Technical Contents

Engineering Guide: Window Pans

Engineering Insight: The Critical Role of Material Selection in Window Pan Applications

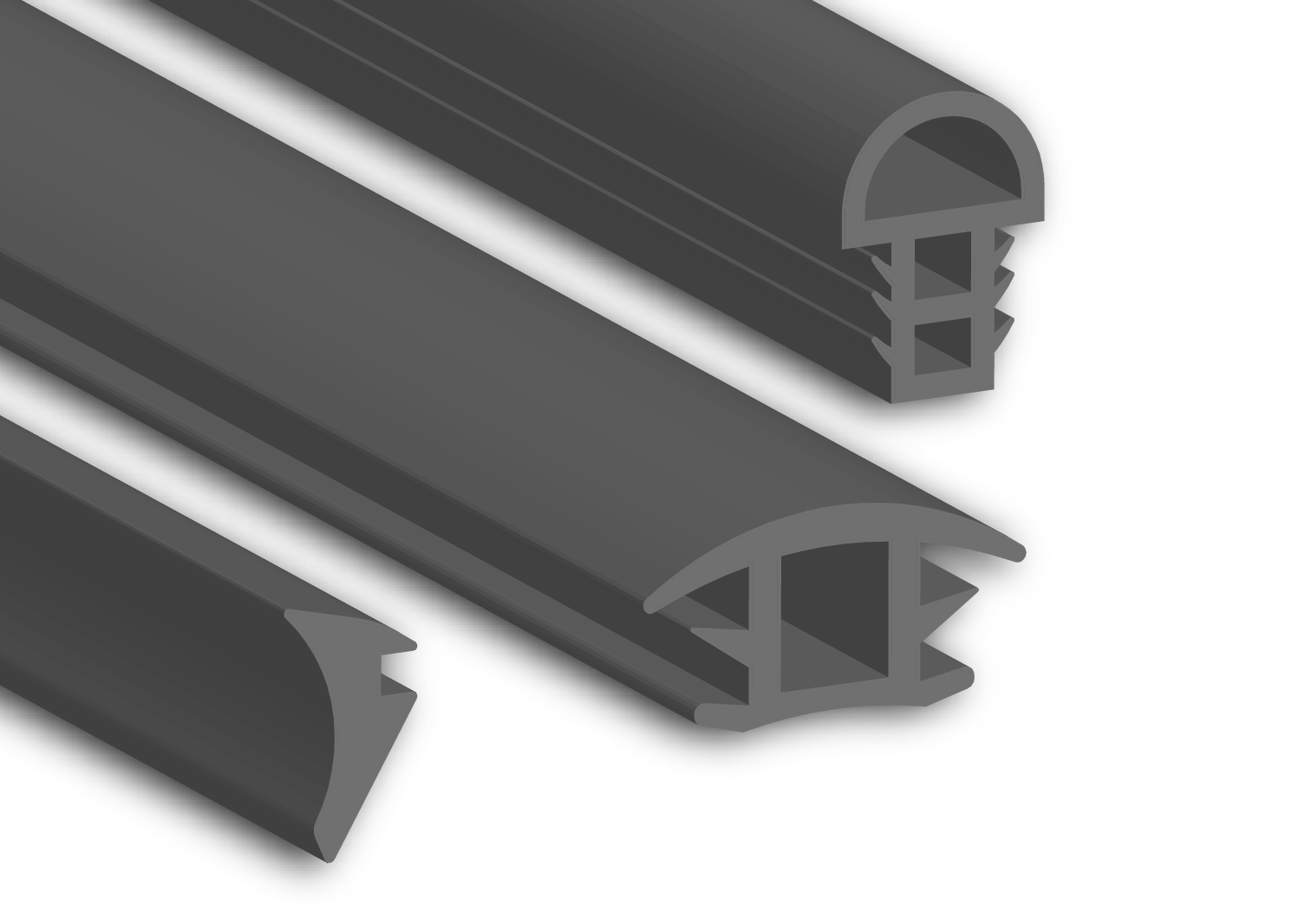

In industrial sealing applications, the term “window pans” refers to precision-engineered rubber components designed to support, seal, and protect transparent panels in enclosures, control systems, and protective housings. These components are commonly deployed in harsh environments including outdoor instrumentation, transportation systems, and industrial automation equipment. Despite their seemingly simple form, window pans are subjected to complex stress profiles involving compression, thermal cycling, UV exposure, and chemical attack. As such, the performance and longevity of these parts are directly tied to the precision of material selection—an aspect where off-the-shelf rubber solutions consistently underperform.

