Technical Contents

Engineering Guide: Window Sealer For Cars

Engineering Insight: The Critical Role of Material Selection in Automotive Window Seals

In the precision-driven domain of automotive sealing systems, the performance and longevity of a window sealer for cars are fundamentally determined by material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf elastomeric solutions, while cost-attractive in the short term, frequently fail to meet the rigorous demands of modern automotive environments. These failures stem from an inadequate understanding of the dynamic interplay between material chemistry, environmental exposure, and mechanical stress.

Automotive window seals operate under extreme conditions—thermal cycling from -40°C to +120°C, prolonged UV radiation, exposure to ozone, road salts, and repeated mechanical compression during door closure. Generic rubber compounds such as standard EPDM or low-grade silicone often degrade prematurely under these conditions, leading to cracking, compression set, and loss of sealing integrity. For example, a standard EPDM formulation may exhibit acceptable initial compression set but rapidly deteriorates under prolonged UV exposure, resulting in surface chalking and micro-cracking that compromise water and noise insulation.

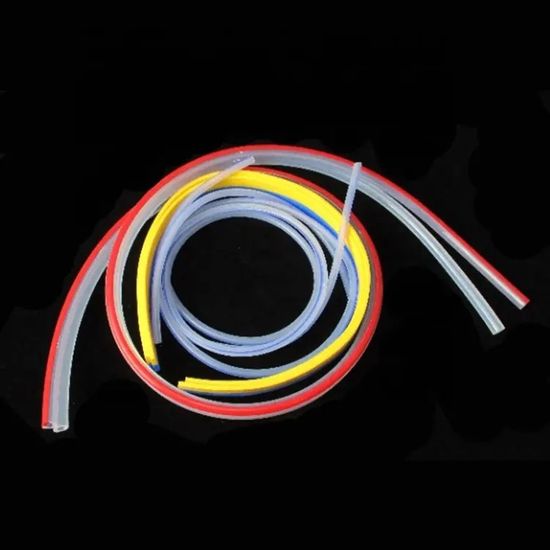

The root cause of such failures lies in the absence of tailored polymer architecture and additive systems. High-performance window seals require engineered elastomers with precise control over crosslink density, filler dispersion, and stabilizer packages. At Baoshida, we utilize specialty-grade EPDM with high ethylene content and third monomer optimization to enhance ozone resistance and thermal stability. For applications requiring superior low-temperature flexibility and UV resistance, we deploy peroxide-cured silicone rubber (VMQ) or fluorosilicone (FVMQ) where fuel and oil resistance are also critical.

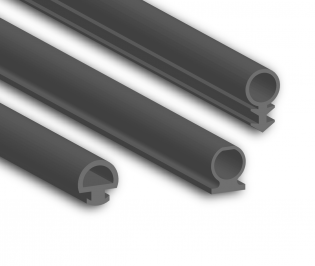

Moreover, material selection must align with the specific design parameters of the sealing profile. A door glass channel seal demands excellent flexibility and low friction, necessitating a Shore A hardness of 55–65 and the integration of internal lubricants. In contrast, a fixed quarter window gasket may prioritize compression set resistance and dimensional stability, requiring a harder compound (Shore A 70–75) with reinforced filler systems.

Off-the-shelf solutions often overlook these nuances, offering a one-size-fits-all approach that sacrifices long-term reliability. In contrast, engineered materials are developed through application-specific testing protocols, including accelerated aging, dynamic compression testing, and weathering simulations. This ensures that the final product maintains sealing force, dimensional accuracy, and aesthetic integrity over the vehicle’s lifetime.

