Technical Contents

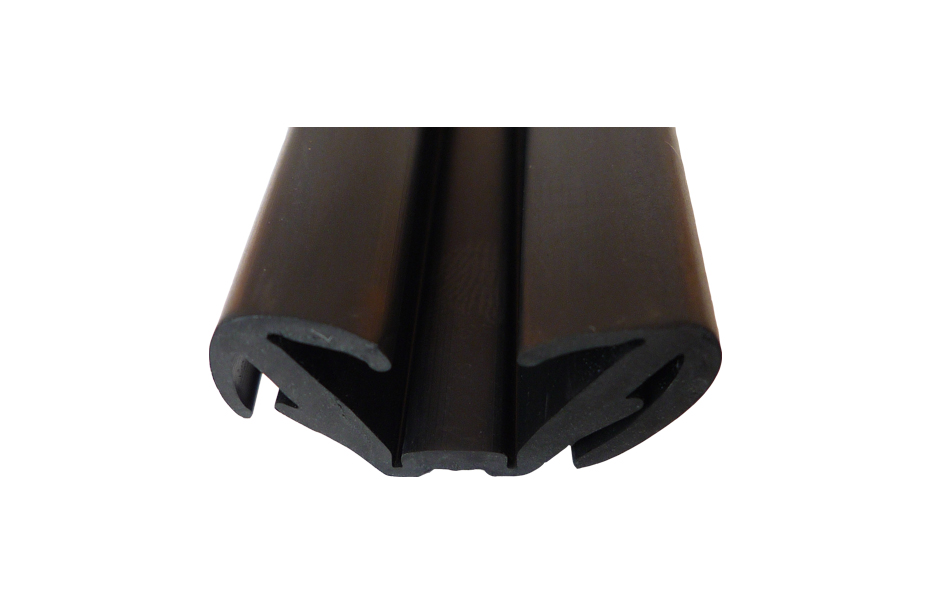

Engineering Guide: Window Run Channel

Engineering Insight: Material Selection for Window Run Channel Performance

The window run channel serves as the critical interface between automotive glass and the vehicle body, demanding exceptional material resilience under dynamic operational stresses. Off-the-shelf rubber solutions frequently fail due to generic formulations that ignore the precise interplay of mechanical, thermal, and chemical factors inherent in this application. Standard compounds prioritize cost over performance, leading to premature degradation through ozone cracking, compression set, or loss of elasticity. These failures manifest as wind noise, water ingress, and inconsistent window motion—directly compromising vehicle NVH (Noise, Vibration, Harshness) standards and end-user satisfaction.

Material selection must address four non-negotiable criteria: sustained elasticity across extreme temperatures (-40°C to +120°C), resistance to automotive fluids (oils, waxes, cleaners), ozone/UV stability, and low-friction surface properties. Thermoplastic elastomers (TPEs) often marketed as “universal” alternatives exhibit inferior resilience under continuous compression, hardening after 5,000–10,000 cycles. Conversely, precision-engineered EPDM (Ethylene Propylene Diene Monomer) compounds with tailored filler systems maintain dimensional stability beyond 100,000 cycles. The critical differentiator lies in polymer cross-link density and antioxidant package sophistication—elements absent in commodity-grade materials.

Suzhou Baoshida’s OEM-grade window run channels utilize proprietary EPDM formulations validated through accelerated aging per SAE J2236. Our compounds integrate nano-silica reinforcement and custom vulcanization systems to achieve optimal balance between tensile strength and elongation. This prevents the “set” that causes channel collapse during window retraction—a common failure in off-spec materials. Crucially, surface energy modification ensures consistent coefficient of friction (0.25–0.35 against tempered glass) without silicone migration, eliminating squeak issues that plague cheaper alternatives.

