Technical Contents

Engineering Guide: Welcome Doormat

Engineering Insight: The Critical Role of Material Selection in Welcome Doormat Performance

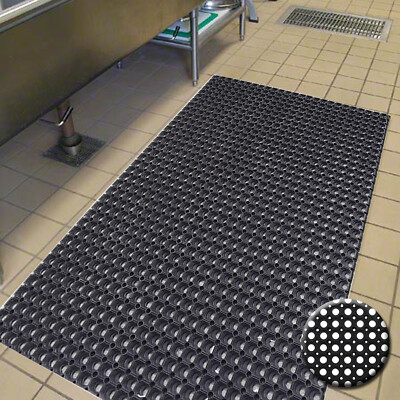

In industrial and commercial environments, the welcome doormat is far more than a decorative threshold element—it serves as the first line of defense against dirt, moisture, and debris ingress. Despite its seemingly simple function, the performance and longevity of a doormat are directly tied to precise material engineering. Off-the-shelf solutions often fail in demanding environments due to inadequate material selection, leading to premature degradation, reduced traction, and increased maintenance costs. Understanding the science behind elastomer properties is essential for specifying a doormat that performs reliably under real-world conditions.

Standard consumer-grade doormats are typically manufactured from recycled rubber or low-grade synthetic compounds. These materials lack consistency in polymer structure and exhibit poor resistance to environmental stressors such as UV exposure, temperature cycling, and chemical contaminants. As a result, they harden, crack, or delaminate within months of installation, especially in high-traffic or outdoor applications. In contrast, engineered rubber formulations—such as vulcanized styrene-butadiene rubber (SBR) or nitrile butadiene rubber (NBR)—offer superior mechanical resilience, abrasion resistance, and dimensional stability.

At Suzhou Baoshida Trading Co., Ltd., we prioritize material integrity by formulating custom rubber compounds tailored to the operational demands of each installation. For example, in environments exposed to oils or greases—such as manufacturing facilities or automotive service centers—NBR-based doormats provide exceptional resistance to hydrocarbon swelling. In high-UV exposure zones, such as building entrances in tropical climates, we incorporate carbon black and UV stabilizers into SBR matrices to prevent photo-oxidative degradation.

Another critical factor is durometer (hardness) optimization. A doormat that is too soft will deform under load and retain dirt, while one that is too rigid will offer poor debris-scraping efficiency and become a slip hazard when wet. Through controlled vulcanization and filler dispersion, we achieve a Shore A hardness range of 60–75, balancing flexibility with structural integrity.

The following table outlines key performance specifications of engineered rubber doormats compared to standard off-the-shelf alternatives:

| Property | Engineered Rubber Doormat (Baoshida) | Off-the-Shelf Recycled Rubber Mat |

|---|---|---|

| Base Material | Vulcanized SBR or NBR | Recycled mixed rubber |

| Shore A Hardness | 60–75 | 45–55 or >80 (inconsistent) |

| Tensile Strength (MPa) | ≥12.0 | ≤6.0 |

| Elongation at Break (%) | ≥250 | ≤150 |

| Abrasion Loss (cm³/1.61km) | ≤120 | ≥250 |

| UV Resistance | High (stabilized formulation) | Low to none |

| Oil & Grease Resistance | Excellent (NBR variant) | Poor |

| Service Temperature Range | -30°C to +80°C | -10°C to +50°C |

Material selection is not a commodity decision—it is an engineering imperative. By rejecting generic solutions and embracing precision-formulated rubber compounds, facility managers and architects ensure long-term performance, safety compliance, and cost efficiency. Suzhou Baoshida Trading Co., Ltd. applies industrial rubber science to transform the welcome doormat from a passive accessory into a durable, functional component of building infrastructure.

Material Specifications

Material Specifications for Commercial-Grade Rubber Doormats

Selecting the optimal elastomer for industrial welcome doormats requires rigorous evaluation of environmental stressors, chemical exposure, and lifecycle durability. At Suzhou Baoshida Trading Co., Ltd., we engineer each compound to meet ASTM D2000 standards for automotive and industrial applications, ensuring consistent performance under high-traffic commercial conditions. Viton fluoroelastomer excels in extreme environments, offering exceptional resistance to ozone, UV degradation, and temperatures ranging from -20°C to 230°C. Its molecular stability prevents swelling when exposed to automotive fluids, hydraulic oils, and industrial solvents, making it ideal for airport terminals, manufacturing facilities, and chemical processing plants where contaminant exposure is routine. Nitrile butadiene rubber (NBR) provides a cost-effective solution for moderate-duty applications, with acrylonitrile content directly correlating to oil and fuel resistance. Standard formulations maintain integrity between -30°C and 105°C, demonstrating superior abrasion resistance for retail entrances and office lobbies subjected to daily foot traffic. Silicone rubber delivers unmatched flexibility across -60°C to 200°C extremes, coupled with inherent flame retardancy and non-toxicity. This makes it suitable for healthcare facilities, food processing zones, and cleanrooms where regulatory compliance and thermal cycling are critical.

