Technical Contents

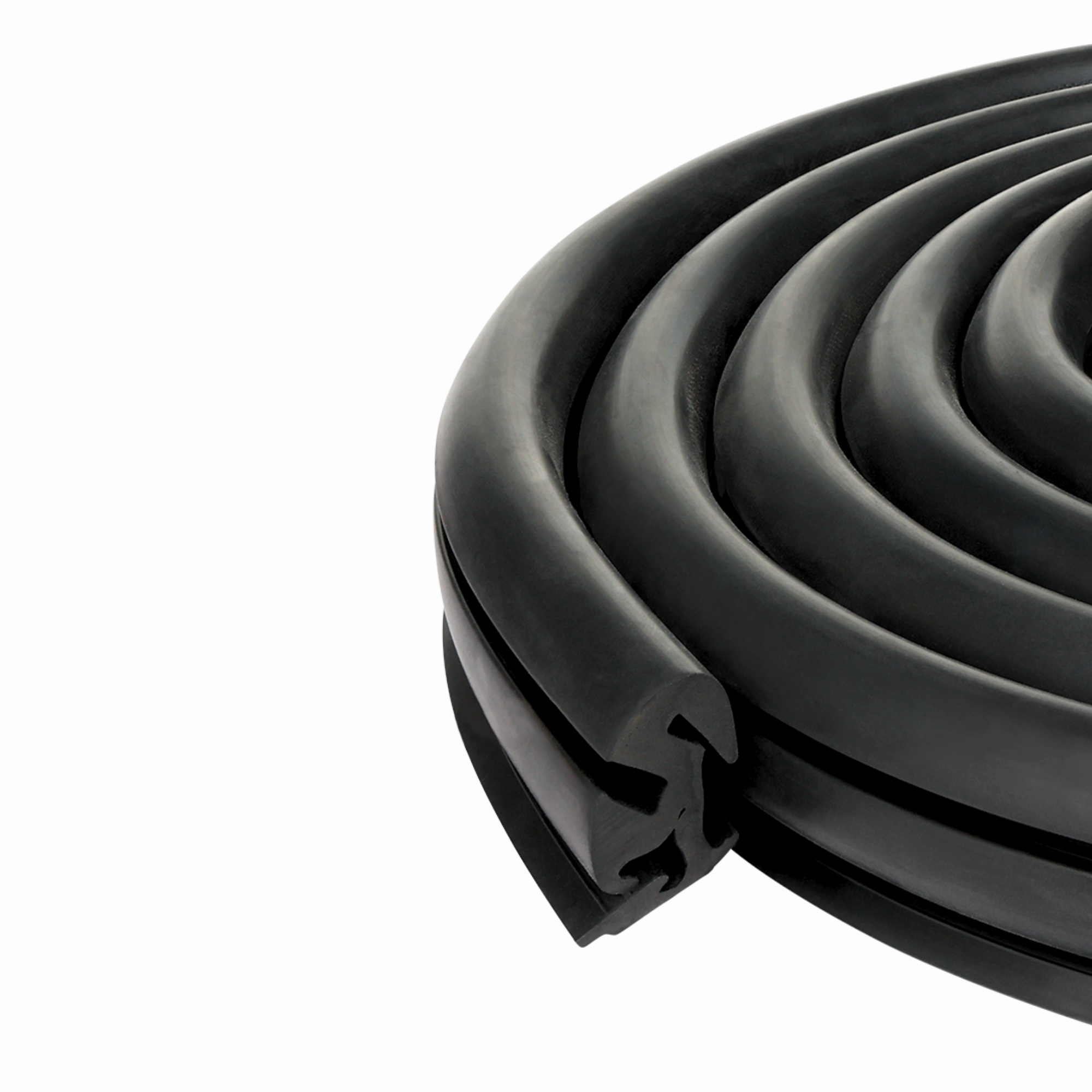

Engineering Guide: Weather Window Seal

Engineering Insight: Weather Window Seal Material Selection Imperatives

The operational integrity of automotive and architectural weather window seals hinges on precise material science, not generic elastomer solutions. Off-the-shelf compounds frequently fail due to inadequate adaptation to the complex stressors inherent in dynamic sealing interfaces. These include cyclic compression, extreme thermal excursions, UV/ozone exposure, chemical contact from environmental pollutants or cleaning agents, and long-term compression set resistance. Standard commodity EPDM formulations, while cost-effective for low-demand applications, lack the tailored polymer architecture and additive systems required for sustained performance in modern window systems.