The table below outlines key performance specifications of advanced elastomers used in precision window sealing applications.

| Material | Temperature Range (°C) | Shore A Hardness | Compression Set (22h, 100°C) | Key Advantages |

|---|---|---|---|---|

| High-Grade EPDM | -50 to +130 | 55–75 | <25% | Excellent ozone and weather resistance; cost-effective |

| Silicone (VMQ) | -60 to +180 | 45–60 | <20% | Superior low-temp flexibility; high thermal stability |

| Fluorosilicone (FVMQ) | -55 to +175 | 50–65 | <22% | Resistant to fuels, oils, and solvents |

| Thermoplastic Vulcanizate (TPV) | -40 to +150 | 50–70 | <30% | Recyclable; good balance of elasticity and strength |

Material selection is not a commodity decision—it is a core engineering imperative. At Suzhou Baoshida Trading Co., Ltd., we partner with OEMs to develop purpose-built rubber seals that exceed durability benchmarks and ensure optimal performance in real-world automotive applications.

Material Specifications

Material Specifications for Automotive Window Sealing Systems

Precision material selection is critical for automotive window sealing performance, directly influencing durability, environmental resistance, and long-term sealing integrity. At Suzhou Baoshida Trading Co., Ltd., we engineer rubber compounds to meet stringent OEM requirements for thermal stability, chemical exposure, and dynamic compression set. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent the primary elastomer families for this application, each offering distinct advantages based on vehicle platform and operational demands. Viton excels in extreme chemical and thermal environments, resisting automotive fluids like brake fluids, coolants, and concentrated detergents at continuous temperatures up to 230°C. Its molecular stability minimizes compression set degradation, ensuring consistent sealing force over 15+ years. Nitrile remains the cost-effective workhorse for standard applications, providing robust resistance to oils, greases, and aliphatic hydrocarbons at temperatures from -40°C to 120°C. However, its vulnerability to ozone and limited high-temperature resilience necessitates careful formulation for exterior-exposed window perimeters. Silicone delivers unparalleled low-temperature flexibility down to -60°C and maintains elasticity across thermal cycles, making it ideal for cold-climate markets. Its inherent UV and ozone resistance prevents surface cracking, though lower tensile strength requires reinforcement for high-stress installation zones.

All compounds undergo rigorous validation per ISO 37, ASTM D2000, and OEM-specific dynamic fatigue testing. Critical parameters include 25% compression set after 70 hours at 100°C (target: <25% for Viton, <35% for NBR, <20% for Silicone), Shore A hardness tolerance of ±3 points, and fluid immersion resistance per SAE J2643. Fillers, plasticizers, and cure systems are optimized to eliminate outgassing that could fog glass or compromise adhesion.

The following table details comparative performance metrics for automotive window seal applications:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Compression Set (70h/100°C) | 15-22% | 30-40% | 18-25% |

| Fuel/Oil Resistance (ASTM Type B) | Excellent | Excellent | Poor |

| Ozone Resistance | Exceptional | Poor | Excellent |

| Tensile Strength (MPa) | 12-18 | 15-25 | 6-10 |

| OEM Cost Tier | Premium | Standard | Mid-Premium |

Material selection must balance fluid exposure profiles, geographic operating conditions, and lifecycle cost targets. Viton is specified for luxury/EV platforms with aggressive coolant formulations, while NBR dominates volume production where cost sensitivity is paramount. Silicone is increasingly adopted for panoramic roofs requiring extreme thermal cycling resilience. Suzhou Baoshida provides custom compound development to bridge performance gaps, including hydrogenated NBR (HNBR) for enhanced ozone resistance and fluorosilicone hybrids for specialized chemical barriers. All formulations comply with REACH, ELV, and VOC emission standards, with traceable batch certification for Tier 1 supply chain integration.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of precision rubber engineering, delivering high-performance window sealing solutions tailored for the automotive industry. Our Engineering Capability division is anchored by a dedicated team of five certified mould engineers and two specialized rubber formulation engineers, enabling end-to-end control over product development, material optimization, and manufacturing scalability. This integrated technical team ensures that every window sealer is engineered to meet stringent OEM standards for dimensional accuracy, environmental resistance, and long-term durability.