Standard rubber profiles are typically formulated for general-purpose use, prioritizing cost-efficiency over environmental resilience. These compounds often lack the tailored polymer architecture required to maintain sealing integrity under sustained mechanical load or fluctuating temperatures. For example, a generic EPDM profile may exhibit adequate UV resistance but fail prematurely due to compression set in high-humidity environments. Similarly, a low-cost silicone compound may offer thermal stability but lack the tensile strength required for long-term retention in dynamic assemblies.

At Suzhou Baoshida Trading Co., Ltd., we approach window pan engineering through a material-first methodology. Each formulation is developed in alignment with the operational parameters of the end application. Key considerations include glass transition temperature (Tg), Shore A hardness, elongation at break, and resistance to ozone, water ingress, and industrial fluids. Our proprietary blends of silicone, fluorosilicone, and specialty EPDM are engineered to meet exacting OEM specifications, ensuring dimensional stability and consistent sealing force over extended service life.

The failure of generic solutions often manifests in micro-leakage, delamination, or extrusion under pressure—issues that compromise not only the integrity of the enclosure but also the reliability of the entire system. In contrast, custom-formulated compounds provide predictable performance across temperature extremes, resist degradation from cleaning agents and atmospheric pollutants, and maintain elasticity over thousands of thermal cycles.

Material performance data for selected compounds used in our window pan manufacturing is summarized below:

| Material | Hardness (Shore A) | Temp Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Resistance Properties |

|---|---|---|---|---|---|

| High-Purity Silicone | 50 ±5 | -60 to +200 | 8.5 | 450 | UV, ozone, steam, low-temp flexibility |

| Fluorosilicone | 60 ±5 | -20 to +175 | 7.0 | 300 | Fuels, oils, solvents, moderate heat |

| Modified EPDM | 55 ±5 | -50 to +150 | 9.2 | 400 | Water, steam, ozone, weathering |

| Nitrile (HNBR) | 70 ±5 | -30 to +135 | 10.5 | 350 | Abrasion, oils, compressed air, mechanical stress |

These formulations are validated through accelerated aging tests, compression set analysis per ASTM D395, and real-world simulation under OEM load conditions. The result is a window pan solution that integrates seamlessly into high-reliability systems—where failure is not an option.

Material Specifications

Material Specifications for Industrial Window Channel Seals

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber solutions for window channel seals in demanding industrial applications. These components require stringent material properties to ensure long-term sealing integrity against environmental stressors including temperature extremes, UV exposure, chemical contact, and mechanical compression. Our technical team rigorously qualifies Viton, Nitrile, and Silicone formulations against OEM performance benchmarks, prioritizing dimensional stability, compression set resistance, and fluid compatibility. Each material serves distinct operational environments, necessitating data-driven selection based on application-specific stress factors.

Viton fluoroelastomers (FKM) deliver exceptional resistance to automotive fluids, fuels, and high-temperature degradation. Standard grades withstand continuous service from -20°C to 230°C, with specialty compounds extending to 300°C. Viton exhibits low compression set (≤25% per ASTM D395 after 70 hrs at 200°C) and tensile strength of 12–18 MPa, making it ideal for engine compartment window seals exposed to biodiesel or hydraulic fluids. However, its higher cost necessitates justification through extreme chemical exposure requirements.

Nitrile rubber (NBR) remains the cost-optimized solution for general-purpose window channels requiring oil and abrasion resistance. Standard formulations operate effectively between -30°C and 120°C, with acrylonitrile content dictating fuel resistance. High-acrylonitrile NBR (45–50%) achieves tensile strength of 20–25 MPa and elongation at break of 300–450%, suitable for door seals in commercial vehicles. Its limitation lies in poor ozone resistance and reduced flexibility below -40°C, requiring protective additives for harsh climates.

Silicone rubber (VMQ) dominates applications demanding extreme temperature resilience and UV stability. It maintains functionality from -60°C to 200°C (specialty grades to 230°C), with elongation exceeding 400% and minimal compression set (≤20% per ASTM D395 at 150°C). Silicone’s inert composition ensures compliance with food-grade and medical standards, though its lower tensile strength (6–9 MPa) and susceptibility to tear propagation require careful profile design for structural window frames.

