We have 3 plastic production suppliers, customers can inquiry, quality control, delivery supervision services.

Plastic Parts: Comprehensive Overview

Type:

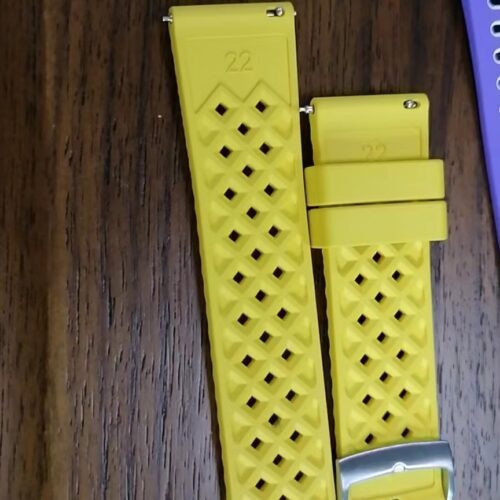

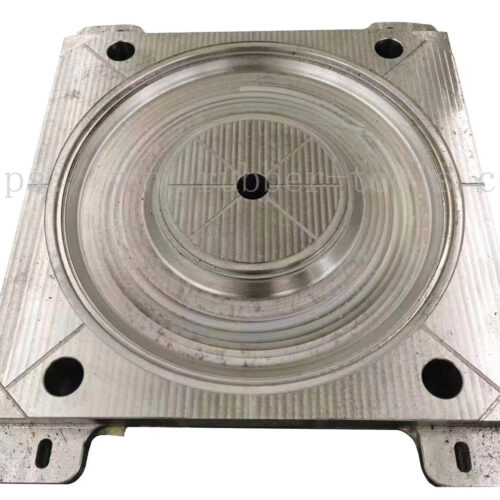

- Injection Molded Parts: These are formed by injecting molten plastic into a mold. Once cooled, the mold is opened to release the part. Commonly used for mass production due to its efficiency and consistency.

- Thermoformed Parts: Plastic sheets are heated until soft and then formed to a specific shape using a mold. Once cooled, the part retains its shape. Ideal for larger items like packaging trays or vehicle door liners.

- Blow Molded Parts: Used primarily for creating hollow objects. Molten plastic is placed inside a mold, then air is blown into it, forcing the plastic to expand and take the shape of the mold.

- Rotational Molded Parts: A heating process that uses rotation to evenly coat the inside of a mold with plastic. This method is typically used for larger, hollow parts like tanks.

Application:

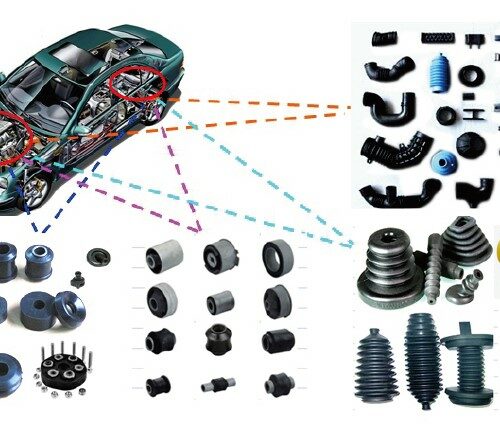

- Automotive Industry: From dashboard components to car bumpers, plastic parts play a crucial role in vehicle design and safety.

- Medical Devices: Plastic parts are used in various medical equipment and tools due to their sterility and precision.

- Consumer Electronics: Casings for phones, TVs, and other devices are often made from plastic parts for their lightweight and durable nature.

- Packaging: Everything from bottle caps to food containers, plastic parts dominate the packaging industry.

- Aerospace: Lightweight and durable plastic parts are used in various components of aircraft and space vehicles.

Benefits:

- Lightweight: Plastic parts significantly reduce the overall weight, which is especially beneficial in industries like automotive and aerospace for fuel efficiency.

- Cost-Effective: Plastic is often cheaper than metals, leading to reduced production costs.

- Corrosion Resistant: Unlike metals, plastics don’t corrode, making them ideal for long-term applications.

- Flexibility in Design: Due to molding techniques, intricate and complex designs can be achieved with plastics.

- Durability: Modern plastics are engineered to be strong, durable, and resistant to various environmental factors.

Features:

- High Tensile Strength: Certain plastic parts can rival the strength of metals, making them suitable for heavy-duty applications.

- Thermal & Electrical Insulation: Plastics are natural insulators, making them perfect for electronic components.