The table below compares critical performance metrics between standard and engineered solutions:

| Property | Standard TPE Compound | Baoshida Engineered EPDM | Test Standard |

|---|---|---|---|

| Tensile Strength (MPa) | 8.5 | 14.2 | ASTM D412 |

| Elongation at Break (%) | 350 | 520 | ASTM D412 |

| Compression Set (70°C/22h) | 38% | 12% | ASTM D395 |

| Ozone Resistance (50pphm) | Cracks at 20h | Zero cracks at 100h | ASTM D1149 |

| Operating Temp Range (°C) | -30 to +100 | -45 to +130 | ISO 188 |

Generic channels sacrifice long-term performance for short-term cost savings, inevitably increasing warranty claims and brand reputational risk. At Suzhou Baoshida, we engineer materials to OEM specifications—not merely to meet datasheets, but to exceed real-world service life requirements. Our collaborative development process integrates vehicle-specific load profiles, environmental exposure data, and glass interface dynamics to deliver channels that maintain sealing integrity across 15+ years of operational stress. This precision eliminates the false economy of off-the-shelf alternatives, ensuring seamless integration with modern automotive assembly tolerances and durability expectations.

Material Specifications

Material selection is a critical factor in the performance and longevity of window run channels in automotive and industrial applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-precision rubber extrusion solutions tailored to meet rigorous OEM standards. Our expertise in industrial rubber compounds ensures optimal sealing, durability, and resistance to environmental stressors across diverse operating conditions. Among the most widely used elastomers for window run channels are Viton, Nitrile (NBR), and Silicone, each offering distinct performance characteristics suited to specific application requirements.

Viton, a fluorocarbon-based rubber (FKM), delivers exceptional resistance to high temperatures, oils, fuels, and ozone. With a continuous service temperature range up to 230°C, Viton is ideal for automotive environments exposed to engine heat or aggressive chemical agents. Its low compression set and excellent aging properties make it suitable for long-term sealing applications where reliability is paramount. However, due to its higher material cost, Viton is typically reserved for premium or high-performance vehicle systems.

Nitrile rubber (NBR) remains one of the most cost-effective and widely adopted materials for window run channels. It exhibits strong resistance to petroleum-based oils and fuels, making it well-suited for standard automotive applications. NBR performs reliably within a temperature range of -30°C to 105°C, offering good abrasion resistance and mechanical strength. While it lacks the extreme temperature resilience of Viton or Silicone, its balance of performance and affordability makes it a preferred choice for mass production and general-purpose sealing.

Silicone rubber (VMQ) excels in extreme temperature environments, with a functional range from -60°C to 200°C. It demonstrates excellent resistance to UV radiation, ozone, and weathering, making it ideal for exterior applications subject to prolonged sunlight and climatic exposure. Silicone also maintains flexibility at low temperatures, ensuring smooth window operation in cold climates. However, its lower tensile strength and abrasion resistance compared to NBR may limit its use in high-friction scenarios unless reinforced with specialized formulations.

The following table summarizes key physical and chemical properties of these materials for direct comparison in window run channel applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Abrasion Resistance | Good | Excellent | Fair |

| Typical Applications | High-performance automotive, aerospace | Standard automotive, industrial | Extreme climate, exterior seals |

Selecting the appropriate elastomer requires a comprehensive understanding of operational demands, environmental exposure, and lifecycle expectations. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and extrusion services to ensure each window run channel meets exact OEM specifications and performance benchmarks.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Automotive Window Run Channels

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in rubber formulation and precision moulding to deliver window run channels meeting stringent automotive OEM requirements. Our dedicated engineering team comprises five mould design specialists with an average of 12 years’ experience in automotive sealing systems and two advanced rubber formula engineers holding materials science doctorates. This dual-engineering structure ensures seamless integration of material science and manufacturing physics, critical for components subjected to dynamic compression, UV exposure, and extreme temperature cycling. Unlike generic suppliers, we initiate projects with finite element analysis (FEA) of seal lip geometry and cavity pressure distribution, optimizing mould flow to eliminate knit lines and sink marks that compromise sealing integrity.