Material Performance Comparison for Window Channel Seals

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness Range (Shore A) | Key Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 12–18 | 150–250 | 60–90 | Automotive fuel-exposed seals, aerospace glazing, chemical processing equipment |

| Nitrile (NBR) | -30 to 120 | 20–25 | 300–450 | 50–90 | Commercial vehicle door seals, hydraulic machinery glazing, general industrial windows |

| Silicone (VMQ) | -60 to 200 | 6–9 | 400–600 | 30–80 | Architectural curtain walls, medical/lab equipment windows, extreme-climate transportation |

Suzhou Baoshida’s OEM partnerships leverage this material science foundation to optimize seal performance. We validate all compounds per ASTM D2000 classification codes, ensuring traceability to international standards. Final material selection must account for dynamic stress factors including cyclic compression, media exposure duration, and regulatory compliance requirements specific to the end-use industry. Our engineering team provides application-specific compound tailoring to meet exacting dimensional and functional tolerances.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber manufacturing expertise, particularly in the design and production of high-performance window pans for demanding applications. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver technically advanced, application-specific solutions under a robust OEM framework. This integrated engineering approach ensures precision, repeatability, and compliance with the strict functional requirements of automotive, construction, and industrial sealing systems.

Our mould engineers bring extensive experience in the design, simulation, and optimization of rubber compression, transfer, and injection moulds. Utilizing advanced CAD/CAM software and finite element analysis (FEA), they develop moulds with precise cavity geometry, optimal venting, and efficient runner systems to minimize flash and ensure consistent part quality. Each window pan design is evaluated for material flow, shrinkage behavior, and ejection dynamics to support high-volume production with minimal scrap rates. The team also conducts Design for Manufacturability (DFM) reviews to align client specifications with production feasibility, reducing time-to-market and tooling costs.

Complementing this capability are our two in-house rubber formula engineers, who specialize in developing custom elastomer compounds tailored to the performance demands of window pan applications. These include resistance to UV degradation, compression set, temperature extremes (-40°C to +120°C), and long-term sealing integrity. By formulating with EPDM, silicone, and specialty synthetic rubbers, we ensure material compatibility with glass, metal frames, and environmental exposure. Our formulation process includes rigorous lab-scale mixing, cure kinetics analysis, and physical property validation to meet OEM material specifications such as ASTM D2000 or customer-specific standards.

Our OEM capabilities are built on a foundation of technical collaboration. From initial concept to mass production, we work closely with clients to co-develop window pan designs that integrate seamlessly into final assemblies. This includes tolerance analysis, prototype sampling, and process validation using Statistical Process Control (SPC). All engineering data, including 3D models, material certifications, and test reports, are fully documented and transferable, ensuring traceability and compliance.

The following table outlines key engineering specifications and capabilities relevant to our window pan manufacturing process:

| Parameter | Specification/Range |

|---|---|

| Mould Design Software | SolidWorks, AutoCAD, Moldflow |

| Rubber Compounding Capacity | 50–500 Shore A hardness |

| Standard Elastomers | EPDM, Silicone, NBR, CR |

| Temperature Resistance | -40°C to +150°C (depending on compound) |

| Tolerance Control | ±0.1 mm (critical dimensions) |

| Tooling Lead Time | 4–6 weeks (standard moulds) |

| Prototype Turnaround | 2–3 weeks |

| OEM Documentation Support | Full DFM, PPAP, IMDS, 3D Drawings |

This convergence of mould engineering, material science, and OEM integration enables Suzhou Baoshida to deliver window pans that meet the highest standards of performance, durability, and manufacturability.

Customization Process

Customization Process for Industrial Rubber Window Seals

At Suzhou Baoshida Trading Co., Ltd., our engineering-driven customization process ensures optimal performance and manufacturability for industrial rubber window seals. We rigorously translate client specifications into high-integrity components through four integrated phases, minimizing iteration and accelerating time-to-market.

Drawing Analysis initiates the workflow. Our engineering team conducts a comprehensive technical review of client CAD drawings and specifications against material science principles and manufacturing capabilities. Critical parameters including dimensional tolerances, cross-sectional geometry, sealing surface requirements, and interface points are validated. We identify potential stress concentrations, draft angles for molding, and material flow considerations early. This phase involves joint review sessions with the client to resolve ambiguities, confirm environmental exposure factors (UV, ozone, temperature extremes), and establish clear acceptance criteria before proceeding. Precise interpretation at this stage prevents costly downstream modifications.

Formulation Development leverages our deep expertise in polymer chemistry. Based on the validated drawing requirements and environmental profile, our rubber formula engineers select the optimal base polymer system—typically EPDM for general automotive/architectural use, silicone for extreme temperatures, or specialty blends for chemical resistance. Key properties like hardness (Shore A), tensile strength, elongation, compression set, and fluid resistance are targeted. The formulation is meticulously balanced, incorporating fillers, plasticizers, curatives, and stabilizers to achieve the precise performance envelope. Material selection is critical for long-term seal integrity under operational stress.