Material failure manifests through critical degradation pathways. Basic EPDM grades experience severe hardening below -30°C due to high glass transition temperatures (Tg), leading to brittle fracture during cold-weather operation. Simultaneously, insufficient antioxidant and antiozonant packages accelerate surface cracking under atmospheric ozone, compromising the primary weather barrier within 18-24 months. Crucially, poor compression set resistance—often exceeding 40% in standard compounds after 70°C aging—results in permanent deformation. This loss of elastic recovery directly causes gap formation between the seal and glass, enabling water ingress, wind noise, and accelerated wear. Such failures are not manufacturing defects but inevitable outcomes of mismatched material properties.

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through engineered elastomer systems where every formulation parameter is optimized for the specific application envelope. Our premium weather seal compounds utilize high-purity, saturated backbone polymers with controlled molecular weight distribution to minimize Tg while maximizing resilience. Critical additives are precision-dosed to form synergistic protective networks against oxidation and ozone attack, validated through accelerated aging per ISO 188 and ASTM D1149. The table below illustrates performance differentials between material grades:

| Material Grade | Glass Transition Temp (°C) | Compression Set (70°C/22h, %) | Ozone Resistance (50 pphm, 40°C, 20% strain) | Typical Failure Mode in Window Seals |

|---|---|---|---|---|

| Standard Commodity EPDM | -45 to -50 | 35-45 | Cracking in < 24h | Water ingress, wind noise after 18mo |

| Baoshida Premium EPDM | -55 to -60 | 15-22 | No cracking after 168h | >10-year service life |

| Specialty FKM Variant | -20 to -25 | 10-18 | Excellent | Extreme chemical exposure scenarios |

Material selection must align with the entire operational profile—not just baseline temperature ranges. For instance, EV window channels face unique challenges from battery coolant splashes requiring enhanced chemical resistance, while sunroof seals demand superior UV stability due to direct solar exposure. Off-the-shelf solutions ignore these nuanced requirements, prioritizing initial cost over lifecycle value. At Suzhou Baoshida, we engineer compounds where compression set remains below 25% after 1,000 hours at 100°C (per ASTM D395), ensuring decades of reliable sealing force retention. The consequence of inadequate material science is not merely warranty claims—it is systemic erosion of brand reputation through compromised vehicle or building performance. Precision formulation is non-negotiable for mission-critical weather sealing.

Material Specifications

Material selection is a critical determinant in the performance and longevity of weather window seals used in automotive, architectural, and industrial applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to deliver optimal sealing integrity under diverse environmental and operational conditions. Our technical expertise ensures that each seal is manufactured using high-performance elastomers tailored to specific application demands. The three primary materials employed in our weather window seal solutions are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages in temperature resistance, chemical compatibility, and mechanical durability.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, ozone, UV radiation, and a broad range of chemicals, including oils, fuels, and acids. This makes Viton an ideal choice for exterior automotive glazing and industrial enclosures exposed to aggressive environments. With continuous service capabilities up to 230°C and intermittent resistance up to 260°C, Viton seals maintain dimensional stability and elastic recovery over extended periods, ensuring reliable performance in extreme conditions.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used for its excellent resistance to petroleum-based oils and fuels. It offers good abrasion resistance and tensile strength, making it suitable for general-purpose sealing in moderate temperature ranges. Nitrile seals perform effectively between -30°C and 120°C, with formulations adjustable to enhance low-temperature flexibility or oil resistance. While less resistant to UV and ozone than Viton or Silicone, NBR remains a cost-effective solution for indoor or sheltered applications where exposure to hydrocarbons is a primary concern.

Silicone rubber provides superior thermal stability across a wide temperature spectrum, operating reliably from -60°C to 200°C. It exhibits excellent resistance to weathering, UV light, and ozone, making it particularly well-suited for exterior architectural glazing and climates with extreme seasonal variations. Silicone’s high gas permeability and low compression set contribute to long-term sealing performance, although it has lower tensile strength and abrasion resistance compared to Viton and Nitrile. It is non-reactive and compliant with many stringent health and safety standards, enabling use in sensitive environments.

The selection of the appropriate elastomer depends on the specific service conditions, including temperature extremes, chemical exposure, mechanical stress, and regulatory requirements. Below is a comparative overview of key physical and chemical properties for Viton, Nitrile, and Silicone materials used in our weather window seal manufacturing.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 (up to 260 intermittent) | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 12–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Very Good |

| Chemical Resistance | Excellent (acids, bases, hydrocarbons) | Good (oils, aliphatic hydrocarbons) | Fair (limited to water, alcohols) |

Each material is processed under strict quality controls using advanced compounding and vulcanization techniques to ensure consistency, durability, and sealing efficiency. Our engineering team collaborates with OEMs to match material properties with application-specific requirements, ensuring optimal performance and lifecycle cost efficiency.

