitate design adjustments for high-pressure sealing. While compression set resistance is moderate (30–40% at 150°C), its non-flammability and consistent performance across extreme temperature cycles justify premium use in aerospace and critical infrastructure.

The following table summarizes key comparative specifications per ASTM D2000 and ISO 188 standards:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -40 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 10–18 | 15–25 | 6–10 |

| Elongation at Break (%) | 150–300 | 250–450 | 200–600 |

| Hardness (Shore A) | 60–80 | 50–90 | 30–80 |

| Compression Set (%)* | <25 | 20–35 | 30–40 |

| Key Fluid Resistance | Fuels, Acids, Oils | Oils, Fuels | Water, Steam |

*Per ASTM D395, 22 hrs at 150°C for FKM/VMQ; 70 hrs at 100°C for NBR.

Material selection must align with fluid exposure, temperature extremes, regulatory requirements, and lifecycle cost targets. Suzhou Baoshida Trading Co., Ltd. leverages decades of OEM partnership experience to formulate custom compounds that optimize these parameters without compromising manufacturability. Our engineering team collaborates closely with clients to translate environmental data into resilient sealing solutions, ensuring compliance with global automotive (SAE J2236), construction (EN 12211), and industrial standards. Precision in raw material sourcing and vulcanization control remains central to delivering weather stripping that performs reliably across 10,000+ door cycles.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering team forms the backbone of our industrial rubber solutions, ensuring precision, durability, and innovation in every weather stripping product we deliver. We maintain a dedicated in-house engineering department comprising five specialized mould engineers and two advanced rubber formula engineers. This integrated team enables us to offer comprehensive OEM (Original Equipment Manufacturer) services tailored to the exacting demands of global automotive, construction, and transportation industries.

Our mould engineers bring over 15 years of combined experience in precision tooling design and rapid prototyping. Utilizing advanced CAD/CAM software such as AutoCAD, SolidWorks, and UG NX, they develop high-tolerance steel and aluminum moulds capable of withstanding high-cycle production environments. Each mould is rigorously tested for dimensional accuracy, compression set resistance, and long-term sealing performance under simulated environmental stress conditions. This ensures that every weather stripping component meets or exceeds international standards including ISO 9001, TS 16949, and ASTM D2000.

Complementing our tooling expertise, our two rubber formula engineers specialize in elastomer material development. They formulate custom rubber compounds based on EPDM, silicone, neoprene, and TPE, optimized for specific performance criteria such as UV resistance, ozone stability, low-temperature flexibility, and compression recovery. By controlling raw material sourcing and compounding in-house, we maintain full traceability and consistency across production batches. This vertical integration allows us to rapidly iterate formulations in response to customer-specific requirements, including low-outgassing needs for automotive interiors or flame-retardant properties for rail applications.

Our OEM capabilities extend from concept to mass production. We support clients through every stage: technical consultation, 3D design validation, material selection, DFM (Design for Manufacturability) analysis, prototype sampling, and PPAP documentation. With an agile development cycle of 15–25 days from design to first article, we accelerate time-to-market while maintaining strict quality control. Our production lines are equipped with PLC-controlled hydraulic presses, automatic extrusion units, and robotic trimming systems, ensuring repeatability and dimensional stability across volumes from 1,000 to over 500,000 units annually.

All weather stripping solutions are validated against critical performance metrics before shipment. Testing includes compression deflection analysis, thermal aging (150°C for 72h), weathering (QUV accelerated exposure), and air/water leakage under dynamic door cycling.

The following table outlines typical technical specifications achievable with our engineered rubber compounds and tooling systems:

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–85 ±5 |

| Tensile Strength | ASTM D412 | ≥8 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +150°C |

| Density | ASTM D297 | 1.15–1.35 g/cm³ |

| Ozone Resistance | ASTM D1149 | No cracking (200 pphm, 40°C, 96h) |

Through a fusion of advanced material science and precision engineering, Suzhou Baoshida delivers weather stripping solutions that perform reliably in extreme environments. Our OEM framework is built for scalability, compliance, and technical collaboration—ensuring every product is engineered to last.

Customization Process

Customization Process for Precision Weather Stripping Doors

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions for weather stripping doors follow a rigorously defined customization workflow. This ensures dimensional accuracy, environmental resilience, and seamless integration with client assembly lines. The process begins with Drawing Analysis, where our engineering team dissects client-provided CAD files and technical specifications. We validate critical parameters including cross-sectional tolerances (±0.1 mm), installation groove compatibility, and dynamic compression requirements. Material compatibility with adjacent substrates (e.g., aluminum, PVC, or steel frames) is assessed alongside operational stress points. This phase identifies potential design conflicts early, preventing costly revisions during tooling.

Formulation leverages our 15+ years of compound development expertise. Based on the environmental exposure profile—such as UV intensity, ozone concentration, or extreme temperature cycling—we select base polymers and curative systems. For standard door applications in temperate climates, EPDM remains optimal due to its ozone resistance and thermal stability. However, formulations are precisely tuned: low-temperature flexibility down to -50°C requires specialized plasticizers, while high-compression-set resistance demands controlled peroxide crosslinking. Our proprietary additive packages enhance abrasion resistance for sliding mechanisms without compromising extrusion flow. Each compound undergoes predictive modeling for compression force-deflection (CFD) behavior to match the door’s operational torque specifications.

