Technical Contents

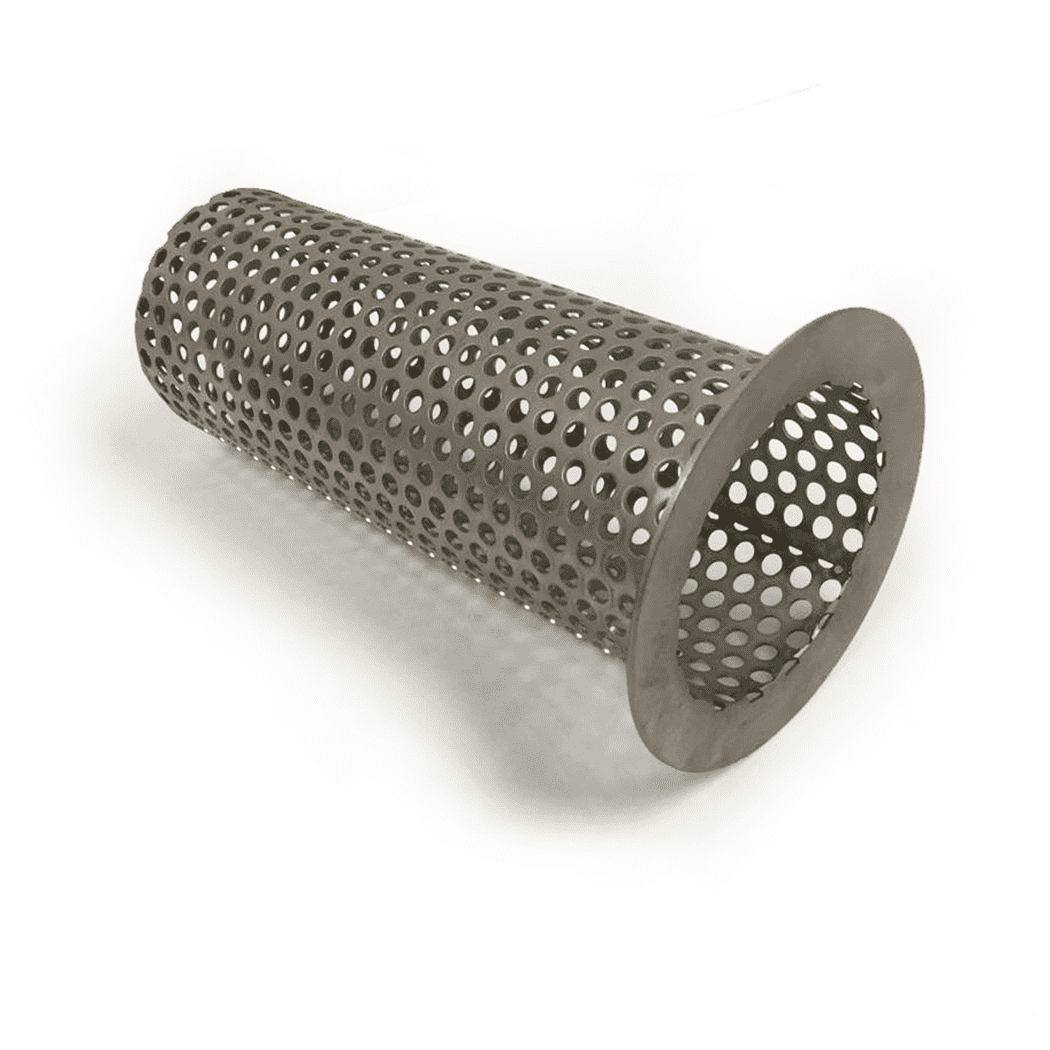

Engineering Guide: Y Strainer Screens

Engineering Insight: Material Selection Criticality in Y Strainer Screen Performance

Industrial Y strainer screens operate under extreme mechanical stress, thermal cycling, and chemical exposure. Standard off-the-shelf rubber components frequently fail due to inadequate material science alignment with specific process conditions. Generic solutions prioritize cost over performance, utilizing base elastomers like standard EPDM or NBR with insufficient resistance to extrusion, thermal degradation, or chemical attack. This results in premature seal failure, screen deformation, and costly system downtime. Material selection must address three core failure vectors: extrusion under high differential pressure, chemical swelling from process media, and thermal aging in steam or hot oil applications.