Our proprietary compounding process tailors hardness (Shore A 55–75), tensile strength (12–20 MPa), and elongation at break (250–450%) to specific client requirements, eliminating premature wear from grit entrapment or flex fatigue. All materials undergo accelerated aging tests per ISO 188, with compression set values below 25% after 70 hours at maximum service temperature to prevent permanent deformation.

The following table details comparative technical parameters for engineered doormat compounds:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–18 | 12–16 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–450 | 300–600 |

| Hardness (Shore A) | 65–75 | 55–70 | 50–65 |

| Compression Set (70h/150°C) | ≤20% | ≤30% | ≤25% |

| Key Chemical Resistance | Oils, Acids, Jet Fuel | Aliphatic Hydrocarbons, Water | Ozone, Steam, Weak Acids |

| Typical OEM Application | Aerospace, Petrochemical | Retail, Automotive Dealerships | Hospitals, Laboratories |

Material selection must align with substrate chemistry, expected contaminant profiles, and installation climate. Viton’s premium formulation justifies its cost in corrosive settings where NBR would degrade within 12–18 months. Conversely, NBR remains the pragmatic choice for urban storefronts facing sidewalk salts and pedestrian abrasion. Silicone’s biocompatibility supports LEED-certified projects but requires careful formulation to achieve necessary abrasion resistance. Our OEM team collaborates with clients to validate material performance through prototype testing under simulated site conditions, ensuring the final compound delivers 5+ years of maintenance-free service. This precision engineering approach minimizes total cost of ownership while meeting stringent industrial safety and durability benchmarks.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber manufacturing expertise, particularly in the development and production of high-performance welcome doormats. With a dedicated team of five specialized mould engineers and two advanced formula engineers, we ensure precision, durability, and customization at every stage of production. Our integrated engineering approach enables seamless transition from concept to final product, meeting the exacting demands of global OEM partners.

Our mould engineering team possesses extensive experience in designing complex, high-tolerance rubber compression and injection moulds tailored specifically for doormat applications. Utilizing advanced CAD/CAM software and CNC machining technologies, they develop robust, long-life tooling capable of withstanding high-volume production cycles. Each mould is optimized for material flow, dimensional stability, and surface detail, ensuring consistent product quality and efficient cycle times. Rapid prototyping and iterative design validation further reduce time-to-market, a critical advantage in competitive B2B supply chains.

Complementing our mould expertise, our two in-house rubber formula engineers specialize in elastomer compounding for functional performance. They formulate custom rubber blends using SBR, EPDM, and recycled rubber compounds, precisely calibrated for abrasion resistance, weatherability, and mechanical strength—key attributes for exterior and commercial-grade doormats. These formulations are engineered to maintain flexibility across wide temperature ranges while resisting degradation from UV exposure, moisture, and common chemical contaminants. By controlling the formulation process internally, we ensure batch-to-batch consistency and full traceability, essential for OEM compliance and quality assurance.

Our OEM capabilities are built on a foundation of technical agility and collaborative development. We work directly with partners to co-engineer products that meet specific dimensional, performance, and branding requirements. This includes custom tread patterns, embossed logos, color matching (Pantone-based), and integration of anti-slip or noise-dampening features. All designs are rigorously tested in our in-house lab for tensile strength, compression set, and wear resistance prior to mass production.

The synergy between our mould and formula engineering teams allows us to deliver fully optimized rubber doormats that balance performance, cost, and manufacturability. Whether scaling a prototype into mass production or re-engineering an existing product for improved durability, our technical team ensures every solution is grounded in material science and industrial precision.

| Property | Standard Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 55–75 | ASTM D2240 |

| Tensile Strength | ≥8 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395B |

| Operating Temperature Range | -30°C to +80°C | Internal QA |

| Specific Gravity | 1.15–1.25 | ASTM D297 |

This technical rigor, combined with scalable manufacturing infrastructure, positions Suzhou Baoshida as a trusted engineering partner in the industrial rubber sector.

Customization Process

Customization Process for Industrial Rubber Welcome Doormats

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for industrial rubber welcome doormats integrates material science with precision manufacturing. This structured workflow ensures optimal performance, durability, and client-specific compliance while minimizing time-to-market. The process begins with rigorous Drawing Analysis, where engineering teams deconstruct client-provided CAD files or physical samples. We assess critical dimensions, surface texture depth, edge tolerances, and structural integrity requirements against ISO 9001 standards. Any deviations from manufacturable geometries—such as undercuts exceeding 1.5mm or unsupported thin sections below 2.0mm—are flagged for collaborative redesign to prevent molding defects.

