Technical Contents

Engineering Guide: Windshield Weatherstrip

Engineering Insight: Windshield Weatherstrip Material Selection Criticality

Windshield weatherstrips represent a high-stakes interface between automotive body integrity and environmental exposure. Generic off-the-shelf solutions frequently fail due to inadequate material science alignment with dynamic operational demands. Standard EPDM compounds often exhibit premature compression set failure below -30°C or above +100°C, directly compromising sealing force retention. This manifests as wind noise, water ingress, and accelerated gasket hardening within 18–24 months—well before vehicle service life targets. The root cause lies in unoptimized polymer architecture: insufficient crosslink density control, substandard antidegradant packages, and filler systems that sacrifice low-temperature flexibility for cost-driven processing ease.

OEM-grade weatherstrips require multi-axis performance validation. UV resistance must exceed 2,000 hours per SAE J2527 without surface cracking, while maintaining Shore A hardness stability within ±5 points across -40°C to +120°C thermal cycling. Crucially, compression set must remain ≤15% after 70 hours at 100°C (ASTM D395 Method B)—a threshold generic compounds typically breach by 25–40%. Failure occurs because commodity suppliers prioritize mold-release compatibility over long-term elastic recovery, neglecting the synergistic effects of dynamic flex fatigue and fluid exposure from washer solvents or road deicers.

The following table contrasts critical performance parameters between generic and engineered solutions:

| Performance Parameter | Generic Off-the-Shelf EPDM | Suzhou Baoshida OEM-Grade EPDM | Test Standard |

|---|---|---|---|

| Compression Set (100°C/70h) | 35–45% | ≤12% | ASTM D395 B |

| Low-Temperature Flex (TR10) | -25°C | -55°C | ASTM D1329 |

| Ozone Resistance (50pphm/40°C) | Cracking in <48h | Zero cracking at 300h | ASTM D1149 |

| Tensile Retention after Aging | 60–70% | ≥90% | ASTM D573 |

| Fluid Resistance (SAE Type 2) | Swell >25% | Swell <8% | ASTM D471 |

Material failure cascades into systemic costs: warranty claims for water damage to electronics, rework labor exceeding $120 per vehicle, and brand erosion from perceived quality lapses. Suzhou Baoshida addresses this through co-engineered compounding—tailoring ethylene content, diene type, and peroxide curing systems to achieve balanced hysteresis and recovery. Our formulations integrate synergistic antioxidant blends that migrate minimally during service, preserving interfacial adhesion to glass and painted flanges. This precision eliminates the trade-offs inherent in catalog-grade materials, where UV stabilizers often compromise low-temperature elasticity.

True weatherstrip reliability demands chemistry calibrated to the vehicle’s specific thermal map, closure dynamics, and geographic deployment. Suzhou Baoshida’s OEM partnerships begin with material lifecycle modeling—not catalog number selection—to ensure sealing integrity persists through 150,000 km of real-world exposure. The cost of generic solutions becomes evident when recalculating total ownership against engineered performance.

Material Specifications

Material selection for windshield weatherstrip applications is critical to ensuring long-term performance, durability, and environmental resistance in automotive systems. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered to meet OEM and Tier-1 supplier standards. Our technical expertise in elastomer formulation enables precise tailoring of compounds for windshield sealing under extreme operational conditions. The three primary elastomers used in high-performance weatherstrip applications—Viton, Nitrile (NBR), and Silicone—each offer distinct advantages depending on the service environment.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, ozone, UV radiation, and automotive fluids such as gasoline, diesel, and brake fluids. This makes Viton an ideal candidate for windshield seals in premium and performance vehicles where thermal stability and chemical resistance are paramount. With a continuous service temperature range up to 230°C and excellent compression set resistance, Viton maintains sealing integrity over extended periods, even under aggressive under-hood conditions. However, its higher material cost and lower flexibility at sub-ambient temperatures require careful design consideration.

Nitrile rubber (NBR) is widely used due to its excellent resistance to oils, greases, and aliphatic hydrocarbons. It offers good mechanical strength and abrasion resistance, making it suitable for cost-sensitive applications where exposure to automotive fluids is moderate. NBR performs reliably within a temperature range of -30°C to 120°C, with some formulations extending to 150°C for short durations. While less effective than Viton in high-temperature environments, NBR provides a balanced combination of performance and cost-efficiency, particularly in standard passenger vehicles.