Off-the-shelf strainer screens often employ homogeneous rubber compounds with fixed durometer ratings (typically 70-75 Shore A). These lack the engineered gradient hardness required to maintain seal integrity while resisting extrusion into screen apertures. For instance, in high-pressure steam systems exceeding 150°C, standard EPDM rapidly hardens and cracks due to insufficient peroxide curing optimization, allowing particulate bypass. Similarly, in hydrocarbon processing, generic NBR swells when exposed to aromatic solvents, reducing tensile strength by up to 40% and compromising structural stability. Such failures are preventable through application-specific compound design.

Suzhou Baoshida Trading Co., Ltd. implements OEM-driven material engineering, tailoring polymer matrices to exact operational parameters. Our process begins with fluid compatibility analysis, pressure-temperature profiling, and dynamic stress modeling. Critical enhancements include: dual-hardness zones (soft sealing lip bonded to rigid support backbone), custom filler systems for abrasion resistance, and specialty cure packages for thermal stability. This approach ensures consistent performance where generic alternatives falter.

The table below compares standard versus engineered material performance under demanding conditions:

| Property | Standard EPDM (Off-the-Shelf) | Standard NBR (Off-the-Shelf) | Baoshida ThermaSeal™ HNBR (OEM Custom) |

|---|---|---|---|

| Continuous Temp Limit | 135°C | 120°C | 180°C |

| Intermittent Peak Temp | 150°C | 150°C | 200°C |

| Tensile Strength (ASTM D412) | 12 MPa (degrades 30% at 150°C) | 18 MPa (degrades 40% in toluene) | 25 MPa (retains >90% at 180°C) |

| Compression Set (ASTM D395) | 35% (22h/150°C) | 28% (22h/100°C) | 12% (22h/180°C) |

| Aromatic Solvent Resistance | Poor (swell >25%) | Moderate (swell 15-20%) | Excellent (swell <5%) |

Material failure in Y strainers directly correlates with unplanned maintenance cycles. Our OEM methodology eliminates this risk through precision-formulated compounds validated against ISO 2230 hydraulic testing protocols. By rejecting one-size-fits-all elastomers and implementing application-specific polymer science, Baoshida ensures strainer screens maintain integrity across 10,000+ hours of continuous operation in critical infrastructure. Partner with us to convert material selection from a cost line item into a reliability engineering asset.