Material Property Comparison for Window Seals

| Material Type | Temperature Range (°C) | Typical Hardness (Shore A) | Key Performance Attributes | Primary Applications |

|---|---|---|---|---|

| Standard EPDM | -50 to +150 | 50 – 75 | Excellent weather/ozone resistance, good compression set | Standard automotive glazing, architectural windows |

| High-Performance EPDM | -55 to +160 | 60 – 80 | Enhanced fluid resistance, lower compression set | Premium automotive, marine glazing |

| Liquid Silicone Rubber (LSR) | -60 to +200 | 30 – 80 | Extreme temp stability, biocompatibility, high purity | Specialty transport, cleanroom windows |

Prototyping & Validation utilizes precision tooling to produce functional samples. Prototypes undergo rigorous in-house testing per ISO 37 (tensile), ISO 815 (compression set), and client-specific protocols including simulated weathering (QUV), thermal cycling, and dynamic seal performance checks. Dimensional verification via CMM ensures conformity to the approved drawing. Client feedback on prototype fit, function, and aesthetics is incorporated, with formulation or tooling adjustments made only if essential. This phase provides tangible proof of concept and de-risks full-scale production.

Mass Production Execution commences only after formal client sign-off on prototypes and PPAP documentation. We deploy automated extrusion and curing lines under strict ISO 9001-controlled conditions. Real-time process monitoring tracks key parameters like temperature profiles, line speed, and cure state. Every production batch undergoes stringent first-article and in-process inspections for dimensional accuracy, physical properties, and surface quality. Comprehensive traceability to raw material batch level is maintained. Our integrated quality management system ensures consistent output meeting the exact specifications validated during prototyping, enabling seamless transition to volume supply for global OEMs.

Contact Engineering Team

For precision-engineered rubber components tailored to the demanding requirements of window panel (window pans) manufacturing, Suzhou Baoshida Trading Co., Ltd. stands as a trusted industrial partner. With deep expertise in rubber formulation and OEM manufacturing, we deliver high-performance sealing, damping, and weatherproofing solutions that ensure structural integrity, acoustic insulation, and long-term durability in modern window systems. Our engineered rubber profiles, gaskets, and integrated seals are designed to meet exact dimensional, thermal, and compression load specifications across residential, commercial, and industrial applications.

At Suzhou Baoshida, we specialize in custom rubber compounds—including EPDM, silicone, neoprene, and thermoplastic elastomers—formulated for optimal UV resistance, ozone stability, and low-temperature flexibility. Each solution is developed in alignment with global building standards and OEM performance benchmarks. Our in-house R&D team collaborates directly with clients to fine-tune material properties such as hardness, tensile strength, and compression set, ensuring seamless integration into window pan assembly lines.

The following table outlines typical rubber specifications used in window pan applications:

| Property | EPDM | Silicone | Neoprene | TPE |

|---|---|---|---|---|

| Hardness (Shore A) | 40–90 | 30–80 | 40–85 | 50–95 |

| Temperature Range (°C) | -50 to +150 | -60 to +200 | -40 to +120 | -40 to +135 |

| Tensile Strength (MPa) | 8–18 | 5–12 | 10–16 | 12–20 |

| Elongation at Break (%) | 200–600 | 200–500 | 250–500 | 300–800 |

| Compression Set (22h, 100°C) | 15–35% | 10–25% | 20–40% | 25–50% |

| Key Features | Excellent weathering resistance, low water absorption | High thermal stability, flexibility at low T | Good flame resistance, moderate weathering | Recyclable, fast processing, design flexibility |

All materials are subject to rigorous quality control under ISO 9001 standards, with full traceability and batch testing. We support clients through prototyping, tooling development, and scalable production runs, ensuring on-time delivery and consistent part performance.

To discuss your window pan rubber solution requirements, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads technical client engagement, bringing over 12 years of experience in polymer science and industrial sealing applications. He provides direct engineering support for material selection, DFM optimization, and compliance documentation.

Reach out via email at [email protected] to initiate a technical consultation. Include your project specifications, performance targets, and production volume estimates to receive a tailored material recommendation and quotation. Our team responds to all inquiries within 24 business hours. For urgent requests, indicate “Priority Engineering Review” in the subject line.

Suzhou Baoshida is committed to advancing rubber technology in architectural systems. Partner with us to achieve superior sealing performance, reduced assembly complexity, and enhanced product lifecycle in your window pan manufacturing process.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).