Prototyping utilizes client-approved materials in short-run extrusion trials. We produce 5–10 meter samples for third-party validation per ASTM D2000 and ISO 1817 standards. Critical tests include 10,000-cycle durability simulations, adhesion peel strength verification, and accelerated aging (1,000 hours QUV exposure). Dimensional conformity is confirmed via CMM scanning against the original CAD model. Client feedback on installation ergonomics and sealing performance triggers micro-adjustments to the durometer profile or lip geometry before final sign-off.

Mass Production commences only after prototype validation. Our ISO 9001-certified facility employs closed-loop extrusion systems with real-time rheometry monitoring to maintain ±2 Shore A hardness consistency. Each production batch undergoes in-process checks for vulcanization completeness (via Mooney viscometry) and surface integrity. Traceability is enforced through laser-etched batch codes linked to raw material certificates. Final inspection includes 100% length measurement and抽样 compression set testing per ASTM D395 Method B. Shipments are palletized with climate-controlled logistics documentation to preserve material properties.

Key performance metrics for our weather stripping compounds are summarized below:

| Property | Standard EPDM Grade | Premium Low-Compression-Set Grade | Test Standard |

|---|---|---|---|

| Shore A Hardness | 65 ± 3 | 70 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | ≥10.0 | ≥12.5 | ASTM D412 |

| Temperature Range (°C) | -40 to +135 | -50 to +150 | ISO 188 |

| Compression Set (%) | ≤25 | ≤15 | ASTM D395 B, 22h |

| Specific Gravity | 1.25 ± 0.02 | 1.30 ± 0.02 | ASTM D297 |

This structured approach minimizes time-to-market while guaranteeing weather stripping performance exceeding OEM durability thresholds. All stages incorporate client feedback loops, ensuring the final product integrates flawlessly into your door assembly ecosystem.

Contact Engineering Team

For industrial manufacturers seeking high-performance weather stripping solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of precision-engineered rubber components. Specializing in industrial rubber solutions, our expertise ensures that every weather stripping door product meets rigorous standards for durability, sealing efficiency, and environmental resistance. As OEMs and system integrators face increasing demands for energy efficiency and long-term reliability in building envelopes, our engineered compounds deliver consistent performance across extreme temperature ranges, UV exposure, and mechanical stress.

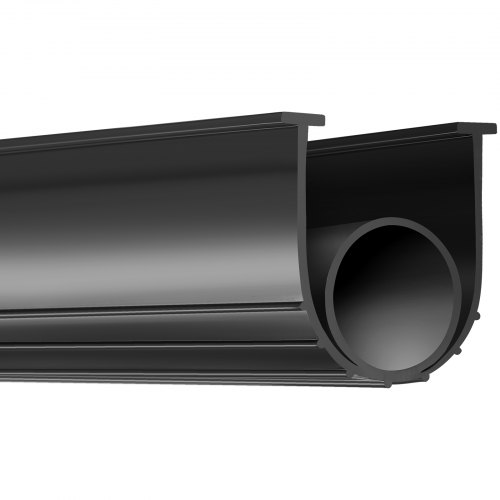

Our weather stripping solutions are formulated using advanced elastomeric materials including EPDM, silicone, and thermoplastic vulcanizates (TPV), each selected for specific application requirements. Whether for commercial architecture, transportation, or industrial enclosures, our profiles are designed to provide optimal compression set resistance, low-temperature flexibility, and long-term resilience against compression fatigue. We support custom profile extrusion, co-extrusion with sealing beads, and automated cutting to length, ensuring seamless integration into your assembly processes.

To ensure compatibility and performance, we conduct rigorous in-house testing across multiple parameters including tensile strength, elongation at break, Shore A hardness, and accelerated aging per ASTM and ISO standards. Our quality management system is aligned with ISO 9001 protocols, enabling traceability, batch consistency, and compliance with international regulatory frameworks.

The following table outlines typical material specifications for our standard weather stripping compounds used in door applications:

| Property | EPDM 70 Shore A | Silicone 60 Shore A | TPV 55 Shore A |

|---|---|---|---|

| Tensile Strength (MPa) | ≥10.5 | ≥8.0 | ≥9.2 |

| Elongation at Break (%) | ≥450 | ≥500 | ≥480 |

| Hardness (Shore A) | 70 ±5 | 60 ±5 | 55 ±5 |

| Compression Set (22h, 70°C) | ≤20% | ≤15% | ≤18% |

| Temperature Range | -40°C to +135°C | -55°C to +180°C | -35°C to +135°C |

| UV and Ozone Resistance | Excellent | Excellent | Good |

Partnering with Suzhou Baoshida means gaining access to technical expertise backed by decades of industrial formulation experience. Our engineering team collaborates directly with clients to optimize material selection, profile geometry, and production methodology—ensuring cost-effective scalability without compromising performance.

For immediate technical consultation or sample requests, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer, at [email protected]. Mr. Boyce leads our client integration efforts, providing direct support in material data sheet review, DFMEA collaboration, and rapid prototyping services. We respond to all inquiries within 12 business hours and offer virtual or on-site technical audits upon request.

Choose Suzhou Baoshida for weather stripping door solutions where precision, performance, and partnership define success. Reach out today to begin engineering the next generation of high-integrity sealing systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).