Silicone rubber (VMQ) exhibits outstanding thermal stability, operating effectively from -60°C to 200°C, with short-term peaks up to 250°C. It demonstrates excellent resistance to UV and ozone degradation, making it well-suited for exterior applications exposed to direct sunlight. Silicone also offers high flexibility at low temperatures and good electrical insulation properties. However, it has relatively poor resistance to fuels and oils, limiting its use in areas with direct fluid exposure. Its softness and compression set characteristics are favorable for sealing applications requiring low closure force.

The following table summarizes key material properties for windshield weatherstrip applications:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 (+150) | -60 to 200 (+250) |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set (22h, 150°C) | Low | Moderate | Low to Moderate |

| Resistance to Oils/Fuels | Excellent | Good to Excellent | Poor |

| UV/Ozone Resistance | Excellent | Good | Excellent |

| Flexibility at Low Temp | Moderate | Good | Excellent |

Selection of the appropriate elastomer depends on the specific environmental and mechanical demands of the application. Suzhou Baoshida Trading Co., Ltd. supports OEMs with customized compounding, rigorous testing, and full compliance documentation to ensure optimal material performance in windshield weatherstrip systems.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Automotive Weatherstrips

Suzhou Baoshida Trading Co., Ltd. delivers advanced engineering expertise for windshield weatherstrip manufacturing, leveraging deep material science and precision tooling to meet stringent automotive OEM standards. Our dedicated team comprises five specialized mold engineers and two certified rubber formula engineers, ensuring end-to-end control from compound development to production validation. This integrated approach guarantees weatherstrips that excel in sealing integrity, durability, and environmental resistance under extreme operational conditions.

Our formula engineering team focuses on custom EPDM and TPE compound design, optimizing cross-link density, filler dispersion, and additive packages for superior ozone resistance, low-temperature flexibility, and minimal compression set. Each formulation undergoes rigorous dynamic mechanical analysis (DMA) and accelerated aging tests per ASTM D2000 and ISO 188 standards, ensuring performance consistency across 150,000+ compression cycles. Critical parameters such as Shore A hardness, tensile strength, and thermal stability are fine-tuned to match OEM-specific vehicle architecture requirements, eliminating field failures due to material degradation.

Complementing this, our mold engineering unit employs 3D simulation software (Moldflow, SolidWorks Simulation) to design zero-defect tooling with micron-level tolerances. We prioritize thermal management, venting geometry, and parting line optimization to prevent flash, weld lines, and dimensional drift during high-volume production. All molds undergo 500+ hour validation runs with real-time cavity pressure monitoring, achieving CpK values ≥1.67 for critical dimensions like bulb profile symmetry and attachment clip alignment. This precision ensures seamless integration with glass run channels and body panels, reducing assembly line downtime for OEM partners.

As a certified Tier 2 supplier, Suzhou Baoshida implements full OEM process ownership—from CAD data review to PPAP documentation. We maintain IATF 16949-compliant control plans with automated SPC tracking for key characteristics, including durometer variance (±2 points) and extrusion dimensional stability (±0.15mm). Our rapid prototyping cell delivers functional samples within 15 days, while dedicated APQP teams collaborate directly with OEM engineering to resolve DFMEA risks pre-launch. This closed-loop methodology has driven 99.8% first-pass yield rates across 12 active global automotive programs.

The following table summarizes core weatherstrip performance specifications achievable through our engineering framework:

| Parameter | Standard Range | Testing Method | OEM Customization Capability |

|---|---|---|---|

| Hardness (Shore A) | 55–75 ±2 | ASTM D2240 | ±1 point tolerance |

| Temperature Range | -40°C to +120°C | ISO 188 | Extended to -55°C |

| Compression Set (22h) | ≤25% at 70°C | ASTM D395 | ≤15% achievable |

| Tensile Strength | ≥8.0 MPa | ASTM D412 | Up to 12.0 MPa |

| Ozone Resistance | No cracks (200pphm) | ASTM D1149 | 500pphm validation |

Suzhou Baoshida’s engineering synergy—where compound science converges with mold physics—enables windshield weatherstrips that exceed OEM lifecycle expectations while minimizing total cost of ownership. We transform material and tooling constraints into competitive advantages for global automotive manufacturers.

Customization Process

Customization Process for Windshield Weatherstrip Manufacturing

At Suzhou Baoshida Trading Co., Ltd., precision and performance define our approach to industrial rubber solutions. Our customization process for windshield weatherstrip follows a structured, engineering-driven methodology: Drawing Analysis → Formulation → Prototyping → Mass Production. This ensures that every component meets the exact functional, environmental, and dimensional requirements of our OEM partners.