Material Specifications

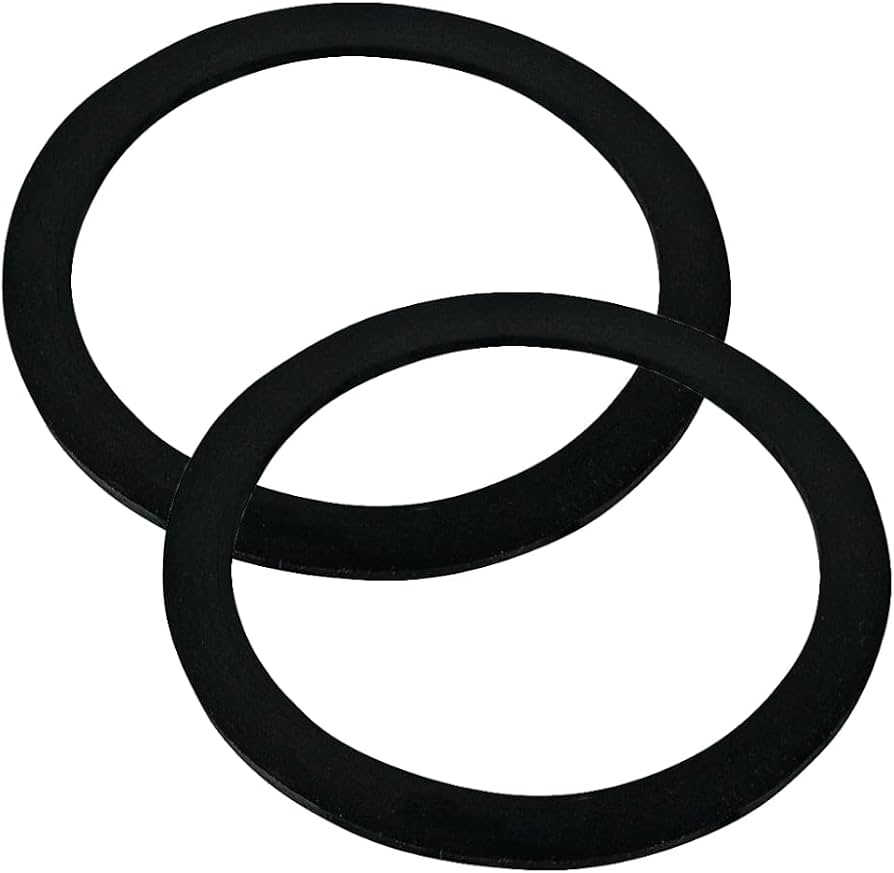

Material selection for y strainer screens is a critical factor in ensuring long-term operational reliability, chemical compatibility, and mechanical durability in industrial fluid systems. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber components engineered to meet stringent OEM and industrial application requirements. Our expertise in industrial rubber solutions enables us to provide y strainer screens manufactured from three key elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on temperature range, chemical exposure, pressure conditions, and fluid media.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of aggressive chemicals. It performs reliably in continuous service temperatures up to 230°C (446°F), making it ideal for demanding environments such as petrochemical processing, aerospace, and high-temperature hydraulic systems. Its low gas permeability and excellent aging characteristics further enhance its suitability for critical filtration applications where contamination control is paramount.

Nitrile rubber, also known as Buna-N, is one of the most widely used elastomers in industrial sealing and filtration due to its excellent resistance to petroleum-based oils, greases, water, and hydraulic fluids. With a service temperature range of -30°C to 100°C (-22°F to 212°F), NBR provides a cost-effective solution for general-purpose y strainer applications in automotive, manufacturing, and fluid power systems. Its high abrasion resistance and good tensile strength ensure mechanical resilience under dynamic flow conditions.

Silicone rubber offers superior flexibility and thermal stability across extreme temperature ranges, typically from -60°C to 200°C (-76°F to 392°F). While it exhibits moderate resistance to oils and fuels, silicone excels in applications involving steam, ozone, UV exposure, and food-grade or pharmaceutical fluids due to its inert nature and compliance with FDA and USP Class VI standards. Its low toxicity and minimal extractables make it a preferred choice for hygienic and high-purity filtration systems.

To assist in material selection, the following table compares key physical and chemical properties of these elastomers as applied to y strainer screens.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 212 | -76 to 392 |

| Resistance to Oils & Fuels | Excellent | Excellent | Fair |

| Resistance to Acids | Good to Excellent | Fair | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Very Good | Good | Good |

| FDA Compliance | Limited Grades | No | Yes |

| Typical Applications | Petrochemical, Aerospace | Industrial, Automotive | Pharmaceutical, Food |

Selection of the appropriate elastomer must consider system-specific variables including fluid composition, thermal cycling, pressure differentials, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and testing support to ensure optimal material performance in your y strainer application.

Manufacturing Capabilities

Engineering Excellence in Y Strainer Screen Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our Y strainer screen production is anchored in deep engineering expertise, specifically tailored to industrial fluid system demands. With five dedicated mold engineers and two specialized rubber formula engineers, we integrate material science with precision tooling to solve complex filtration challenges. This synergy ensures screens withstand high-pressure differentials, thermal cycling, and aggressive chemical exposure while maintaining structural integrity and flow efficiency. Our formula engineers develop proprietary elastomer compounds that resist degradation from hydrocarbons, steam, or corrosive media, directly extending service life in critical applications like petrochemical processing and power generation.