Manufacturing Capabilities

Engineering Capabilities for Precision Weather Window Seals

Suzhou Baoshida Trading Co., Ltd. deploys a dedicated engineering team comprising five specialized mold designers and two advanced rubber formulation scientists to deliver mission-critical weather window seals for global automotive and architectural OEMs. This integrated expertise ensures seals exceed stringent environmental durability, compression set resistance, and dimensional stability requirements under extreme operational conditions. Our formula engineers optimize elastomer molecular architecture through precise control of polymer selection, filler dispersion, and cross-link density, directly addressing industry pain points like ozone-induced cracking, thermal degradation, and loss of sealing force over 15+ year service lifecycles.

Material science drives our performance differentiation. We develop custom EPDM and TPE compounds with tailored additive packages to achieve exacting client specifications for UV resistance, low-temperature flexibility down to -50°C, and adhesion to glass/metal substrates without primers. Every formulation undergoes rigorous accelerated aging per ASTM D2240 and ISO 188 protocols, with real-time validation against OEM-specific field failure modes. This eliminates costly post-production adjustments and ensures first-pass compliance with global standards like GMW14125, VW50180, and JIS K 6259.

Our OEM partnership model integrates engineering resources directly into client NPI workflows. Mold engineers utilize 3D simulation (Moldflow) to preempt flow imbalances and weld line weaknesses in complex multi-cavity tools, reducing prototype iterations by 40%. Concurrently, formula engineers provide material data packs with traceable batch certificates, enabling seamless PPAP documentation. This closed-loop system guarantees dimensional repeatability within ±0.1mm tolerances across production runs exceeding 500,000 units, with full material traceability from polymer batch to finished part.

Critical Performance Specifications Achieved

| Material Type | Hardness (Shore A) | Temp Range (°C) | Tensile Strength (MPa) | Compression Set (% @70°C/22h) | Ozone Resistance (pphm) |

|---|---|---|---|---|---|

| Custom EPDM | 55-75 | -55 to +150 | 8.5-12.0 | ≤15 | 50 (no cracking) |

| Advanced TPE | 60-80 | -45 to +135 | 6.0-9.5 | ≤25 | 100 (no cracking) |

OEM clients leverage our engineering infrastructure for rapid validation of design-for-manufacturability adjustments, accelerating time-to-market by 25%. We maintain ISO/TS 16949-certified processes with in-house labs for real-time durometer, specific gravity, and thermal analysis testing, ensuring 100% lot conformance. Suzhou Baoshida’s engineering synergy transforms weather seal challenges into competitive advantages through material innovation, precision tooling, and OEM-aligned execution. Partner with us to convert sealing performance into brand reliability.

Customization Process

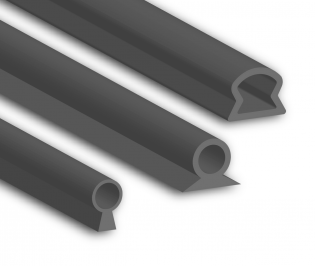

Drawing Analysis

The customization process for precision rubber weather window seals begins with comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering teams conduct a detailed review of customer-provided CAD files or technical drawings to verify dimensional accuracy, tolerance specifications, and functional requirements. This phase ensures compatibility with the intended window frame geometry, installation method, and environmental exposure conditions. Critical parameters such as cross-sectional profile, length tolerances, compression set requirements, and mating surface interface are evaluated. Any discrepancies or opportunities for design optimization are flagged and discussed with the client to align technical expectations before material selection proceeds. This step is essential to prevent costly revisions during later stages and ensures the final product delivers consistent sealing performance under real-world conditions.

Formulation Development

Following drawing validation, the rubber compound formulation is engineered to meet the specific performance demands of the application. Weather window seals are exposed to UV radiation, temperature extremes, moisture, ozone, and mechanical compression, necessitating a tailored elastomer solution. Our formulation engineers select base polymers—commonly EPDM for its superior weather resistance or silicone for extreme temperature stability—then optimize the additive package. This includes reinforcing fillers, vulcanizing agents, antioxidants, plasticizers, and pigments to achieve target hardness (Shore A), tensile strength, elongation at break, and low-temperature flexibility. The formulation is also designed to ensure compatibility with adjacent materials such as glass, aluminum, or painted surfaces to prevent staining or adhesion issues. Each compound is documented and batch-controlled to guarantee repeatability across production cycles.