- Chemical Resistance: Many plastics can resist acids, bases, and other chemicals, making them ideal for industrial use.

- UV Resistance: Some plastic parts are treated to resist harmful UV rays, ensuring they don’t degrade under sunlight.

- Recyclability: Many plastic parts can be recycled, promoting sustainability and reducing environmental impact.

FAQs about Plastic Parts

1. What are the primary manufacturing methods for plastic parts? Answer: The primary manufacturing methods include injection molding, thermoforming, blow molding, and rotational molding. The choice of method depends on the part’s design, application, and production volume.

2. Are plastic parts durable enough for heavy-duty applications? Answer: Absolutely. Modern engineering plastics are designed to be robust and durable, suitable for various heavy-duty applications, from automotive components to industrial machinery.

3. How do plastic parts fare against environmental factors? Answer: Many plastic parts are resistant to environmental factors like UV rays, moisture, and chemicals. Specific treatments and additives can enhance their resistance to ensure longevity in challenging conditions.

4. Can plastic parts be customized in terms of color and design? Answer: Yes, plastic parts offer great flexibility in design and can be manufactured in a wide range of colors, shapes, and sizes to meet specific requirements.

5. Are plastic parts environmentally friendly? Answer: Many plastic parts are recyclable, reducing their environmental impact. Additionally, the production of plastic parts often consumes less energy compared to metals, further promoting sustainability.

6. How do plastic parts compare in cost to metal parts? Answer: Generally, plastic parts are more cost-effective than metal parts, especially in high-volume production. The reduced weight also leads to savings in transportation and assembly.

7. What industries commonly use plastic parts? Answer: Plastic parts are ubiquitous and find applications in industries like automotive, aerospace, medical, consumer electronics, packaging, and many more.

8. How do I choose the right type of plastic for my application? Answer: The choice of plastic material depends on the specific requirements of the application, such as strength, flexibility, temperature resistance, and chemical exposure. Consulting with a plastic parts manufacturer or expert can guide you to the best choice.

9. Can plastic parts handle high temperatures? Answer: Certain plastics, like high-performance thermoplastics, can handle elevated temperatures without deforming or losing their properties. It’s essential to select the right plastic type based on the temperature requirements of the application.

10. How do I ensure the quality and consistency of plastic parts in bulk production? Answer: Partnering with a reputable manufacturer, ensuring stringent quality control measures, and regular testing are key to maintaining the quality and consistency of plastic parts in mass production.

FAQs for Plastic Parts Buyer

1. What manufacturing techniques do you employ for producing plastic parts? Answer: We utilize state-of-the-art manufacturing processes, including injection molding, thermoforming, and blow molding, ensuring precision and consistency in every part we produce.

2. How do you ensure the durability and longevity of your plastic parts? Answer: Our plastic parts are crafted from high-grade materials, tested rigorously for strength and durability. We also incorporate specific additives when needed to enhance resistance against environmental factors.

3. Can you customize plastic parts to meet specific design requirements? Answer: Absolutely. We pride ourselves on our ability to work closely with clients to customize designs, ensuring the final product aligns perfectly with their specifications and application needs.

4. How do your plastic parts compare in terms of environmental impact? Answer: We are committed to sustainability. Many of our plastic parts are recyclable, and our manufacturing processes are optimized to minimize waste and energy consumption.

5. What measures do you take to ensure consistent quality in bulk orders? Answer: Quality is paramount to us. We have stringent quality control measures in place, from raw material sourcing to final product inspection, ensuring every part meets our high standards.

6. Are your plastic parts resistant to chemicals and UV radiation? Answer: Yes, our plastic parts are designed to resist a wide range of chemicals and UV exposure. We can also incorporate specific treatments or materials based on the application’s requirements.

7. What industries do you primarily serve with your plastic parts? Answer: We cater to a diverse range of industries, including automotive, aerospace, medical devices, electronics, and more. Our expertise allows us to serve varied industrial needs with precision.

8. How competitive are your prices for plastic parts compared to other manufacturers? Answer: While we prioritize quality, we also ensure our pricing remains competitive. Our advanced manufacturing techniques and efficient processes allow us to offer high-quality parts at cost-effective rates.

9. Can you provide samples before we place a bulk order? Answer: Certainly. We believe in our product quality and are happy to provide samples for your evaluation.

10. How do you handle tight production schedules and urgent orders? Answer: With our advanced manufacturing facilities and dedicated team, we are equipped to handle tight schedules and ensure timely delivery without compromising on quality.