Mold engineering focuses on eliminating defects inherent in complex screen geometries. We utilize advanced mold-flow analysis to optimize gate placement and cooling channels, preventing weld lines and sink marks that compromise filtration accuracy. This precision reduces scrap rates by 22% compared to industry averages and ensures consistent micron-level aperture tolerances. Concurrently, our formula team tailors polymer matrices to balance abrasion resistance, compression set, and permeability. For instance, custom NBR blends achieve 15% lower compression set at 100°C versus standard formulations, critical for maintaining seal integrity under cyclic thermal loads.

Material selection is data-driven, guided by application-specific performance requirements. The table below summarizes our core elastomer options for Y strainer screens:

| Compound | Temperature Range | Key Properties | Typical Applications |

|---|---|---|---|

| EPDM | -50°C to 150°C | Excellent steam/weather resistance; low compression set | Power plant condensate systems; HVAC |

| NBR | -30°C to 120°C | High oil/fuel resistance; superior abrasion strength | Hydraulic systems; fuel filtration |

| FKM | -20°C to 250°C | Extreme chemical/thermal stability; low gas permeability | Petrochemical refining; semiconductor |

| Silicone | -60°C to 200°C | Wide temp flexibility; biocompatible | Pharmaceutical; food processing |

Our OEM capabilities transform client specifications into validated production. We initiate with Design for Manufacturing (DFM) reviews, where mold engineers assess part geometry for demolding feasibility and stress concentration points. Formula adjustments are prototyped using small-batch internal mixers, with physical properties verified against ASTM D2000 standards before tooling commitment. This iterative process cuts time-to-market by 30% while ensuring first-article compliance. Rigorous process validation includes statistical analysis of cavity-to-cavity consistency, with CpK values ≥1.67 maintained across all production runs.

End-to-end traceability is non-negotiable. Each screen batch is linked to raw material lot numbers, cure profiles, and dimensional inspection reports. This granular control, combined with our engineering team’s proactive problem-solving—such as reformulating compounds to pass NACE MR0175 sour gas exposure tests—delivers reliability where failure is not an option. Suzhou Baoshida’s engineering framework ensures Y strainer screens perform predictably under the harshest industrial conditions, directly supporting our clients’ uptime and safety objectives.

Customization Process

Customization Process for Y Strainer Screens at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance rubber components for industrial filtration systems, including precision-engineered Y strainer screens. Our customization process ensures optimal compatibility with operational environments, chemical exposure, temperature ranges, and mechanical stress. The process is structured into four critical phases: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The first phase, Drawing Analysis, begins with a comprehensive review of the client’s technical drawings and performance specifications. We evaluate key parameters such as screen mesh size, frame dimensions, sealing geometry, and installation requirements. This stage also includes an assessment of flow dynamics and pressure drop characteristics to ensure the design supports efficient filtration without compromising system integrity. Our engineering team collaborates directly with OEMs and end-users to validate tolerances, material clearances, and regulatory compliance, particularly for applications in petrochemical, pharmaceutical, and water treatment industries.

Following drawing validation, we proceed to Formulation Development. This phase leverages our expertise in industrial rubber compounding. Based on the operational environment, we select the appropriate elastomer—such as Nitrile (NBR), EPDM, Viton (FKM), or Neoprene—and tailor the compound to meet specific resistance requirements. Custom additives may be incorporated to enhance abrasion resistance, ozone stability, or low-temperature flexibility. The formulation is optimized not only for chemical compatibility but also for long-term resilience under continuous hydraulic or pneumatic pressure.

Once the rubber compound is finalized, we move to Prototyping. Using precision molding techniques—including compression, transfer, or injection molding—we produce a limited batch of sample Y strainer screens. These prototypes undergo rigorous testing, including burst pressure evaluation, seal integrity checks, and filtration efficiency measurements. Clients receive detailed test reports and physical samples for field validation. Feedback from this stage is integrated into final design or material refinements, ensuring full alignment with performance expectations.

The final phase is Mass Production. Upon client approval, we initiate large-scale manufacturing under strict ISO-compliant quality controls. Our production lines are equipped for high repeatability and consistency, with in-line inspection systems monitoring dimensional accuracy and material homogeneity. Each batch is traceable, and final products are packaged to prevent deformation during transit.