Our mould engineers possess extensive expertise in precision tooling design, utilizing advanced CAD/CAM software and finite element analysis (FEA) to simulate part performance under real-world conditions. This enables rapid prototyping, cavity optimization, and robust tolerance management—critical for achieving consistent sealing performance across complex automotive glass interfaces. From initial concept to production-ready tooling, our team ensures cycle time efficiency, parting line precision, and ejection system reliability, minimizing flash and dimensional drift during high-volume extrusion and vulcanization.

Complementing our tooling expertise, our two in-house rubber formula engineers focus on material science innovation, developing custom EPDM and TPE compounds that meet exact OEM performance criteria. These formulations are engineered to deliver optimal compression set resistance, UV and ozone stability, low-temperature flexibility (down to -40°C), and adhesion compatibility with automotive glass and body substrates. Through rigorous laboratory testing and accelerated aging protocols, we validate compound performance across dynamic sealing scenarios, ensuring long-term weather-tight integrity.

Our OEM capabilities are built on a foundation of technical collaboration and process transparency. We work directly with automotive Tier 1 suppliers and OEMs to co-develop sealing profiles that integrate seamlessly into assembly line processes, supporting just-in-time delivery and full traceability. Our engineering team provides full documentation packages, including 3D models, material certifications (e.g., UL, RoHS, REACH), and process FMEAs, ensuring compliance with IATF 16949 quality standards.

The following table outlines key technical specifications for our standard automotive window sealer products:

| Parameter | Typical Value | Test Standard |

|---|---|---|

| Material Type | EPDM, TPE, Silicone (custom) | ASTM D1418 |

| Hardness (Shore A) | 50–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥8.0 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (24h, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature Range | -40°C to +130°C | ISO 1817 |

| Density | 1.15–1.30 g/cm³ | ASTM D297 |

| Adhesion Strength (to glass) | ≥4.5 kN/m | ISO 4624 |

By combining advanced material science with precision engineering, Suzhou Baoshida delivers window sealing systems that meet the evolving demands of modern automotive design—ensuring acoustic comfort, water intrusion protection, and aesthetic integration across vehicle platforms.

Customization Process

Customization Process for Automotive Window Seals

At Suzhou Baoshida Trading Co., Ltd., our customization process for precision rubber window seals follows a rigorously defined sequence to ensure seamless integration with OEM assembly lines and uncompromised performance. This methodology eliminates guesswork, reduces time-to-market, and guarantees adherence to stringent automotive durability standards.

Drawing Analysis

We initiate every project with comprehensive GD&T (Geometric Dimensioning and Tolerancing) validation against the client’s CAD models and physical master samples. Our engineering team cross-references critical features—including cavity profiles, insertion forces, and mating surface radii—against ISO 11970 and SAE J2236 standards. This phase identifies potential tooling conflicts or material flow issues early, preventing costly revisions during prototyping. Tolerance stack-up analysis is performed to ensure ±0.1 mm dimensional stability under operational temperature ranges (-40°C to +120°C).

Formulation Development

Based on the validated design parameters, our rubber compounding laboratory tailors EPDM or TPE formulations to meet exact functional requirements. Key variables include compression set resistance for long-term weather sealing, Shore A hardness (65–75) for optimal glass channel retention, and ozone/UV stability per ASTM D1149. We optimize cross-link density using peroxide curing systems to balance flexibility and resilience, while incorporating nano-silica reinforcement for abrasion resistance during automated assembly. All formulations undergo accelerated aging tests simulating 100,000 km exposure.

Prototyping & Validation

Precision-molded prototypes are produced using client-specified tool steel grades (e.g., H13) and subjected to multi-stage validation. This includes:

Metrological verification via CMM (Coordinate Measuring Machine) against nominal dimensions

Dynamic testing on OEM-simulated door assemblies to measure insertion force hysteresis

Environmental chamber cycling (-40°C to +85°C) with 95% RH for 500 hours

Adhesion strength measurement per ISO 813 using 180° peel tests

Client feedback is integrated within 72 hours to refine tooling or material adjustments.