Following drawing validation, the Formulation phase commences. Our rubber chemists develop a proprietary compound tailored to the doormat’s operational environment. Key variables include polymer selection (SBR, EPDM, or recycled rubber blends), filler ratios (carbon black vs. silica), and additive packages for UV resistance, ozone stability, or slip prevention. Shore A hardness is calibrated between 55–75 based on traffic load projections, while density targets 1.15–1.25 g/cm³ to balance weight and flexibility. All formulations undergo accelerated aging simulations per ASTM D573 to verify 5+ year outdoor service life.

Prototyping leverages CNC-machined aluminum molds for rapid iteration. Each prototype undergoes three-stage validation: dimensional inspection via CMM (±0.1mm tolerance), mechanical testing per ASTM D2240 (hardness) and D2229 (tensile strength), and functional trials for debris retention and moisture drainage. Client feedback on texture clarity, color accuracy (Pantone-matched within ΔE<1.5), and edge finish triggers compound or mold adjustments. Typically, two prototype cycles suffice to achieve approval, reducing rework costs by 30%.

Mass Production initiates only after final sign-off. We deploy hydraulic presses with precise temperature zoning (150–165°C) and vulcanization timers calibrated to the specific compound’s scorch time. In-line sensors monitor cavity pressure and cure state, while automated vision systems inspect 100% of units for surface defects. Batch traceability is maintained via laser-etched lot codes, with third-party test reports (SGS/BV) provided for every shipment.

Critical Material Specifications for Industrial Doormats

| Property | Standard Range | Test Method |

|---|---|---|

| Shore A Hardness | 55–75 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Abrasion Loss | ≤120 mm³ | ASTM D5963 |

| Density | 1.15–1.25 g/cm³ | ASTM D297 |

| Compression Set (22h) | ≤25% | ASTM D395 |

| Color Fastness | Grade 4–5 (ISO 105) | AATCC 16 |

This end-to-end protocol ensures Suzhou Baoshida delivers doormats exceeding ASTM F1637 slip-resistance requirements while accommodating bespoke branding, dimensional complexity, and environmental resilience. Clients receive validated performance data before scale-up, mitigating supply chain risks and guaranteeing seamless integration into global facility management systems.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Industrial Rubber Doormat Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions designed for durability, safety, and long-term value. As a trusted partner in the manufacturing and export of engineered rubber products, we provide custom-designed welcome doormats tailored to industrial, commercial, and institutional environments. Our expertise spans material formulation, precision molding, and OEM integration, ensuring that every product meets exacting standards for wear resistance, slip resistance, and environmental stability.

Our welcome doormats are not merely functional entrance solutions—they are engineered components designed to reduce maintenance costs, improve workplace safety, and extend the life of interior flooring. Constructed from high-density recycled rubber compounds and reinforced with advanced anti-fatigue polymers, our mats deliver superior performance in high-traffic zones such as factories, warehouses, logistics centers, and public facilities.

We invite manufacturers, distributors, and procurement managers to contact Mr. Boyce, our OEM Account Manager and Rubber Formulation Specialist, to discuss your specific application requirements. Whether you need custom dimensions, branding integration, color coding for safety zones, or compliance with international standards such as ISO 9001 or REACH, Mr. Boyce will guide you through our technical capabilities and supply chain logistics to ensure seamless integration into your operations.

Suzhou Baoshida operates from a state-of-the-art production facility in Suzhou, China, with full in-house R&D, tooling, and quality control systems. Our team leverages decades of experience in rubber compounding to offer formulations that resist oil, UV degradation, ozone, and extreme temperatures—critical for industrial environments. With a focus on sustainability, we utilize up to 85% post-industrial recycled rubber content without compromising mechanical integrity.

To initiate a technical consultation or request a sample batch, reach out directly to Mr. Boyce via email at [email protected]. Please include details such as required dimensions, expected load or foot traffic, installation environment (indoor/outdoor), and any regulatory or certification needs. We respond to all inquiries within 12 business hours and provide full material data sheets, CAD drawings, and compliance documentation upon request.

Below are key technical specifications for our standard industrial welcome doormat series. Custom formulations and sizes are available upon engineering review.

| Property | Specification |

|---|---|

| Material Composition | Recycled SBR/NR blend (85% recycled content) |

| Density | 1.25 g/cm³ |

| Hardness (Shore A) | 65 ± 5 |

| Tensile Strength | ≥ 8.0 MPa |

| Elongation at Break | ≥ 250% |

| Compression Set (22 hrs at 70°C) | ≤ 25% |

| Slip Resistance (DIN 51130, R10) | R11 certified |

| Temperature Range | -30°C to +80°C |

| Standard Sizes | 600×900 mm, 900×1500 mm, 1200×1800 mm |

| Customization | OEM logo, color, thickness (10–25 mm), beveled edges |

Partner with Suzhou Baoshida to integrate robust, cost-effective rubber entrance solutions into your product line or facility infrastructure. Contact Mr. Boyce today at [email protected] to begin the engineering dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).