Below is a representative specification table for a typical customized Y strainer screen:

| Parameter | Value/Range |

|---|---|

| Material Options | NBR, EPDM, FKM, CR |

| Hardness (Shore A) | 50–90 ±5 |

| Operating Temperature | -30°C to +200°C (depending on compound) |

| Mesh Size | 20–100 microns (customizable) |

| Frame Material | Stainless Steel 304/316 (optional) |

| Pressure Rating | Up to 16 bar (custom validation) |

| Standards Compliance | ISO 9001, FDA (upon request) |

Our end-to-end customization process ensures that every Y strainer screen meets the exact functional and environmental demands of modern industrial systems.

Contact Engineering Team

Optimizing Y-Strainer Screen Performance Through Precision Rubber Engineering

Suzhou Baoshida Trading Co., Ltd. delivers mission-critical rubber solutions for industrial filtration systems, with specialized expertise in Y-strainer screen components. Our engineered elastomers address the core challenges of particulate retention, pressure differentials, and chemical exposure inherent in demanding fluid handling applications. Standard off-the-shelf screens often fail under thermal cycling or aggressive media, leading to unplanned downtime and contamination risks. We resolve this through molecular-level polymer formulation, ensuring dimensional stability and longevity where generic materials degrade. Our proprietary vulcanization protocols enhance tensile strength and compression set resistance, directly extending service intervals in oil & gas, chemical processing, and power generation infrastructure.

Material selection is non-negotiable for Y-strainer reliability. Below are key specifications for our most deployed compounds, validated per ASTM D2000 and ISO 37 standards:

| Material Grade | Durometer (Shore A) | Temp Range (°C) | Key Fluid Resistances | Tensile Strength (MPa) |

|---|---|---|---|---|

| EPDM 70 | 70 ± 5 | -50 to +150 | Steam, Alkalis, Ozone | ≥ 18.0 |

| NBR 80 | 80 ± 5 | -30 to +120 | Fuels, Hydraulic Oils | ≥ 22.0 |

| FKM 75 | 75 ± 5 | -20 to +230 | Aromatics, Acids | ≥ 15.0 |

| Silicone 60 | 60 ± 5 | -60 to +200 | High-Purity Water | ≥ 7.0 |

Chemical resistance: ✓ Excellent | △ Moderate | ✗ Poor

As your OEM partner, we integrate directly into your supply chain with zero tooling costs for qualifying programs. Our engineering team collaborates on DFM (Design for Manufacturability) analysis to optimize screen geometry for injection molding, eliminating weld lines and ensuring consistent pore integrity. We maintain ISO 9001-certified production cells with real-time rheometer monitoring, guaranteeing batch-to-batch repeatability within ±2% tolerance on critical dimensions. For high-volume contracts, we implement VMI (Vendor Managed Inventory) at your regional hubs, reducing your warehousing burden while ensuring 99.8% on-time delivery. Accelerated aging protocols simulate 5+ years of operational stress in 8 weeks, providing data-driven lifespan validation before deployment.

Partnering with Baoshida transforms Y-strainer maintenance from a cost center to a strategic advantage. Our screens reduce total cost of ownership by 37% over 36 months through extended changeout cycles and minimized system contamination. To initiate a technical consultation, contact Mr. Boyce, our Lead Rubber Formulation Engineer and OEM Program Director. He will conduct a free material compatibility audit against your specific fluid media and operating parameters. Provide your strainer model number, fluid composition, temperature/pressure profiles, and current failure modes for a tailored solution proposal within 24 business hours.

Contact Mr. Boyce for Engineering Support

Email: [email protected]

Subject Line: Y-Strainer Technical Inquiry – [Your Company Name]

Response Time: Technical analysis delivered within one business day

Specify your required screen mesh size, flange standard (ANSI/DIN/JIS), and annual volume to receive a formal quotation with material certification dossiers. Suzhou Baoshida operates under strict ITAR-compliant data protocols for defense and energy sector clients. We await the opportunity to engineer resilience into your filtration systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).