Prototyping and Validation

Once the formulation is finalized, prototype seals are produced using precision extrusion and splicing techniques. These prototypes are subjected to rigorous in-house testing, including compression deflection analysis, accelerated aging (heat, UV, humidity), and air/water infiltration testing under simulated installation conditions. Dimensional inspection is performed using coordinate measuring machines (CMM) to confirm conformity to the original drawing. Prototype feedback is shared with the client for fit, form, and function evaluation. Adjustments to material or geometry are implemented as needed, ensuring optimal performance prior to scale-up.

Mass Production

After prototype approval, the project transitions to mass production. Utilizing automated extrusion lines, high-frequency splicers, and inline quality monitoring systems, we maintain tight control over consistency and throughput. Each production batch undergoes statistical process control (SPC), with material certificates and test reports provided. Logistics and packaging are customized to protect the seals during transit and facilitate OEM assembly line integration.

| Property | Typical Value | Test Standard |

|---|---|---|

| Hardness (Shore A) | 60 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 9 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤ 25% | ASTM D395 |

| Operating Temperature | -40°C to +135°C | Internal Protocol |

| Specific Gravity | 1.35 ± 0.05 | ASTM D297 |

Contact Engineering Team

Technical Collaboration for Precision Weather Window Seals: Partner with Suzhou Baoshida

Achieving optimal performance and longevity in automotive and architectural weather window seals demands more than standard elastomer compounds; it requires engineered material science solutions tailored to specific environmental stressors and dimensional tolerances. At Suzhou Baoshida Trading Co., Ltd., we operate at the intersection of advanced rubber formulation and precision manufacturing, serving global OEMs with mission-critical sealing components. Our expertise spans EPDM, silicone, and specialty fluoroelastomers, rigorously tested to exceed industry benchmarks for compression set, ozone resistance, and thermal stability under continuous exposure. Generic seal solutions often fail prematurely due to inadequate material selection or inconsistent production control, leading to costly field failures, warranty claims, and reputational damage. We mitigate these risks through collaborative development, where our engineering team works directly with your design specifications to formulate compounds that address unique challenges like extreme temperature cycling, chemical exposure, or stringent acoustic requirements. This proactive partnership ensures the final seal integrates seamlessly into your assembly process while delivering decades of reliable service life.

Our manufacturing infrastructure adheres strictly to ISO 9001 and IATF 16949 standards, featuring computer-controlled extrusion lines, multi-cavity molding presses with real-time process monitoring, and comprehensive in-house laboratory validation. Every batch undergoes rigorous quality assurance protocols, including Shore A hardness verification, tensile strength testing, and accelerated aging simulations per ASTM D2000 and SAE J2236 standards. The table below summarizes critical performance parameters achievable with our optimized formulations for weather window applications:

| Property | Test Standard | Typical Performance Range | Significance for Weather Seals |

|---|---|---|---|

| Compression Set (70h, 70°C) | ASTM D395 | ≤ 15% | Critical for maintaining sealing force over time; prevents leaks |

| Tensile Strength (MPa) | ASTM D412 | 8.0 – 12.0 | Ensures durability during installation and service |

| Elongation at Break (%) | ASTM D412 | 250 – 400 | Accommodates window movement without fracture |

| Temperature Range (°C) | ISO 188 | -50 to +150 | Guarantees flexibility in extreme climates |

| Ozone Resistance (50 pphm) | ASTM D1149 | No cracks (200h) | Prevents surface cracking in polluted atmospheres |

| Shore A Hardness | ASTM D2240 | 60 ± 5 | Balances sealing pressure with ease of assembly |

Initiating technical collaboration with Suzhou Baoshida begins with a detailed review of your application requirements, environmental exposure profiles, and dimensional constraints. Our engineering team, led by Mr. Boyce, specializes in translating complex OEM specifications into validated rubber formulations and production-ready tooling solutions. Mr. Boyce possesses over 15 years of experience in automotive sealing systems and maintains direct oversight of all critical client projects from material development through PPAP submission. He is your dedicated technical liaison for resolving material compatibility issues, optimizing cost-in-use through compound refinement, and ensuring seamless integration into your supply chain. Do not compromise on a component where material integrity directly impacts end-user safety and satisfaction. Contact Mr. Boyce directly via email at [email protected] to schedule a technical consultation. Provide your specific performance targets, dimensional drawings, and environmental conditions; our team will respond within 24 business hours with a preliminary material recommendation and feasibility assessment. Partner with Suzhou Baoshida for precision-engineered weather seals where scientific rigor meets industrial reliability. Your next-generation sealing solution starts with a technical dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).