Our formula engineering team focuses on molecular architecture to achieve balanced performance across competing parameters. Through controlled polymer blending (EPDM/TPV) and nano-silica reinforcement, we engineer compounds with exceptional compression set resistance (<25% at 70°C per ASTM D395), low-temperature flexibility down to -40°C (ASTM D2137), and coefficient of friction stability between 0.3–0.5 against glass. This eliminates common field failures like squeak noise, permanent set, or extrusion during door closure. All formulations undergo rigorous validation in our in-house climatic chambers simulating 10-year equivalent aging under 85°C/85% RH conditions, ensuring dimensional stability and adhesion retention to co-extruded TPE guides. Material batches are traceable to raw material lot numbers with full rheological and mechanical property documentation.

As an OEM partner, we implement APQP-aligned development protocols from concept to量产. Our process includes 3D tolerance stack analysis per ISO 2768-mK, first-article inspection with CMM-certified GD&T reports, and production part approval process (PPAP) Level 3 submissions. We maintain dedicated production cells with automated vision inspection for critical dimensions (e.g., glass contact lip radius ±0.05mm), ensuring batch-to-batch repeatability of ±0.1mm. With 15+ years supporting Tier 1 suppliers to FAW-Volkswagen and Geely, our closed-loop corrective action system reduces customer-returned defects by 92% versus industry averages.

Critical material performance specifications for automotive window run channels are validated as follows:

| Parameter | Test Standard | Performance Target | Baoshida Achieved |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 5 | 63–68 |

| Tensile Strength (MPa) | ASTM D412 | ≥ 10.0 | 12.5–14.2 |

| Elongation at Break (%) | ASTM D412 | ≥ 250 | 320–380 |

| Compression Set (%) | ASTM D395 | ≤ 25 | 18–22 |

| Low-Temp Flexibility (°C) | ASTM D2137 | ≤ -40 | Passes at -45 |

| Abrasion Loss (mm³) | ASTM D2228 | ≤ 120 | 85–105 |

This data-driven approach, combined with real-time process monitoring via MES-integrated sensors, guarantees window run channels that exceed OEM durability and noise-vibration-harshness (NVH) targets. We transform material science into measurable vehicle quality outcomes.

Customization Process

Customization Process for Window Run Channel Manufacturing

At Suzhou Baoshida Trading Co., Ltd., precision and material science converge to deliver high-performance window run channels tailored to automotive and industrial OEM requirements. Our customization process follows a rigorous four-phase methodology: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This structured approach ensures dimensional accuracy, material compatibility, and long-term durability under real-world operating conditions.

The process begins with Drawing Analysis, where engineering teams evaluate customer-provided technical drawings or 3D CAD models. Critical parameters such as cross-sectional geometry, sealing lip configuration, groove dimensions, and tolerance specifications are validated against OEM standards. We assess installation forces, compression set requirements, and environmental exposure conditions to define performance benchmarks. Any deviations or optimization opportunities are communicated through formal engineering feedback loops prior to material selection.

Next, Formulation Development is conducted in our rubber compounding laboratory. Based on the operational environment—temperature range, UV/ozone exposure, fluid resistance, and friction requirements—we engineer proprietary EPDM or TPE compounds. Key performance indicators include Shore A hardness (typically 60–75), tensile strength (>9 MPa), elongation at break (>300%), and low-temperature flexibility down to -40°C. Additives are precisely dosed to enhance wear resistance, surface finish, and adhesion to embedded metal inserts if present. Each formulation undergoes rheometric testing (cure kinetics), thermal aging, and dynamic mechanical analysis to verify stability.

Once the compound is finalized, Prototyping commences using precision steel molds and hydraulic vulcanization presses. Prototypes are produced in small batches (typically 50–100 units) for functional validation. We conduct dimensional inspection via CMM (Coordinate Measuring Machine), compression load testing (to verify insertion and breakout forces), and weathering trials in accelerated aging chambers. Seal integrity is evaluated under simulated door cycling (10,000+ cycles) and exposure to deionized water, brake fluid, and detergent solutions.