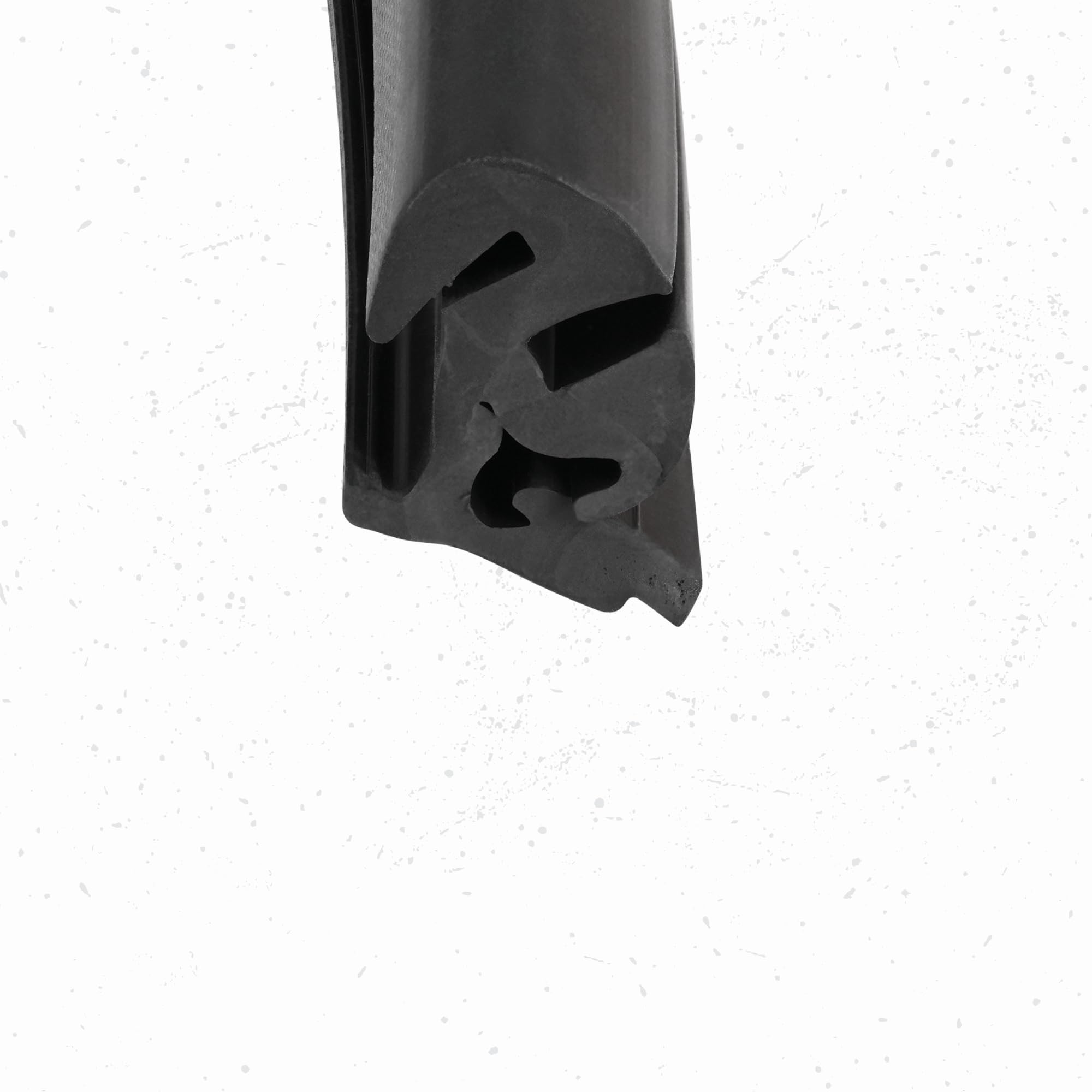

The process begins with Drawing Analysis, where our technical team evaluates the customer-provided 2D/3D CAD models and engineering specifications. Critical parameters such as cross-sectional profile, installation groove dimensions, tolerance limits (±0.1 mm typical), and mating surface geometry are rigorously reviewed. We assess sealing pressure distribution, compression set requirements, and environmental exposure conditions (UV, ozone, temperature cycling). This stage also includes material compatibility checks with adjacent components such as glass, painted metal, and adhesives. Any design ambiguities or potential manufacturability issues are flagged early, and we collaborate with the client to resolve them before progression.