Mass Production Ramp-Up

Upon PPAP (Production Part Approval Process) Level 3 sign-off, we transition to high-volume manufacturing under IATF 16949-certified protocols. Each production batch undergoes 100% visual inspection and automated dimensional scanning. Statistical Process Control (SPC) monitors critical parameters in real-time, with Cp/Cpk ≥1.67 maintained for all key characteristics. Logistics are synchronized with JIT/JIS systems, ensuring containerized shipments arrive at assembly plants with <0.1 ppm defect rates.

Critical Performance Specifications

| Parameter | Test Standard | Target Value | Tolerance |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 70 | ±1.5 |

| Compression Set (22h/70°C) | ISO 815 | ≤15% | ±2% |

| Tensile Strength | ISO 37 | ≥12 MPa | ±0.8 MPa |

| Elongation at Break | ISO 37 | ≥350% | ±25% |

| Low-Temperature Flex | ISO 1432 | Pass at -50°C | N/A |

This end-to-end engineering discipline ensures every window seal delivers leak-proof integrity across 15+ years of vehicle service life while meeting the exacting demands of global automotive platforms. Our process reduces customization lead times by 30% compared to industry averages through integrated digital twin simulations and in-house tooling expertise.

Contact Engineering Team

For automotive manufacturers and Tier-1 suppliers seeking high-performance window sealing solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of precision rubber engineering. Specializing in the development and supply of advanced rubber seals for automotive glazing systems, we deliver products engineered for durability, weather resistance, and dimensional accuracy. Our window sealers are designed to meet the rigorous demands of modern vehicle assembly, ensuring optimal acoustic insulation, water tightness, and long-term compression set resistance across diverse climatic conditions.

At Suzhou Baoshida, we understand that window sealing is not a commodity—it is a critical interface between structural integrity and passenger comfort. Our engineering team applies material science and real-world testing data to formulate EPDM, silicone, and TPE-based compounds tailored to OEM specifications. Each window sealer undergoes stringent quality control, including tensile strength verification, ozone resistance testing, and dynamic compression analysis, to ensure compliance with international standards such as ISO 1817, ASTM D2000, and VDA 6.3.

We invite global partners to contact Mr. Boyce, OEM Account Manager and Rubber Formula Engineer, to discuss your current or upcoming window sealing requirements. Whether you are launching a new EV platform requiring low-noise glazing seals or optimizing existing production lines for improved sealing consistency, Mr. Boyce brings technical depth and supply chain insight to every engagement. With direct access to formulation labs and tooling partners in the Yangtze River Delta, we offer rapid prototyping, DFMEA support, and scalable manufacturing solutions backed by IATF 16949-certified processes.

Our commitment extends beyond product delivery—we partner with clients through the entire development lifecycle, from initial material selection to on-site technical audits. By aligning our R&D capabilities with your design goals, we reduce assembly defects, minimize warranty risks, and enhance overall vehicle NVH performance.

Below are key technical specifications representative of our standard automotive window sealing compounds:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥300% |

| Compression Set (24h, 70°C) | ASTM D395 | ≤20% |

| Operating Temperature Range | — | -40°C to +130°C |

| Ozone Resistance | ASTM D1149 | No cracking (200 ppm, 40°C, 96h) |

| Specific Gravity | ASTM D297 | 1.25 ± 0.05 |

To initiate a technical consultation or request a sample submission, please contact Mr. Boyce directly at [email protected]. Include your project timeline, performance requirements, and preferred material class for a targeted response. We respond to all inquiries within 12 business hours and support communication in English, Mandarin, and German. Partner with Suzhou Baoshida for window sealing solutions engineered with precision, validated by performance, and delivered with industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).