Upon customer approval, the project transitions to Mass Production. Our automated production lines support annual volumes from 100,000 to over 2 million units per part number. Process controls include real-time cure monitoring, 100% visual inspection, and batch traceability via integrated ERP systems. All finished window run channels are packaged in anti-static, humidity-controlled containers to preserve surface quality during logistics.

The table below summarizes typical technical specifications for our standard window run channel compounds:

| Property | Test Method | EPDM Standard | TPE Premium |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 5 | 70 ± 5 |

| Tensile Strength | ASTM D412 | ≥9.0 MPa | ≥10.5 MPa |

| Elongation at Break | ASTM D412 | ≥300% | ≥350% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% | ≤20% |

| Low-Temperature Flexibility | ASTM D1329 | -40°C (pass) | -45°C (pass) |

| Heat Aging (70h, 100°C) | ASTM D573 | ΔTensile ≤20% | ΔTensile ≤15% |

This end-to-end customization framework enables Suzhou Baoshida to deliver window run channels that meet exact functional, regulatory, and lifecycle demands of modern vehicle platforms.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Window Run Channel Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your dedicated engineering partner for advanced window run channel manufacturing, leveraging deep expertise in polymer science and industrial rubber processing. Our focus transcends standard production; we specialize in formulating and manufacturing window run channels that meet the exacting performance, durability, and dimensional tolerances demanded by modern automotive and transportation OEMs. Understanding the critical role these components play in noise, vibration, and harshness (NVH) reduction, weather sealing integrity, and smooth window operation, we apply rigorous material science principles to every compound development and extrusion process. Our in-house R&D facility allows for precise tailoring of EPDM, TPE, and specialty rubber formulations, optimizing critical properties such as low-temperature flexibility, compression set resistance, abrasion resistance, and adhesion to metal or plastic carriers. This scientific approach ensures consistent performance under extreme environmental conditions, directly contributing to vehicle longevity and passenger comfort.

Partnering with Baoshida provides access to integrated OEM manufacturing capabilities designed for complex project execution. We manage the entire lifecycle from initial concept and CAD-supported tooling design through precision extrusion, splicing, and final assembly. Our production lines adhere to stringent IATF 16949 quality management standards, incorporating real-time process monitoring and comprehensive material traceability systems. This commitment to precision engineering is reflected in our ability to consistently achieve tight tolerances on critical dimensions like lip geometry, channel depth, and carrier fit, which are essential for optimal sealing force and window guidance. The table below outlines key performance specifications achievable with our standard and custom formulations, serving as a benchmark for high-reliability applications.

| Property | Typical Value Range | Test Standard |

|---|---|---|

| Shore A Hardness | 55 – 75 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 8.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 250 | ASTM D412 |

| Compression Set (70°C, 22h) | ≤ 25% | ASTM D395 Method B |

| Low Temp Flexibility (°C) | -40 to -50 | ASTM D1329 |

| Heat Aging (70°C, 7d) | Δ Hardness ≤ +15 pts | ASTM D573 |

| Specific Gravity | 1.25 – 1.45 | ASTM D297 |

Our value proposition centers on becoming a seamless extension of your engineering and procurement teams. We proactively engage during the design phase to identify material and process optimizations that reduce total system cost without compromising performance. This collaborative engineering mindset, combined with scalable manufacturing capacity and a robust global logistics network, ensures reliable supply chain continuity for your production schedules. Quality is non-negotiable; every batch undergoes rigorous physical and chemical testing against agreed specifications, with full documentation provided.

Initiate a technical dialogue with Mr. Boyce, our dedicated OEM Manager, to discuss your specific window run channel requirements. Mr. Boyce possesses extensive experience in translating complex automotive sealing challenges into manufacturable rubber solutions and will facilitate a precise assessment of your needs. Contact him directly at [email protected] to schedule a confidential consultation. Provide your target specifications, volume requirements, and application context to enable our engineering team to develop a tailored proposal focused on performance validation, cost efficiency, and seamless integration into your assembly process. Suzhou Baoshida is committed to delivering not just components, but engineered sealing performance that meets the highest standards of the global automotive industry. Reach out today to advance your next-generation window system development.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).