Following drawing validation, we proceed to Formulation Development. Based on the application environment—such as automotive exterior exposure to -40°C to +120°C temperature ranges and chemical resistance needs—we engineer a proprietary rubber compound. Our standard base materials include EPDM (ethylene propylene diene monomer) for superior weather resistance, often enhanced with carbon black or mineral fillers for mechanical strength. Additives are precisely dosed to optimize UV stability, compression set (<25% at 70°C for 22 hours), and low-temperature flexibility. All formulations are documented under internal batch control codes and subjected to preliminary lab testing for rheological behavior and cure kinetics.

Prototyping is conducted using precision extrusion and splicing techniques to produce functional samples. These prototypes are fabricated in controlled conditions replicating mass production tooling, ensuring accurate representation of final part quality. Each sample undergoes dimensional verification via coordinate measuring machines (CMM) and is tested for sealing force, tensile strength, elongation at break, and durability under simulated aging (e.g., 1500 hours QUV exposure). Feedback from customer trials is integrated for refinement before final sign-off.

Upon approval, the project transitions into Mass Production. We deploy automated extrusion lines with inline laser gauging for real-time diameter control, ensuring consistency across production runs. Every batch is traceable, with full material certifications (RoHS, REACH, ISO 17025-compliant test reports) provided. Production output is scalable from 10,000 to over 500,000 units monthly, depending on complexity and client demand.

Our systematic workflow ensures that windshield weatherstrips deliver optimal sealing performance, longevity, and dimensional accuracy across diverse automotive platforms.

| Parameter | Standard Specification | Test Method |

|---|---|---|

| Material Base | EPDM | ASTM D1418 |

| Hardness (Shore A) | 60 ± 5 | ASTM D2240 |

| Tensile Strength | ≥9 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (70°C, 22h) | ≤25% | ASTM D395B |

| Operating Temperature | -40°C to +120°C | Internal |

| UV Resistance | 1500h QUV-A, no cracking | ISO 4892-3 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Windshield Weatherstrip Solutions

Achieving optimal sealing performance, noise reduction, and longevity in automotive windshield weatherstrips demands rigorous material science and manufacturing precision. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered EPDM and TPE formulations tailored to the exacting demands of global OEMs and Tier-1 suppliers. Our weatherstrips undergo stringent validation for compression set resistance, UV stability, and low-temperature flexibility—critical factors in preventing water ingress, wind noise, and premature failure across diverse climatic conditions. With integrated R&D facilities and ISO/TS 16949-certified production lines, we translate complex technical specifications into consistent, high-yield components that meet AS568, DIN 3051, and OEM-specific standards.

Our engineering team collaborates directly with clients during the design phase to optimize cross-section geometry, durometer profiles, and adhesion properties—ensuring seamless integration with glass bonding systems and body-in-white tolerances. Unlike commodity suppliers, we prioritize material formulation integrity, utilizing proprietary sulfur-cure systems and nano-reinforced polymers to enhance durability without compromising extrusion efficiency. Every batch is traceable via blockchain-enabled quality records, providing full transparency from raw material sourcing to final shipment. This commitment minimizes production line disruptions and warranty liabilities for your assembly operations.

For technical validation, we provide comprehensive material test reports including:

| Property | Test Standard | Typical Value Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–75 |

| Tensile Strength (MPa) | ASTM D412 | ≥10.0 |

| Elongation at Break (%) | ASTM D412 | ≥300 |

| Compression Set (22h/70°C) | ASTM D395 | ≤25% |

| Temp. Range (°C) | ISO 188 | -40 to +120 |

Initiate your project with Suzhou Baoshida by contacting Mr. Boyce, our dedicated OEM Manager, who possesses 14 years of experience in automotive sealing systems. Mr. Boyce will coordinate a technical deep dive into your application requirements, including CAD cross-section analysis, DFM feedback, and accelerated life-cycle testing protocols. Submit your RFQ with material specifications, volume forecasts, and target cost parameters to receive a tailored solution within 72 hours. We maintain strategic inventory hubs in Shanghai and Rotterdam to support just-in-time delivery for European and North American production schedules, reducing your logistics overhead by up to 22%.

Partner with an engineering-led supplier that treats your quality metrics as our non-negotiable baseline. Contact Mr. Boyce directly at [email protected] to schedule a virtual factory audit or request sample kits for material validation. Specify your vehicle platform and annual volume requirements to receive a customized technical dossier outlining formulation chemistry, process capability indices (CpK ≥1.67), and scalability timelines. Suzhou Baoshida—where molecular precision meets automotive excellence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).